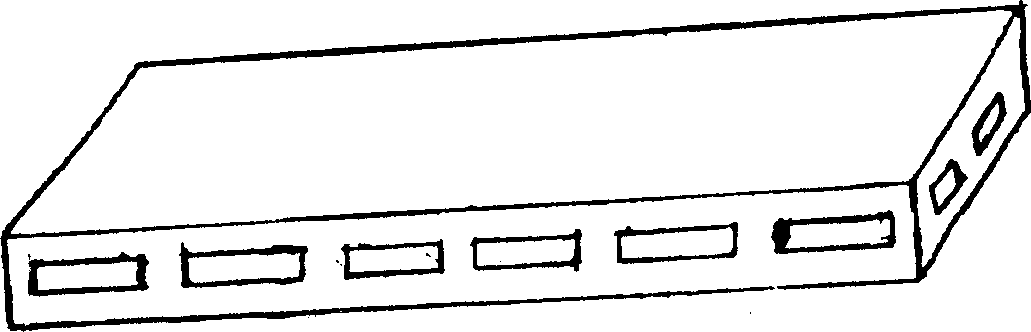

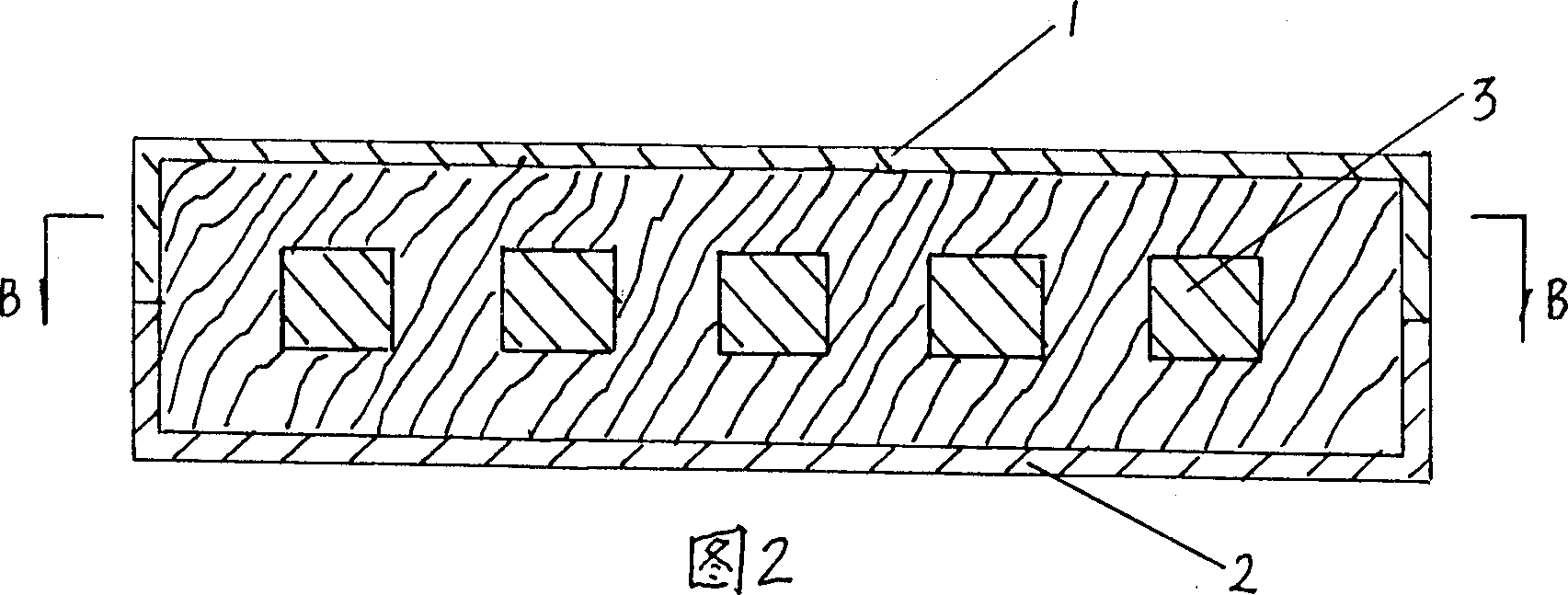

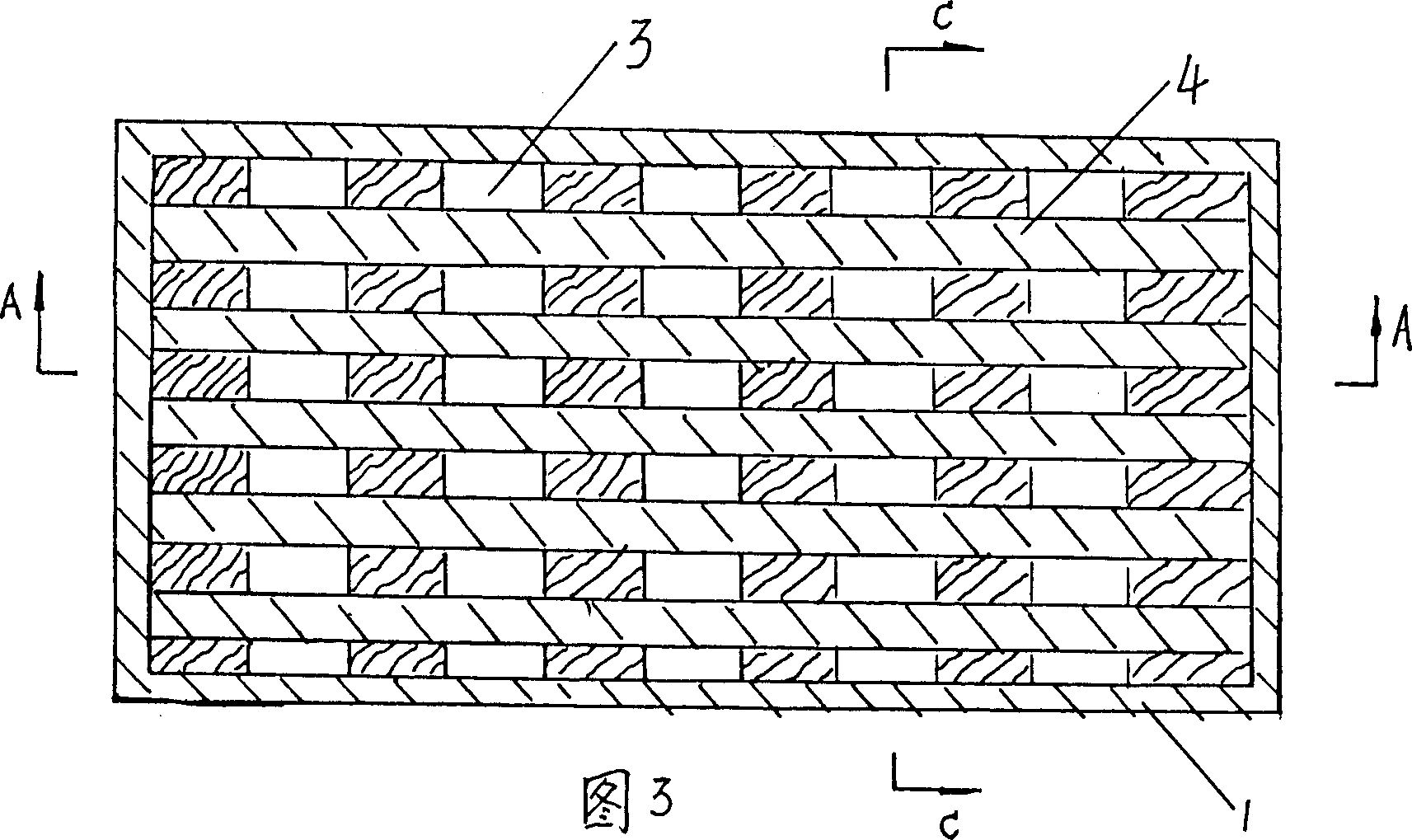

Making process of light environment-protecting board as building material

A manufacturing method and technology of building material panels, applied in the field of building material panel manufacturing, can solve problems such as many voids at wet and dry joints, heavy building panels themselves, and weakened product strength, so as to improve impact resistance, enhance overall strength, and work efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Lightweight environmentally friendly hollow partition wall panels, the ratio of main raw materials and auxiliary materials are as follows: main raw materials: 1. Orange stem is 35%, 2. Phosphorus waste residue powder is 15%, 3. Magnesium oxide is 10%, 4. , Anhydrous magnesium sulfate 10%, auxiliary materials: 1. Bentonite is 5%, 2. Copper naphthenate is 3%, 3. White carbon black is 7%, 4. Quartz powder is 7%, 5. Copper is 3%, 6, sodium hexametaphosphate is 2%, and 7, potassium sodium silicate is 3%. Production is carried out according to the operation method and forming mold described in the technical scheme.

Embodiment 2

