Patents

Literature

101results about How to "Reduce incineration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing titanium white

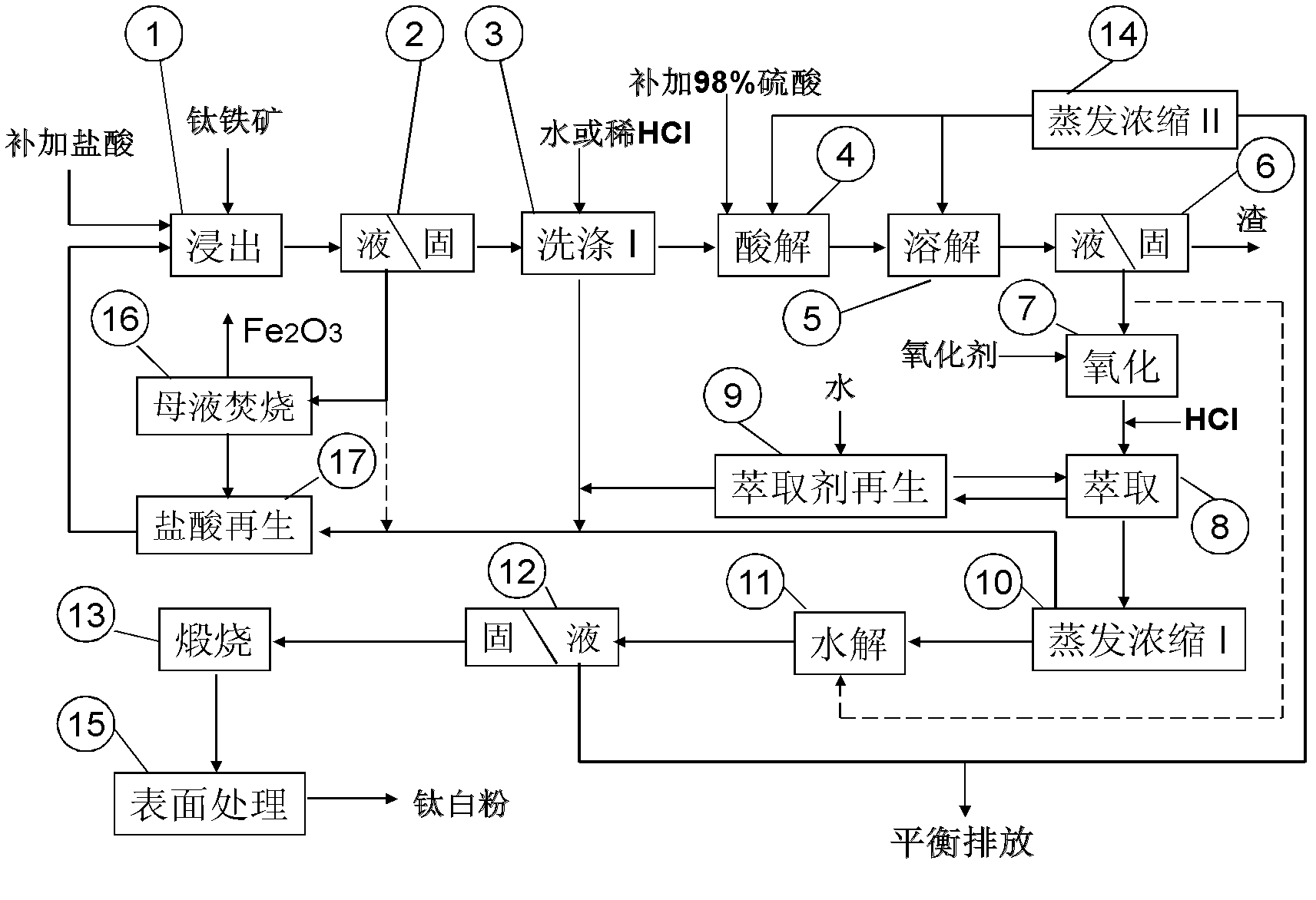

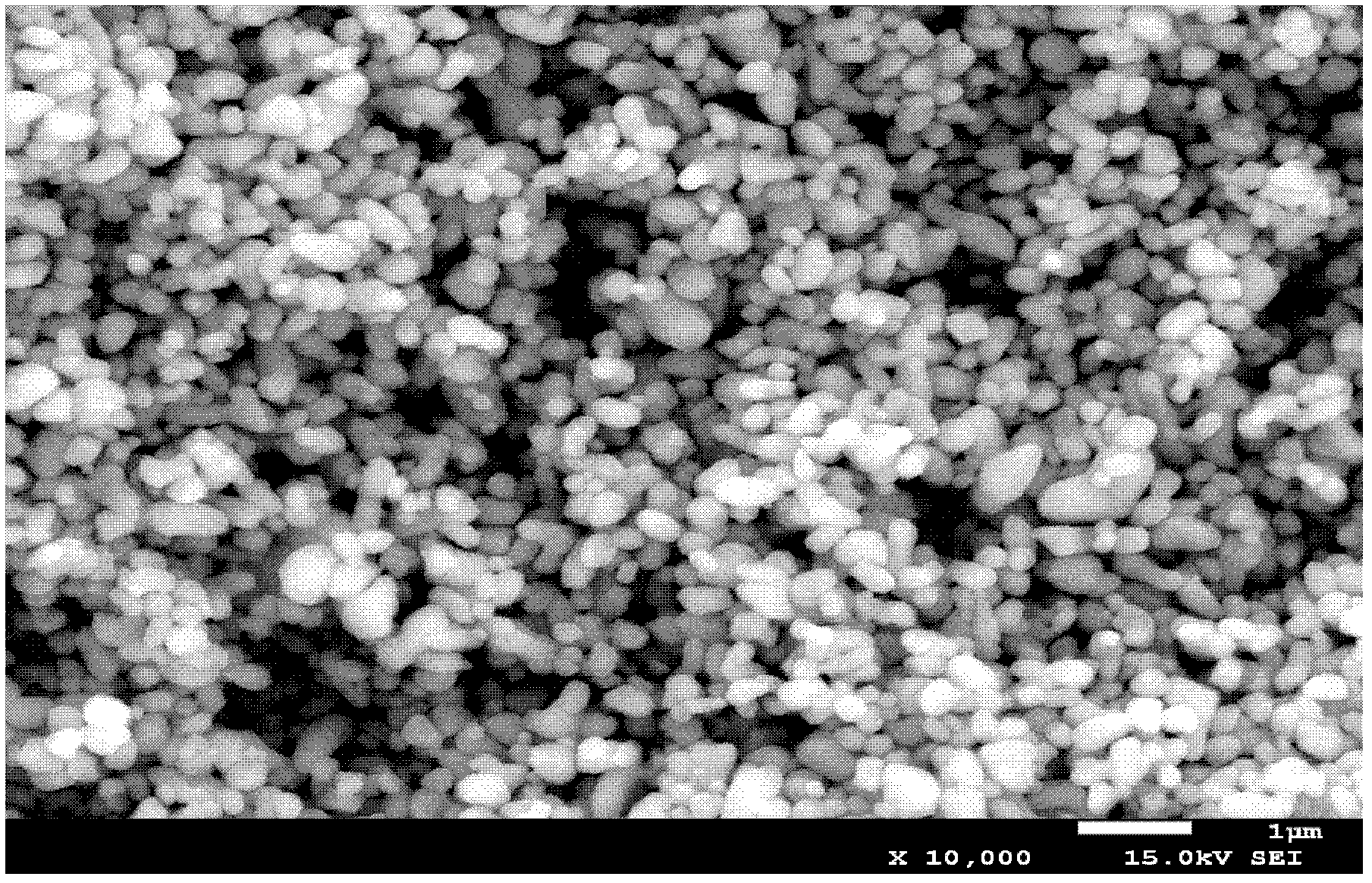

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

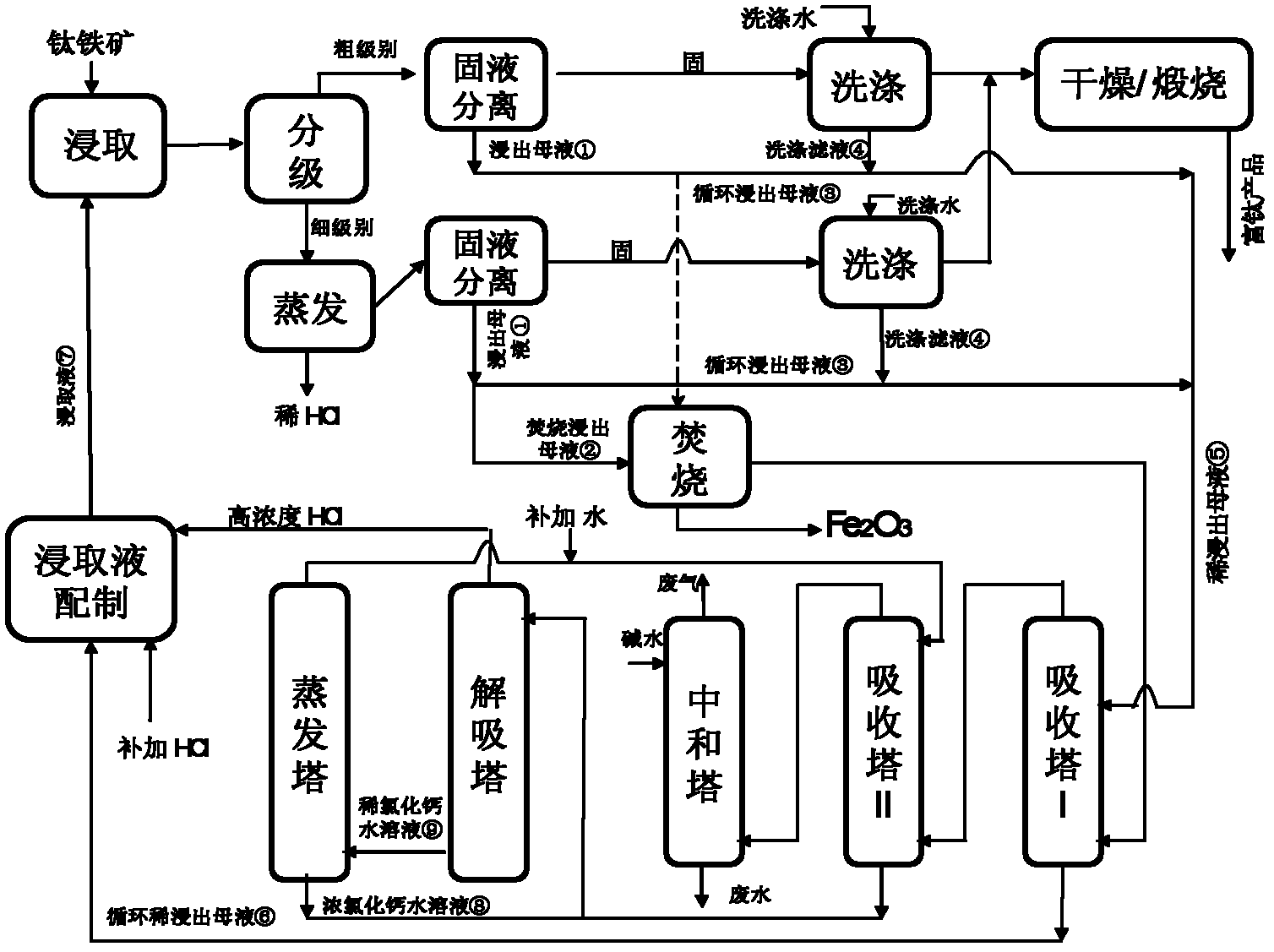

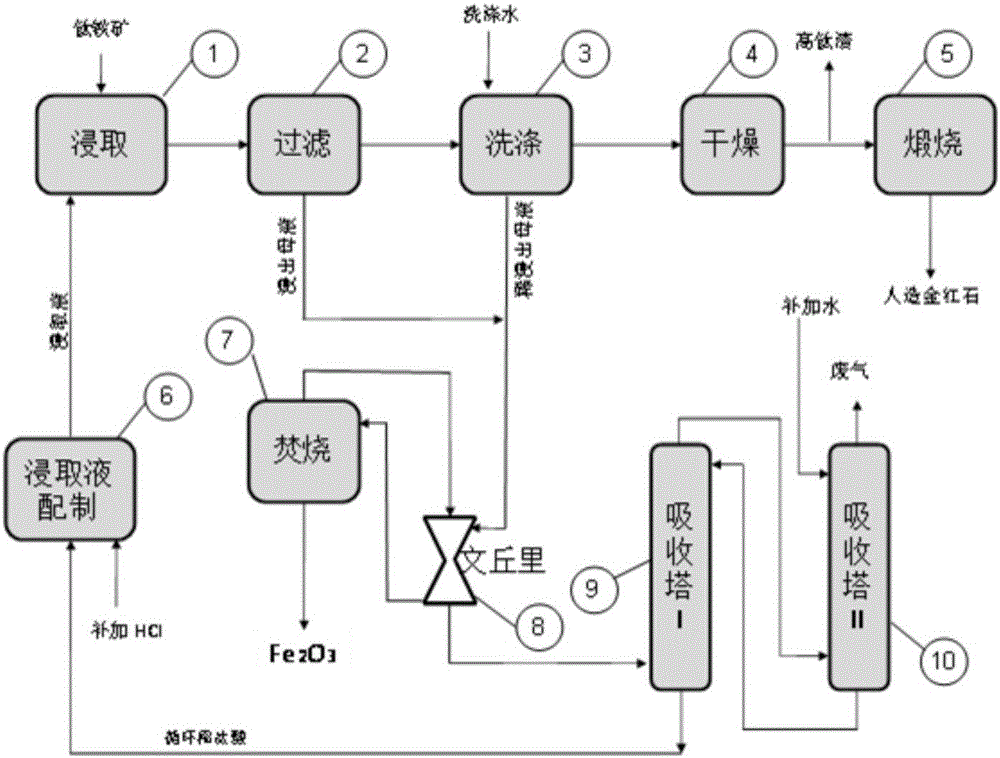

Method for treating hydrochloric acid leachate of ferrotitanium materials

InactiveCN102352437AReduce incinerationReduce processing energy consumptionPregnant leach solutionMaterial balance

