Viscosity reducer by emulsification for heavy oil

A technology of emulsification viscosity reduction and viscosity reduction agent, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of increasing the cost of emulsification viscosity reduction, unsuitable for super heavy oil viscosity reduction, and unsuitable compounds, etc. problem, to achieve the effect of low cost, high salt resistance and strong salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Among the present invention, the preparation method of the anionic oligomeric surfactant having the structure shown in formula (I) preferably comprises: under Mannich reaction condition, alkali, taurine, formaldehyde and alkylphenol are mixed in organic solvent Carry out contact reaction in the mixed solvent that forms with water, wherein, described alkali is at least one in lithium hydroxide, sodium hydroxide and potassium hydroxide, and described alkylphenol is p-position alkylphenol, taurine The molar ratio of alkali, formaldehyde and alkylphenol is 1:1-3:2-3:1-2.

[0039] In the present invention, preferably, under Mannich reaction conditions, the alkali, taurine and formaldehyde are first dissolved in a mixed solvent formed of an organic solvent and water, and then an alkylphenol is added to carry out the contact reaction.

[0040] In the present invention, the alkylphenol can be a conventional alkylphenol capable of forming anionic oligomeric surfactants of the fo...

preparation example 1

[0052] Use ethylene glycol monomethyl ether and water as a mixed solvent (volume ratio of 7:3), the amount of the mixed solvent is 200mL, add 64g of potassium hydroxide, 125g of taurine and 63g of formaldehyde to dissolve completely Finally, after reacting at 25°C for 2 hours, add 275g of p-nonylphenol, heat to reflux, react for 4h, evaporate the solvent at 70°C and 0.03MPa, and obtain a viscous oily anionic oligomeric surfactant A1.

