System and method for recycling copper slag waste heat and directly reducing and extracting iron

A technology for slag waste heat and copper recovery, which is applied to furnace types, furnaces, shaft furnaces, etc. to reduce energy consumption, improve waste heat recovery rate, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

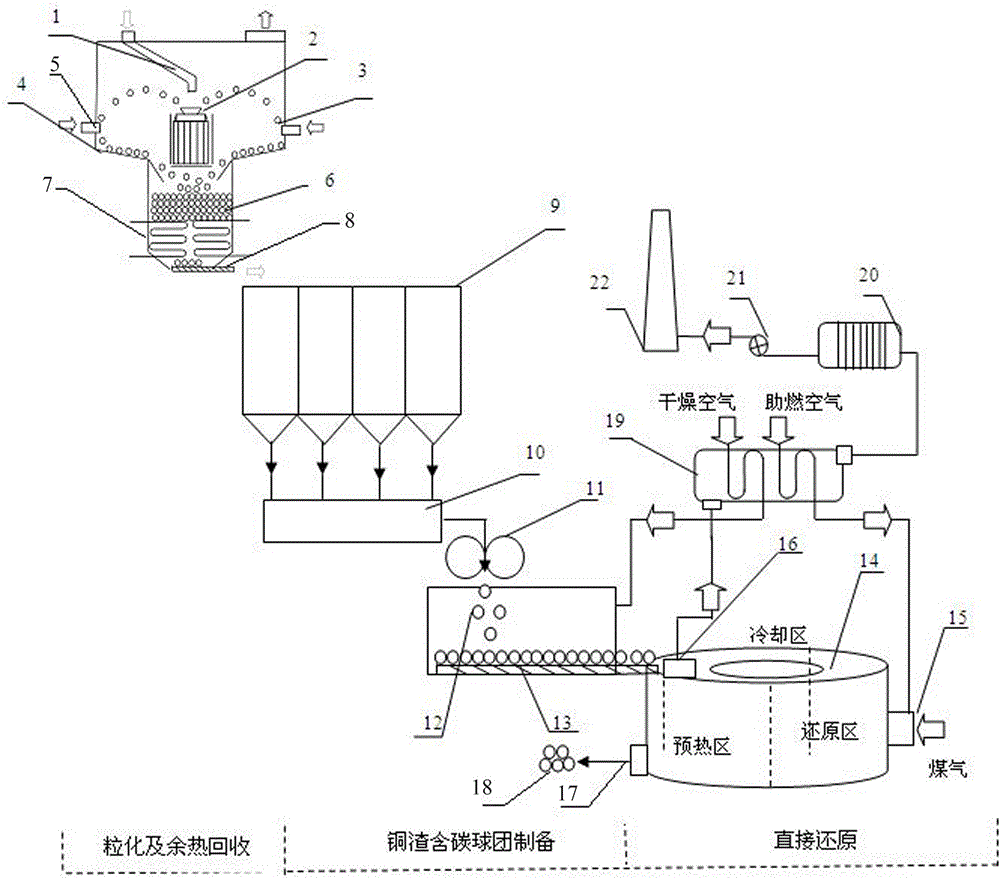

[0043] The structure of the system for recovering waste heat from copper slag and directly reducing and extracting iron in this embodiment is as follows: figure 1 As shown, it consists of slag granulation and waste heat recovery device, copper slag carbon-containing pellet preparation device and direct reduction device;

[0044] The slag granulation and waste heat recovery device described therein includes a slag granulation component and a waste heat recovery component, and the slag granulation component consists of a slag slag tank 1, a centrifugal granulation device 2, a blower 5 and a slag particle collection device 4 The slag particle collection device 4 is a funnel-shaped container with a wide top and a narrow bottom. The centrifugal granulation device 2 capable of high-speed rotation is arranged inside the slag particle collection device 4, and the slag slag tank 1 extends into the slag particle collection device from above. Inside the slag particle collection device 4,...

