Guide sliding shoe remanufacturing method

A technology of guiding slipper and remanufacturing, applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of difficulty in controlling the depth of wear-resistant layers, reducing the strength of wear-resistant layers, and affecting the depth of wear-resistant layers, etc. To achieve the effect of easy guarantee of size and wear resistance, enhanced wear resistance, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

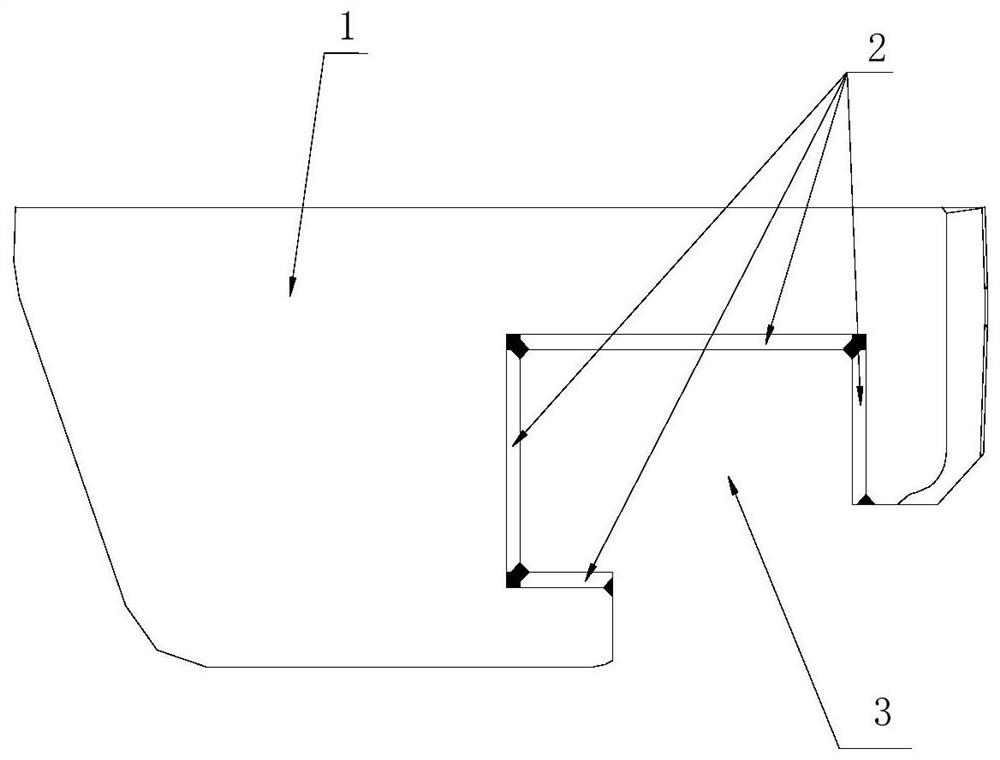

[0029] Such as figure 1 Shown, a kind of guiding shoe remanufacturing method comprises the following steps:

[0030] The first step is to determine whether the guide shoe 1 meets the remanufacturing standard. Specifically, check whether the guide shoe 1 has any appearance defects such as damage and missing, whether there are breaks and cracks in the guide groove 3 and other places, and whether the guide groove 3 is damaged or not. The degree of wear of the original wear-resistant layer, the tolerances of various sizes and shapes and the roughness of the surface, the hardness of the guide shoe 1 itself and the original wear-resistant layer, conduct non-destructive testing on the guide shoe 1 as a whole, and determine whether there is Other hidden flaws.

[0031] The remanufacturing standard is: the mating surfaces of the guide shoe 1 and the pin row include the upper mating surface, the lower mating surface, the left mating surface and the right mating surface, and the limit v...

Embodiment 2

[0041] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0042] The chamfer is 45°, the width of the chamfer is 5mm, a total of 4 chamfers are processed, the welding angle is 15°, the angle of the second groove is 45°, and the width of the second groove is 5mm.

[0043] Use J506 / J507 electrode for arc welding. The diameter of the electrode is 3.2mm. The welding current is 90-130A. Medium heat preservation, ready to use.

[0044] After the remanufacturing is completed, the appearance and quality of the weld are inspected, and the inspection results are as follows: the appearance of the weld is flat, without cracks, pores, slag inclusions, burrs, dirt and other defects; the quality of the weld meets the JBT6062-20071 level inspection; The manufacturing dimensions, geometric tolerances and roughness meet the design requirements of the original drawings; the hardness test for remanufacturing should comply with GB / T231.1-2018.

Embodiment 3

[0046] The same part of this embodiment and embodiment two will not be repeated, the difference is:

[0047] Use ER50-6 and equivalent welding wire for gas shielded welding. The diameter of the welding wire is 1.2mm. There must be no oil and rust on the surface of the welding wire. The welding current is 180-220A.

[0048] After the remanufacturing is completed, the appearance and quality of the weld are inspected, and the inspection results are as follows: the appearance of the weld is flat, without cracks, pores, slag inclusions, burrs, dirt and other defects; the quality of the weld meets the JBT6062-20071 level inspection; The manufacturing dimensions, geometric tolerances and roughness meet the design requirements of the original drawings; the hardness test for remanufacturing should comply with GB / T231.1-2018.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com