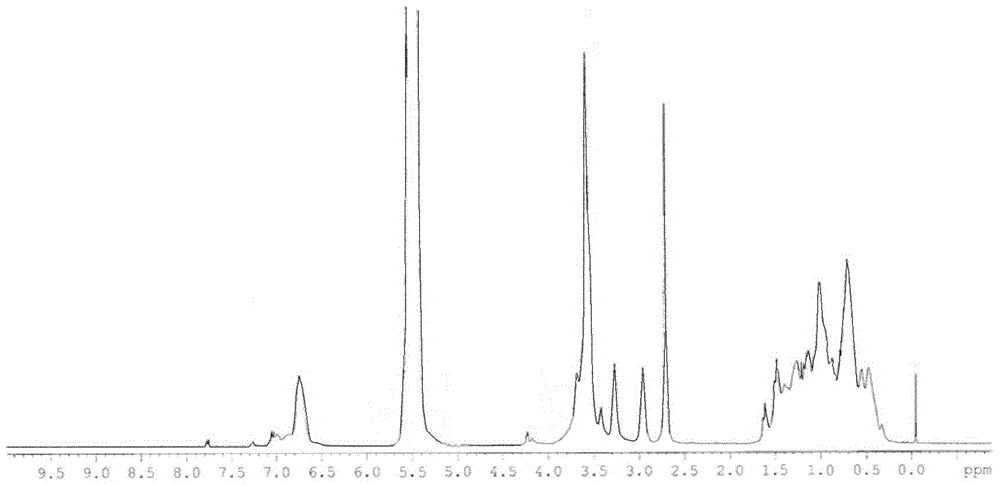

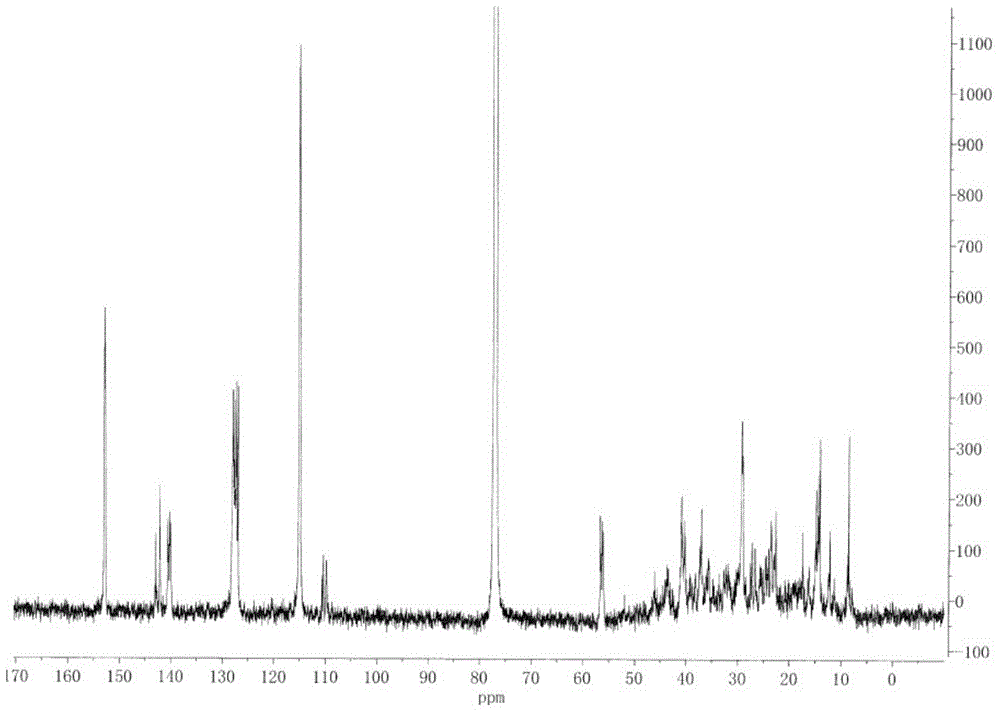

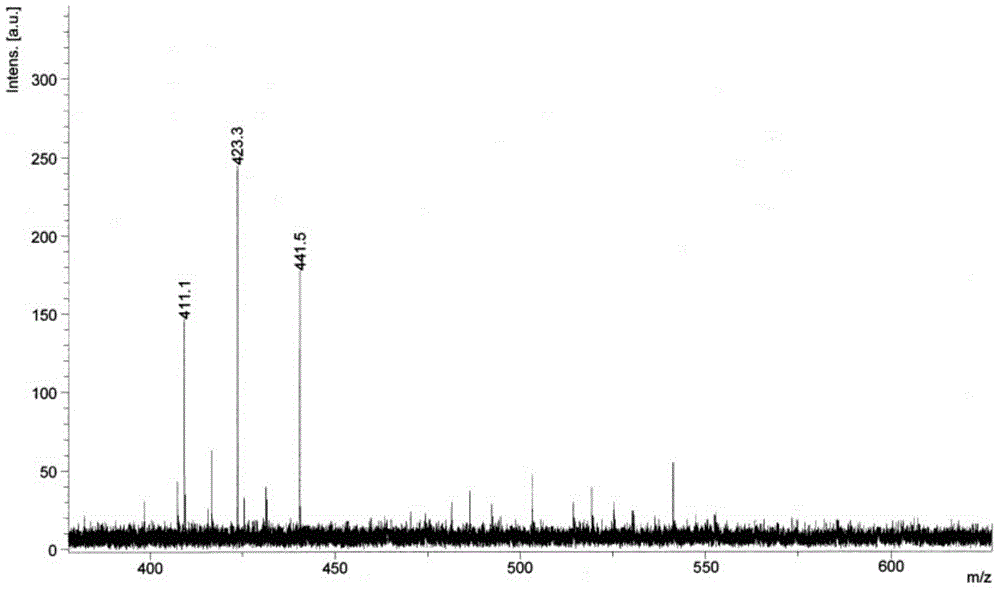

[0053] Carry out hydrogen spectrum, carbon spectrum and mass spectrometry respectively to anionic oligomeric surfactant A1, the hydrogen spectrum, carbon spectrum and mass spectrometry results of A1 are respectively as follows figure 1 , figure 2 , image 3 As shown, it can be drawn from the above spectrogram that the structural formula of A1 is as follows:

[0054]

preparation example 2

[0056] Use tetrahydrofuran and water as a mixed solvent (volume ratio 16:4), the amount of the mixed solvent is 150mL, add 48g of sodium hydroxide, 125g of aminoethanesulfonic acid and 63g of formaldehyde to it, and dissolve it completely at 30°C After reacting for 2 hours, add 275g of p-octylphenol and heat to reflux. After reacting for 6 hours, evaporate the solvent at 50°C and 0.01MPa to obtain viscous oily anionic oligomeric surfactant A2.

[0057] Carry out proton spectrum, carbon spectrum and mass spectrometry respectively to anionic oligomeric surfactant A2, wherein, the mass spectrometry result of A2 is as follows Figure 4 As shown, the hydrogen spectrum and the carbon spectrum spectrum diagram are not shown, it can be drawn from the above spectrum diagram that the structural formula of A2 is as follows:

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com