Preparation method of lithium vanadium phosphate positive electrode material

A positive electrode material, lithium vanadium phosphate technology, applied in the field of lithium ions, can solve the problem of discharge specific capacity decline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

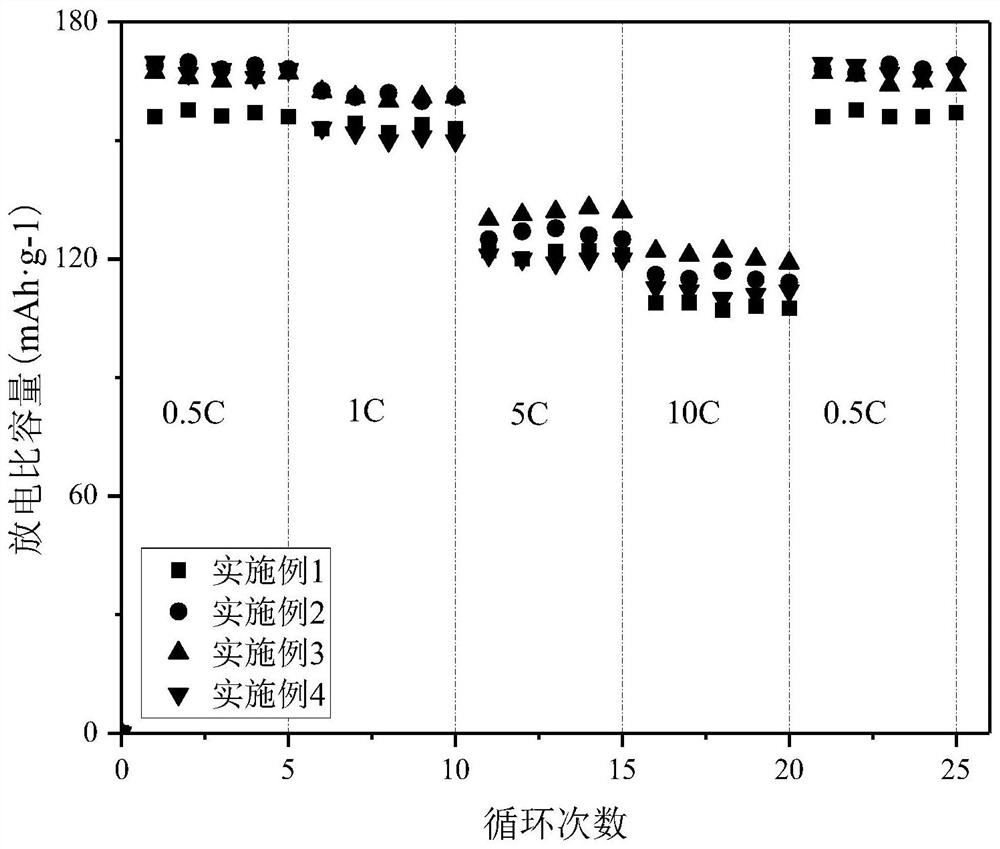

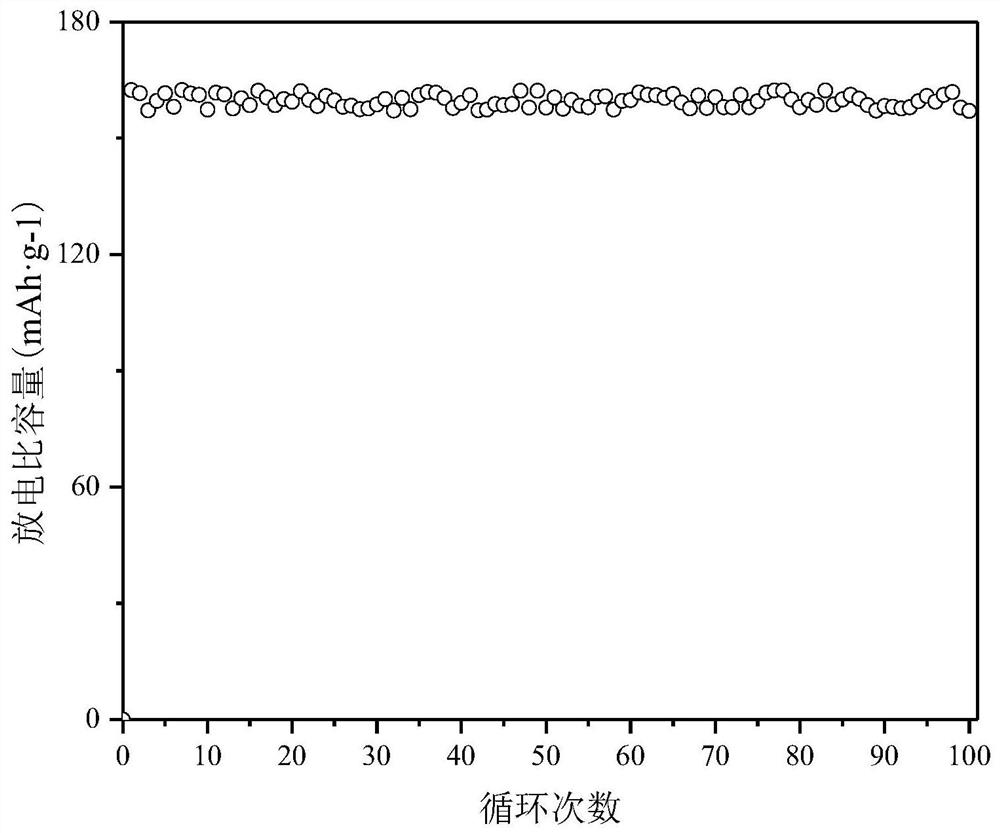

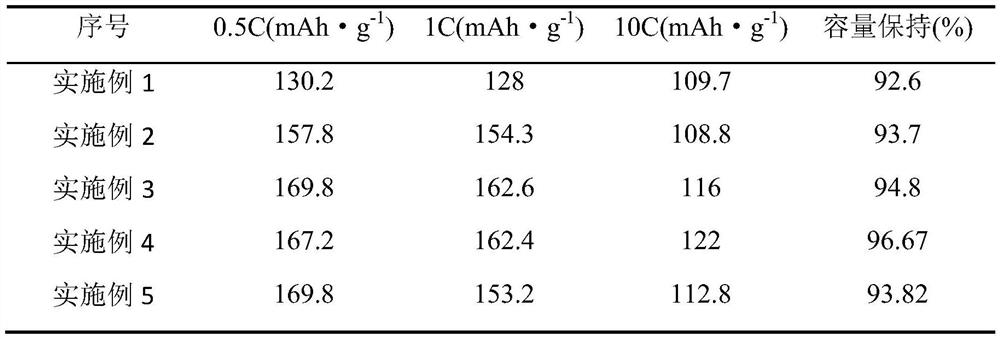

Examples

preparation example Construction

[0027] Embodiments of the present invention provide a method for preparing a lithium vanadium phosphate positive electrode material, comprising the following steps:

[0028] 1) the NH 4 VO 3 , LiOH, NH 4 h 2 PO 4 and glucose by mass ratio NH 4 VO 3 :LiOH:NH 4 h 2 PO 4 : Glucose = 100: (30-40): (145-155): (27.5-29.5) was added to 800-1200mL deionized water, heated in a water bath at 60-80°C, and the stirring speed was 400-800r·min -1 , stirred for 30-60min to make a slurry;

[0029] 2) Pass the slurry into the spray dryer and atomize and spray it out to obtain the precursor, wherein the air inlet temperature of the spray dryer is controlled at 200-300°C, the outlet air temperature is controlled at 80-100°C, and at the same time, the Send dry air flow in the direction, the direction of the air flow is the same as the direction in which the solution is ejected;

[0030] 3) Collect and weigh the prepared precursor, weigh 6%-8% of the weight of the precursor, and mix it ...

Embodiment 1

