Coal additive and preparation method thereof

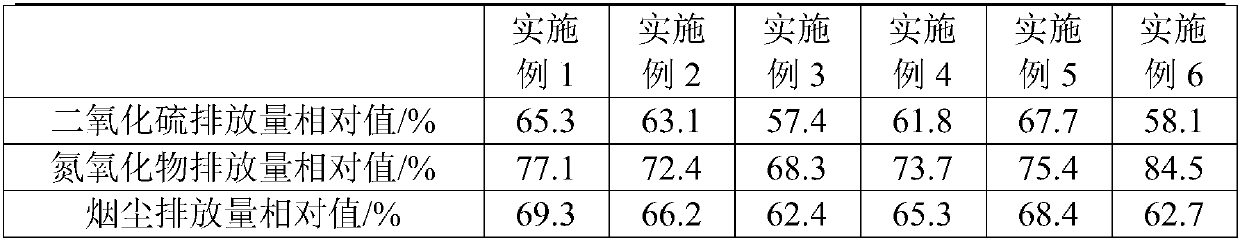

A technology of coal additive and bulking agent, applied in the field of coal additive and its preparation, can solve the problems of environmental pollution, generation of smoke and dust, etc., and achieve the effects of expanding the combustion area, increasing the combustion calorific value, and eliminating coking at the end of the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A method for preparing a coal additive, comprising the steps of:

[0051] Step 1: According to parts by weight, weigh potassium permanganate, potassium perchlorate, ferric chloride, aluminum oxide, calcium magnesium acetate, barium succinate, lauryl polyoxyethylene ether, lauric acid diethanolamide, calcium hydroxide, hydrogen Sodium oxide, polyoxyethylene, catalyst, bulking agent, dispersant, foaming agent, water, urea;

[0052] Step 2: Add potassium permanganate, potassium perchlorate, ferric chloride, aluminum oxide, calcium magnesium acetate, barium succinate, lauryl polyoxyethylene ether, lauric acid diethanolamide, calcium hydroxide, sodium hydroxide, Polyoxyethylene, catalyst, bulking agent, dispersant, foaming agent and urea, just stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com