Method for treating ferrotitanium material hydrochloric acid lixivium

A hydrochloric acid leaching and leaching technology, which is applied in the field of hydrometallurgy, can solve the problem of large amount of incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

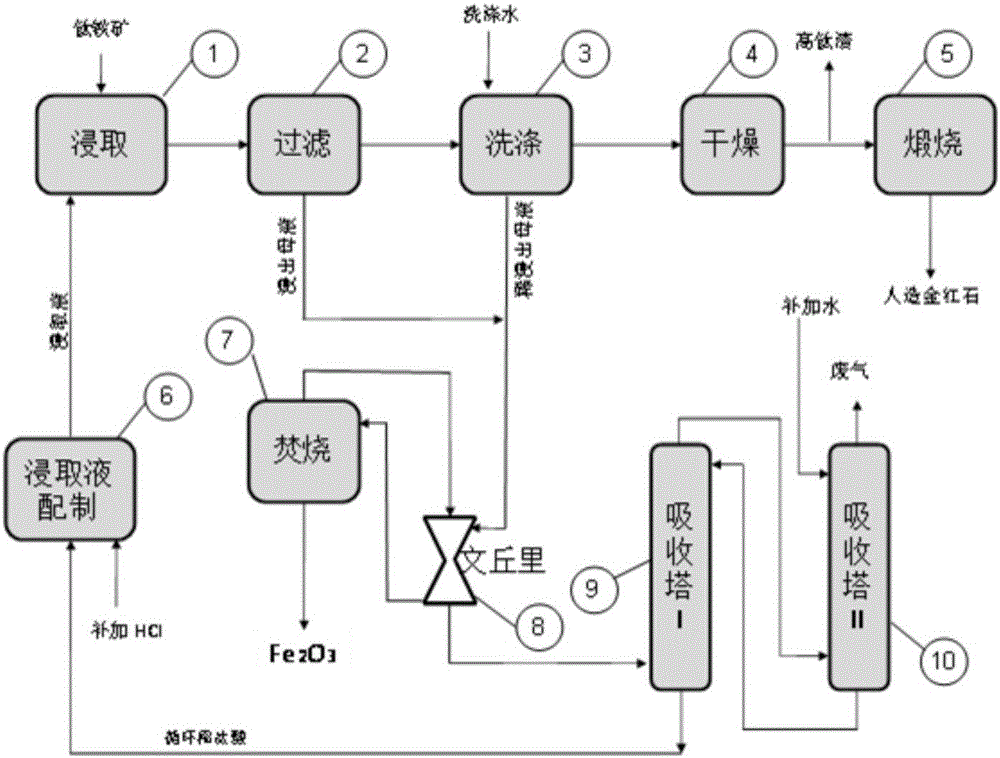

[0089] Embodiment 1 Conventional titanium concentrate hydrochloric acid pressure leaching and leaching mother liquor full incineration treatment (see figure 1 )

[0090] 1. Add 8 tons of titanium concentrate to the leaching ball with a diameter of 4.3 meters. The main components of the titanium concentrate are shown in Table 7.

[0091] The main chemical composition (%) of table 7 embodiment 1 raw material titanium concentrate

[0092] Al 2 o 3

CaO TF MgO SiO 2

TiO 2

V 2 o 5

0.91 1.12 32.55 4.01 3.58 46.12 0.1

[0093] 2. Pump 26.4 meters 3 The leaching solution containing 18% dilute hydrochloric acid is poured into leaching balls with a diameter of 4.3 meters, and preheated to 95°C. The total impurities such as Fe, Ca and Mg in the leach solution are less than 10g / L.

[0094] 3. After feeding 3 tons of steam at 140°C, react for 4 hours.

[0095] 4. Release the leached material and cool down to 70°C.

[0096] 5. ...