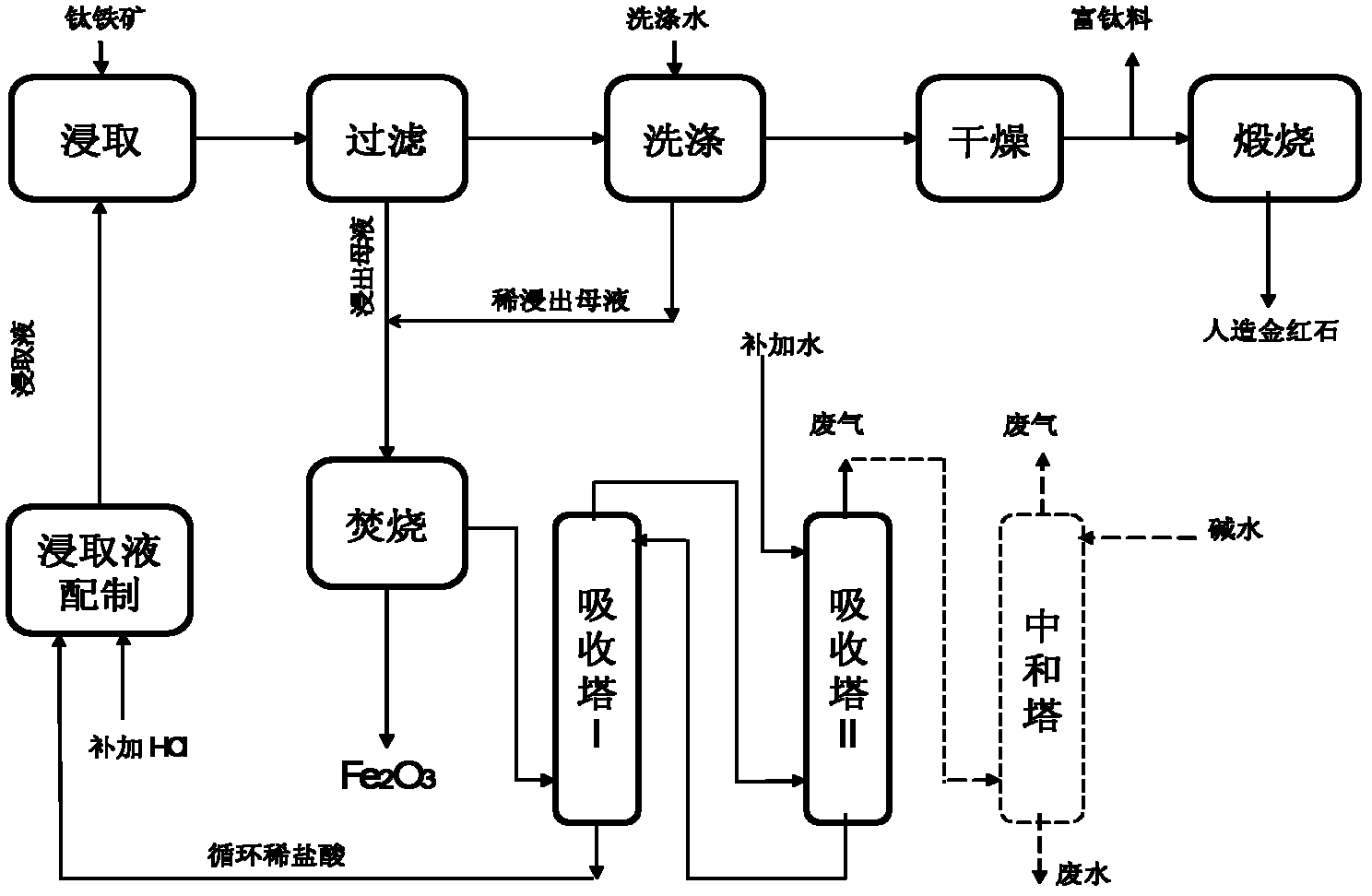

The invention provides a method for treating hydrochloric acid leachate of ferrotitanium materials. The method comprises the following steps of: dividing and burning leached mother liquid which is obtained by leaching the ferrotitanium materials by using hydrochloric acid leaching liquid; recovering hydrogen chloride obtained by burning for regeneration and cyclic utilization of the leaching liquid. By the method provided by the invention, the leachate is divided according to material balance of the leach elements (mainly comprising iron) of the hydrochloric acid leachate; and one part of theleachate after division is burned and the other part of the leachate is directly or indirectly absorbed by the hydrochloric acid to return to the leaching procedure, so that completely closed circuitcirculation is formed. By the method provided by the invention, the defect of overlarge energy consumption in the burning procedure after the ferrotitanium materials are leached by the conventional hydrochloric acid can be overcome and the burning quantity of the leached mother liquid can be reduced by 40 to 55 percent, so that the energy consumption of the whole process can be reduced by 35 to 45 percent. The method has a good industrial application prospect.

Owner:沙立林 +1

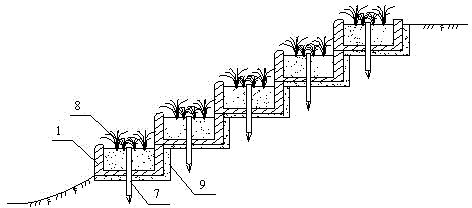

Method for maintaining and reproducing evergreen lawn

ActiveCN103477846AExtended green periodImprove productivityCultivating equipmentsSoilless cultivationLand productivityCold season

The invention discloses a method for maintaining and reproducing an evergreen lawn. The method includes technological steps of (1), selecting a warm-season lawn green land and determining rejuvenation and maintenance time of a lawn; (2), taking rejuvenation and maintenance measures; (3), manufacturing a cold-season soil-free grass carpet; (4) selling the cold-season soil-free grass carpet and restoring the growth of the warm-season lawn. The method has the advantages that the built lawn is rejuvenated and maintained on the same lawn area, the new lawn with the area one to two times that of the built lawn is reproduced simultaneously, accordingly, the green period of the built lawn is prolonged, the new lawn with the large area is reproduced, and a novel mode for maintaining and reproducing the evergreen lawn is formed; the land productivity is high, the production cost is low, and economical, social and environmental benefits are obvious; as observed by tests, manufacture of the soil-free grass carpet rarely affects the lawn of the green land, and the growth of the lawns is unaffected even if dormant periods in different years are properly shortened.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

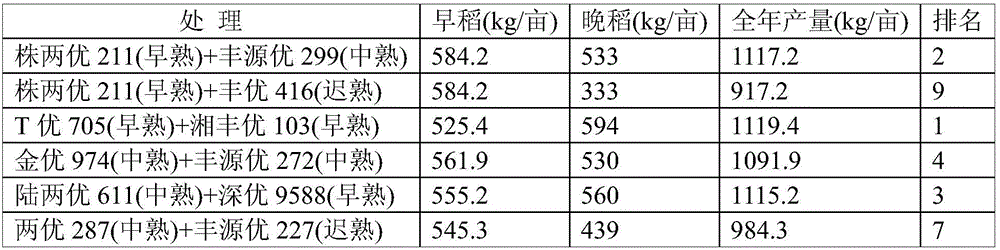

Solanum tuberosum and double cropping rice rotation crop rotation culture method for improving south double cropping rice paddy soil micro-aggregate structure

InactiveCN106069031AIncrease resourcesReduce non-point source pollutionCultivating equipmentsRice cultivationInsect diseaseEconomic benefits

The invention provides a solanum tuberosum and double cropping rice rotation crop rotation culture method for improving a south double cropping rice paddy soil micro-aggregate structure, and belongs to the field of agricultural production. The method mainly comprises the first step of solanum tuberosum high-yield cultivation and the second step of early rice and late rice high-yield cultivation, wherein the first step comprises the substeps of preparation before seeding, variety selection, cutting of seed solanum tuberosum, seeding at suitable time and coverage of straw and a mulching film, field management comprising timely film breaking, topdressing, drainage and insect disease prevention, timely harvesting, and field returning of solanum tuberosum stem leaves and straw for coverage, and the second step comprises the substeps of variety selection, seedling transplanting, filed management comprising scientific fertilization, weeding, irrigation and insect disease prevention, timely harvesting and field returning of straw. By means of the method, south double cropping rice paddy winter agriculture can be reasonably developed, the rice paddy soil micro-aggregate structure is effectively improved, soil is fertilized, economic benefits of solanum tuberosum in one season are increased on the basis of ensuring the double cropping rice yield, the purposes of improving the rice paddy soil structure and obtaining high-yield year-round crops are achieved, and the popularization value is high.

Owner:HUNAN SOIL & FERTILIZER INST

Novel environment-friendly and fireproof composite biomass board

InactiveCN101786852ALow priceWide variety of sourcesSolid waste managementCeramic shaping apparatusSodium silicateScrap

The invention relates to the technical field of decorating and building materials, in particular to a novel environment-friendly and fireproof biomass board. The board is characterized by comprising the following components in percentage by weight: 65.0-75.0% of biomass packings, 15.0-25.0% of sodium silicate, 5.0-10.0% of sodium fluosilicate and 0.05-1.0% of fiberglass mesh, wherein the biomass packings are wood scraps, wood branches or crop straws. The environment-friendly and fireproof composite biomass board prepared by organically combining the wastes with good impact resistance and nail holding power, such as crop straw fibers or wood fibers, fiberglass with excellent tensile property and inorganic adhesives with unique fireproofness and waterproofness can be widely applied to the household products such as furniture, indoor and outdoor decoration of buildings, advertisement designing, building templates and other special-purpose boards.

Owner:王春莉

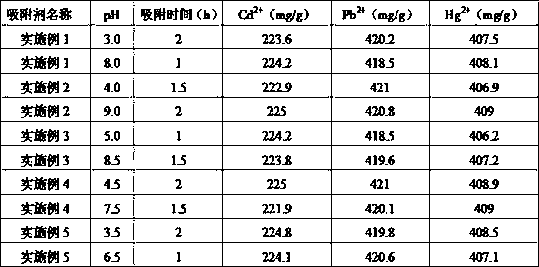

Preparation method and application of bagasse mercapto-biosorbent

InactiveCN103191703AImprove adsorption capacityHas sulfhydryl propertiesOther chemical processesWater/sewage treatment by sorptionAcetic acidFiltration

The invention discloses a preparation method and an application technology of a bagasse mercapto-biosorbent. The preparation method is characterized by comprising the following steps of: adding 35-45wt% of mercaptoacetic acid, 18-25wt% of tetrahydrofuran, 12-22wt% of alkalized bagasse and 0.15-1.0wt% of concentrated sulphuric acid in a triangular flask with a plug, performing a sealed room-temperature reaction for 2-4 hours, and adding 8-18wt% of sodium sulphide and 8-18wt% of water, wherein the sum of the percentages of all the components is 100%; plugging, and performing a static reaction for 48-60 hours at 40-45 DEG C; and then washing with deionized water, performing suction filtration until the filtrate is neutral, washing by a small amount of ethanol, placing in an oven at 55-65 DEG C and drying, so as to obtain the bagasse mercapto-biosorbent, wherein the bagasse mercapto-biosorbent is high in adsorption capacity for Cd2, Pb<2+> and Hg<2+>, fast in adsorption speed, good in physicochemical stability and mechanical stability, strong in regeneration capacity, high in repeated use times, low in cost, and capable of utilizing agricultural waste.

Owner:UNIV OF JINAN

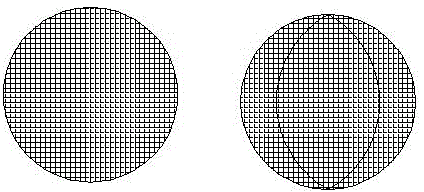

Method for preparing biochar by using blue algae

The invention discloses a method for preparing biochar by using blue algae, which comprises the following steps: 1. preparing raw materials; 2. freeze-dry; 3. carbonization; 4. granulation. Biochar prepared by utilizing that method for preparing biochar from blue algae of the present invention is a carbon-rich solid by-product remaining after pyrolysis of biomass in an anaerobic or hypoxic state.Because of its high carbon content, well-developed pore structure and good corrosion resistance, it can retain water, nutrients, adsorb organic matter, heavy metals and other pollutants, and is an ideal soil improver and adsorbent, and can slow down greenhouse benefit, improve soil, increase crop yield and reduce environmental pollution. Biochar is an ideal adsorbent because of its well-developedpore structure and abundant surface functional groups, which can remove organic matter and heavy metals, especially heavy metals.

Owner:SUZHOU ACADEMY OF AGRI SCI

Novel method of salt-isolating cultivation improvement of saline-alkali soil through straw

InactiveCN107580817ASalt-isolated improvementReduce salt contentAgriculture gas emission reductionSoil-working methodsAlkali soilSoil organic matter

The invention discloses a method of salt-isolating cultivation improvement of saline-alkali soil through straw and relates to the technical field of saline-alkali improvement. Rising channels of capillary water in high-salt soil is cut off through a straw salt-isolating filter layer, and salt washing is performed on the saline-alkali soil by using rainfall or irrigation water. Meanwhile, humus formed by the decomposition of straw and organic fertilizers is used for adsorbing salt ions, neutralizing the alkali of the soil and improving the soil microenvironment. The structure of the method comprises a straw salt-isolating filter layer which is laid on the upper part of the saline-alkali soil, an organic fertilizer layer at the upper part of the salt-isolating filter layer and a cultivationlayer at the uppermost part from bottom to top. Also, deep ditches are dug between two ridges, and isolation ditches are dug around improved areas. In the method, borrowed soil is not needed, washingand salt washing of the salt soil can be realized with the aid of natural rainfall and irrigation water after covering the straw isolating layer with soil on site, and the cost is reduced. The methodof improving saline-alkali soil is suitable for various saline-alkali soil environment conditions, is a high-efficiency and easy-to-operate method for saline-alkali soil improvement and horticulturalplant cultivation. In addition, the crop straw is used as the salt-isolating layer, so that the reuse of a large amount of straw can be realized to improve the organic matter of the soil, and meanwhile, the method is beneficial for solving the problem of straw burning, and reducing the environmental pollution.

Owner:NANJING AGRICULTURAL UNIVERSITY

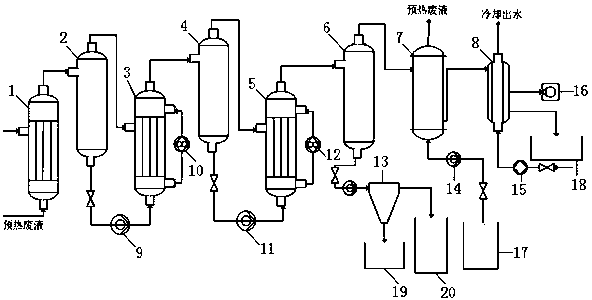

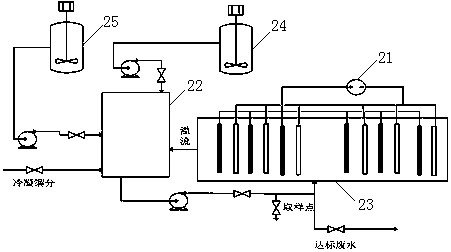

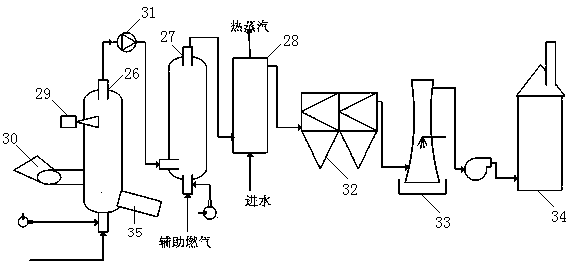

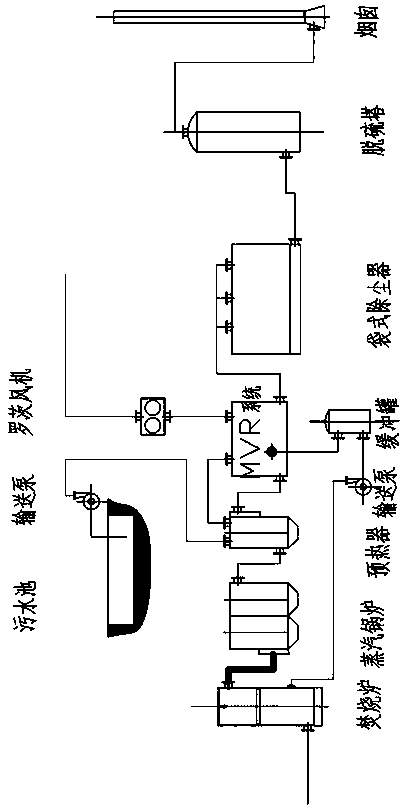

Treatment system for high-salt high-concentration organic wastewater and method

ActiveCN107601742AAvoid melting and cokingAvoid cloggingDispersed particle filtrationWater contaminantsHigh concentrationEvaporation

The invention relates to a treatment system for high-salt high-concentration organic wastewater and a method. The system comprises an evaporation concentration unit, an electrocatalytic oxidation unitand a burning unit, wherein the evaporation concentration unit comprises an evaporation concentrator, a separator, a preheater, a condenser, a vacuum pump and a conveying pump; the electrocatalytic oxidation unit comprises a direct current power supply, a circulating cylinder, an electrocatalytic oxidation tank and a drug dosing system; the burning unit comprises a low-temperature burning chamber, a high-temperature burning chamber, a waste heat recovering device and a tail gas purifying device. The invention also provides a treatment method for the high-salt high-concentration organic wastewater. According to the invention, the characteristics of evaporation concentration method, electrocatalytic oxidation method and burning method are combined, the treatment efficiency for the high-salthigh-concentration organic wastewater is high, the adaptability to the concentration change of the wastewater is high, the treatment cost is low and the requirement of wastewater emission after reaching standard is met.

