Novel environment-friendly snow-melting agent and preparation method thereof

A snow-melting agent, an environmentally friendly technology, applied in the field of environmentally friendly snow-melting agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

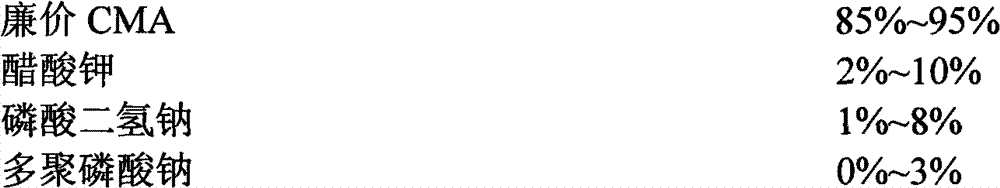

Method used

Image

Examples

Embodiment 1

[0016] 1. Production of cheap CMA primary products through the reaction between glacial acetic acid and dolomite (Ca / MgO) or limestone (Ca / MgCO3). Use highly active hydrated dolomite [Ca(OH)2 / Mg(OH)2] to ensure n(Mg) / n(Ca)=7 / 3, and an excess of 2%, to ensure a certain pH value to achieve the best good response. The product contains 10% to 35% of generated water, and the initial product often also contains excessive acid or alkali, and then the pH of the solution is adjusted to 7 with sodium dihydrogen phosphate or ammonium dihydrogen phosphate.

[0017] 2. The by-product emulsion in the milk cheese production process is used as the raw material, and most of the solid components are removed through osmosis. The obtained whey is cyclically fermented in a fixed cell bioreactor, the cell density in the fermentation broth is 30g / L, the temperature is controlled at 37°C, the whey is fermented with S.lactis lactic acid bacteria strain to produce lactic acid, and then C.formicoacetic...

Embodiment 2

[0020] 1. React MgO with excess acetic acid to form a mixed solution of magnesium acetate and acetic acid, and then neutralize the unreacted acetic acid with hydrated limestone to obtain CMA. During the reaction, ensure that n(Mg) / n(Ca)=7 / 3. The optimal composition of CMA as a deicing agent is n(Mg) / n(Ca)=7 / 3, which is close to the lowest eutectic point (-37) of the two acetates, and has a high heat capacity. During the drying process, It is not easy to decompose at 100°C. Compared with the composition of equimolar CMA, it is not easy to scale on concrete.

[0021] 2. The by-product emulsion in the milk cheese production process is used as the raw material, and most of the solid components are removed through osmosis. The obtained whey is cyclically fermented in a fixed cell bioreactor, the cell density in the fermentation broth is 30g / L, the temperature is controlled at 37°C, the whey is fermented with S.lactis lactic acid bacteria strain to produce lactic acid, and then C.f...

Embodiment 3

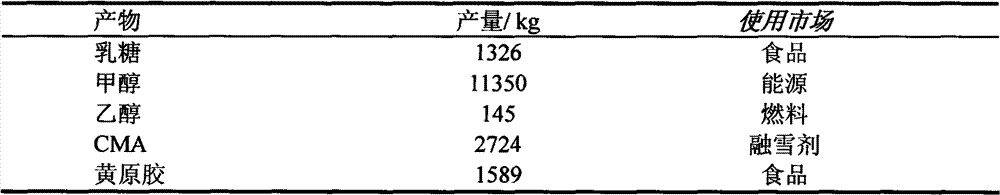

[0024] 1. The by-product emulsion in the milk cheese production process is used as the raw material, and most of the solid components are removed through osmosis. The obtained whey is cyclically fermented in a fixed cell bioreactor, the cell density in the fermentation broth is 30g / L, the temperature is controlled at 37°C, the whey is fermented with S.lactis lactic acid bacteria strain to produce lactic acid, and then C.formicoaceticum is used Acetobacter strains ferment lactic acid to acetic acid. Control the temperature at 75-85°C, then use secondary or tertiary amine to extract acetic acid, use calcium magnesium oxide or calcium magnesium carbonate as stripping agent, and the stripping product is CMA. The process can also adopt the method of coupling reaction and separation, that is, extractive fermentation method, to improve conversion rate and yield. In the process, the yields of lactic acid and acetic acid fermentation are respectively 98.8% and 96.7%, and the total yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com