Embodiment 2

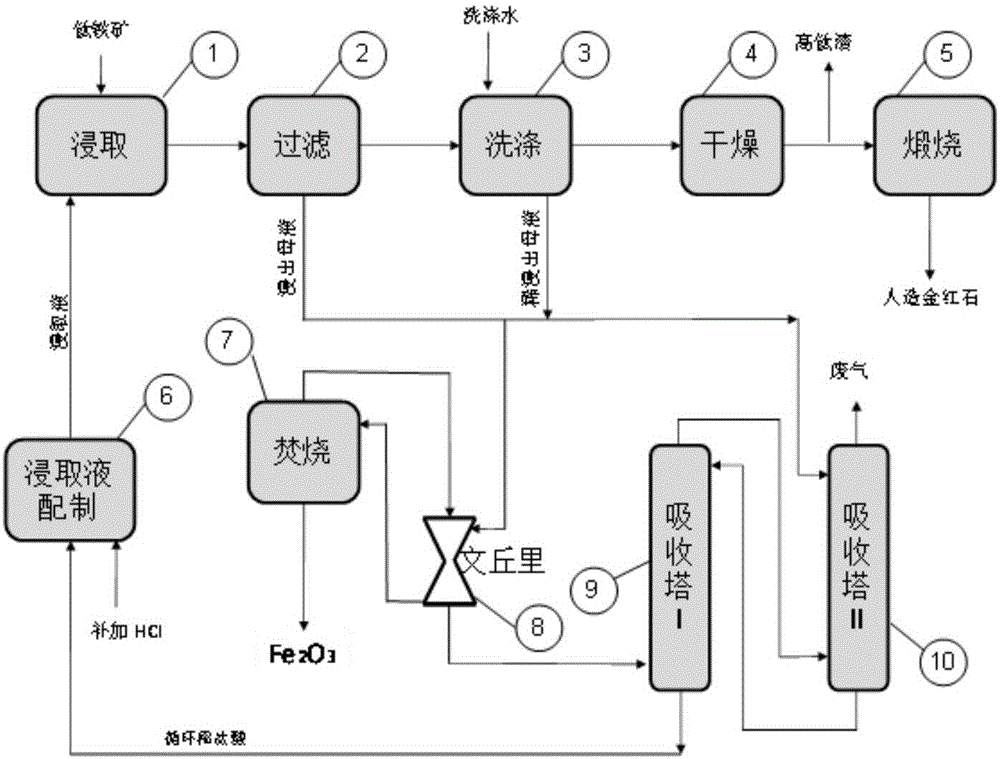

[0102] Embodiment 2 titanium concentrate hydrochloric acid pressure leaching and leaching mother liquor split flow incineration treatment (see figure 2 )

[0103] 8 tons of titanium concentrate are added to the leaching ball with a diameter of 4.3 meters. The main components of the titanium concentrate are shown in Table 8.

[0104] Pump 26.4 meters 3 The leaching solution containing 18% hydrochloric acid and soluble chloride salts is poured into leaching balls with a diameter of 4.3 meters and preheated to 95°C. The main components of the leaching solution ⑦ are shown in Table 9.

[0105] The main chemical composition (g / L) of table 9 embodiment 2 leach solution ⑦

[0106] Al 3+

Ca 2+

TF Mg 2+

HCl 0.42 0.65 38.60 2.81 195

[0107] 3. After feeding 3 tons of steam at 140°C, the pressure is 0.35Mpa, and react for 2 hours.

[0108] 4. Release the leached material and cool it down to 70°C by flash evaporation and air cooling.

[0...

Embodiment 3

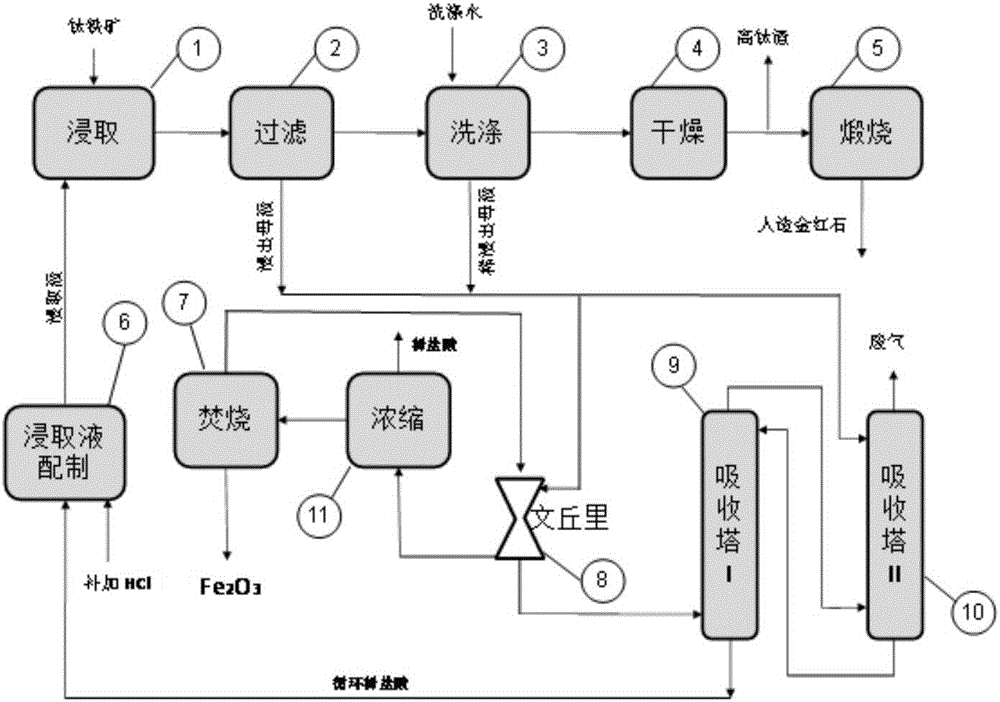

[0116] Embodiment 3 Titanium concentrate hydrochloric acid pressure leaching and leaching mother liquor treatment of the present invention (see image 3 )

[0117] With the incineration leaching mother liquor 21.13 meters of embodiment 2 3 , The chemical composition of the incineration leaching mother liquor is shown in Table 11.

[0118] The main chemical composition of table 11 incineration leaching mother liquor (g / L)

[0119] TCl -

Volume (m 3 )

Al 3+

Ca 2+

TF Mg 2+

HCl 251.16 21.13 1.34 2.08 123.22 8.98 45

[0120] 1. Venturi pre-concentration

[0121] The exhaust gas from the incinerator passes through the cyclone dust collector and the incineration and leaching mother liquor is mixed in the Venturi to cool down and evaporate to cool. The main chemical composition of the medium-concentration incineration leaching mother liquor discharged from the Venturi is shown in Table 12.

[0122] 21.13 meters 3 18.42 mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com