Seat headrest rod and manufacturing process thereof

A production process and headrest rod technology, which is applied to seat frames, chairs, and other seating furniture, can solve the problems of passenger safety hazards, lower production efficiency, and high roughness, so as to save the grinding process and ensure product quality , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

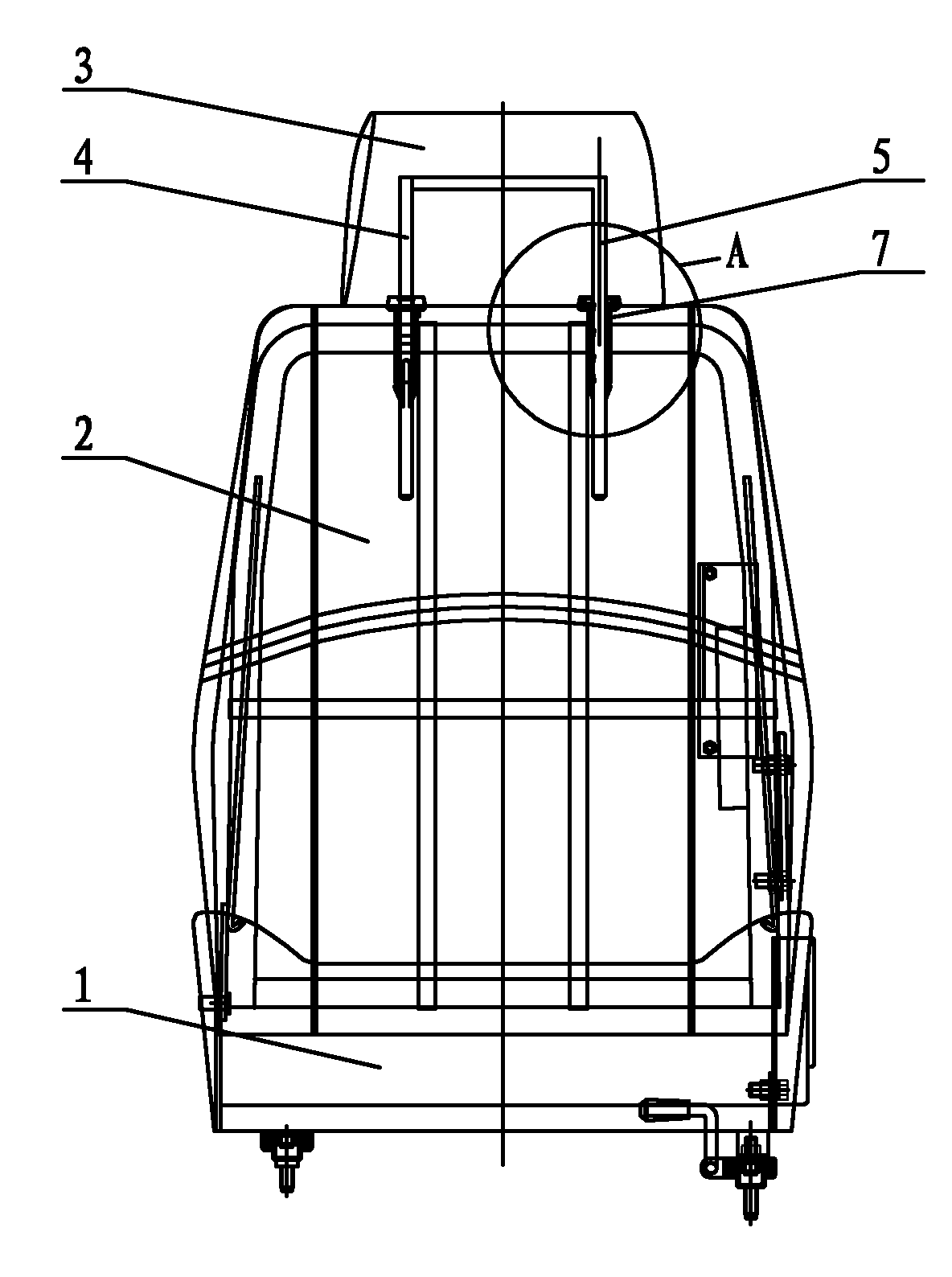

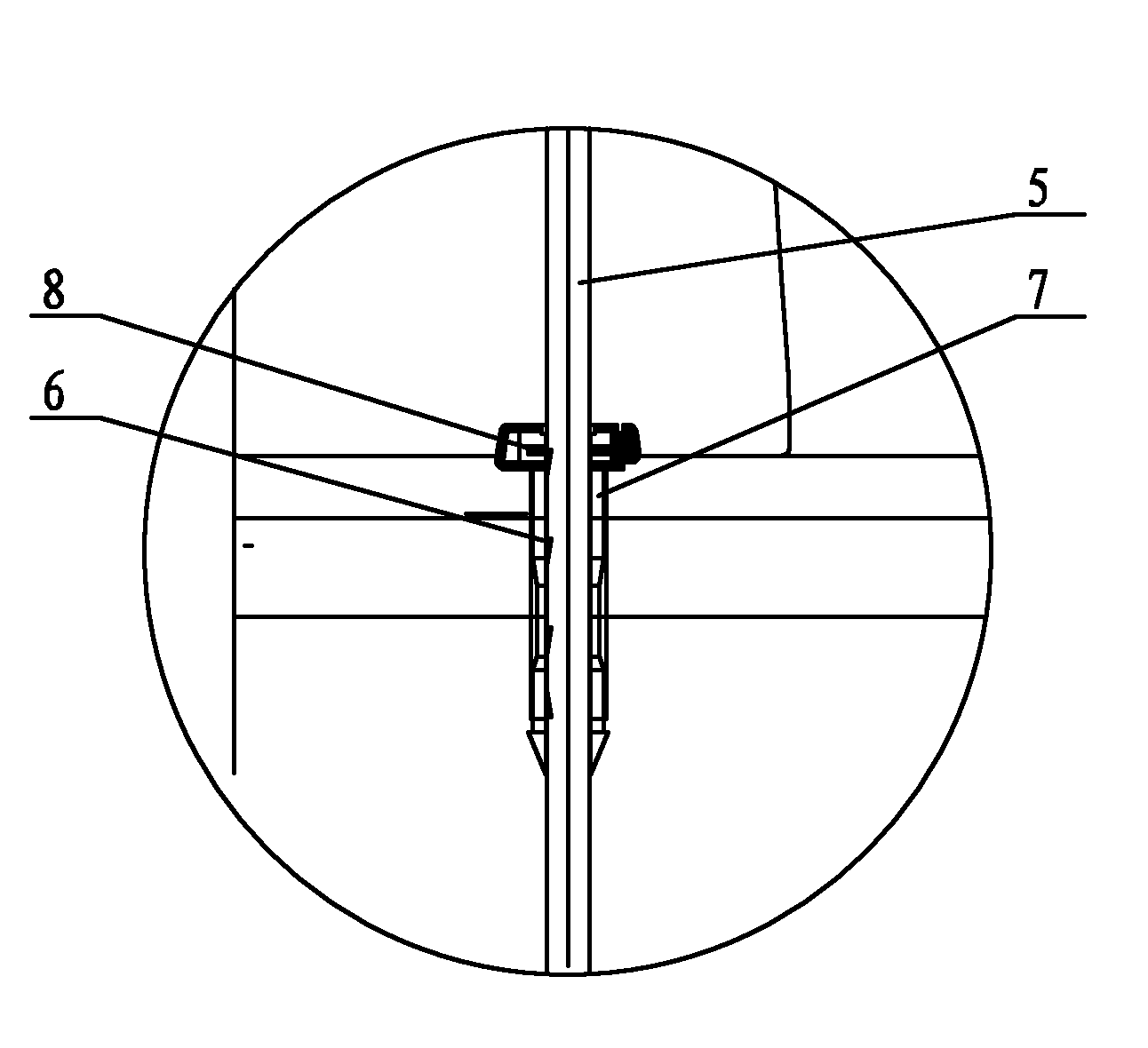

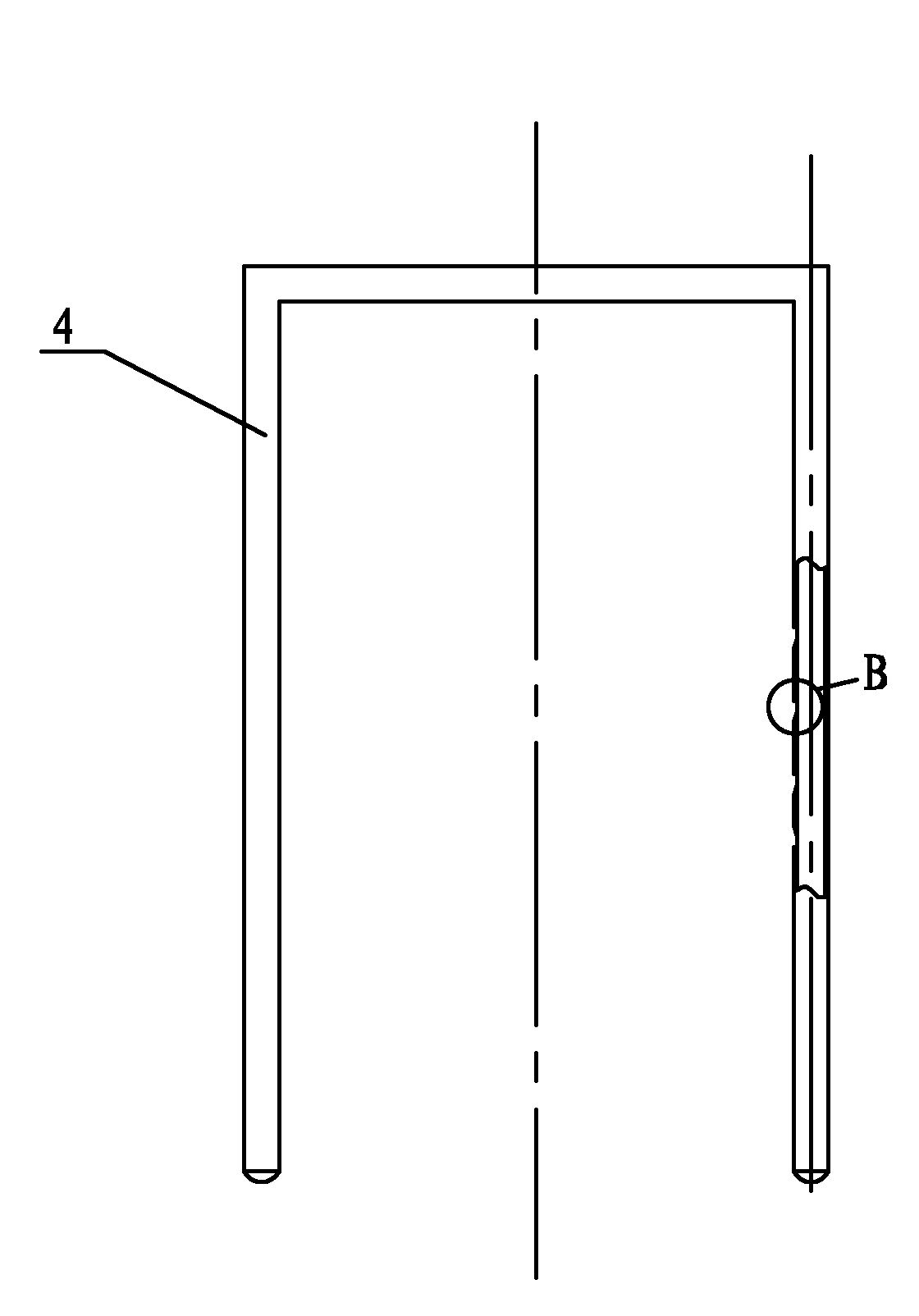

[0040] Such as Figure 4a As shown, the seat headrest rod of the present invention includes a horizontal bar 11 and two vertical bars 12, and the two vertical bars 12 are integrally connected with the two ends of the horizontal bar 11 respectively, the vertical bars 12 are hollow tubes, and one of the vertical bars The rod 12 is longitudinally provided with 4 opening grooves 13, combined with Figure 4b As shown, the open groove 13 includes an integrally formed upper side wall 14, a groove bottom 15 and a lower side wall 16, the outer end of the upper side wall 14 is vertically connected with the pipe wall of the vertical rod 12, and the upper end of the groove bottom 15 is connected with the upper side wall. The inner end of 14 is vertically connected, the inner end of the lower side wall 16 is fixedly connected with the lower end of the groove bottom 15, the outer end of the lower side wall 16 is fixedly connected with the tube wall of the vertical rod 12, and the lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com