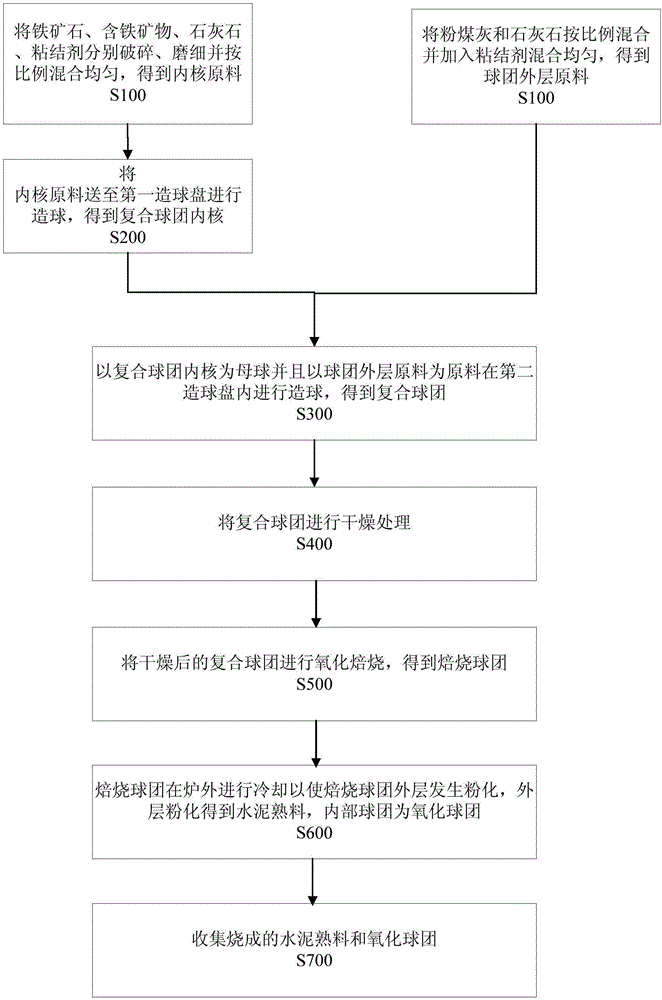

Method for producing cement clinker and oxide pellets

A technology of cement clinker and oxidized pellets, which is applied in the field of metallurgy, can solve the problems of low grinding index, many harmful elements, and difficulty in blast furnace smelting, and achieve the effects of saving electric energy, good metallurgical performance, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