Owner:湖南绿网环保科技有限责任公司

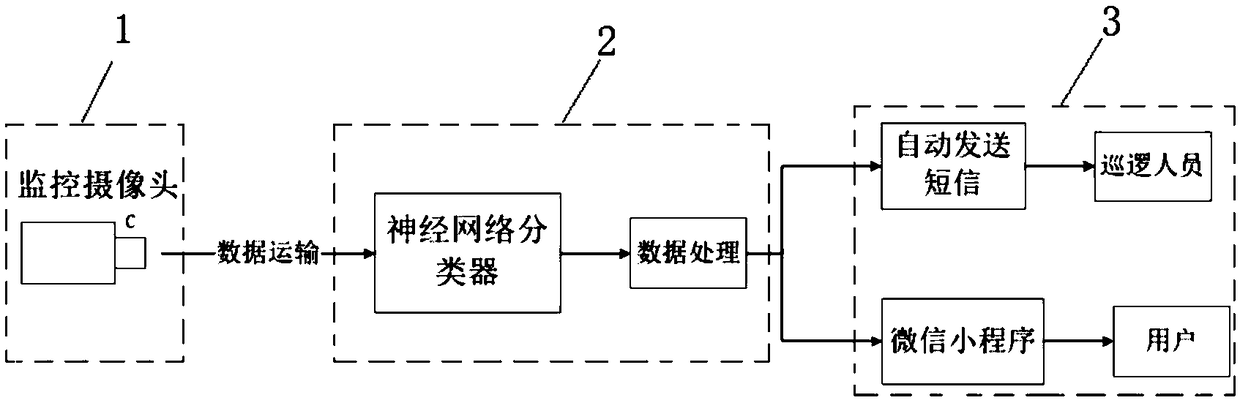

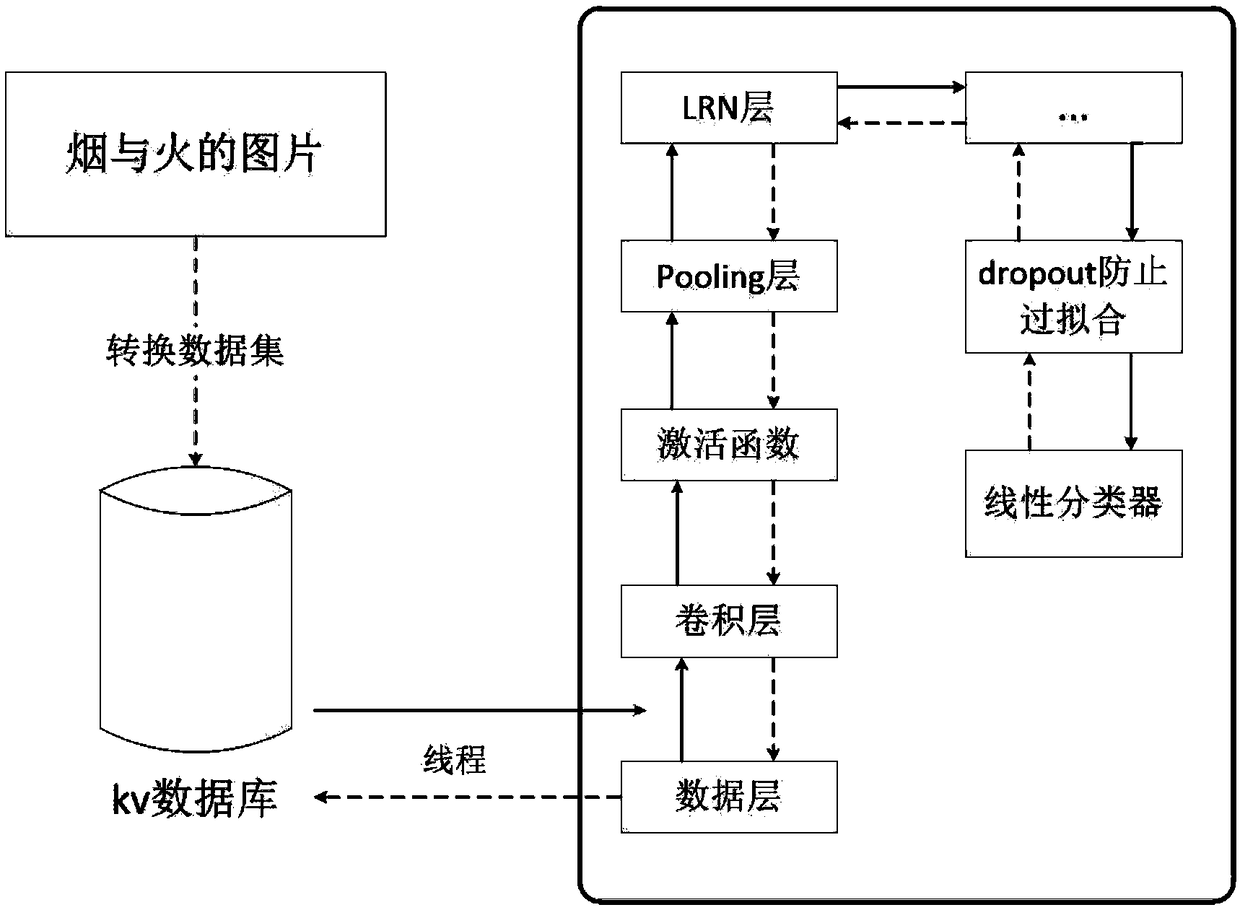

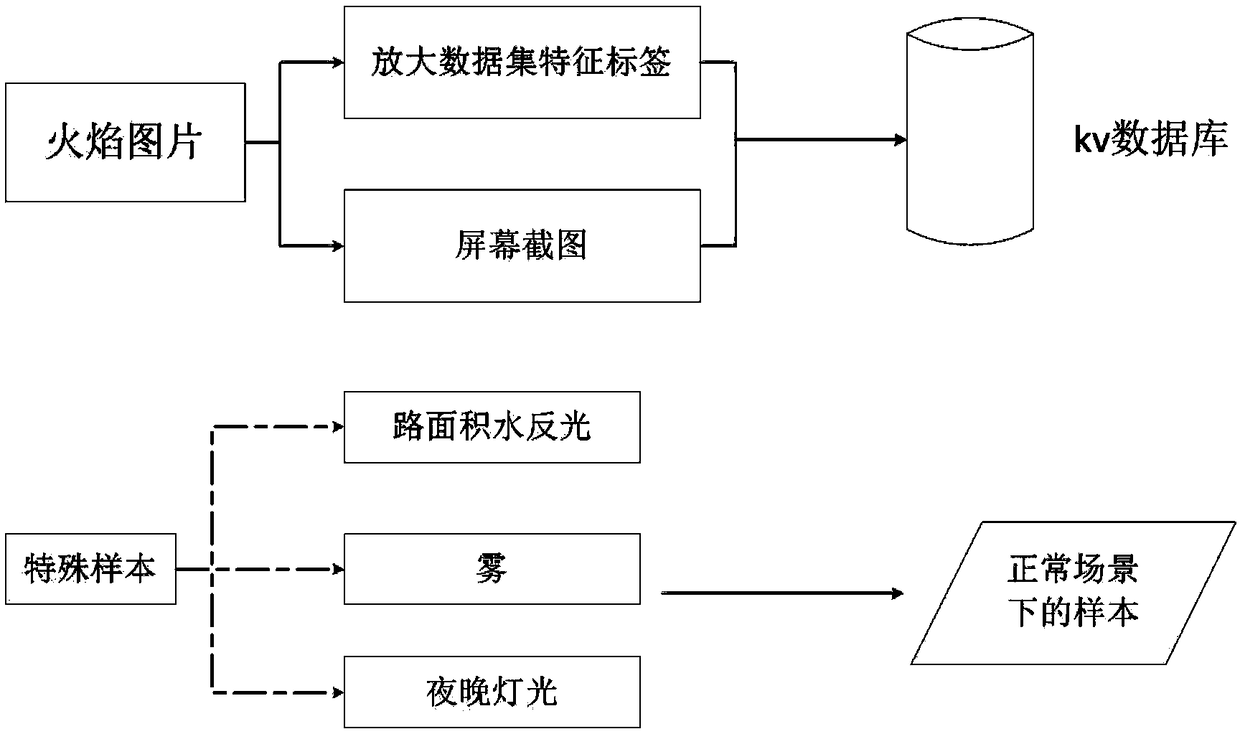

Surveillance video straw burning inspection method based on deep neural network

InactiveCN108777777AReduce incinerationReduce workloadBiological neural network modelsCharacter and pattern recognitionPattern recognitionData set

The invention discloses a surveillance video straw burning inspection method based on a deep neural network, which belongs to the technical field of information. A smoke / fire recognition and processing module based on a neural network classifier is built based on a deep learning neural network frame. The smoke / fire recognition and processing module adopts a method of intercepting each ten frames of video as a picture to increase a data set and amplify a data set feature label, a residual network is optimized, and the accuracy of recognizing an abnormal event in an image and a video is thus improved. According to judgment results towards smoke and fire in certain areas by the neural network classifier, the smoke / fire recognition and processing module gives an alarm to an inspection person and common users automatically, and monitoring on a straw burning event is further realized.

Owner:JIANGSU UNIV OF TECH

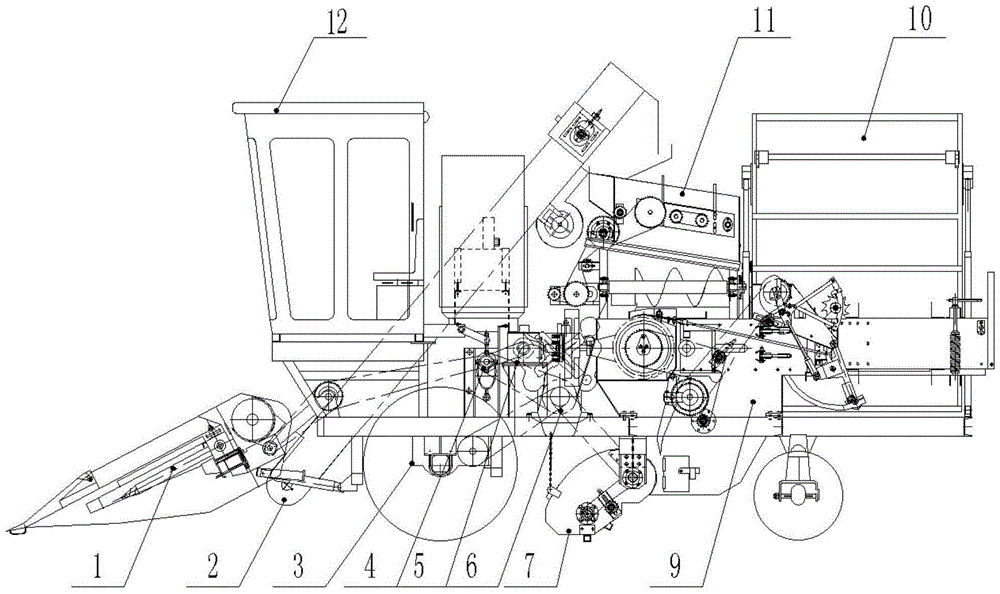

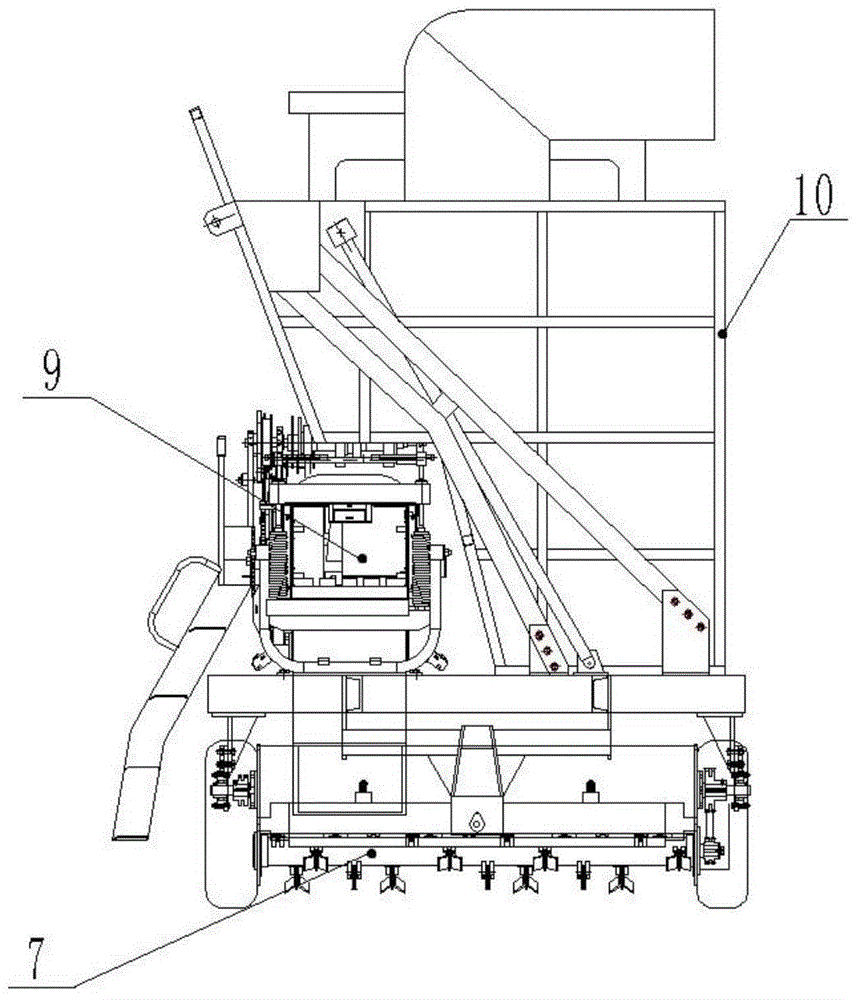

Self-walking type corn straw recycling and baling combined harvester

ActiveCN105191574ASolve problems such as recyclingImprove breathabilityMowersBalingAgricultural engineeringCombine harvester

The invention discloses a self-walking type corn straw recycling and baling combined harvester. The self-walking type corn straw recycling and baling combined harvester is mainly composed of a harvesting platform, a cluster elevator, a base plate, a middle shaft, a speed changing box, an engine, a grain tank and a cluster peeling mechanism; the harvester further comprises a straw collector and a baling device; the baling device is fixedly mounted at the left side of the base plate along the advancing direction of the harvester; the straw collector is located at the middle section of the harvester and is fixedly mounted under the base plate through a collector hanging bracket; and a conveying hole of the straw collector is aligned to a material storage room of the baling device. According to the self-walking type corn straw recycling and baling combined harvester, harvesting and cluster picking, peeling and boxing of corns, and whole-process work of crushing, collecting, rubbing, automatically pressing the straws into square bales can be finished in one step; and the picking of the corn clusters and the recycling of the corn straws can be carried out synchronously. The difficulties of harvesting of the straws of all the corns in the land and recycling of the straws and the like are overcome.

