Organic/inorganic composite environment-friendly snow melting agent and preparation method thereof

An environment-friendly, inorganic composite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of large influence of ambient temperature, pollution of groundwater, low snow melting efficiency, etc., and achieve simple preparation process, low corrosion, Good snow melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

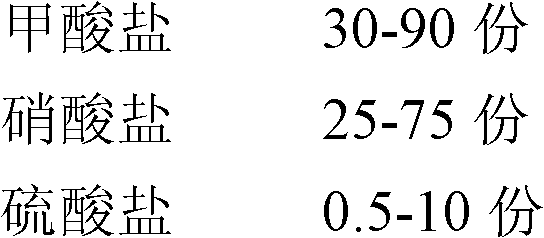

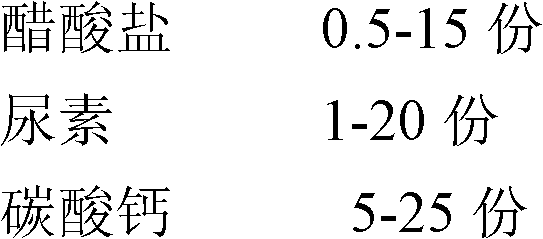

Method used

Image

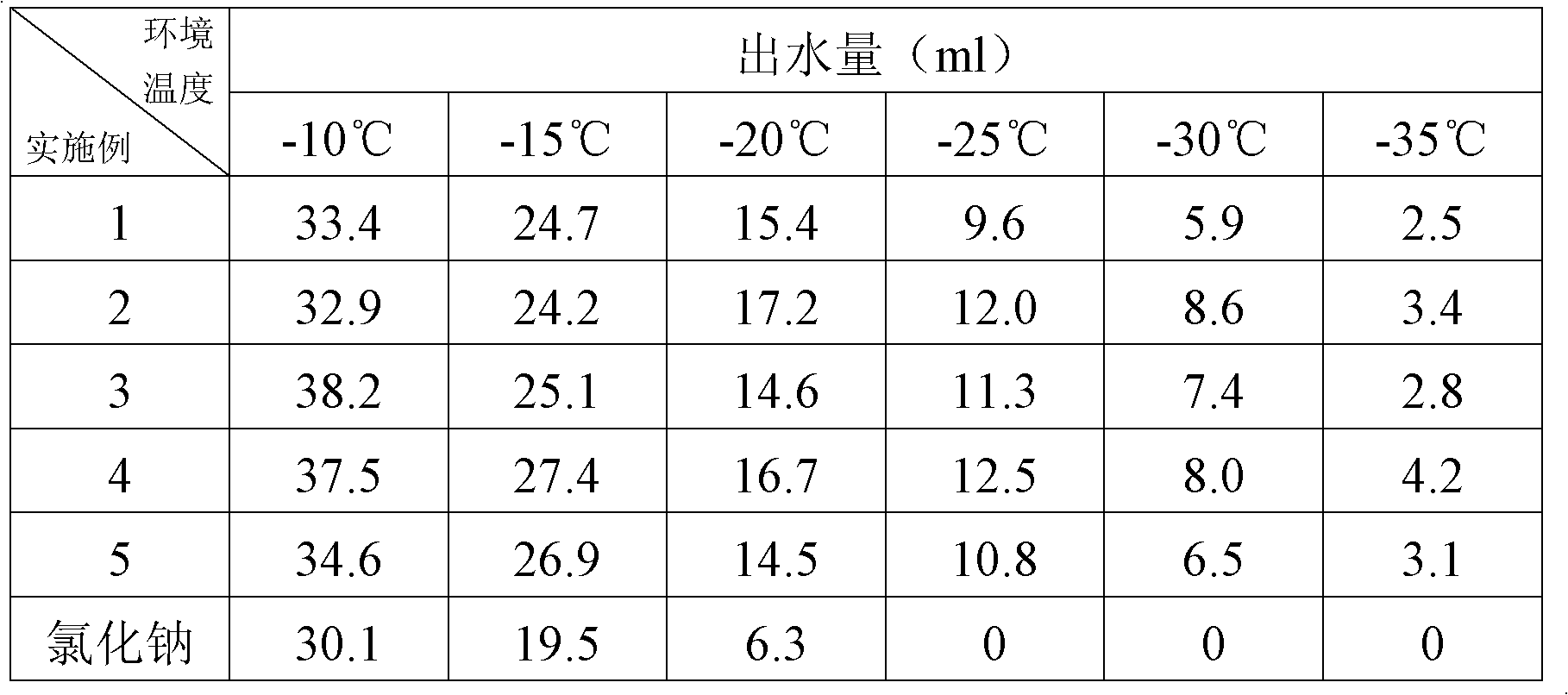

Examples

Embodiment 1

[0015] Preliminarily mix 90 parts by mass of sodium formate, 20 parts by mass of calcium nitrate, 5 parts by mass of potassium nitrate, 0.5 parts by mass of potassium sulfate, 0.5 parts by mass of magnesium acetate, and 4 parts by mass of urea. Mesh sieve, then fully mixed with 25 parts by mass of calcium carbonate particles, immediately sealed in a plastic film bag, and sealed with a woven bag to obtain the deicing agent of the present invention.

Embodiment 2

[0017] 20 parts by mass of sodium formate, 10 parts by mass of potassium formate, 40 parts by mass of magnesium nitrate, 35 parts by mass of sodium nitrate, 10 parts by mass of potassium sulfate, 5 parts by mass of calcium acetate, and 5 parts by mass of urea were preliminarily mixed uniformly, and then the initial mixture was passed through Pulverize with a pulverizer and pass through a 40-mesh sieve, then fully mix with 20 parts by mass of calcium carbonate particles, immediately seal it in a plastic film bag, and seal it with a woven bag to obtain the deicing agent of the present invention.

Embodiment 3

[0019] Preliminarily mix 55 parts by mass of sodium formate, 25 parts by mass of potassium formate, 40 parts by mass of calcium nitrate, 3 parts by mass of sodium sulfate, 15 parts by mass of sodium acetate, and 17 parts by mass of urea. Mesh sieve, fully mixed with 5 parts by mass of calcium carbonate particles, immediately sealed in a plastic film bag, and sealed with a woven bag to obtain the deicing agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com