Safe injector

A technology of safety syringes and push rods, which is applied in the field of self-destructing safety syringes and safety syringes. The effect of great convenience and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

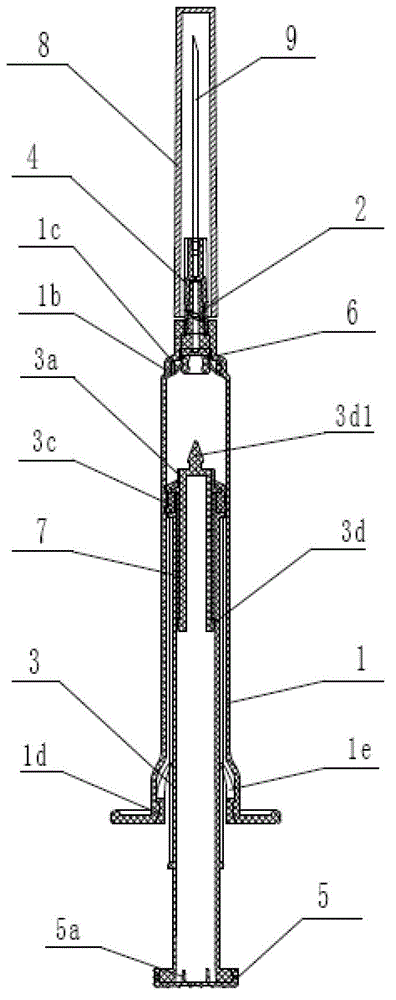

[0065] A kind of safety syringe of the present invention, as Figure 1 to Figure 16 As shown, it includes a syringe 1 and a push rod 3, and the push rod 3 is inserted into the inner cavity of the syringe 1 from the large mouth end thereof,

[0066] It is characterized by:

[0067] The push rod 3 is a cylindrical structure, and there is a small section of push tube 3a longitudinally on the top of the push rod 3. The inner diameter of the push tube 3a is smaller than the inner diameter of the push rod 3 cylinder. A beam joint plane 3b is formed between them, the push tube 3a on the top of the push rod 3 is closely matched with the drum-shaped sealing ring 3d4 of the conical head pull back rod 3d for sealing, and the outer wall of the push rod 3 is provided with a chuck 3e;

[0068] Also includes connecting tube 2 and injection needle 10;

[0069] The injection needle 10 includes: an injection needle seat 4, an injection needle tube 9 and a protective sheath 8;

[0070] The co...

Embodiment 2

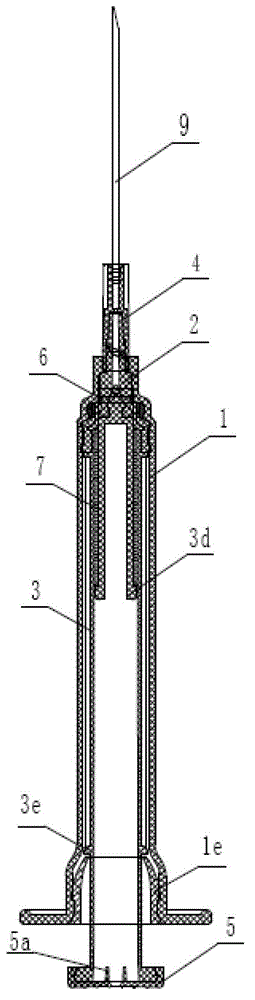

[0077] This embodiment is basically similar to Embodiment 1, as Figure 1-16 As shown, the difference is:

[0078] A safety syringe in this embodiment also includes anti-rotation ribs 8a and anti-slip ribs 8b on the inner and outer surfaces of the protective sleeve 8, the protective sleeve 8 is inserted on the injection needle hub 4, and protects the injection needle tube 9. The protective sleeve The anti-rotation ribs 8a on the inner surface of the injection needle holder 4 and the anti-rotation ribs 4c on the injection needle holder 4 are interlaced and inserted in opposite directions, which is convenient for tightening before injection and screwing when replacing the injection needle 10. The anti-slip ribs 8b on the outer surface of the protective cover 8 are easy to hold Hold, the injection needle tube is made of metal material.

Embodiment 3

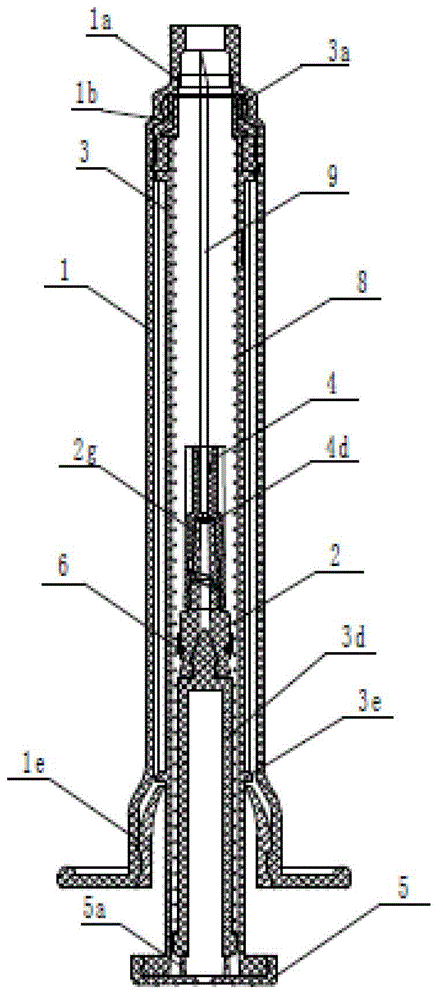

[0080] This embodiment is substantially similar to any one of embodiment 1 or 2, as Figure 1-16 As shown, the difference is that:

[0081] It also includes that the overall material for making the conical head pullback rod 3d is selected from an elastomer material, and the conical head pullback rod 3d includes: a conical head 3d1, a conical head neck 3d2, an end plane 3d3 and a drum-shaped sealing ring 3d4, and a push rod 3 During assembly, the push rod 3 push tube 3a part is designed as a conical head 3d1 structure, the conical head 3d1 is connected to the whole body through the conical head neck 3d2, and the conical head neck 3d2 is stuck downward with the push rod 3 push tube 3a The solid part is set as a drum-shaped sealing ring 3d4 structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com