High-rigidity and high-toughness modified PMMA material and preparation method thereof

A high-toughness, high-rigidity technology, applied in the field of high-rigidity and high-toughness modified PMMA materials and its preparation, can solve problems such as blackness, weather resistance, scratch resistance evaluation, weather resistance decline, coloring decline, etc., to improve durability Effects of light and scratch resistance, improved impact toughness, and improved entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

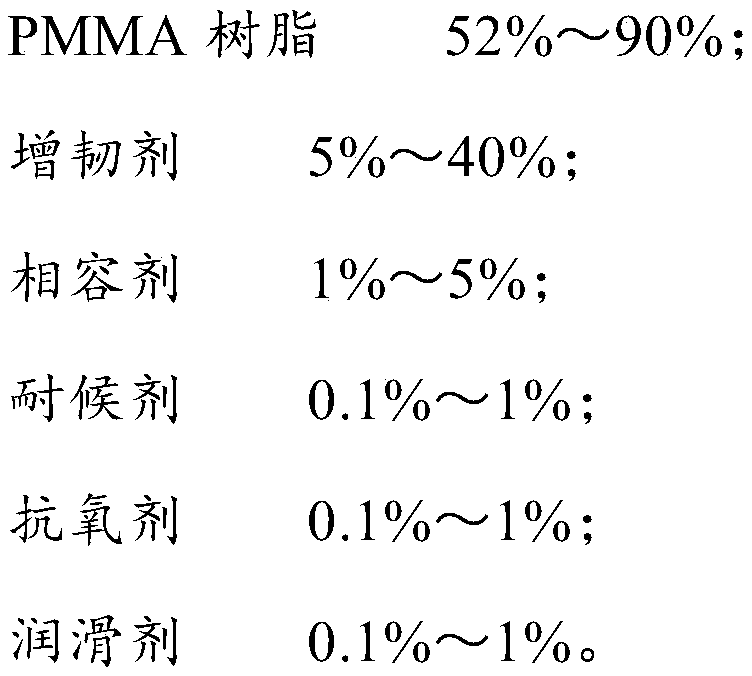

Method used

Image

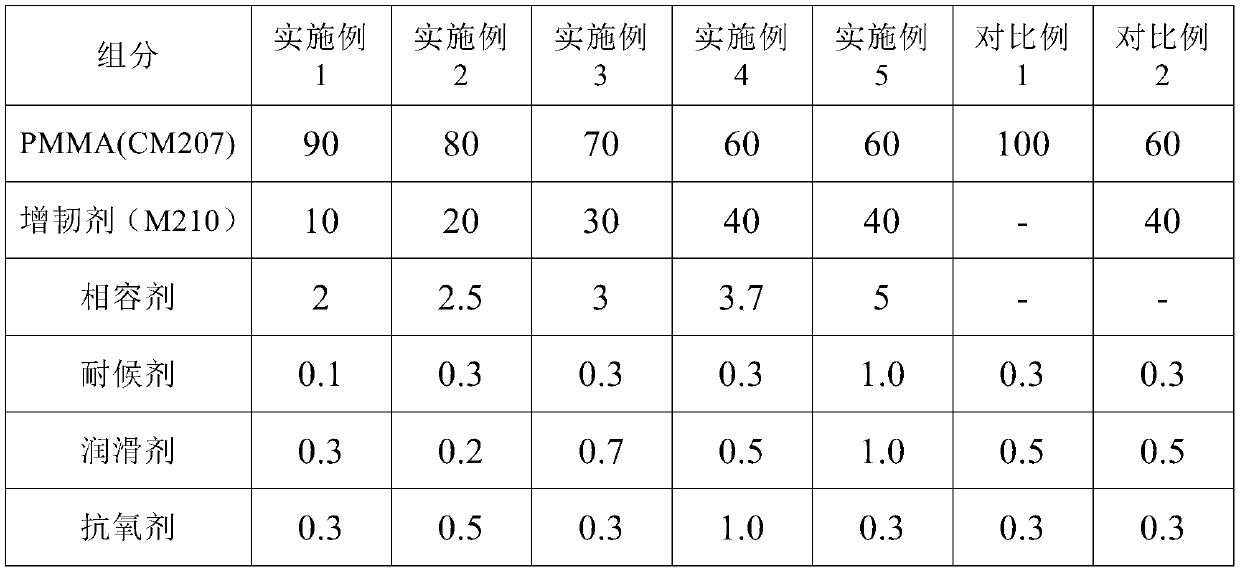

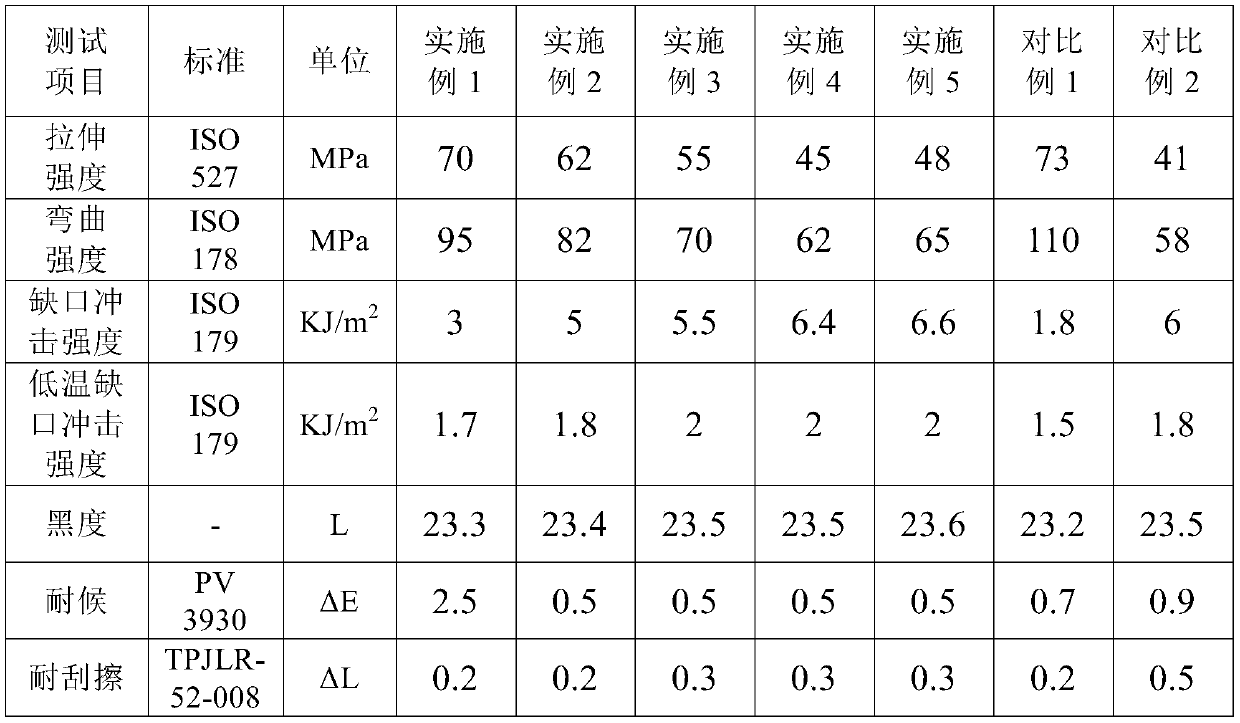

Examples

Embodiment 1

[0028] (1) By weighing parts by weight of each raw material listed in Table 1, take PMMA resin (CM207), toughening agent (M210), compatibilizer (KL-E4370), antioxidant (antioxidant 168), Add the 6 raw materials of weather resistance agent (2-(2'-hydroxy-5'-octylphenyl)-benzotriazole) and lubricant (pentaerythritol stearate) into the high mixer and stir for 3 minutes at a speed of 50rpm ;

[0029] (2) Add to the main feeder of the twin-screw extruder, adjust the main feed and the main engine speed, and finally enter the twin-screw extruder for extrusion and granulation; the twin-screw extruder has 11 barrels , the vacuum ports are located in the sixth and ninth sections of the barrel; the temperature distribution of the twin-screw extruder is as follows: from the feed section to the head: 200°C, 210°C, 220°C, 220°C, 225°C, 225°C, 220°C, 220°C, 220°C, 220°C, 225°C, the screw speed is 400rpm;

[0030] (3) The extruded material is cut into pellets after water cooling, and the pe...

Embodiment 2

