A joint gasification nozzle of coal liquefaction residue and coal water slurry and its application

A technology of coal liquefaction residue and combined gasification, which is applied to liquid injection devices, granular/powder fuel gasification, injection devices, etc. Improve the efficiency of energy recovery and improve the effect of atomization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

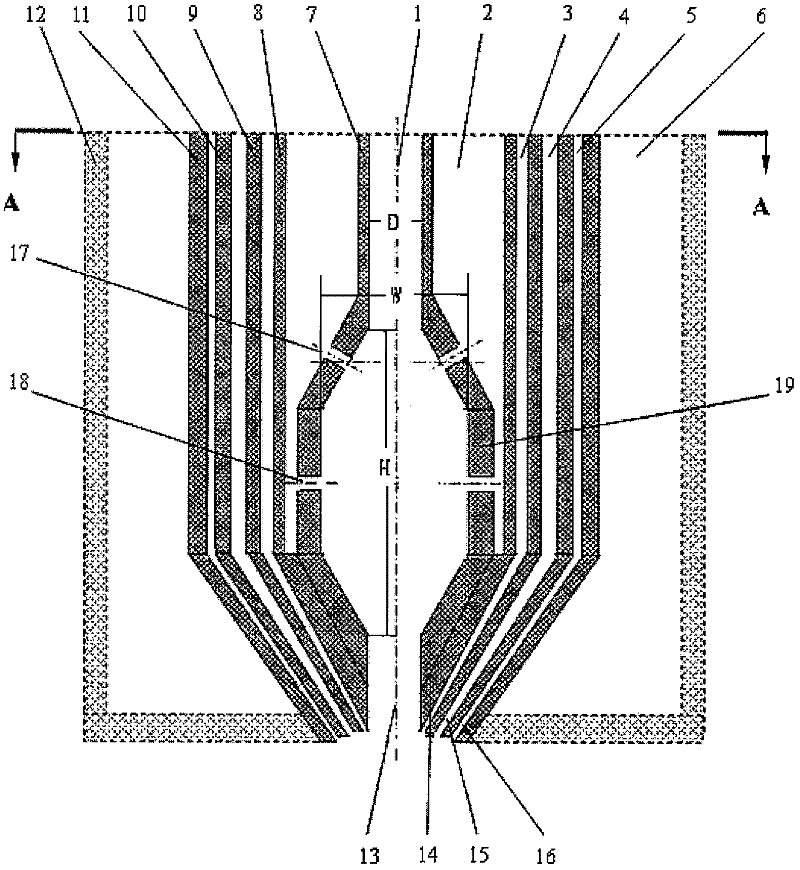

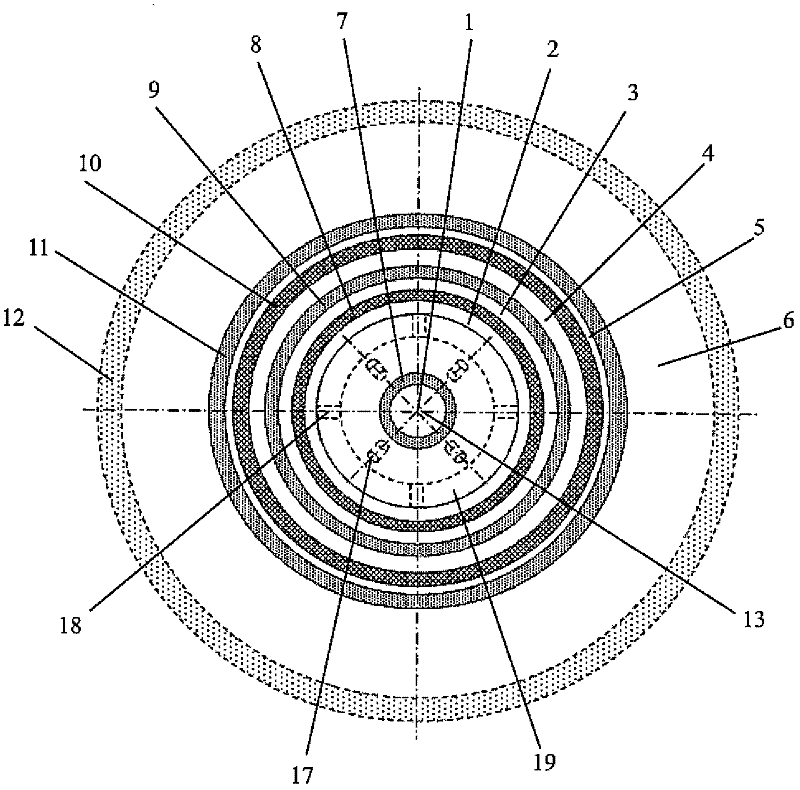

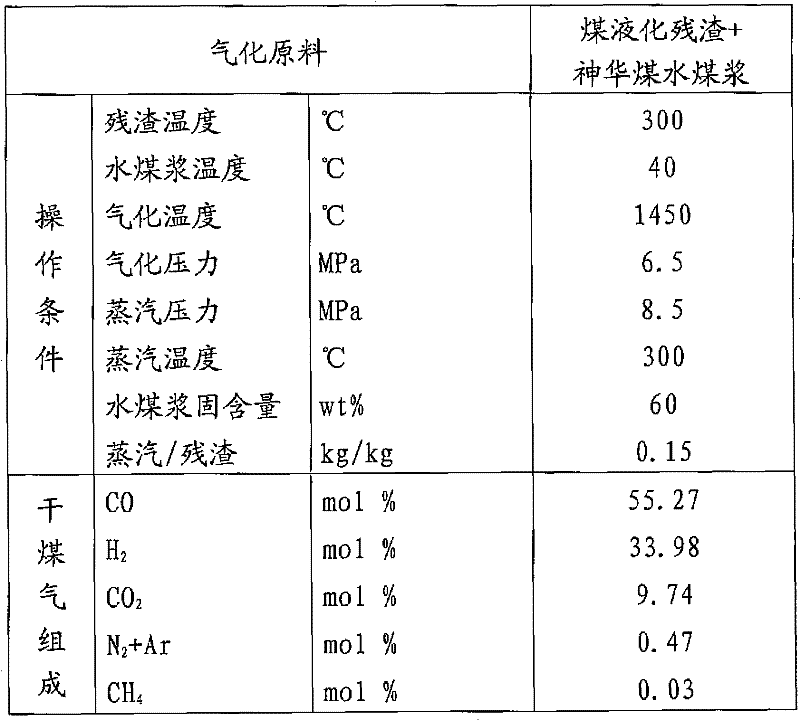

[0049] put one such as figure 1 The gasification nozzle shown is set in a Texaco coal-water slurry gasifier, and the gasification raw material and gasification agent are sprayed into the gasifier from top to bottom. The high-temperature viscous coal liquefaction residue obtained from the oil residue discharge of the coal direct liquefaction unit of China Shenhua Coal to Oil Chemical Co., Ltd. is used as one of the gasification raw materials, and the Shenhua coal produced in Shenfu Dongsheng Coalfield is made into a concentration Coal-water slurry with 60wt% (i.e. solid content of coal-water slurry) is used as another gasification raw material, and the above-mentioned two gasification raw materials are jointly gasified in the gasifier by direct feeding to produce syngas (CO+H 2 ). The mass ratio of the coal liquefaction residue entering the gasification nozzle per unit time to the dry coal contained in the Shenhua coal-water slurry entering the gasification nozzle per unit ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com