[0034] Take 200g analytically pure NH 4 VO 3 , 60g of LiOH, 295g of NH 4 h 2 PO 4 and 55.5g of glucose were added to 800mL of deionized water, and the temperature of the water bath was controlled at 60°C and stirred for 45min to obtain a slurry.

[0035] The resulting slurry is atomized and sprayed out through a spray dryer. Under the action of air flow, the precursor is obtained in the collecting device.

[0036] The obtained precursor was weighed. Then, 6% glucose by weight of the precursor was weighed and mixed. Put the mixture in a continuous sintering furnace, pass in protective gas for 0.5h, exhaust the air in the sintering furnace, and sinter at 650°C for 6h to obtain Li 3 V 2 (PO 4 ) 3 . Grind for later use.

Embodiment 2

[0038] Take 200g analytically pure NH 4 VO 3 , 70g of LiOH, 300g of NH 4 h 2 PO 4 and 57g of glucose were added into 1200mL of deionized water, and the temperature of the water bath was controlled at 60°C and stirred for 60min to obtain a slurry.

[0039] The resulting slurry is atomized and sprayed out through a spray dryer. Under the action of air flow, the precursor is obtained in the collecting device.

[0040] The obtained precursor was weighed. Then weigh 7% of the precursor mass of glucose for mixing, put the mixture in a continuous sintering furnace, pass through a protective gas for 0.5h, exhaust the air in the sintering furnace, and sinter at 650°C for 7h to obtain Li 3 V 2 (PO 4 ) 3 . Grind for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com