Owner:张自衡 +2

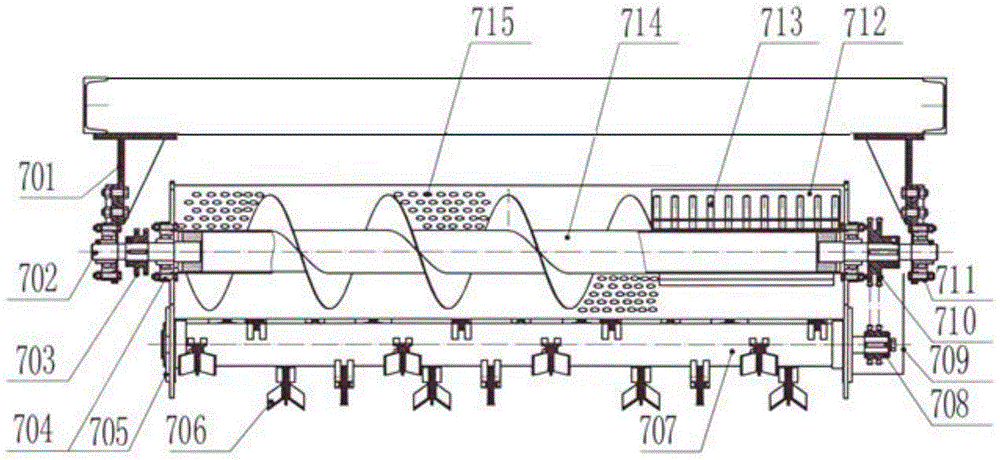

Straw crushing and field returning device

InactiveCN105103797AReduce generationSimple structureCrop conditionersMowersCombustionAgricultural residue

The invention provides a straw crushing and field returning device. The straw crushing and field returning device comprises a bottom plate, a supporting device, a scraping plate device, a conveyor belt device, a rolling wheel device and a crushing device, wherein the supporting device comprises a first supporting pillar, a supporting platform, a second supporting pillar, a third supporting pillar, a fixed plate, a first bracket and a first transverse rod; the crushing device comprises a first frame body, a second frame body, a third frame body, first rolling wheels, second rolling wheels, first crushing teeth, a third rolling wheel and second crushing teeth; the scraping plate device comprises a second bracket, a first inclined rod, a scraping plate and a second inclined rod; the conveyor belt device comprises a cushion block, a first supporting rod, a second supporting rod, a third supporting rod, a rotating wheel and a conveyor belt; the rolling wheel device comprises a third bracket, a circular wheel, convex blocks, vertical rods and a horizontal rod; the third bracket is L-shaped; one end of the third bracket is fixedly connected with the upper surface of the third frame body and the other end of the third bracket is vertically downwards arranged. With the adoption of the straw crushing and field returning device, agricultural residues including straws and the like can be sufficiently crushed, and the generation of garbage and the combustion of the straws are reduced.

Owner:江苏强丰农业发展有限公司

Manufacturing method and application of ecological straw brick or ecological straw ball

The invention discloses a manufacturing method and application of an ecological straw brick or an ecological straw ball. The manufacturing method of the ecological straw brick comprises the following steps: (1) placing collected straws in a pulverizer, and smashing the straws into granular substances of 1.0 cm; 2) adding copper isocaprylate of which the mass is 3% of that of the straws and quick lime of which the mass is 50% of that of the straws into the smashed straw particles; 3) uniformly stirring the straw particles, cement, a water-reducing agent, gravels, a self-made green additive and water; 4) manufacturing the mixture into a shape like a brick; 5) curing, and removing a mould; 6) drying, so as to obtain the required ecological straw brick. The manufacturing method of the ecological straw brick or the ecological straw ball has the advantages as follows: the ecological straw brick or the ecological straw ball is manufactured by taking waste straws as raw materials, so that the incineration of straws is reduced, and the atmospheric environment is improved; the manufactured ecological straw brick or the ecological straw ball is light in mass, large in porosity and rough in surface, has certain strength, can replace certain concrete slope protection materials to be applied to ecological slope protection projects or ecological stone mesh-box projects, and greatly improves the operation efficiency of ecological rehabilitation projects.

Owner:HOHAI UNIV

Straw liquefied liquid for improving soil, preparation method thereof and soil improving method

ActiveCN105967942ARaise the pHBalance pHContaminated soil reclamationOrganic fertilisersPotassiumNitrogen

The invention relates to a straw liquefied liquid for improving soil, a preparation method thereof and a soil improving method. Crop straws adopted as a main raw material are liquefied in water under certain conditions according to a certain mass ratio without any catalyst, and the straw liquefied liquid and soil are mixed and stirred, or the straw liquefied is directly sprinkled or irrigated. The method only adopts water as a medium to liquefy the straws without any catalyst, the straw liquefied liquid has soil acidity-alkalinity improving and nutrition supplementing functions, and can be applied to balance the acidity and the alkalinity of the soil, supply N, P, K and other organic matter nutrients, promote growth of crops and improve the output. The straw liquefying method has the advantages of simplicity, wide applicability, great reduction of the application amount of chemical fertilizers, reduction of straw burning, and reduction of environment pollution induced by straw burning. The straw liquefied liquid can kill harmful pathogens left on straws, and reduces harms of the harmful pathogens carried by the straws to subsequent cultivation.

Owner:JILIN UNIV

Environment-friendly energy-saving activated carbonized light-weight wall material as well as production method and application thereof

InactiveCN102515679AWith sound insulationWith insulationCarbon compoundsChemical industryBiological activated carbonCarbonization

The invention discloses an environment-friendly energy-saving active carbonized light-weight wall material which comprises 60-80% biological activated carbon and 20-40% of binding material according to a volume ratio. The invention also discloses a production method of the environment-friendly energy-saving active carbonized light-weight wall material. The production of the biological activated carbon comprises the following steps of: (1) pulverizing crops to obtain crop powder; (2) making the crop powder into crop particles by using a particle forming machine; and (3) carbonizing the crop particles to obtain the biological activated carbon by using a carbonization furnace. The invention also discloses an application of the environment-friendly energy-saving active carbonized light-weight wall material. The environment-friendly energy-saving active carbonized light-weight wall material is used for making gypsum hollow building blocks, gypsum cast-in-place walls and gypsum sandwiched building blocks. When used for building partition walls and interior and exterior decoration building blocks, the environment-friendly energy-saving active carbonized light-weight wall material has the advantages of light weight, sound insulation, heat insulation and air purification.

Owner:梁艺翰

Special nutrition pot for Gobi desert, preparation method and application thereof

ActiveCN107343451AImprove molding rateShorten the timeGrowth substratesCulture mediaHigh oxygenAgriculture

The invention relates to a special nutrition pot for a Gobi desert, a preparation method and an application thereof. The special nutrition pot for the Gobi desert is prepared from the following raw materials in percentages by weight: 55-65% of sludge and agricultural waste fermentation nutrient matrix, 25-30% of bentonite, 5-10% of attapulgite, 3.5-4% of biochar, 0.7-1.2% of a biodegradable flocculant and 0.3-0.5% of a physical light mixture. On one hand, the environmental protection problem of harmless resource utilization of production and life sludge wastes and agricultural wastes is solved; and on the other hand, organic matters in the sludge wastes and agricultural wastes can be effectively utilized, the finally produced special nutrition pot for the Gobi desert has the effects of environmental biodegradablity, high-oxygen humus, heat retention property and low temperature resistance, moisture adsorption, water storage and retention, drought avoidance, root protection, slow release of nutrients, land fertilization and soil improvement, and is suitable form massive industrial seedling of tree seedlings; use of a lot of plastic containers is reduced; the roots are not damaged in transplantation; and the special nutrition pot is especially suitable for popularization in alpine regions, water-deficient areas and serious soil desertification areas.

Owner:王效雷

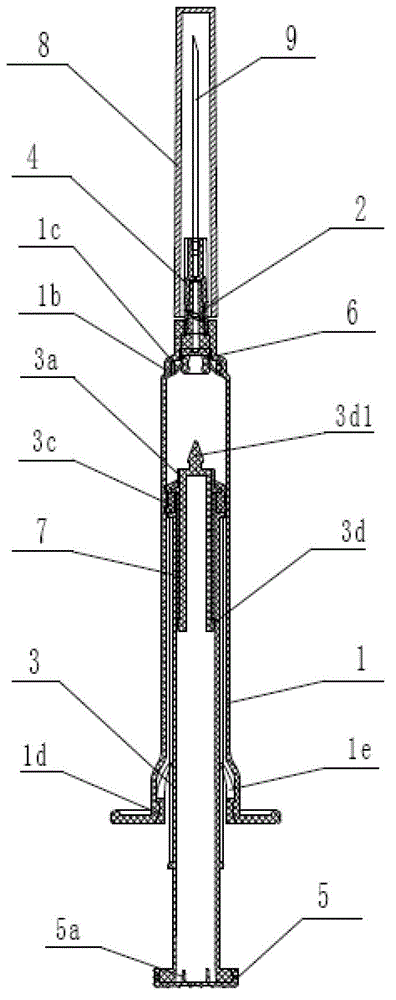

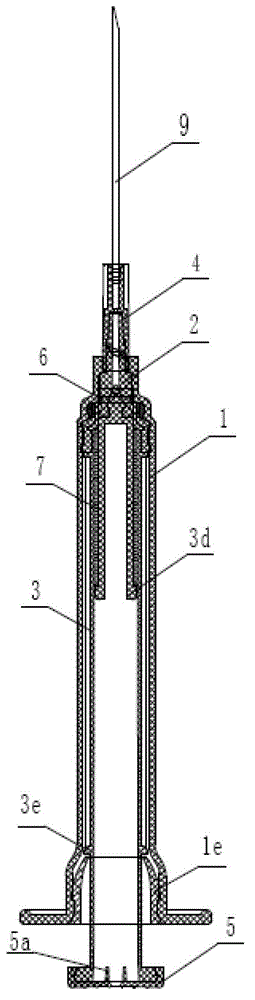

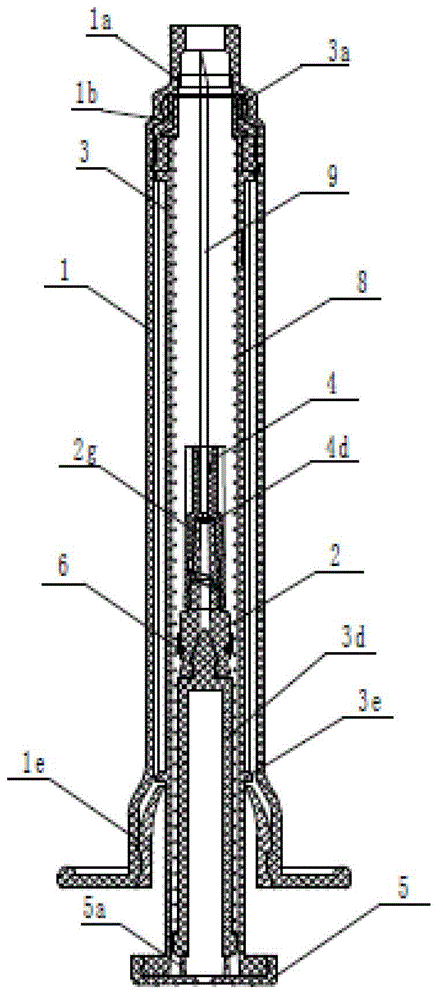

Safe injector

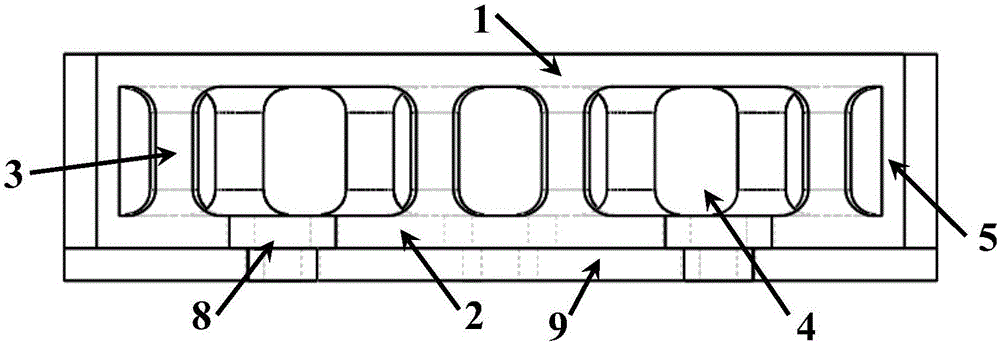

InactiveCN103330976AImprove convenienceImprove reliabilityInfusion syringesIntravenous devicesProduction lineSyringe needle

The invention discloses a safe injector which relates to the technical field of medical instruments, and comprises a needle cylinder (1) and a push rod (3), as well as an injection needle (10) and a connecting tube (2), wherein the injection needle (10) can be replaced as per use requirements. According to the invention, when the safe injector is in use, the traditional operating custom is barely changed, the use is convenient, and the effect is reliable; the injection needle (10) can retract and hide through an automatic retraction mechanism after finishing injecting to ensure that medical staff can be free from the unexpected harm of a contaminated needlepoint; after the injection is completed, the push rod (3) cannot be pulled back as being clamped by clamping rings (1e), so that the push rod cannot be reused, the real disposable injector is realized, and further the cross transmission of blood-borne diseases is avoided; support sheets (1c) are adopted to support the connecting tube (2), and a conical head pulling back rod (3d) is sleeved with a compression spring (7) in a flat pressing annular manner, so that the structural design is more reasonable, the safe injector is more suitable for the automatic assembly production of a production line, the quality is reliable, the qualification rate is high, and the cost is reduced.