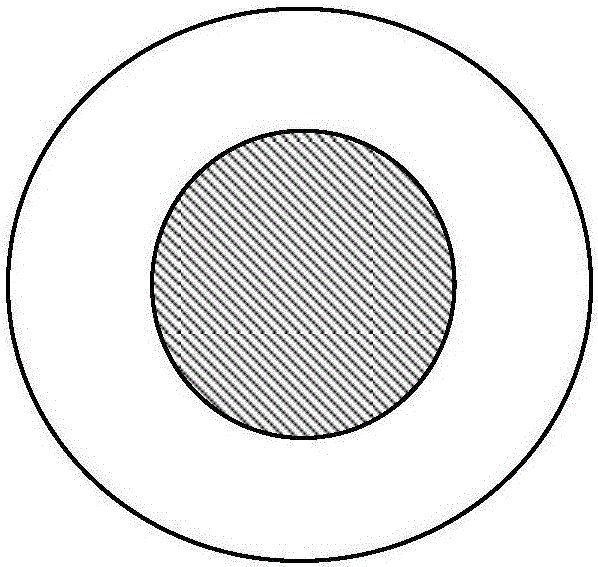

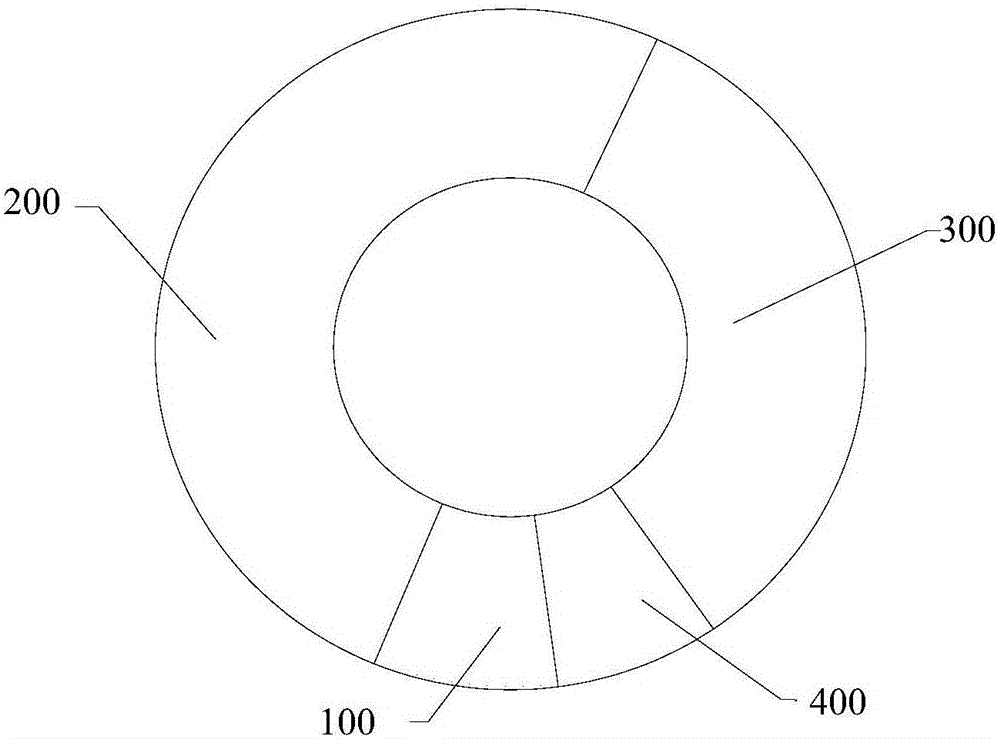

Embodiment 1

[0040] The pyrite, copper smelting slag, limestone, and binder are respectively crushed and ground to about 0.075mm, which accounts for 8% of the screen. After that, 68 parts by weight of pyrite, 30 parts by weight of copper smelting slag, 20 parts by weight of limestone and 6 parts by weight of binder were mixed uniformly, and the pellet core was formed in the first pelletizing plate, and passed through a sieve The sieving device performs sieving, and the particle size is about 9-14mm for the next step. After the particle size does not meet the requirements, it will continue to be used as the pelletizing raw material. The fly ash and limestone are in accordance with the CaO / SiO contained in the cement clinker produced 2 =2 ratio for compounding and adding 4% of the total raw material weight percentage of binder, mixing uniformly. The fly ash and limestone mixture and the prepared pellet cores are fed into the second pelletizing disk through a feeder, and the water volume and t...

Embodiment 2

[0043] The pyrite, nickel smelting slag, limestone, and binder are all crushed and ground to about 0.075mm, which accounts for 10% of the screen. Afterwards, 78 parts by weight of pyrite, 20 parts by weight of nickel smelting slag, 23 parts by weight of limestone and 4 parts by weight of binder were mixed uniformly, and the pellet core was formed in the first pelletizing disc, and passed through a sieve The sieving device performs sieving, and the particle size is about 9-14mm for the next step, and the particle size that does not meet the requirements is processed and continues as the pelletizing raw material. The fly ash and limestone are in accordance with the CaO / SiO contained in the cement clinker produced 2 =2.2 proportion of ingredients and adding 6% of the total raw material mass percentage of binder, mixing uniformly. The fly ash and limestone mixture and the prepared pellet cores are fed into the second pelletizing disk through the feeder, and the water volume and the...

Embodiment 3

[0046] Pyrite, blast furnace vanadium-titanium slag, limestone, and binder are respectively crushed and ground to about 0.075mm, accounting for 12% of the screen. After that, 88 parts by weight of pyrite, 10 parts by weight of blast furnace vanadium-titanium slag, 25 parts by weight of limestone and 2 parts by weight of binder were mixed uniformly to form a pellet core in the first pelletizing plate, and passed The sieving device performs sieving, the particle size is about 9-14mm for the next step, and the particle size does not meet the requirements for processing and continues as the pelletizing raw material. The fly ash and limestone are in accordance with the CaO / SiO contained in the cement clinker produced 2 =2.4 ratio of ingredients and 8% of the total raw material mass percentage of binder is added, and the mixture is uniform. The fly ash and limestone mixture and the prepared pellet cores are fed into the second pelletizing disk through a feeder, and the water volume a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com