Antifreezing water reducing agent and preparation technique thereof

The technology of a water reducing agent and an antifreezing agent is applied in the field of antifreezing water reducing agent and its preparation, and can solve the problems of rapid loss of concrete slump, poor water reducing effect of water reducing components, and poor dispersibility of water reducing agent. , to achieve good water reduction effect, enhance antifreeze effect, and increase strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

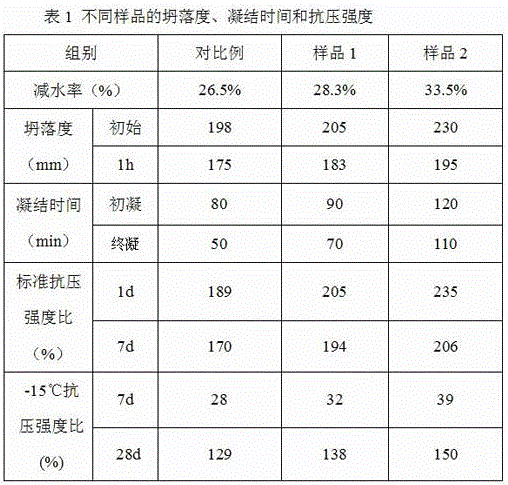

Examples

Embodiment 1

[0019] An antifreeze type water reducer. The raw material for preparing the antifreeze type water reducer is composed of a main material and an antifreeze of 10% by weight of the main material, wherein, according to the weight ratio, the main material is composed of 100 parts aliphatic water reducer and 150 parts It is composed of sodium metaphosphate and 10 parts of early strength agent. The antifreeze agent is composed of 0.5 parts of air-entraining agent, 3 parts of calcium magnesium acetate, 1 part of 2-mercaptoethane sulfonate sodium salt, 2 parts of tetraethylene glycol monooctyl ether, It is composed of 10 parts of nano diatomaceous earth and 5 parts of steel fiber.

[0020] Before the antifreeze agent is used to prepare the antifreeze type water reducing agent, pine wood extract of 5% by weight of the antifreeze agent is added in advance, and the pine wood extract is sequentially crushed, extracted, hydrolyzed, filtered, and dried from the pine tree trunk. The specific op...

Embodiment 2

[0028] An antifreeze type water reducer. The raw material for preparing the antifreeze type water reducer is composed of a main material and an antifreeze of 10% by weight of the main material, wherein, according to the weight ratio, the main material is composed of 105 parts of aliphatic water reducer and 165 parts It is composed of sodium metaphosphate and 12 parts of early strength agent. The antifreeze agent consists of 1 part of air-entraining agent, 4 parts of calcium magnesium acetate, 4.5 parts of 2-mercaptoethane sulfonate sodium salt, 3 parts of tetrapolyethylene glycol monooctyl ether, It is composed of 12.5 parts of nano diatomaceous earth and 6.5 parts of steel fiber.

[0029] Before the antifreeze agent is used to prepare the antifreeze type water reducing agent, pine wood extract of 5% by weight of the antifreeze agent is added in advance, and the pine wood extract is sequentially crushed, extracted, hydrolyzed, filtered, and dried from the pine tree trunk. The spe...

Embodiment 3

[0037] An antifreeze type water reducer. The raw material for preparing the antifreeze type water reducer is composed of a main material and an antifreeze of 10% by weight of the main material, wherein, according to the weight ratio, the main material consists of 110 parts of aliphatic water reducer and 158 parts It is composed of sodium metaphosphate and 15 parts of early strength agent. The antifreeze agent consists of 0.8 parts of air-entraining agent, 5.5 parts of calcium magnesium acetate, 2.5 parts of 2-mercaptoethane sulfonate sodium salt, 3.5 parts of tetraethylene glycol monooctyl ether, It is composed of 11 parts of nano diatomaceous earth and 7.5 parts of steel fiber.

[0038] Before the antifreeze agent is used to prepare the antifreeze type water reducing agent, pine wood extract of 5% by weight of the antifreeze agent is added in advance, and the pine wood extract is sequentially crushed, extracted, hydrolyzed, filtered, and dried from the pine tree trunk. The speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com