Preparation process and application of calcium magnesium acetate

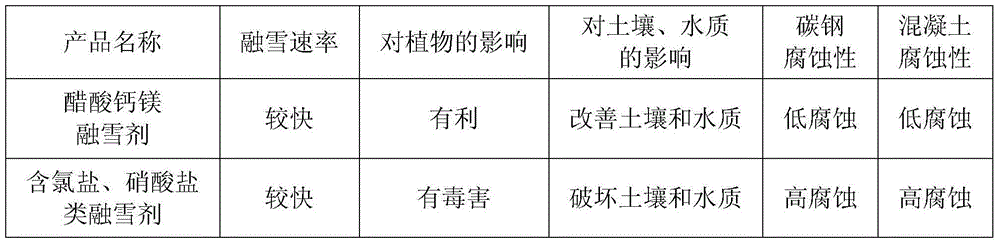

A preparation technology of calcium magnesium acetate, applied in carboxylate preparation, carboxylate preparation, organic compound preparation, etc., can solve problems such as damage, human health hazards, water pollution, etc., and achieve control of air pollution and equipment investment Less and more productive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

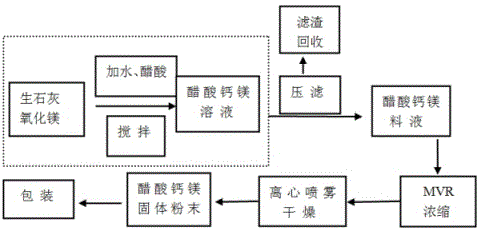

[0044] figure 1 It is a process flow diagram for the preparation of calcium magnesium acetate. Such as figure 1 Shown, the preparation technology of calcium magnesium acetate (CMA) comprises the following processing steps:

[0045] (1) Preparation of calcium magnesium acetate solution: 8.9kg of quicklime and 34kg of magnesium oxide are added to the reactor according to the molar ratio of calcium and magnesium in the reaction raw materials is 6:4, and then 60kg of water is added to the reactor to meet the requirements of water and quicklime and oxidation The mass ratio of the total amount of magnesium is 1.4:1. After fully stirring, 97.1kg of acetic acid is added for reaction. The reaction temperature is kept at 70-80°C. When the pH value of the solution is 7-8, stop adding acetic acid. Finally, the total amount of acetic acid and quicklime The molar ratio to the total amount of magnesium oxide is 3.6:1, and then stirred and reacted for 4 to 5 hours to obtain calcium magnesiu...

Embodiment 2

[0051] (1) Preparation of calcium magnesium acetate solution: 8.9kg of quicklime and 27kg of magnesium oxide are added to the reactor according to the molar ratio of calcium and magnesium in the reaction raw materials of 6.5:3.5, and then 60kg of water is added to the reactor to meet the requirements of water and quicklime and oxidation The mass ratio of the total amount of magnesium is 1.7:1. After fully stirring, add 80.1kg of acetic acid to react. The reaction temperature is kept at 70-80°C. When the pH value of the solution is 7-8, stop adding acetic acid. Finally, the total amount of acetic acid and quicklime The molar ratio to the total amount of magnesium oxide is 4:1, and then stirred and reacted for 4 to 5 hours to obtain calcium magnesium acetate solution;

[0052] (2) press filtration: the calcium magnesium acetate solution that reacts carries out solid-liquid separation through filter press again, promptly obtains feed liquid and filter residue of calcium magnesium ...

Embodiment 3

[0057] (1) Preparation of calcium magnesium acetate solution: 8.9kg of quicklime and 22kg of magnesium oxide are added to the reaction kettle according to the molar ratio of calcium and magnesium in the reaction raw materials being 7:3, and then 60kg of water is added to the reaction kettle to meet the requirements of water and quicklime and oxidation. The mass ratio of the total amount of magnesium is 1.9:1. After fully stirring, 68.1kg of acetic acid is added for reaction. The reaction temperature is maintained at 70-80°C. When the pH value of the solution is 7-8, stop adding acetic acid. Finally, the total amount of acetic acid and quicklime The molar ratio to the total amount of magnesium oxide is 4.5:1, and then stirred and reacted for 4 to 5 hours to obtain calcium magnesium acetate solution;

[0058] (2) press filtration: the calcium magnesium acetate solution that reacts carries out solid-liquid separation through filter press again, promptly obtains feed liquid and fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com