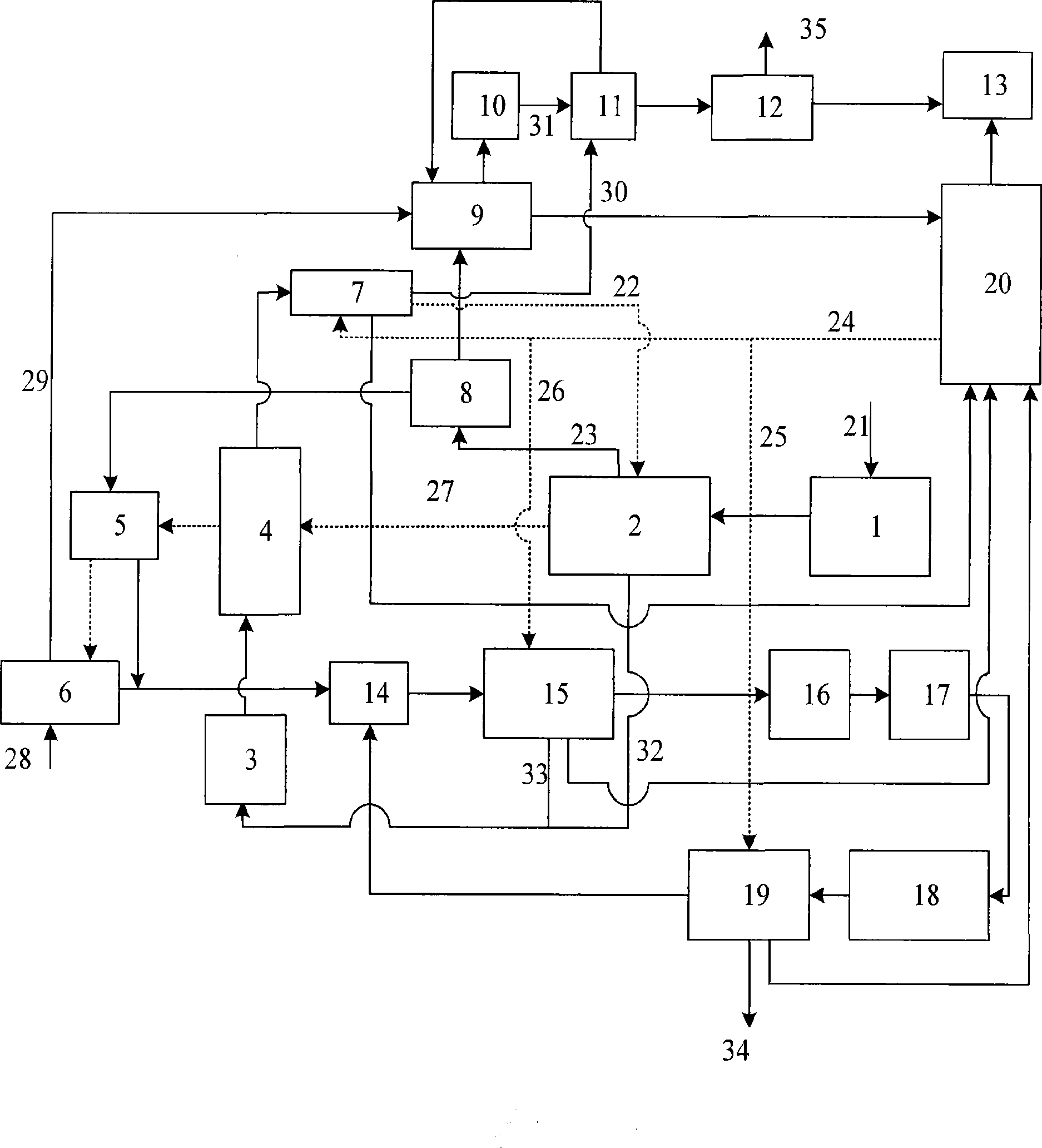

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

A waste gas treatment and waste water technology, which is applied in process technology, waste residue, furfural production enterprise energy saving and three waste treatment transformation, waste gas treatment integrated process, furfural production process optimization energy saving and waste water field, can solve waste residue, waste gas cannot be completely treated, waste water Solve the problems of large investment and high operating cost, and achieve the effect of low equipment maintenance cost, low operating cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0024] The function and process operation parameters of each main equipment in the system are as follows:

[0025] Acid mixing pool 1: The raw materials and the catalyst are mixed and mixed well here.

[0026] Hydrolysis pot 2: the main reaction area, in this equipment, the raw materials for furfural production react to form furfural in the presence of catalysts under high temperature and high pressure water vapor atmosphere.

[0027] pH value adjustment pool 3: After the waste water generated in the reaction enters this equipment, limestone and dolomite are added to neutralize the waste water, and the slag is removed after continuous sedimentation.

[0028] Heat exchanger 4: In this equipment, the wastewater from 3 exchanges heat with the high-temperature aldehyde vapor from hydrolysis pot 2, and the temperature of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com