Small-diameter collecting pipe branch pipe drawing process tooling

A collection tube and small-diameter technology, which is applied in the field of drawing process tooling for small-diameter manifold branch pipes, can solve the problems of difficulty in ensuring the straightness and surface quality of the main pipe, affecting metal properties, and waste of metal materials, so as to achieve efficient use of materials. , The effect of reducing the influence of metal properties and reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

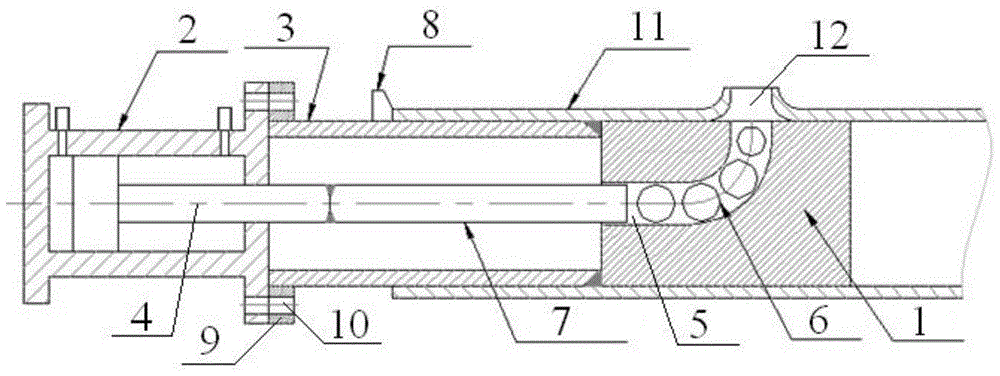

[0015] The key is that the process tooling for small-diameter collecting pipe branch drawing is: the process tooling includes a cylindrical mold 1, an oil cylinder 2, and a guide sleeve 3, one end of the mold 1 is fixedly connected with one end of the guide sleeve 3, and the other end of the guide sleeve 3 One end forms a locking fit with the oil cylinder 2, the diameter of the mold 1 and the outer diameter of the guide sleeve 3 are equal to the inner diameter of the manifold 11, the telescopic rod 4 of the oil cylinder 2, the guide sleeve 3 and the mold 1 are arranged coaxially, and the guide sleeve 3 is The positioning device forms axial positioning with the manifold 11, and one end of the fixed connection between the mold 1 and the guide sleeve 3 is provided with a horizontal ball hole matching the telescopic rod 4, and the side wall of the mold 1 is provided with a vertical ball hole radially, The horizontal ball hole and the vertical ball hole are connected to form a steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com