Surface strengthening treatment device for actively and rotatablely rolling and planishing head of roll compactor

A surface strengthening and treatment device technology, which is applied in the field of mechanical parts manufacturing, can solve the problems of impossibility of accurate control of precision and smoothness, unevenness, serious wear of balls 12, etc., to achieve mass production, reduce pressure head wear, and improve efficacy Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

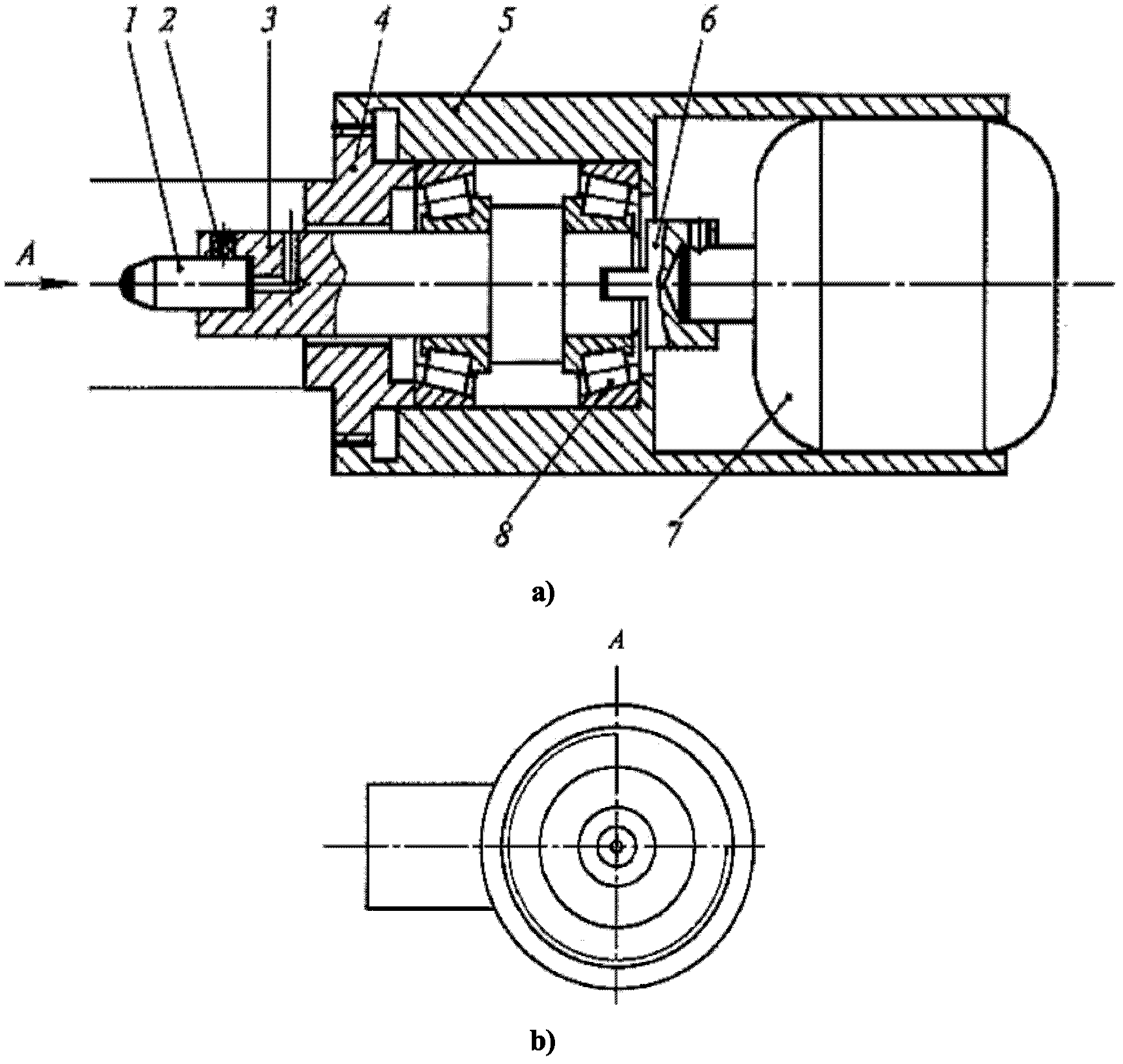

[0032] Such as figure 2 As shown, the present embodiment carries out finishing rolling and strengthening the surface of the workpiece through the following device. The device includes: a housing 5 and a pressure head 1 with a spherical working part arranged in sequence therein, a transmission shaft 3, a double-row radial bearing 8, clutch 6 and motor 7.

