Method for producing cement and vitriol from desulfurized gesso of flue gas

A technology for desulfurization of gypsum and flue gas, applied in the direction of sulfur trioxide/sulfuric acid, etc., to achieve the effects of wide application range, reduction of calcined fuel coal consumption, investment cost and operating cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

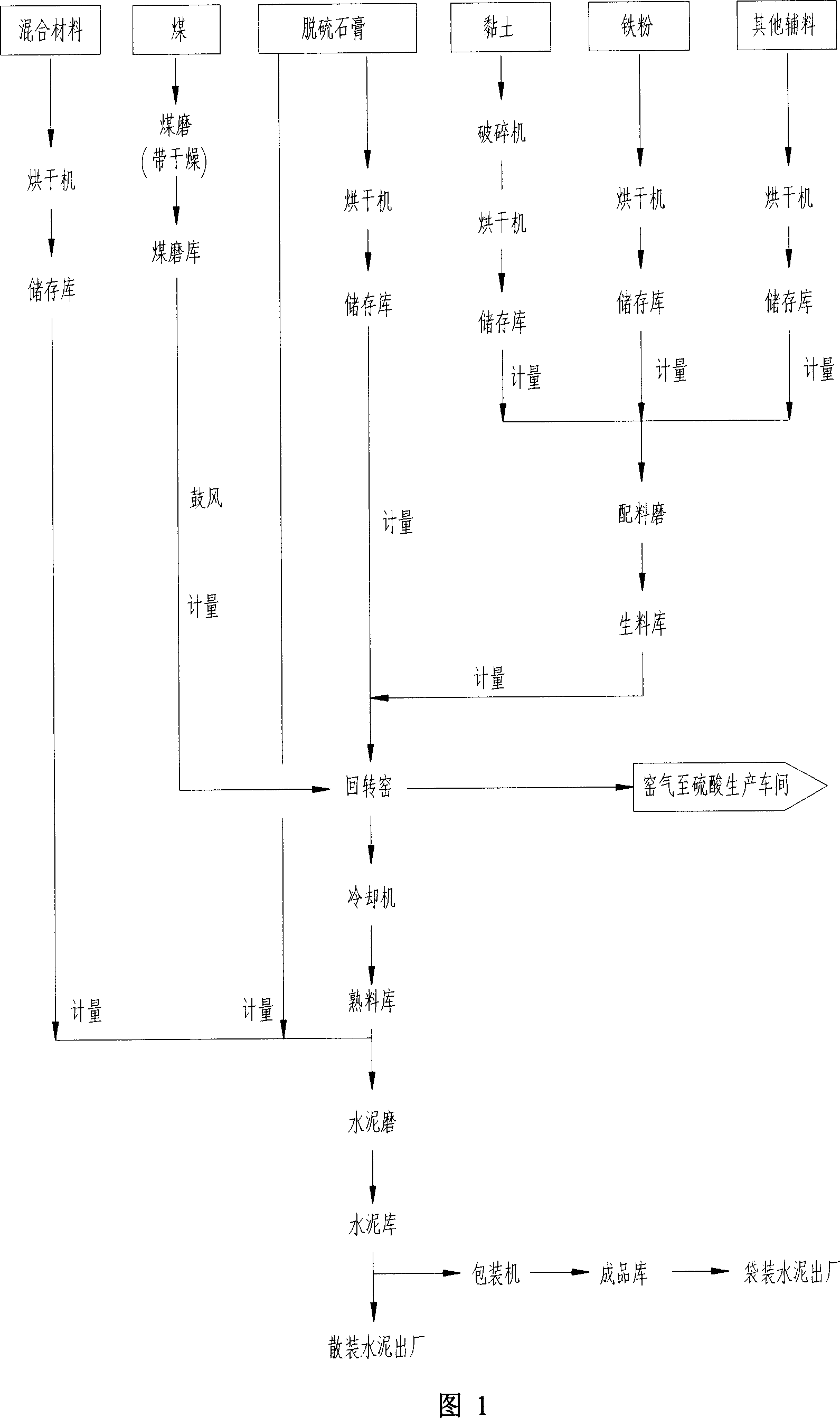

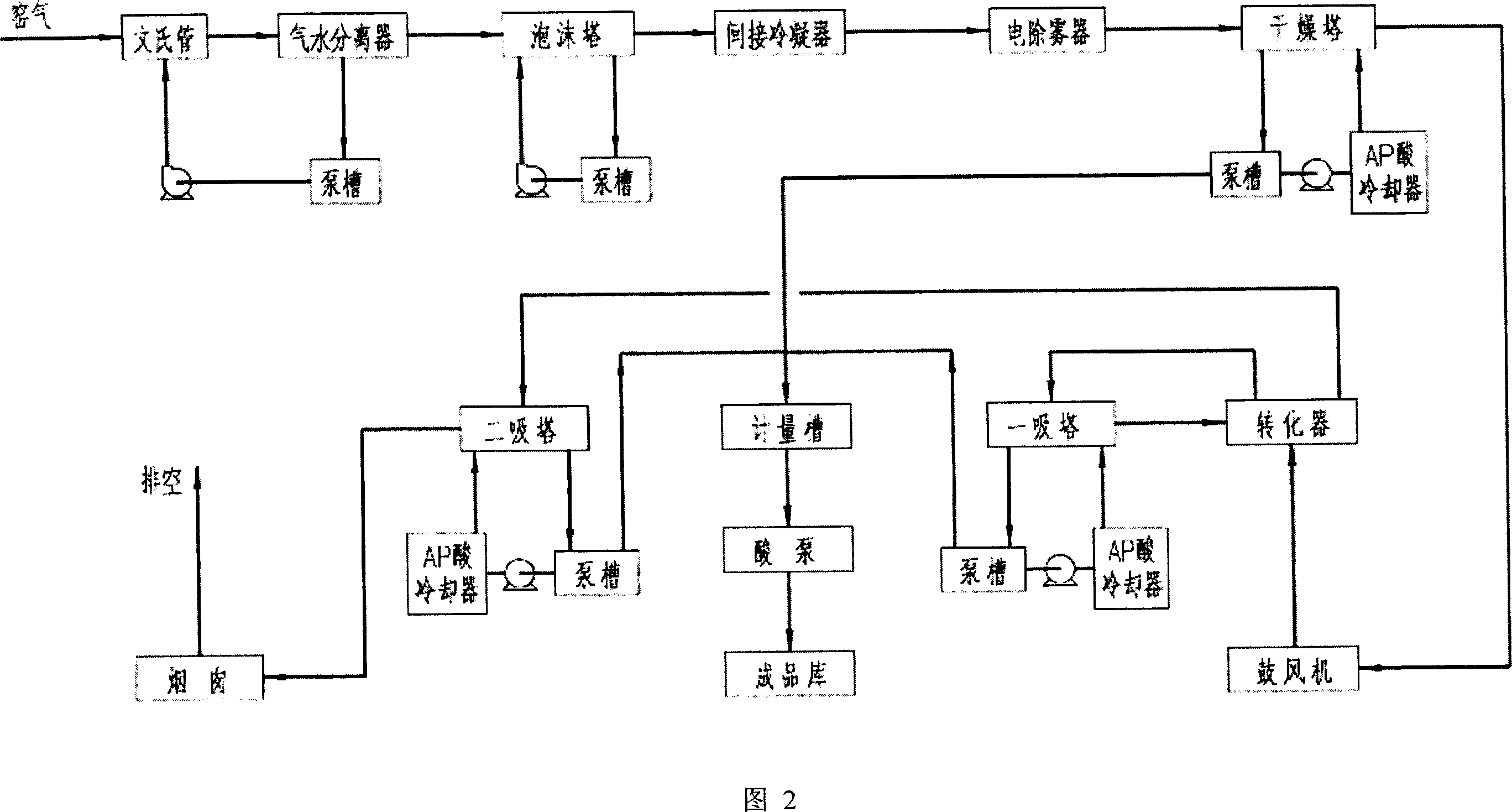

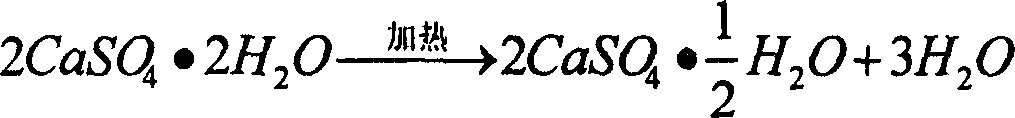

Method used

Image

Examples

Embodiment 1

[0032] 1. The raw materials used in raw meal ingredients are shown in Table 1. The reducing agent is industrial anthracite, and its fixed carbon mass content is 54.68%.

[0033] raw material name

[0034] 2. Weigh 188.73g of flue gas desulfurization gypsum, 19.15g of clay, 2.425g of pyrite slag, 6.798g of fly ash and 17.81g of industrial anthracite, which have been dried at 80℃ for 3 hours to remove free water, and mixed and pressurized to make After the cylindrical sample is placed in a watch glass, put into the drying box, the temperature of the drying box is increased to 105 ℃ and dried for 1.5 hours to remove the free