Owner:江苏富田汇康医疗器械有限公司

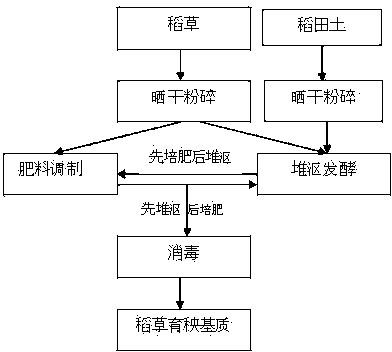

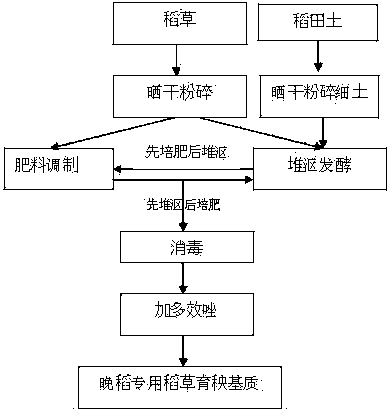

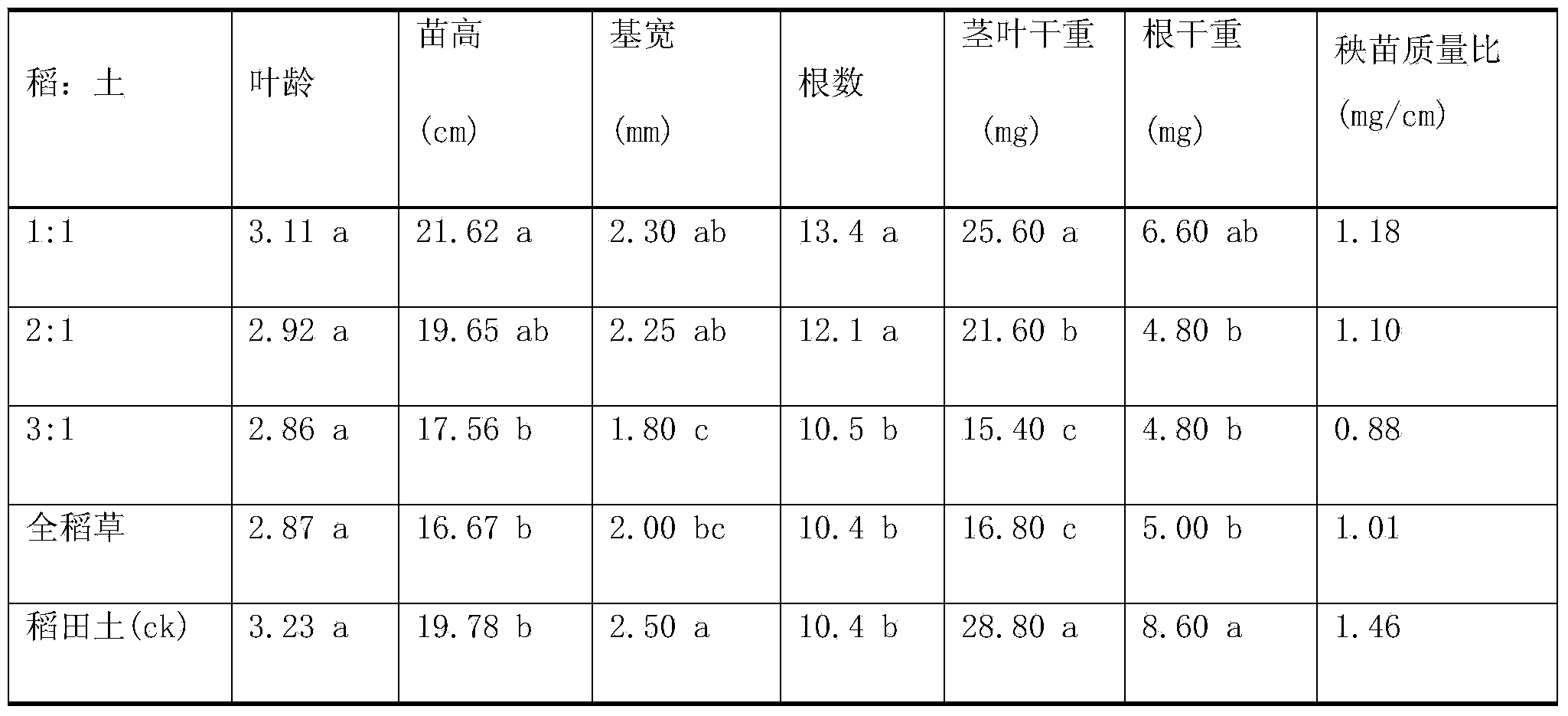

New sprout cultivation matrix by taking straw as rice and manufacturing method thereof

Disclosed are a new sprout cultivation matrix by taking straw as rice and a manufacturing method of the matrix. The matrix is composed, by weight, 75 percent to 80 percent of the straw, 20 percent to 25 percent of rice field fine earth, fertilizer and water. The manufacturing method of the matrix comprises the following steps of firstly, drying and smashing the straw, secondly, modulating the fertilizer and blending the matrix, thirdly, performing stack retting and fermentation, and fourthly, performing disinfection treatment. According to the matrix, waste in the rice production is fully recycled, manufacturing and operation are easy and convenient to implement, and the rice seedling quality is good.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

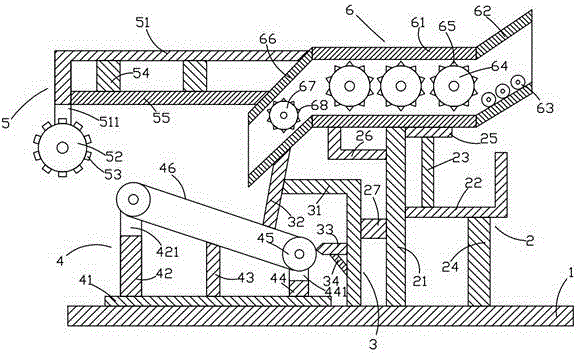

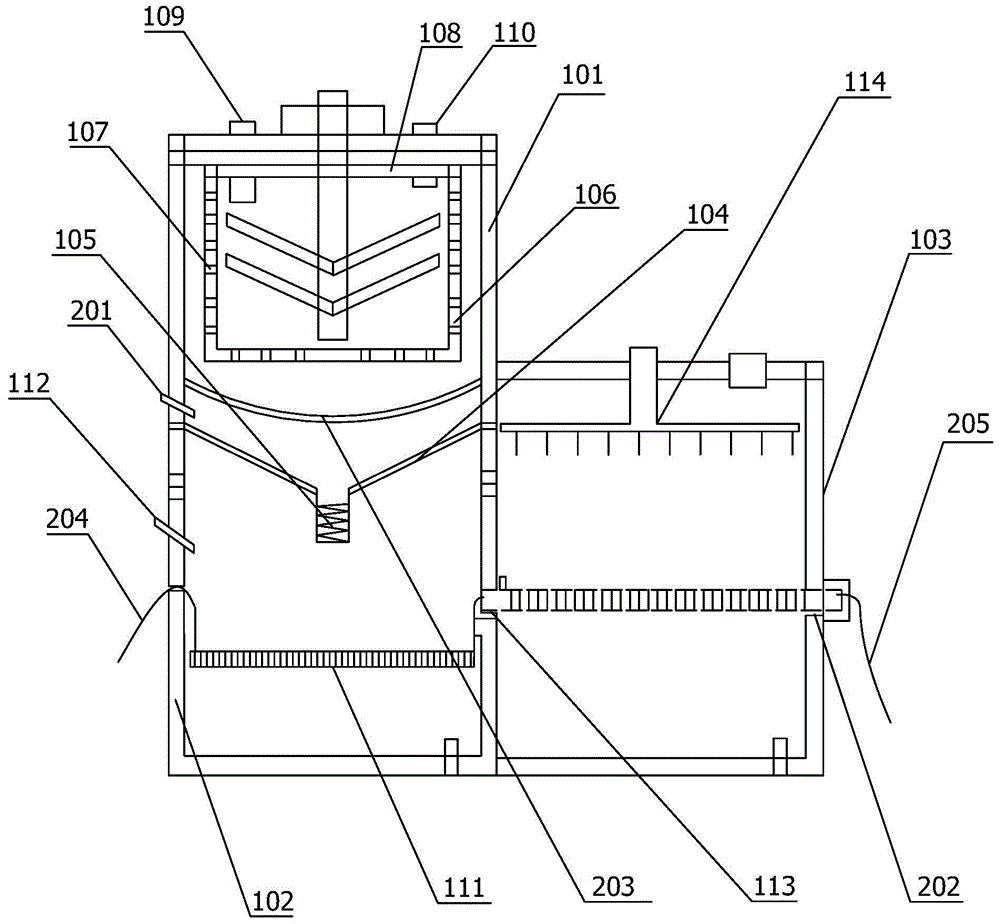

Sludge treatment method and device

ActiveCN104386893AHydrophilic breakEasy to separateSludge treatment by de-watering/drying/thickeningNature of treatment waterChemical reactionSludge

The invention provides a sludge treatment method and device, relating to the field of waste recycling. The method comprises the following steps: adding strong acid or strong base solution with weight not lower than 10% of the weight of to-be-treated sludge to the to-be-treated sludge and stirring the substances to react to obtain a solid-liquid mixture; carrying out solid-liquid separation on the solid-liquid mixture to obtain filtrate and a solid part; carrying out solid-liquid separation after concentrating the filtrate to obtain a solid precipitate; drying the solid precipitate and then adding water to elute the solid precipitate to obtain a recycled solution and a solid insoluble substance respectively; regulating the pH value of the solid part to be neutral and landfilling or burning the solid part after compressing the solid part. The method provided by the invention has the beneficial effects that the degradation time of pollutants is reduced through chemical reaction, so that a great number of pollutional components are dissolved in strong acid or strong base and a small quantity of solid parts which basically do not contain pollution sources is obtained, thus reducing the burning quantity and the area occupied by landfilling and avoiding secondary pollution.

Owner:许国胜

Preparation method of straw feed

InactiveCN105961839AHigh nutritional valueReduce incinerationBacteriaFood processingIntracellular substanceFodder

The invention relates to a straw feed and a preparation method thereof. The preparation method comprises the following steps of culturing extremely halophilic archaea-halogranum amylolyticum TNN58; after the culturing of thalli is completed, performing cell pyrolysis by a water pyrolysis method. After centrifugal treatment, solids mainly comprise biological degradable plastics PHBV and part of intracellular substances, and precipitates can be used for PHBV extraction; supernatant contains a large quantity of nutrient substances, so that when the supernatant is added to straw, the content of nutrient substances such as protein in the straw can be effectively increased, and the nutrient value of the straw can be increased.

Owner:BEIJING UNION UNIVERSITY

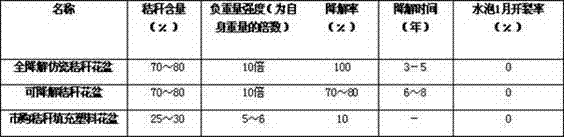

Fully degradable ceramic-imitated straw flowerpot and manufacture method thereof

The invention discloses a fully degradable ceramic-imitated straw flowerpot and a manufacture method of the flowerpot. The manufacture method comprises the following steps: using crushed straw powder as materials, adding a gelatin adhesive, wherein the weight ratio of the straw powder to the gelatin adhesive is 1 to 0.5-0.8; mixing the materials, and then thermo-forming to obtain the fully degradable ceramic-imitated straw flowerpot. The industrial gelatin adopted in the invention is modified in a cross-linking manner by silane coupling agent Kh-550, zinc chloride and a borax composite modifier; the advantages of the silane coupling agent Kh-550, zinc chloride and the borax composite modifier are used for achieving a good effect. Hydroxide radical in the gelatin protein is closed to reduce the water solubility of the gelatin; a peptide chain of the gelatin protein is lengthened to generate part coordination compound, so that the flexibility of the gelatin is reinforced, and the degradation characteristic of the glue solution is kept. The fully degradable ceramic-imitated straw flowerpot product is applied to domestic urban landscaping, landscape modeling and beautifying, ecological tourism, holiday villages, families, units, public places, catering industry, wine shops, hotels, conference rooms, offices, schools, clubs, hospitals, villages, and the like.