[0037] Example 2: Relief decorations, the ratio of the main raw materials and auxiliary materials is as follows: Main raw materials: 1. Orange stem is 30%, 2. Phosphorus waste residue powder is 25%, 3. Magnesium oxide is 10%, 4. Anhydrous Magnesium sulfate is 5%, auxiliary materials: 1. Bentonite is 15%,

[0038] 2. Copper naphthenate is 5%,

[0039] 3. Cuprous sulfate is 3%,

[0040] 4. Sodium hexametaphosphate is 4%,

[0041] 5. Potassium and sodium silicate is 3%.

[0042] Production is carried out in accordance with the process method and forming mold described in the technical scheme.

Embodiment 3

[0044] The proportions of the main raw materials and auxiliary materials of the solid reinforced light-weight environmentally friendly building materials board are as follows:

[0045] main ingreadient:

[0046] 1. The orange stem is 25%,

[0047] 2. Phosphorus waste slag powder is 28%,

[0048] 3. Magnesium oxide is 5%,

[0049] 4. Anhydrous magnesium sulfate is 10%,

[0050] Supplementary materials:

[0051] 1. Pengrun soil is 5%,

[0052] 2. Copper naphthenate is 3%,

[0053] 3. White carbon black is 6%,

[0054] 4. Quartz powder is 7%,

[0055] 5. Cuprous sulfate is 4%,

[0056] 6. Sodium hexametaphosphate is 3%,

[0057] 7. Potassium and sodium silicate is 4%;

[0058] Manufactured in accordance with the production method described in the technical plan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com