Jacquard non-woven fabric and preparation method thereof

A non-woven, mass fraction technology, used in non-woven fabrics, textiles and papermaking, etc., to achieve the effect of increasing areal density, soft hand feeling, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

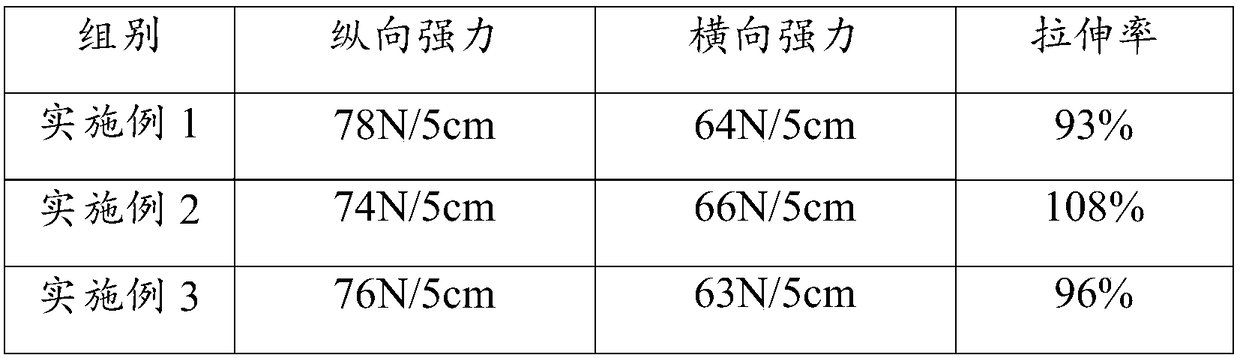

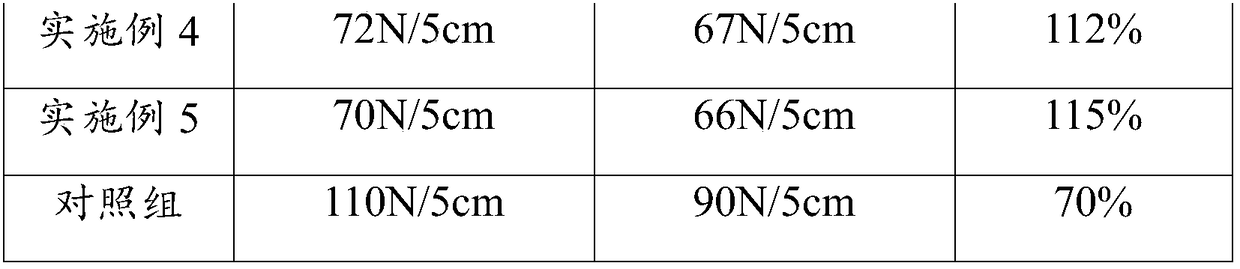

Examples

preparation example Construction

[0030] According to one aspect of the present invention, a kind of preparation method of jacquard non-woven fabric, described preparation method comprises the following steps:

[0031] First, the three-dimensional hollow crimped fiber and ordinary polyester staple fiber are mixed and then opened, carded, laid and drawn in sequence to obtain a fiber web, and the polypropylene fiber is separately prepared to produce a polypropylene spunbonded fabric; then the fiber web and polypropylene The spun-bonded fabric is compounded to obtain a double-layer composite material; then the double-layer composite material is sequentially subjected to the steps of needle-punching and hot-pressing jacquard to obtain a jacquard non-woven fabric.

[0032] The preparation method of the jacquard non-woven fabric provided by the present invention first mixes the three-dimensional hollow crimped fiber and ordinary polyester staple fiber to obtain a fiber mesh, and then composites the fiber mesh and pol...

Embodiment 1

[0047] A jacquard nonwoven fabric, which is mainly made of the following raw materials in parts by mass: 45 parts of three-dimensional crimped hollow fiber, 20 parts of polypropylene fiber and 55 parts of ordinary polyester staple fiber.

[0048] The preparation method of above-mentioned jacquard non-woven fabric, comprises the following steps:

[0049] First, the three-dimensional hollow crimped fiber and ordinary polyester staple fiber are mixed and then opened, carded, laid and drawn in sequence to obtain a fiber web, and the polypropylene fiber is separately prepared to produce a polypropylene spunbonded fabric; then the fiber web and polypropylene The spun-bonded cloth is compounded to obtain a double-layer composite material; then the double-layer composite material is sequentially subjected to the steps of needle-punching and hot-pressing jacquard to obtain a jacquard non-woven fabric;

[0050] The grammage of above-mentioned fiber net cotton is 35g / m 2 ; The weight of...

Embodiment 2

[0054] A jacquard nonwoven fabric, which is mainly made of the following raw materials in terms of parts by mass: 30 parts of three-dimensional crimped hollow fibers, 15 parts of polypropylene fibers and 45 parts of ordinary polyester staple fibers.

[0055] The preparation method of above-mentioned jacquard non-woven fabric, comprises the following steps:

[0056] First, the three-dimensional hollow crimped fiber and ordinary polyester staple fiber are mixed and then opened, carded, laid and drawn in sequence to obtain a fiber web, and the polypropylene fiber is separately prepared to produce a polypropylene spunbonded fabric; then the fiber web and polypropylene The spun-bonded cloth is compounded to obtain a double-layer composite material; then the double-layer composite material is sequentially subjected to the steps of needle-punching and hot-pressing jacquard to obtain a jacquard non-woven fabric;

[0057] The grammage of the above fiber net cotton is 35~65g / m 2 ; The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com