A kind of processing method of multi-layer composite shaped down flakes

A processing method and multi-layer composite technology, which is applied in textiles, papermaking, non-woven fabrics, adhesives, etc., can solve problems such as uneven filling of down, clumsy filling methods, and increased fiber space, so as to reduce labor costs and solve resource shortages , increase the effect of entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

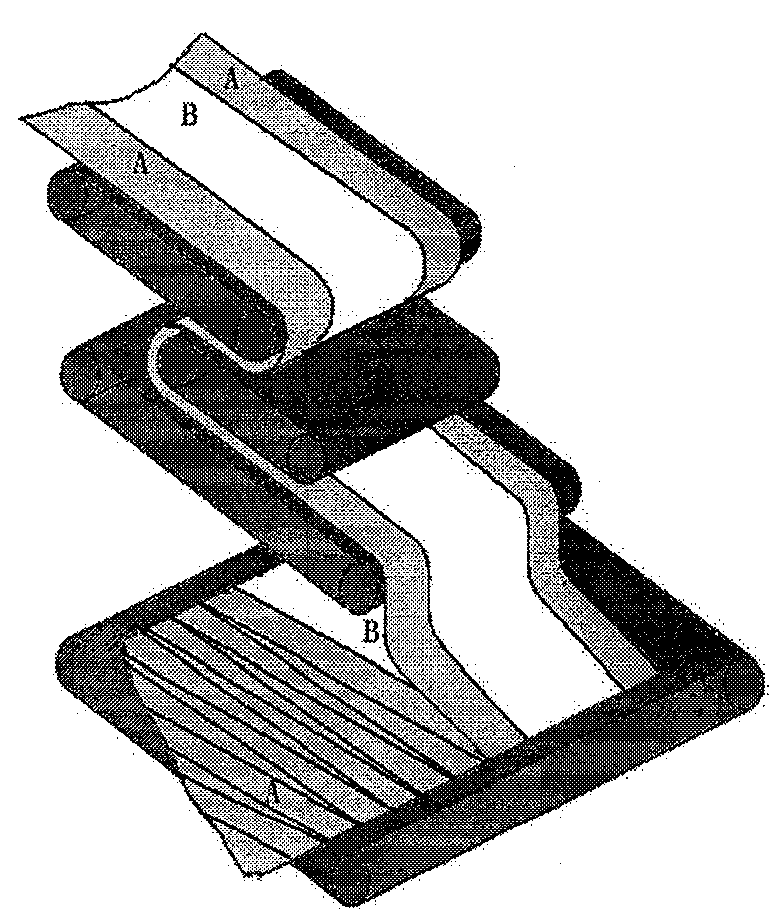

[0038] Such as figure 1 As shown, the production of oil-absorbing down flakes:

[0039] 1. The down material is pinnae, and the mixing ratio is generally: the down (pinne) content of mixed material B is 70%, ES hot-melt fiber 20%; the down content of mixed material A is 20%, polyester 40%, ES hot-melt fiber 40%.

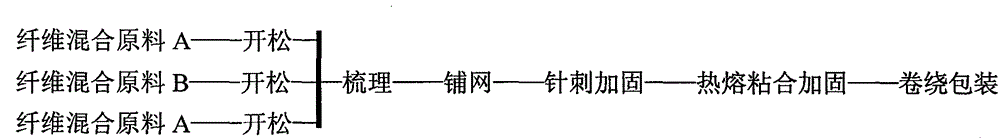

[0040] 2. Process flow such as image 3 as shown,

[0041] 3. Carding adopts a cover-type carding machine. The raw material feeding box of the carding machine is divided into 5 grids along the machine width (1.5m), that is, 5 small raw material feeding boxes are formed, and the width of 1 and 5 boxes is 0.2 m, the width of No. 2 box in the middle is 0.9m, so the blending ratio of the carded fiber web along the width direction of the machine is ABA, in which the width of the fiber web of part B is 0.9m, and the fiber web of part A on both sides is 0.3m .

[0042] 4. The netting adopts cross-laying, and the fiber net after laying is in a sandwich structure, which is...

Embodiment 2

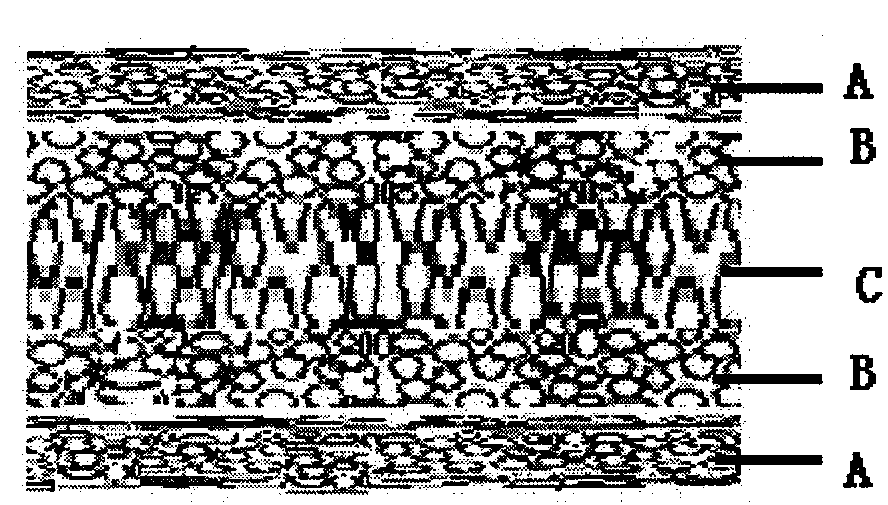

[0046] Such as figure 2 As shown, the production of down flakes for winter protection:

[0047] 1. The down material is high-grade down, and the mixing ratio is generally: the down (high-grade) content of mixed material C is 70%, 4080 hot-melt fiber 20%; the down content of mixed material B is 20%, polyester 40%, 4080 hot-melt Fiber 40%; down content of mixed raw material A is 0%, polyester 60%, ES heat-melt fiber 40%.

[0048] 2. Process flow such as Figure 4 shown.

[0049] 3. Carding adopts a flat carding machine. The raw material feeding box of the carding machine is divided into 5 grids along the machine width (1.5m), that is, 5 small raw material feeding boxes are formed, and the width of 1 and 5 boxes is 0.1m. , Boxes 2 and 4 have a width of 0.20m, and box No. 3 in the middle has a width of 0.9m. The raw material distribution of the carded fiber web along the width direction of the machine is ABCBA, wherein the width of the fiber web in part C is 0.9, and the part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com