Owner:漳浦中龙红麻籽贸易有限公司

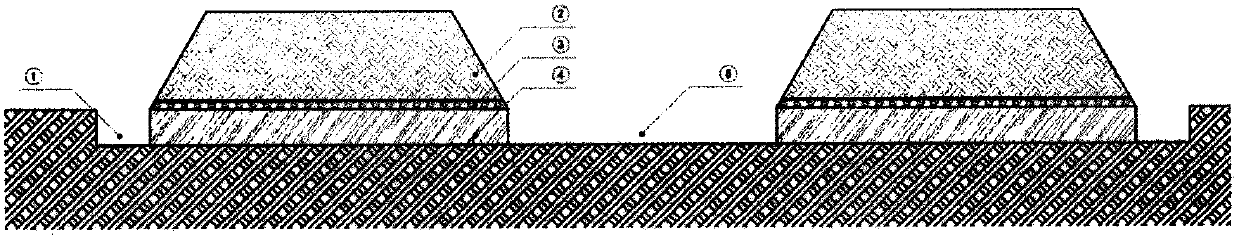

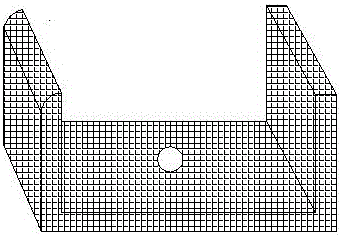

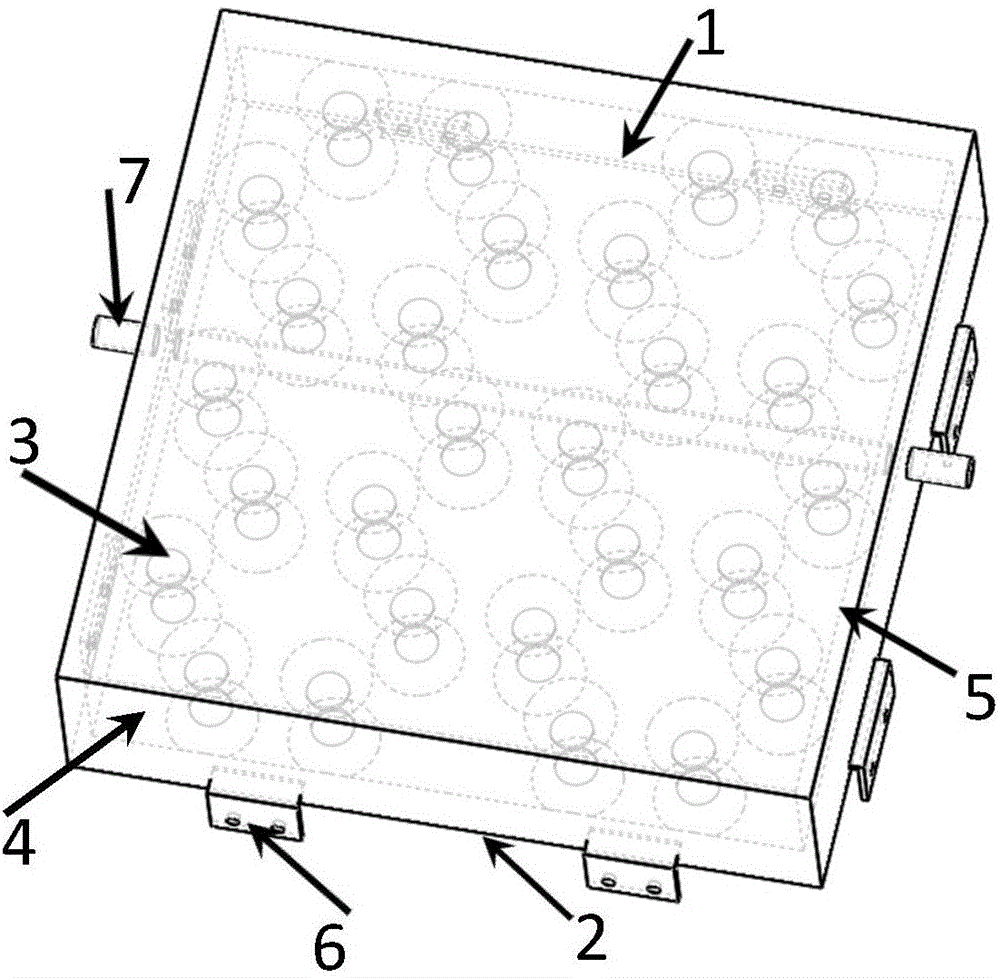

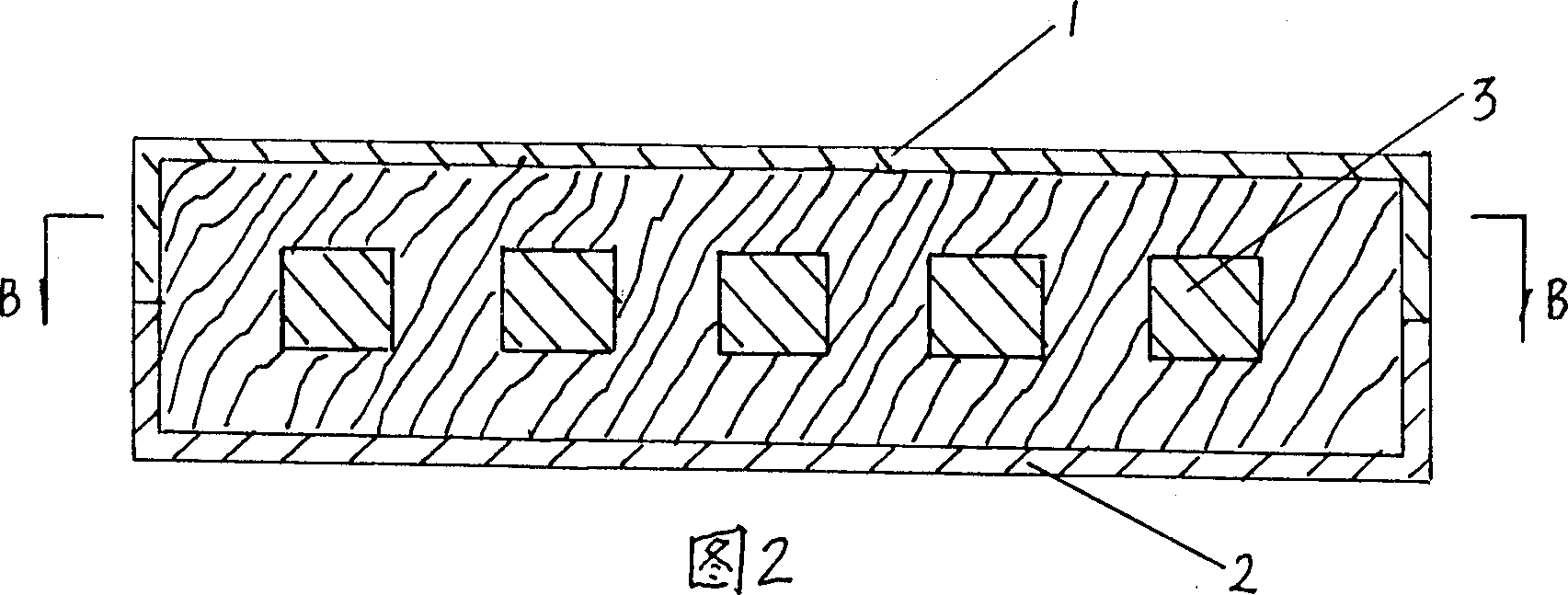

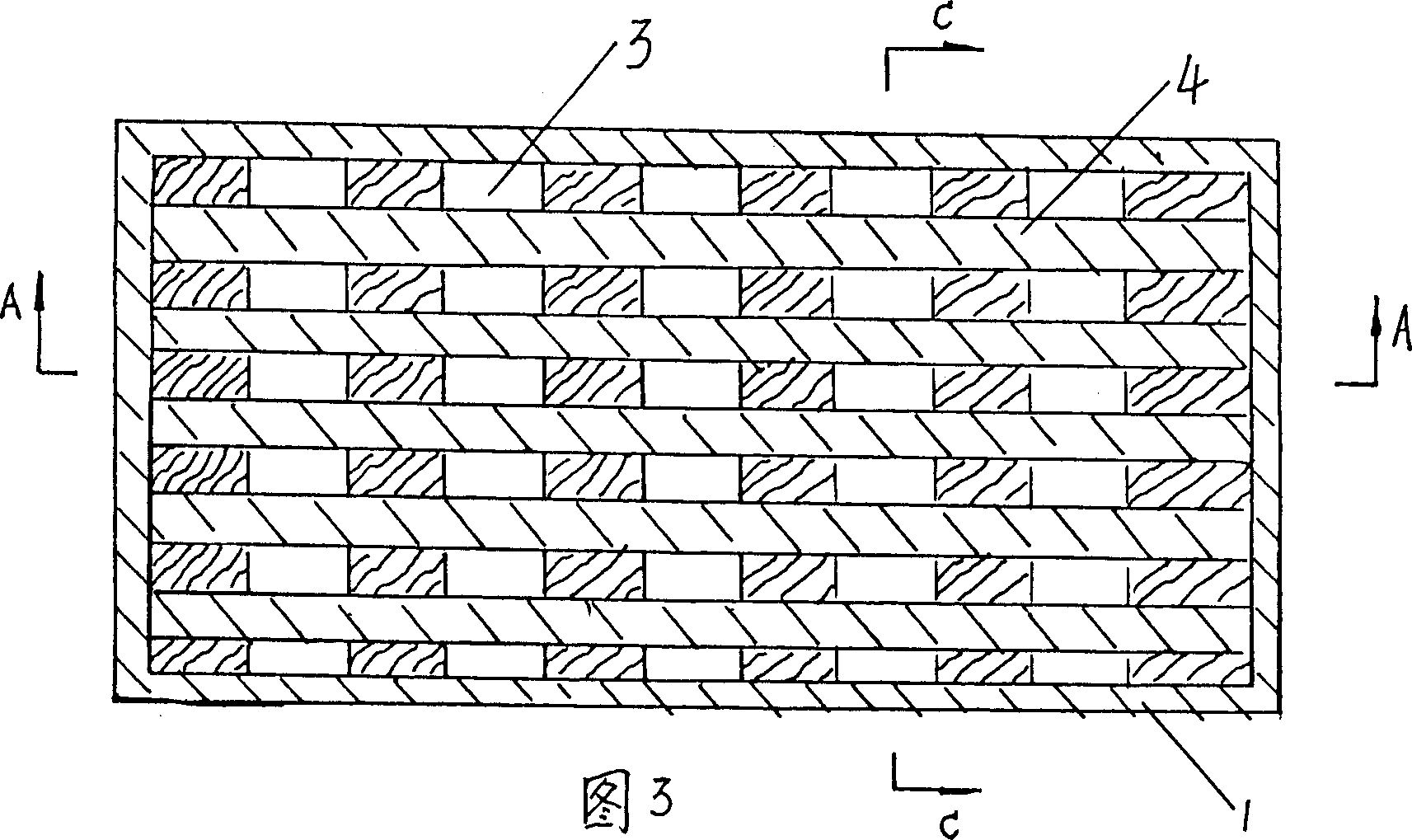

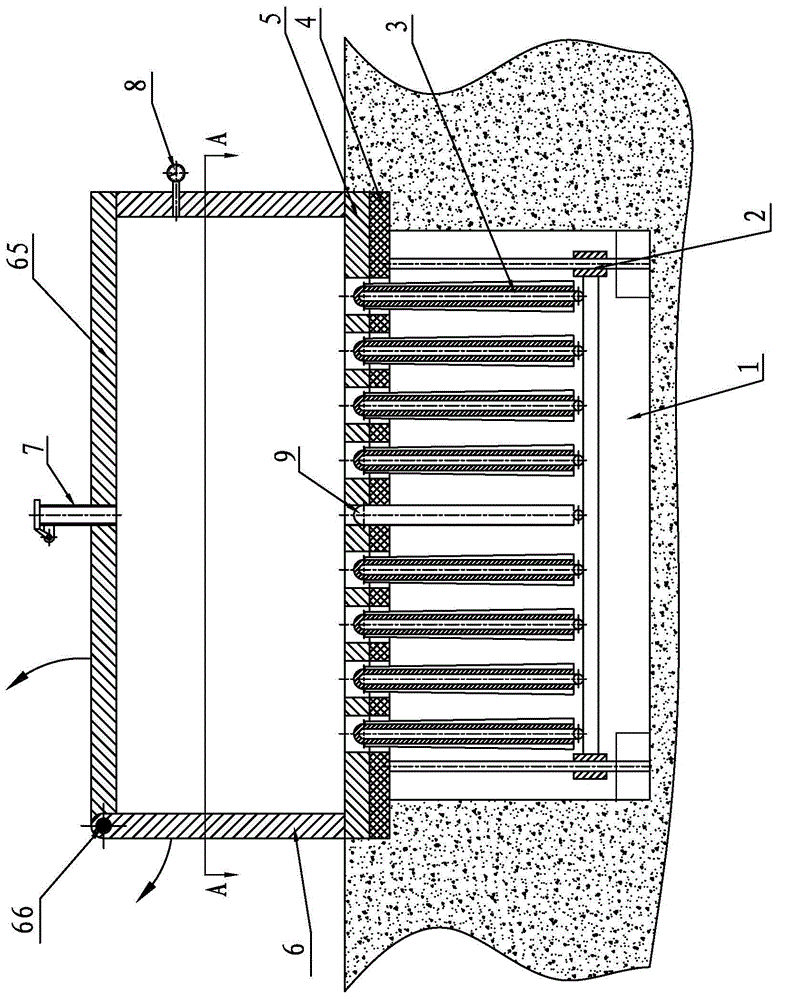

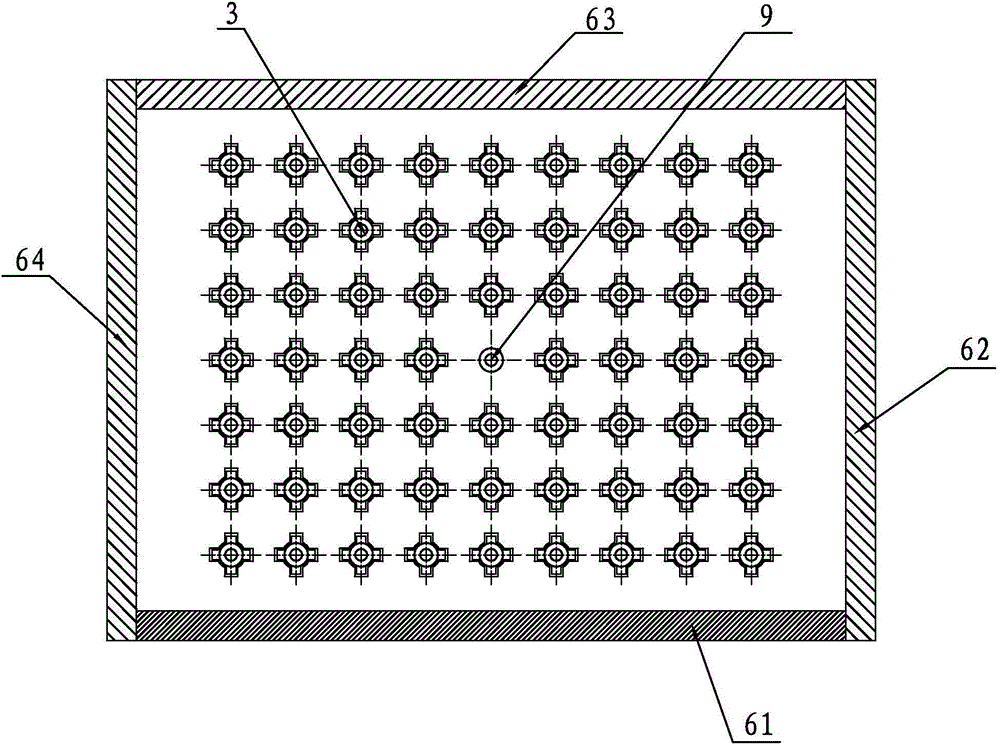

Integrated straw sandwich filling wall preparation method and integrated straw sandwich filling wall

ActiveCN106592856AEliminate engineering quality effectsImprove construction efficiencyCeramic shaping apparatusBuilding componentsCompression moldingSlurry

The invention discloses an integrated straw sandwich filling wall preparation method and an integrated straw sandwich filling wall. The preparation method comprises the steps that a straw sandwich layer is prepared, through holes which are arranged according to rules are formed in a straw block subjected to compression molding, and transition conical surfaces are machined on the upper surface and the lower surface of the straw block respectively; the straw sandwich layer is placed in a mold frame, and the height is set for the straw sandwich layer through the distance of a cushion block and the inner bottom face of the mold frame; uniformly stirred self-compacting concrete and chopped basalt fiber mixed slurry is injected into the mold frame, primary whole casting molding is conducted according to preparation processes from bottom to top, the mixed slurry forms a lower stressed skin on the bottom surface of the straw sandwich layer, the mixed slurry forms an upper stressed skin on the upper surface of the straw sandwich layer, and the mixed slurry forms small columns which are connected with the upper stressed skin and the lower stressed skin in the through holes of the straw sandwich layer. The filling wall has the distinct characteristics and advantages in the aspects of heat preservation, structural integrity, system integration, construction efficiency, environmental friendliness and the like.

Owner:SOUTHEAST UNIV

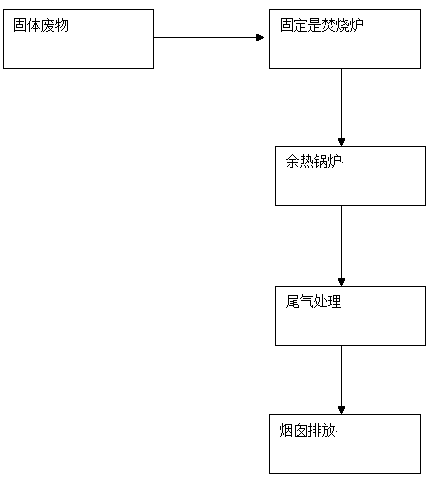

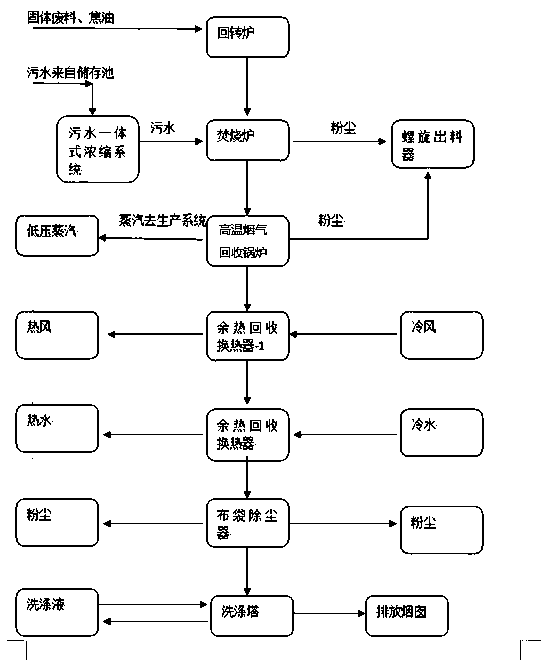

Industrial waste treatment technology and device thereof

PendingCN108726614ANo energy consumptionNo addedWater/sewage treatment by heatingIncinerator apparatusHigh concentrationToxic industrial waste

The invention discloses an industrial waste treatment technology and a device thereof. A method comprises the steps that hazardous waste of tar and the like is subjected to incineration, high-concentration high-salinity sewage is subjected to incineration, the two segments of incineration are combined to form a secondary complete incineration system, hazardous pollutants are removed, and the solidhazardous waste is treated when sewage incineration is conducted; meanwhile, high-temperature waste heat and medium-temperature waste heat are recycled, so that the sewage treatment cost is reduced;an integrated sewage concentration system is adopted, so that the sewage incineration quantity is reduced by 40%-60%, the sewage treatment cost can be saved by 30% or above, the direct cost of sewageincineration is reduced, whole system energy consumption is low, and sewage treatment recycling is achieved.

