Self-rotating needle

A self-rotating and needle-punching technology, which is applied in acupuncture machines, textiles, papermaking, non-woven fabrics, etc., can solve the problems of increased investment by non-woven fabric manufacturers, low fiber bundle work efficiency, and increased needle consumption. Small impact force, improved entanglement force, and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

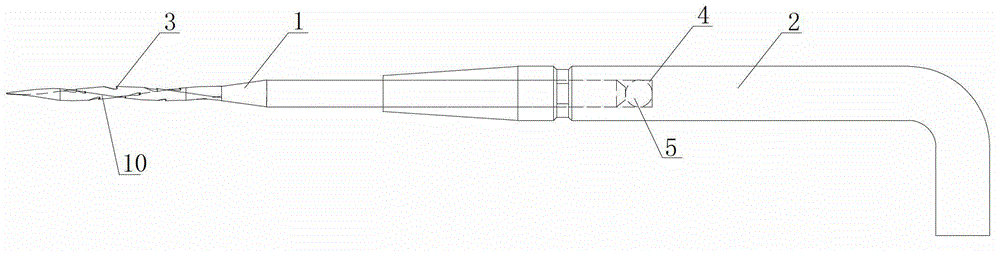

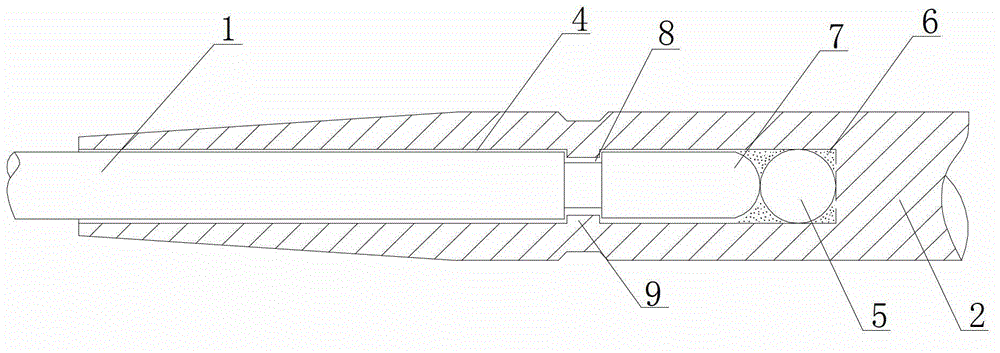

[0024] Such as figure 1 , figure 2 As shown, the self-rotating needle of the present invention includes a needle body 1 and a needle shaft 2, barbed hooks 3 are arranged at intervals on the needle body 1, the needle body 1 and the needle shaft 2 are separately arranged, and one side of the needle shaft 2 is provided with a blind hole 4 , the needle body 1 is inserted into the blind hole 4 and rotates relative to the blind hole.

[0025] The needle body 1 is provided with a lock ring 8 sunken inwardly, and the needle bar 2 is provided with an inwardly protruding card table 9 corresponding to the lock ring, and the card table 9 is stuck on the periphery of the lock ring 8 and maintains a certain gap. The ring 8 is free to rotate relative to the deck 9 . A protrusion 7 is provided at the end of the needle body, and a steel ball 5 is provided at the bottom of the blind hole, and the steel ball 5 contacts with the protrusion 7 at one point. The protrusion 7 adopts a sphere. Gr...

Embodiment 2

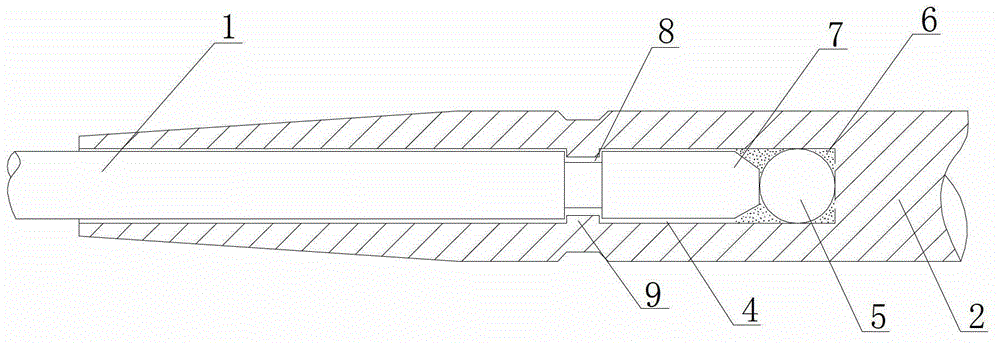

[0028] Such as image 3 As shown, the protrusion 7 adopts a trapezoidal cylinder.

[0029] Others are with embodiment 1.

Embodiment 3

[0031] Such as Figure 4 As shown, the side of the needle bar 2 connected with the needle body 1 is provided with four opening grooves 11 along the axial direction, and the opening of the blind hole 4 is provided with four inverted bosses 12 along the inner circumference of the needle bar 2, and the needle body 1 A locking groove 13 is provided at the position corresponding to the inverted boss 12 , and the inverted boss 12 is stuck in the locking groove 13 .

[0032] When in use, the needle body 1 is inserted into the needle bar 2, since the inner side of the needle bar 2 is provided with an inverted boss 12, and the needle body 1 is provided with a card slot 13, after the needle body 1 is inserted into the needle bar 2, the inverted boss 12 is just stuck in the In the slot 13, the needle body 1 and the needle bar 2 can be positioned due to the inversion of the boss, and the needle body 1 can rotate freely relative to the needle bar 2. When the needle body 1 is damaged, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com