water in the material; then take out the test block and put it in the corundum crucible and put it into the muffle furnace, slowly Raise the temperature to 1250°C for 1.5 hours, then heat to 1450°C for 1.5 hours to obtain cement clinker. The clinker rate value is: KH (lime saturation coefficient) 0.94; SM (silicic acid rate) 2.5; IM ( Iron rate) 1.55. ...

Embodiment 2

[0041] 1. Same as 1 in Example 1.

[0042] 2. Weigh 188.86g of flue gas desulfurization gypsum, 16.67g of clay, 2.714g of pyrite slag, 8.880g of fly ash and 17.82g of industrial anthracite, which have been dried at 80℃ for 3 hours to remove free water, and mixed and pressurized to make After the cylindrical sample is placed in a watch glass, put into the drying box, the temperature of the drying box is increased to 105 ℃ and dried for 1.5 hours to remove the free water in the material; then take out the test block and put it in the corundum crucible and put it into the muffle furnace, slowly Raise the temperature to 1250°C for 1.5 hours, then heat to 1450°C for 1.5 hours to obtain cement clinker. The clinker rate value is: KH (lime saturation coefficient) 0.95; SM (silicic acid rate) 2.3; IM ( Iron rate) 1.6.

[0043] The chemical analysis of the cement clinker obtained above is shown in Table 4.

[0045] The phase composition of the clinker can b...

Embodiment 3

[0049] 1. Same as 1 in Example 1.

[0050] 2. Weigh 187.72g of flue gas desulfurization gypsum, 18.28g of clay, 2.693g of pyrite slag, 7.841g of fly ash and 17.47g of industrial anthracite, which are dried at 80℃ for 3 hours to remove free water, and mixed and pressurized to make After the cylindrical sample is placed in a watch glass, put into the drying box, the temperature of the drying box is increased to 105 ℃ and dried for 1.5 hours to remove the free water in the material; then take out the test block and put it in the corundum crucible and put it into the muffle furnace, slowly Raise the temperature to 1250°C for 1.5 hours, then heat to 1450°C for 1.5 hours to obtain cement clinker. The clinker rate value is: KH (lime saturation coefficient) 0.95; SM (silicic acid rate) 2.3; IM ( Iron rate) 1.6.

[0051] The chemical analysis of the cement clinker obtained above is shown in Table 6.

[0053] The phase composition of the clinker can be calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com