[0032] (1) By weighing parts by weight of each raw material listed in Table 1, take PMMA resin (CM207), toughening agent (M210), compatibilizer (KL-E4370), antioxidant (oxidant inhibitor 1010), The six raw materials of weathering agent (2-(2'-hydroxyl-5'-octylphenyl)-benzotriazole), lubricant (barium stearate, magnesium stearate) are added to the high-speed mixer at a high speed Stir at 100rpm for 5 minutes;

[0033] (2) Add to the main feeder of the twin-screw extruder, adjust the main feed and the main engine speed, and finally enter the twin-screw extruder for extrusion and granulation; the twin-screw extruder has 11 barrels , the vacuum ports are located in the sixth and ninth sections of the barrel; the temperature distribution of the twin-screw extruder is as follows: from the feed section to the head: 200°C, 215°C, 215°C, 218°C, 220°C, 225°C, 230°C, 220°C, 220°C, 220°C, 225°C, the screw speed is 450rpm;

[0034] (3) The extruded material is cut into pellets after wate...

Embodiment 3

[0036] (1) By weighing the parts by weight of each raw material listed in Table 1, take PMMA resin (CM207), toughening agent (M210), compatibilizer (KL-E4370), antioxidant (oxidant inhibitor 618), Add the 6 raw materials of weather resistance agent (2-hydroxy-4-n-octyloxy-benzophenone) and lubricant (fatty acid amide, pentaerythritol stearate) into the high mixer and stir at a speed of 100rpm for 10 minutes;

[0037] (2) Add to the main feeder of the twin-screw extruder, adjust the main feed and the main engine speed, and finally enter the twin-screw extruder for extrusion and granulation; the twin-screw extruder has 11 barrels , the vacuum port is located in the sixth and ninth sections of the barrel; the temperature distribution of the twin-screw extruder is as follows: from the feed section to the head: 205°C, 210°C, 215°C, 220°C, 225°C, 230°C, 235°C, 220°C, 218°C, 215°C, 220°C, the screw speed is 400rpm;

[0038] (3) The extruded material is cut into pellets after water c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com