Embodiment 2

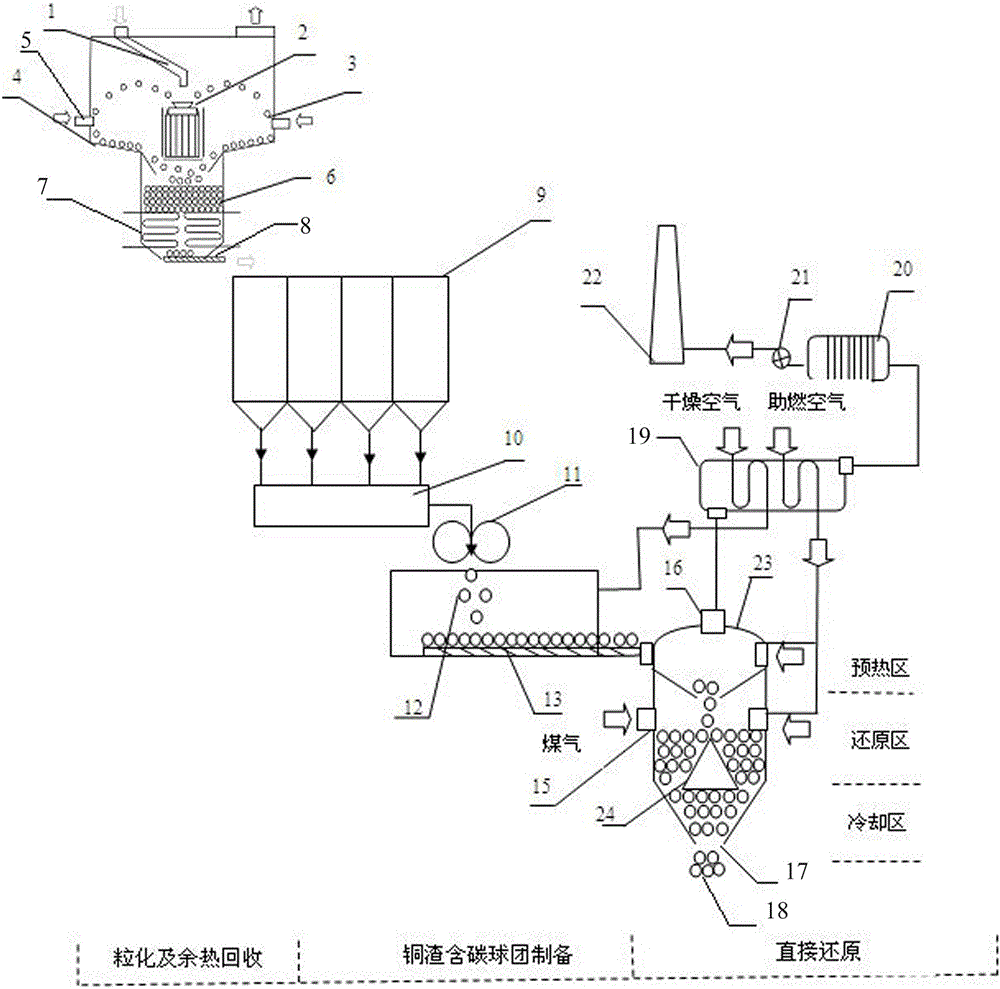

[0056] The structure of the system for recovering waste heat from copper slag and directly reducing and extracting iron in this embodiment is as follows: figure 2 As shown, it consists of slag granulation and waste heat recovery device, copper slag carbon-containing pellet preparation device and direct reduction device;

[0057] The slag granulation and waste heat recovery device described therein includes a slag granulation component and a waste heat recovery component, and the slag granulation component consists of a slag slag tank 1, a centrifugal granulation device 2, a blower 5 and a slag particle collection device 4 The slag particle collection device 4 is a funnel-shaped container with a wide top and a narrow bottom. The centrifugal granulation device 2 capable of high-speed rotation is arranged inside the slag particle collection device 4, and the slag slag tank 1 extends into the slag particle collection device from above. Inside the slag particle collection device 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com