Owner:PINGYUAN ZHONGDE TAIXING ENVIRONMENTAL PROTECTIONTECH & EQUIP CO LTD

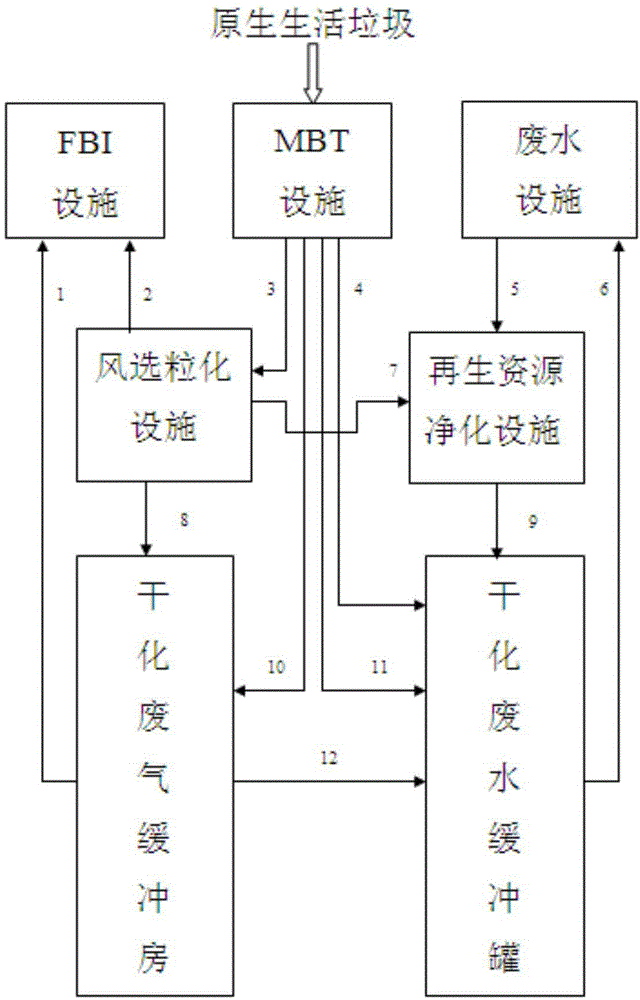

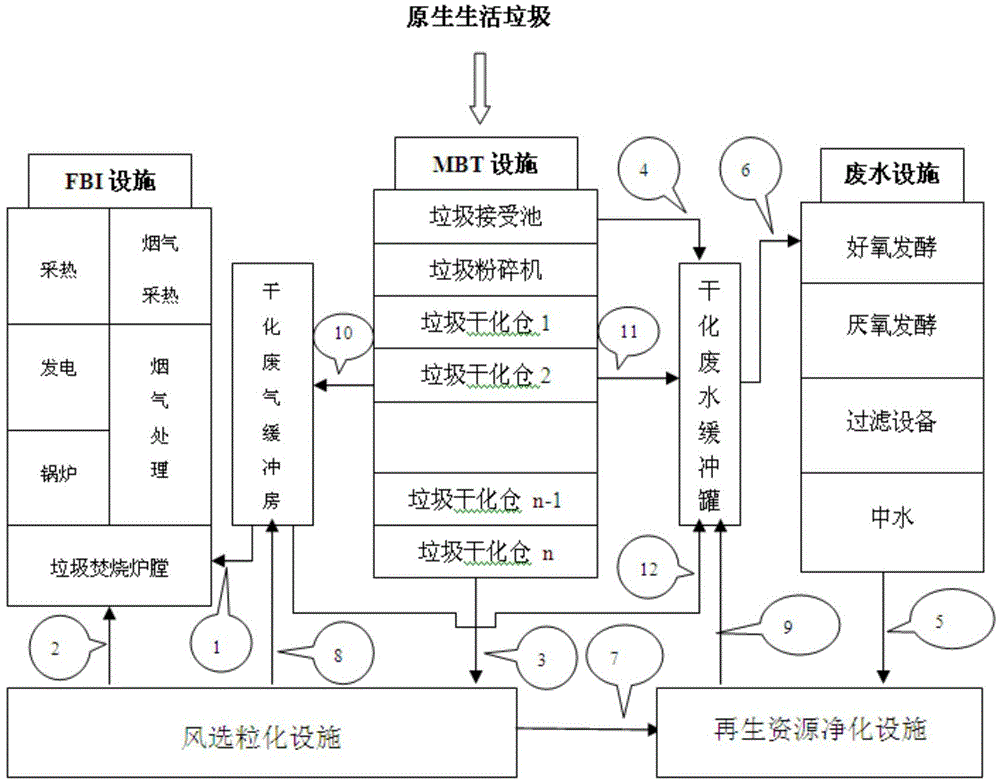

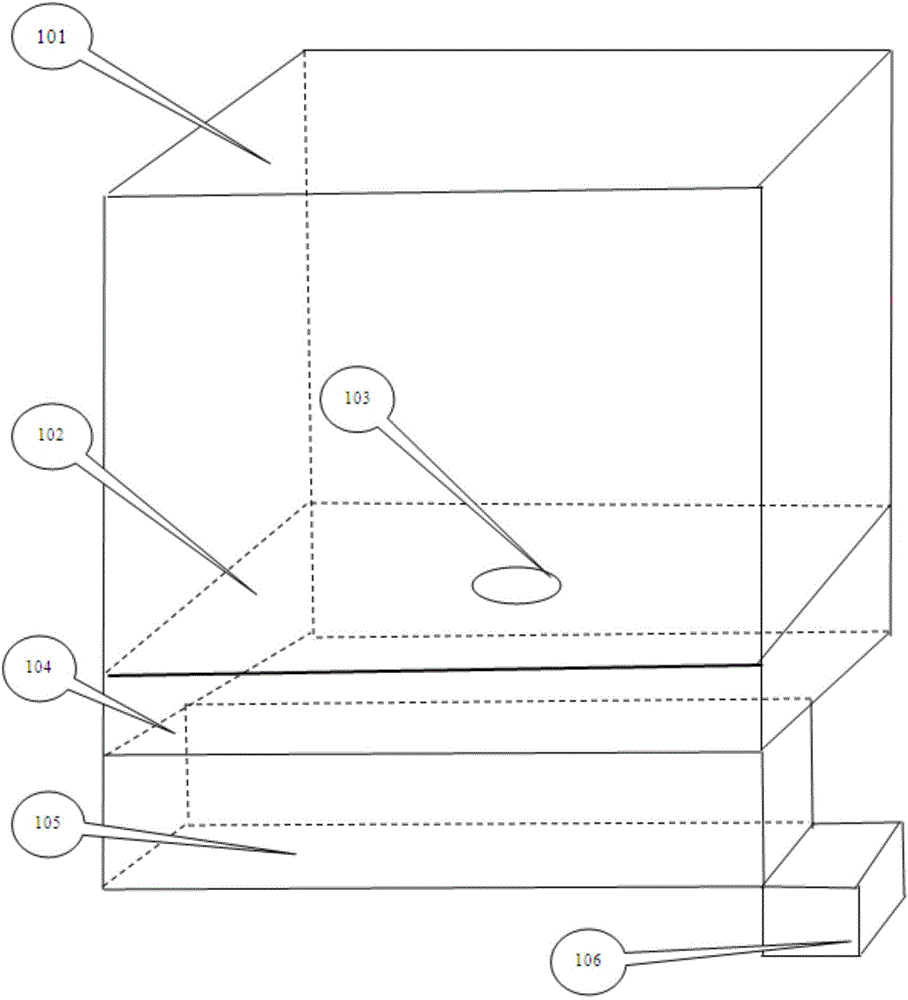

Integrated household refuse incineration treatment method and device

ActiveCN104791805ASimple equipment structureSimple to buildMembrane filtersIncinerator apparatusMechanical biological treatmentTreatment costs

The invention discloses an integrated household refuse incineration treatment method. The method includes the steps of conducting waste water removal and drying on native household refuse through an MBT facility to obtain refuse physical water, dried refuse, dried waste gas and dried waste water; conducting winnowing and pelletization on the dried refuse to obtain pelletized refuse, the heavy object part of the dried refuse and pelletized waste gas; conducting incineration treatment on the pelletized refuse through an FBI facility or a grate furnace facility; conducting separation and purification on the heavy object part of the dried refuse through a renewable resource purification facility to obtain renewable resources and purified waste water, wherein the MBT is the mechanical biological treatment technology, and the FBI is the fluidized bed incineration technology. By means of the method, the treatment cost of household refuse can be reduced, economic benefits can be obtained, the amount of generated renewable resources is large, no secondary pollution is caused, and the expanding performance is good; in addition, the invention further provides a device used for the method.

Owner:奚振华

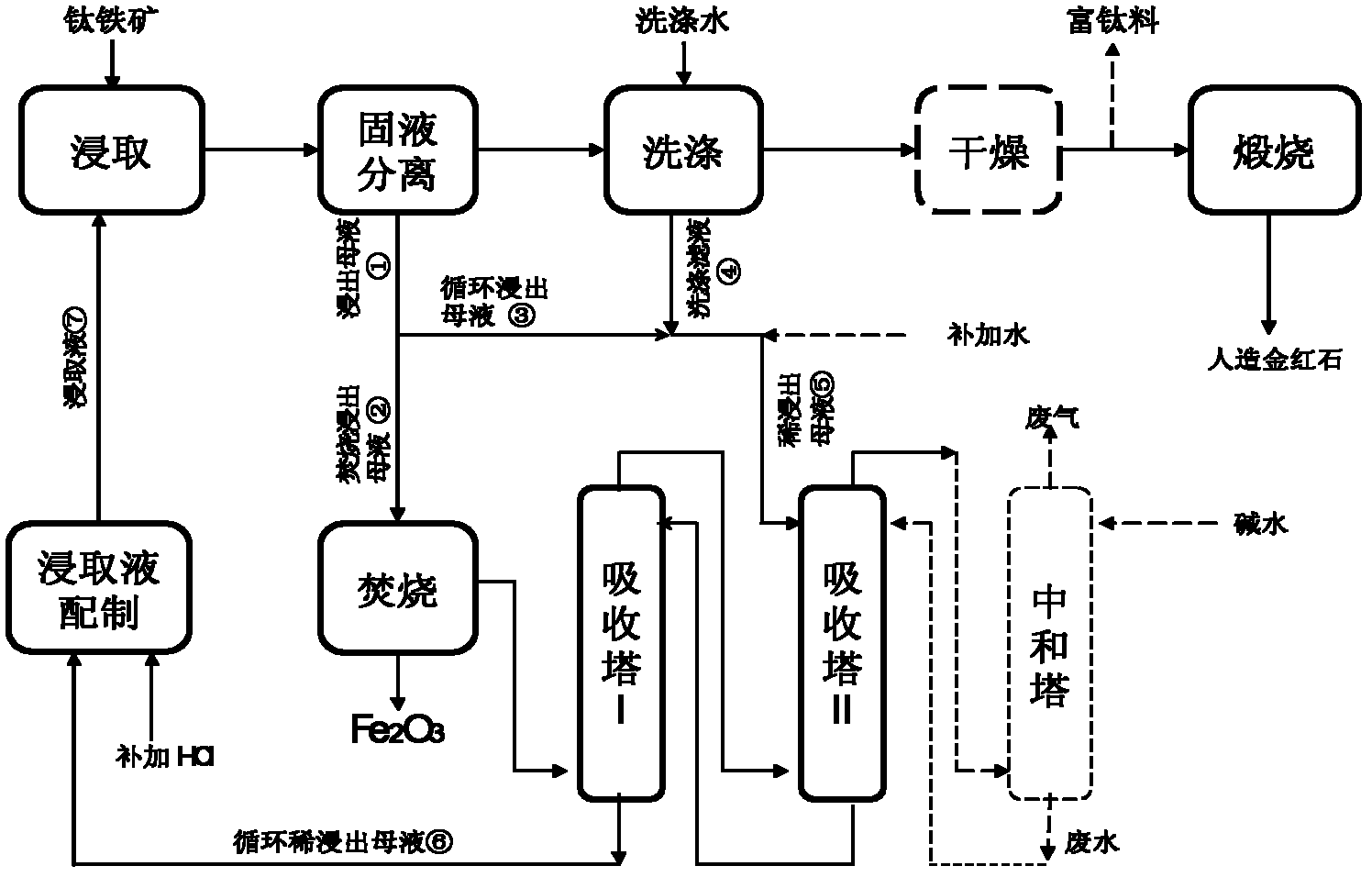

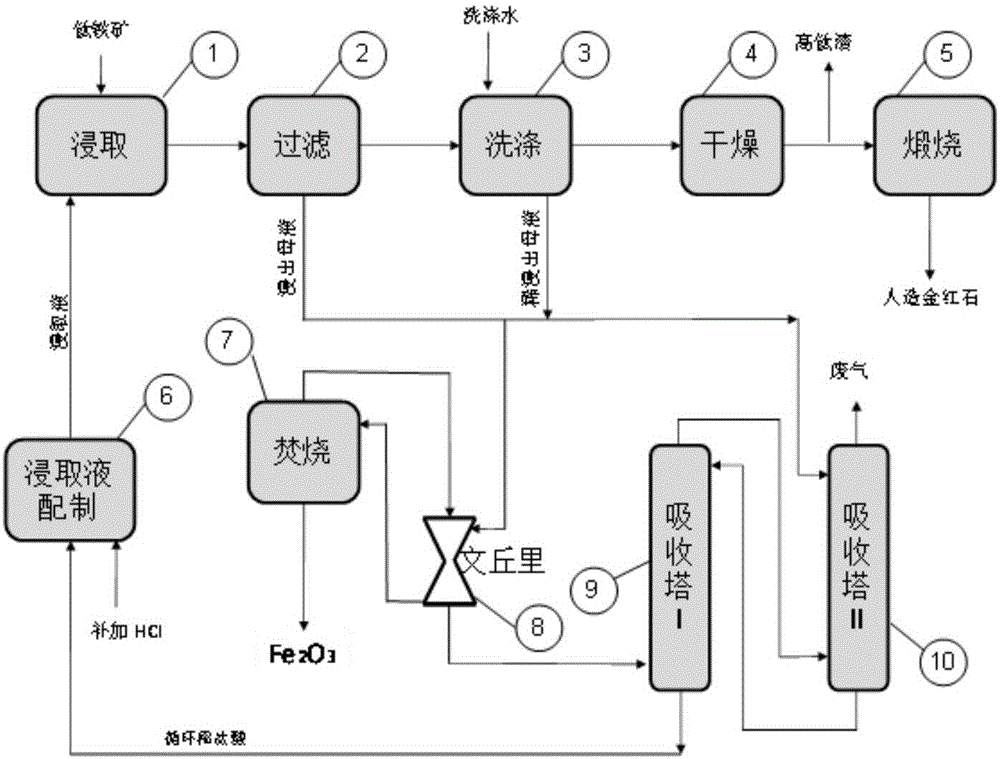

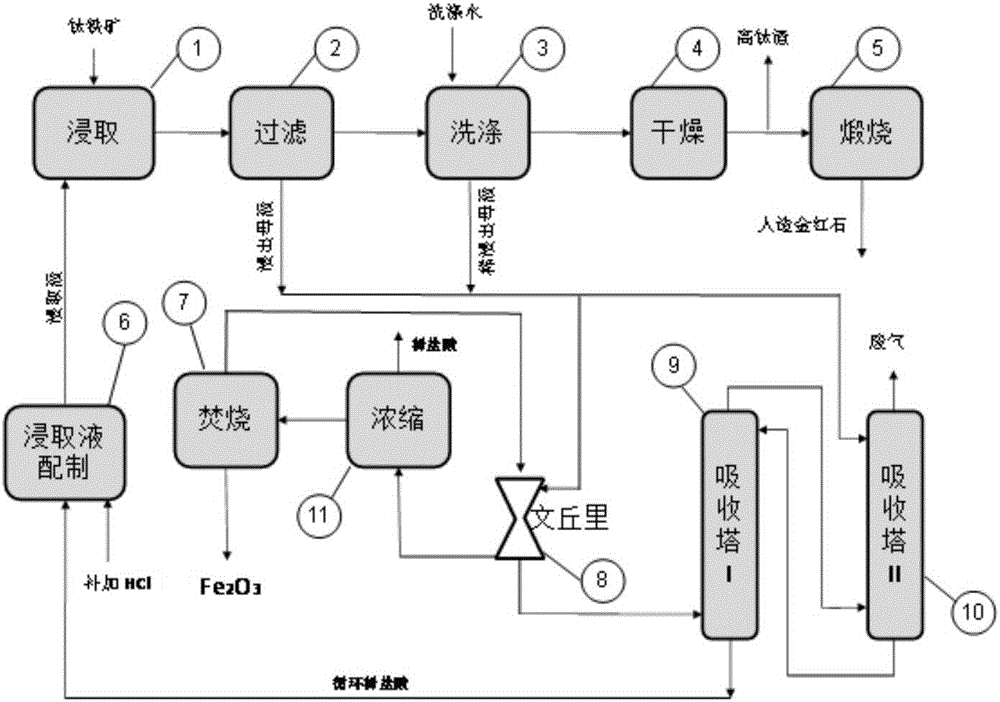

Method for treating ferrotitanium material hydrochloric acid lixivium

The invention provides a method for treating ferrotitanium material hydrochloric acid lixivium. The method comprises the steps that leached mother liquor obtained through leaching of ferrotitanium materials via the hydrochloric acid lixivium is subjected to flow dividing, then incineration leaching mother liquor and circulation leaching mother liquor are obtained, and after the incineration leaching mother liquor is subjected to Venturi preconcentration and multiple-effect evaporation concentration, the incineration leaching mother liquor is incinerated through an incinerator, and hydrochloric acid is recycled for lixivium regeneration. By the adoption of the method, the defect that after the ferrotitanium materials are leached through the hydrochloric acid, the incineration amount and energy consumption in the incineration procedure are too large can be overcome, the incineration amount of the leaching mother liquid can be reduced by 26.65%, accordingly, the energy consumption of the whole technology is reduced by 18%, and good industrial application prospects are achieved.

