Method for preparing light building material ceramic particle by utilizing slate sawn mud

A technology for building materials pottery and slate, which is applied in applications, ceramic products, household appliances, etc., can solve the problems of difficulty in utilization, uneven particle size, poor plasticity, etc., and achieve simplified production process, low production cost, and compact The effect of increasing the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The chemical composition of the used slate saw mud (dried) is shown in Table 2.

[0018] The chemical composition (%) of table 2 slate saw mud

[0019] SiO 2

al 2 o 3

CaO

MgO

K 2 O+NaO

Fe 2 o 3

FeO

57.30

18.90

0.65

0.60

3.85

0.80

7.50

SO 2

C

MnO

P 2 o 5

LOSS

0.20

2.80

0.15

0.95

6.30

[0020] The ratio of raw materials is (mass percentage): 70% of slate saw mud (moisture content 30% ± 2%), 30% of slate dry powder, and 1.5% sodium silicate binder (mixed in ball forming solution in water).

[0021] The slate sawing mud is muddy at the beginning due to its high water content, and becomes a large mud mass after the surface is air-dried. It needs to be mixed with slate powder (particles smaller than 1mm from crushed slate) in a twin-shaft mixer Stir to form loose particles, and then enter the ball forming machine...

Embodiment 2

[0026] The ratio of raw materials is: 65% of slate saw mud (water content 30%±2%), 35% of slate powder, and 1.5% of sodium silicate binder.

[0027] The raw materials are mixed and stirred in a test mixer to become granular, and the balls of ф5-20mm are made in a drum granulator, and the balls are put into a corundum crucible, put into a high-temperature furnace, dried and pre-fired at 300°C for 10 minutes, and then placed Put it into a silicon carbide rod high-temperature furnace for calcination at 1150°C for 30 minutes, then take it out of the furnace and cool to room temperature.

Embodiment 3

[0029] The ratio of raw materials is: 100% slate saw mud (water content 15% ± 1%), and 1.5% sodium silicate binder is added outside.

[0030] The slate sawing mud is made into ф5-20mm balls in a drum granulator, put the balls into a corundum crucible, put them in a high-temperature furnace, dry and pre-fire at 300°C for 10 minutes, and then put them into a silicon carbide rod high-temperature furnace Calcined at 1150°C for 30 minutes, then cooled to room temperature.

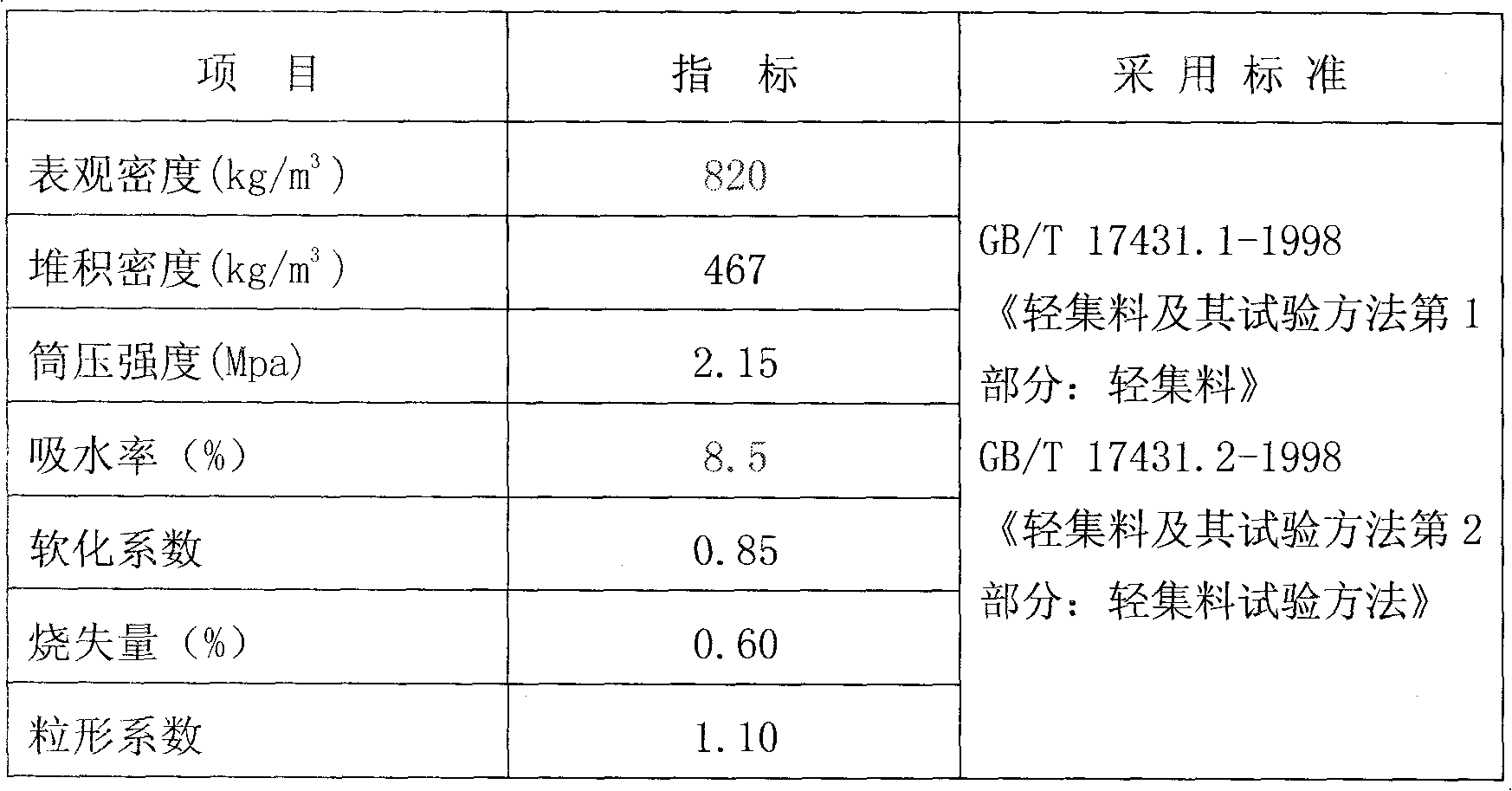

[0031] The product part performance technical index of embodiment 2-3 is shown in Table 4.

[0032] Table 4 Some performance indicators of different example products

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com