Humectants for inhibiting flying dust of calcium carbonate and preparation method of humectants

The technology of a dust suppressant and a moisturizing agent is applied in the field of a moisturizing agent for suppressing dust emission of calcium carbonate and its preparation field. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

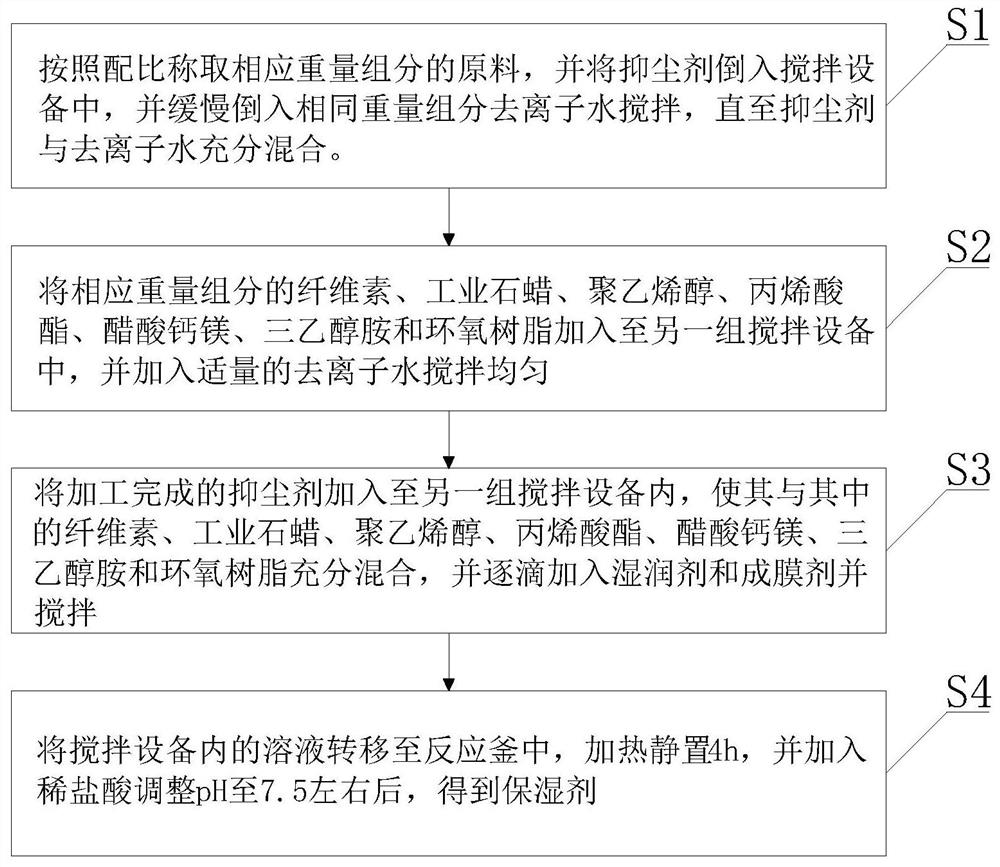

[0032] see figure 1 , a humectant for suppressing calcium carbonate dust, comprising the following components by weight: 20 components of crust dust suppressant, 5 components of water-soluble dust suppressant, 28 components of wetting agent, 25 components of film-forming agent, 15 components of Divided into cellulose, 15 components of industrial paraffin, 2 components of polyvinyl alcohol, 2 components of acrylate, 2 components of calcium magnesium acetate, 2 components of triethanolamine and 3 components of epoxy resin.

[0033] see figure 1 In order to better demonstrate the preparation process of the moisturizing agent for suppressing calcium carbonate dusting, the present embodiment now proposes a preparation method of a moisturizing agent for suppressing calcium carbonate dusting, comprising the following steps:

[0034] Step 1: Weigh the raw materials of the corresponding weight components according to the proportion, pour the crust dust suppressant and water-soluble du...

Embodiment 2

[0045] A humectant for suppressing calcium carbonate dust, comprising the following components by weight: 5 components of crust dust suppressant, 20 components of water-soluble dust suppressant, 28 components of wetting agent, 25 components of film-forming agent, 15 components Cellulose, 15-component industrial paraffin, 2-component polyvinyl alcohol, 2-component acrylate, 2-component calcium magnesium acetate, 2-component triethanolamine and 3-component epoxy resin.

[0046] see figure 1 In order to better demonstrate the preparation process of the moisturizing agent for suppressing calcium carbonate dusting, the present embodiment now proposes a preparation method of a moisturizing agent for suppressing calcium carbonate dusting, comprising the following steps:

[0047] Step 1: Weigh the raw materials of the corresponding weight components according to the proportion, pour the crust dust suppressant and water-soluble dust suppressant into the mixing equipment, and slowly pou...

Embodiment 3

[0059] A humectant for suppressing calcium carbonate dust, comprising the following components by weight: 10 components of crust dust suppressant, 10 components of water-soluble dust suppressant, 28 components of wetting agent, 25 components of film-forming agent, 15 components of Cellulose, 15-component industrial paraffin, 2-component polyvinyl alcohol, 2-component acrylate, 2-component calcium magnesium acetate, 2-component triethanolamine and 3-component epoxy resin.

[0060] see figure 1 In order to better demonstrate the preparation process of the moisturizing agent for suppressing calcium carbonate dusting, the present embodiment now proposes a preparation method of a moisturizing agent for suppressing calcium carbonate dusting, comprising the following steps:

[0061] Step 1: Weigh the raw materials of the corresponding weight components according to the proportion, pour the water-soluble dust suppressant and crust dust suppressant into the mixing equipment, and slowly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com