[0033] The pressure head is fixed in the center hole of the transmission shaft 3 by the screw 2, and the transmission shaft 3 is supported and fixed by the double-row radial bearing 8, and the bearing 8 is fixed in the housing 5, and the housing 5 is installed in the metal processing equipment superior. Nut 4 is screwed on housing 5 left ends, and its degree of tightness can adjust bearing 8 positions. The transmission shaft 3 is connected with the clutch 6 connected with the electric motor 7 .

[0034] The above-mentioned device is then installed on metal processing equipment, such as a lathe adapted to the workpiece to ...

Embodiment 2

[0044] The chain rollers are finished and strengthened.

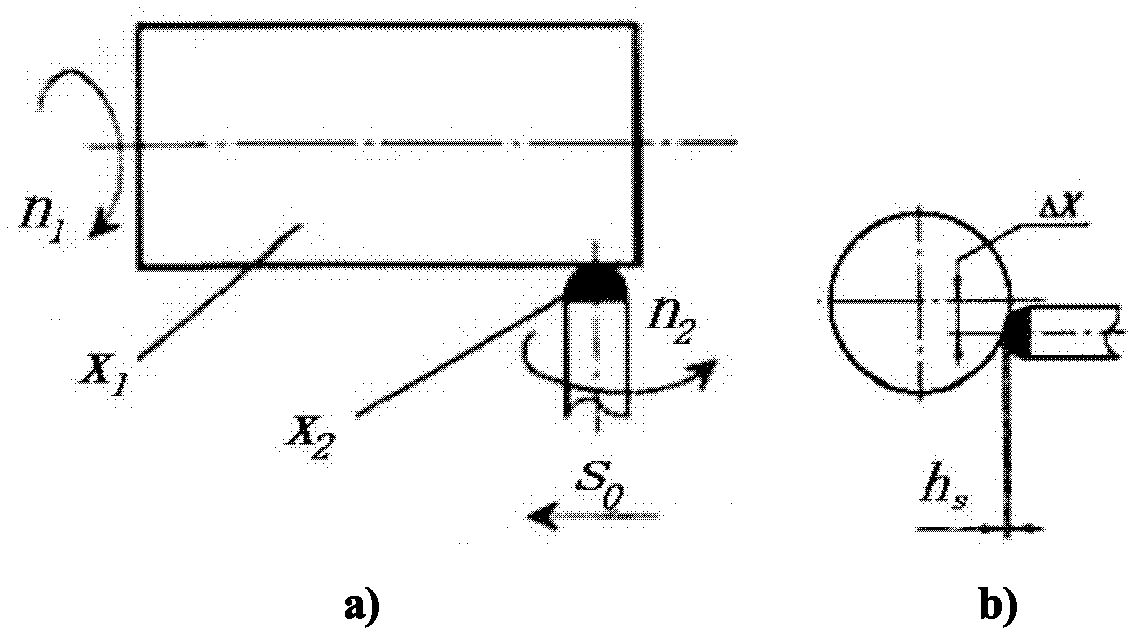

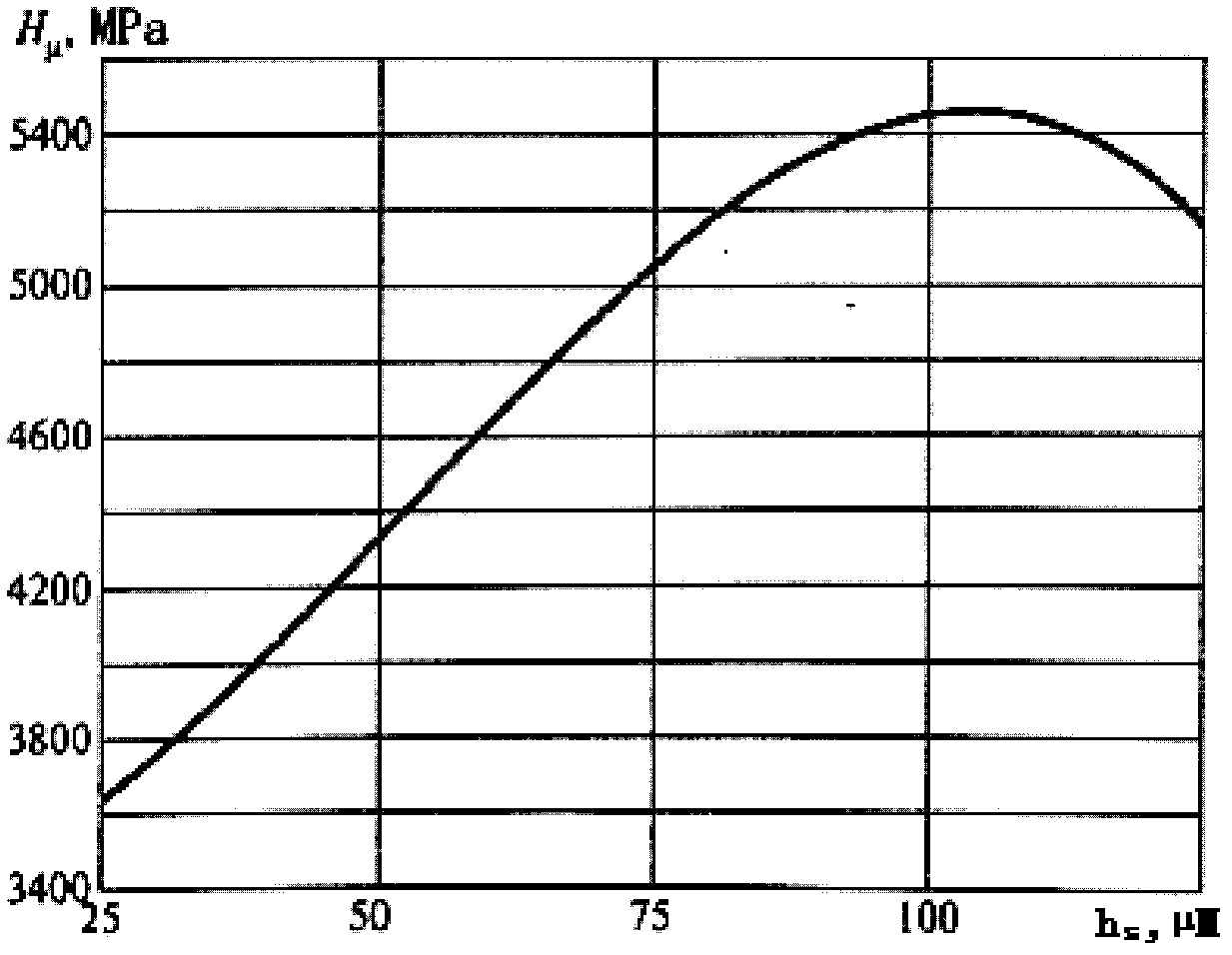

[0045] The roller part diagram of this embodiment is shown in Figure 6 . The material is 20 steel. After the roller is cold extruded and punched, it is installed on the main shaft of the instrument lathe and fixed with a clamp. Will figure 2 The rolling flattening unit shown is mounted on a lathe carriage. After the lathe is started, turn on the rolling and flattening device again, so that the pressure head gradually touches the cylindrical surface of the left end of the roller, close the clutch, and the rolling can be carried out. v=26m / min at h s = Under the condition of 85μM, the corresponding feeding amount S 0 shown in Figure 4 . In order to ensure the maximum microhardness value of the surface layer, the rolling feed is about S 0 =0.08mm / rpm, at this time the surface microhardness H μ is 5000, and the surface roughness of the workpiece is R a = 0.08 to 0.12 μm. The process of fine turning and grindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com