Straw crushing and field returning device

A straw crushing and supporting device technology, applied in the field of agricultural machinery, can solve the problems of damage to the device, difficult to control the height from the ground, and crushing the soil with a crushing blade, so as to protect the environment, reduce the burning of straw, and achieve a rapid crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

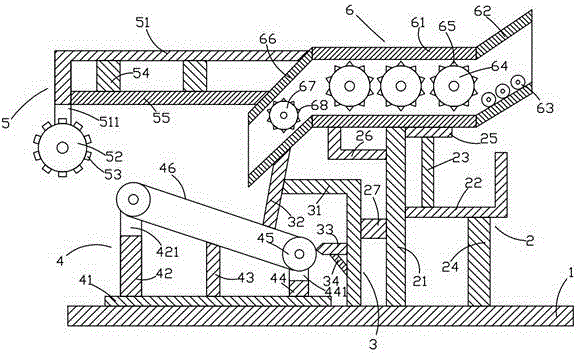

[0019] Such as figure 1 As shown, the straw crushing and returning device of the present invention includes a base plate 1, a support device 2 located above the base plate 1, a scraper device 3 located on the left side of the support device 2, and a conveyor belt located on the left side of the scraper device 3. The device 4, the roller device 5 located above the conveyor belt device 4 and the crushing device 6 located on the right side of the roller device 5.

[0020] Such as figure 1 As shown, the base plate 1 is in the shape of a cuboid, and the base plate 1 is placed horizontally. The support device 2 includes a first support column 21, a support platform 22 on the right side of the first support column 21, a second support column 23 above the support platform 22, and a second support column 23 below the support platform 22. Three support columns 24 , a fixing plate 25 above the second support column 23 , a first bracket 26 on the left side of the first support column 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com