Owner:有研资源环境技术研究院(北京)有限公司

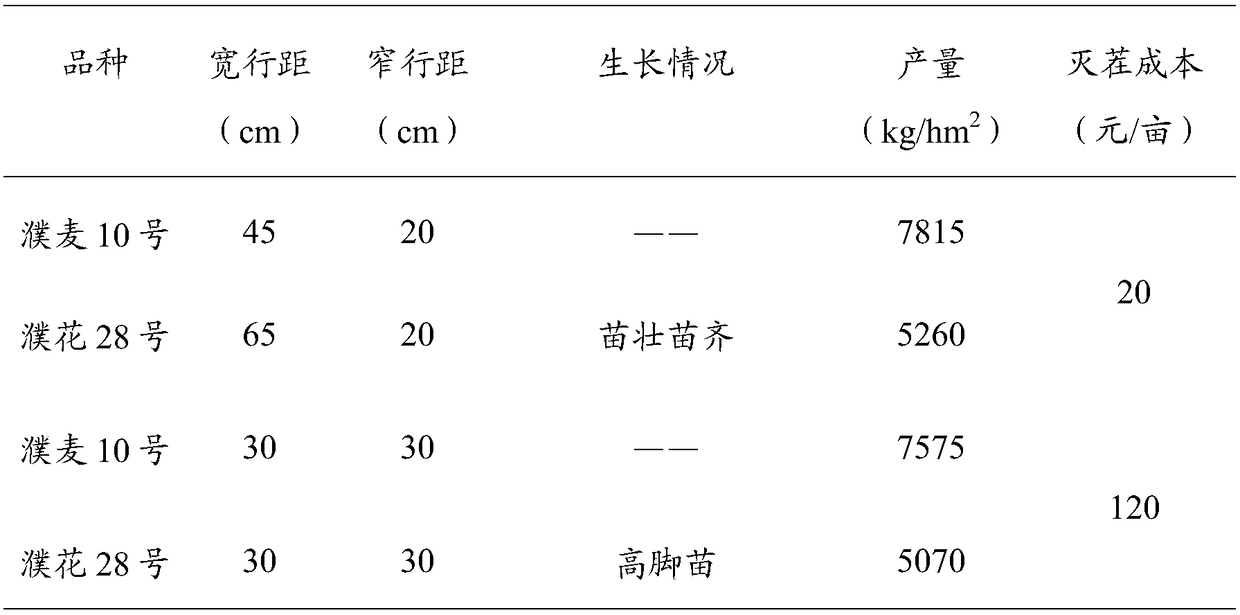

Wheat-peanut double-high-yield planting mode suitable for entire mechanization

InactiveCN109392631AAchieve double high yieldRealize the whole process of mechanized operationFabaceae cultivationCereal cultivationSeederProblem of time

The invention discloses a wheat-peanut double-high-yield planting mode suitable for entire mechanization, and belongs to the technical field of wheat-peanut cultivation. The planting mode includes thefollowing steps: (1) preparation before sowing; (2) sowing: planting wheat in wide and narrow rows, wherein the wide row spacing is 45 cm, and the narrow row spacing is 20 cm, and performing double-row wide-breadth planting, wherein the breadth width is 10 cm, and 85 cm in width forms one band; in the middle and late May of next year, mechanically sowing peanuts in drill in wide rows of the wheatby using a small power seeder, and conducting planting in two rows with a row spacing of 20 cm, wherein a spacing between the peanuts and wheat is 12.5 cm; (3) field management; and (4) harvesting; the problem of time-consuming, labor-consuming and low yield of interplanting the wheat with peanuts is solved.

Owner:濮阳市农业科学院

Making process of light environment-protecting board as building material

The present invention relates to the production process of one kind of light environment-protecting board as building material. Of the board, the main material includes the mixture of wheat straw and one of rice straw, bagasse and saw dust, waste phosphate rock powder, magnesia and anhydrous magnesium sulfate; and the supplementary material includes bentonite, copper naphthenate, white carbon black, calgon and copper sulfite.

Owner:蒋启良

Preparation method of culture material of Morchella genus cultivar and method for cultivating Morchella genus cultivar by using culture material

InactiveCN109122041ALess investmentSave on sterilization processCalcareous fertilisersCultivating equipmentsLimewaterCrop

The invention discloses a preparation method of a culture material of a Morchella genus cultivar and a method for cultivating the Morchella genus cultivar by using the culture material. The preparation method comprises the steps: (1), taking crop straw pieces, performing soaking in limewater of a concentration of 10-20%, and conducting soaking at room temperature for 20-30 days so as to obtain soaked straw pieces; and (2), drying the soaked straw pieces obtained in the step (1) at 75-80 DEG C so as to obtain the culture material which is alkaline. The prepared culture material has certain ability of microbial pollution resistance, so that the effects of time and labor saving are achieved at the key step of production of the Morchella genus cultivar; and no sterilization operation is neededin the preparation process of the culture material and the corresponding strain production step, so that the efficiency is improved.

Owner:INST OF SOIL FERTILIZER SICHUAN ACAD OF AGRI SCI

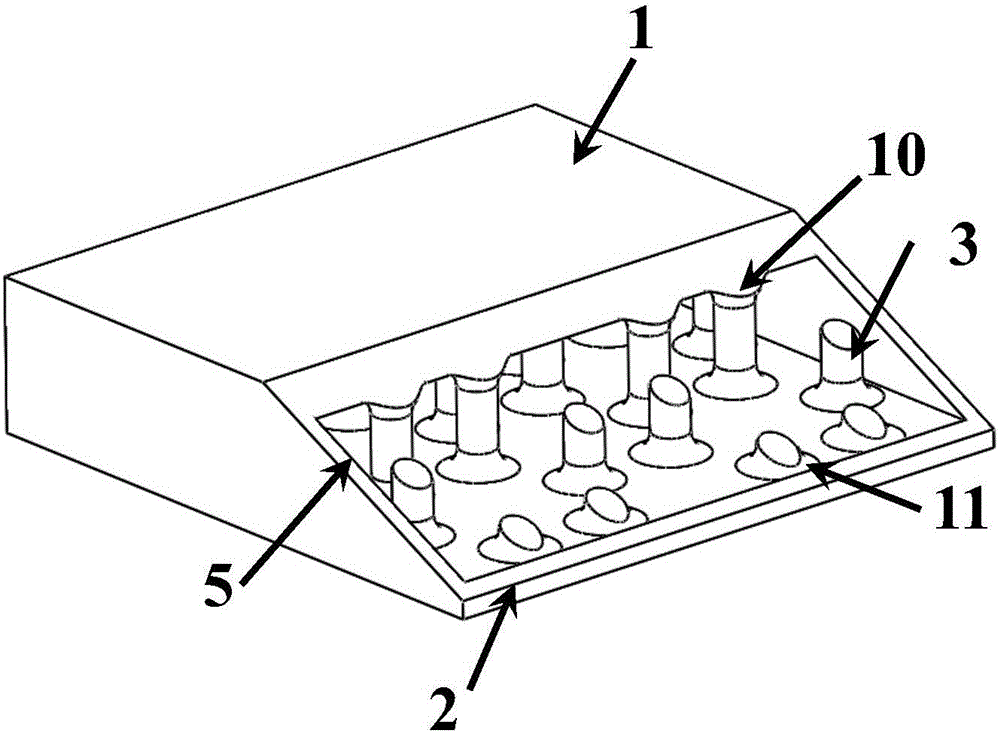

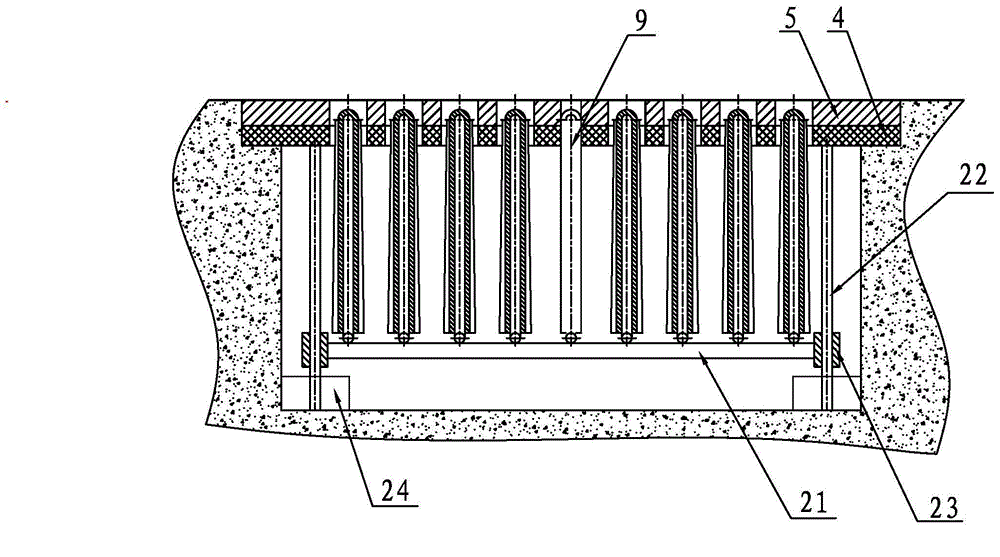

Efficient anaerobic fermentation device for straw feed and application method thereof

ActiveCN104544511AFermentation temperature difference narrowedIncrease cooling areaFeeding-stuffInsulation layerCore temperature

The invention provides an efficient anaerobic fermentation device for straw fee. The device comprises a supporting seat pit, a synchronous lifting mechanism, a guide heat transfer part, a heat insulation layer, a steel bottom plate, a heat preserving fermenting box body, a pressure exhausting pipe, a side surface temperature measuring sensor and a core temperature measuring sensor; the steel bottom plate and the heat insulation layer are sequentially arranged on an upper opening of the supporting seat pit; the synchronous lifting mechanism is arranged in the supporting seat pit; the guide heat transfer part and the core temperature measuring sensor are respectively inserted into guide holes formed in the steel bottom plate and the heat insulation layer by sleeving; the lower ends of the guide heat transfer part and the core temperature measuring sensor are both mounted on the synchronous lifting mechanism; the heat preserving fermenting box body is arranged above the steel bottom plate to cover the supporting seat pit; the pressure exhausting pipe is arranged on a top plate of the heat preserving fermenting box body; the side surface temperature measuring sensor is arranged on the sidewall of the heat preserving fermenting box body; the core temperature measuring sensor is arranged in a distribution area of the guide heating part. With the adoption of the device, the straws can be subjected to efficient anaerobic fermentation; the temperature in straw fermentation can be kept stable and uniform, and thus the straws can be industrially fermented into base feed.

Owner:李文跃

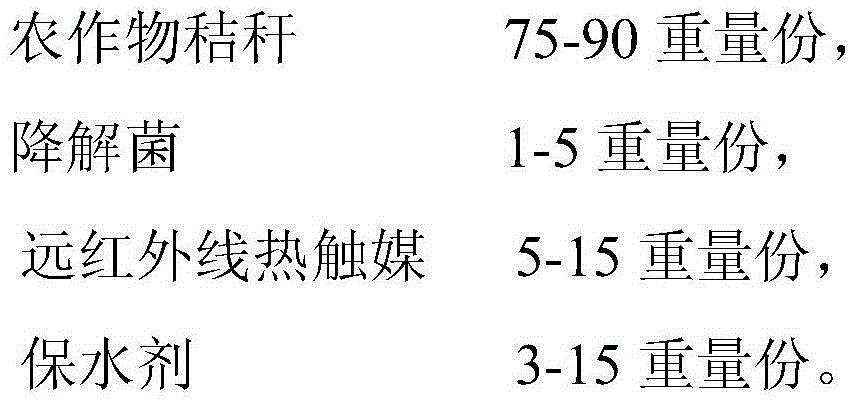

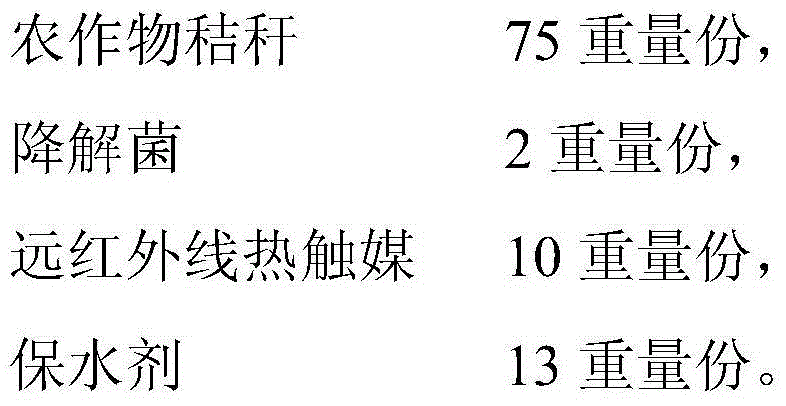

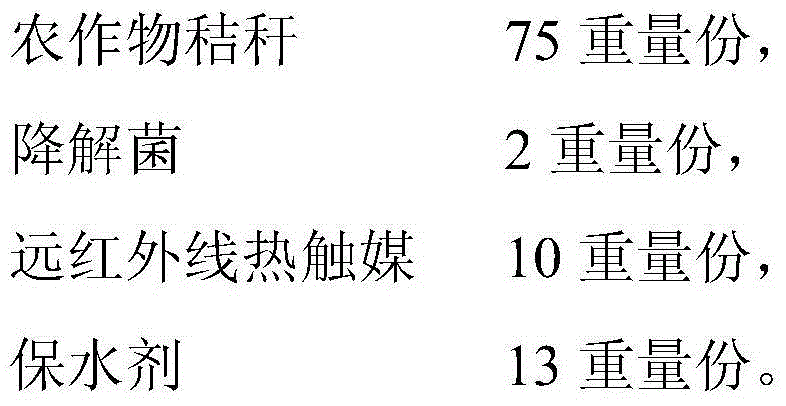

Water-retaining paper mulch film

ActiveCN104098921AGuaranteed demandImprove water retentionClimate change adaptationPlant protective coveringsFiberPlastic mulch

The invention discloses a water-retaining paper mulch film. The preparation raw materials of the water-retaining paper mulch film include: 75-90 parts by weight of crop straw, 5-15 parts by weight of a far infrared heat catalyst, and 3-15 parts by weight of a water-retaining agent. The water-retaining paper mulch film also includes degrading bacteria. The water-retaining paper mulch film contains the water-retaining agent, can better absorb water and retain water, provides adequate moisture to crop, and guarantees the water demand of crop during growth. According to the invention, crop straw is employed as the basic raw material to prepare the water-retaining paper mulch film, which is rich in plant fiber and can be used as a crop growth fertilizer after degradation.

Owner:广州万吉生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com