Preparation method and application of bagasse mercapto-biosorbent

A technology of biosorbent and bagasse, which is applied in the cross field of environment and materials, can solve the problem of no metal ion adsorption, etc., and achieve the effect of fast adsorption, easy control of conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

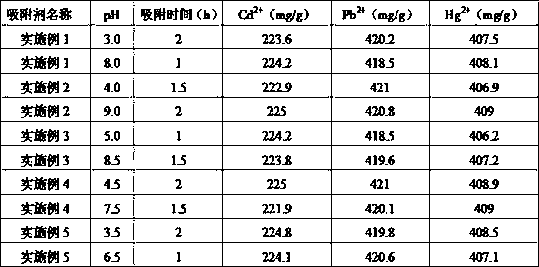

Examples

Embodiment 1

[0022] (1) Bagasse pretreatment: Wash the squeezed bagasse with water to remove soil and impurities, put it in a container and soak it in water for 40 hours, then boil it for 30 minutes, wash it with deionized water for 3 times, dry it in vacuum and crush it with 40 mesh Sieve through a sieve to obtain pretreated bagasse;

[0023] (2) Bagasse alkalization treatment: Soak the pretreated bagasse in 10% NaOH aqueous solution for 20 hours, boil for 1 hour, wash with deionized water after cooling until neutral, filter with suction, and dry to obtain Alkalized bagasse;

[0024] (3) Preparation of mercapto-bagasse biosorbent: In a stoppered Erlenmeyer flask, add 22 mL of thioglycolic acid and 13 mL of tetrahydrofuran, add 4 drops of concentrated sulfuric acid, mix well, add 8 g of alkalized bagasse, seal and react at room temperature for 2 h, then Add 10mL of 50% sodium sulfide aqueous solution, stopper, and react at 45°C for 50 h, then wash with deionized water, filter with suction...

Embodiment 2

[0026] (1) Bagasse pretreatment: Wash the squeezed bagasse with water to remove soil and impurities, put it in a container for 30 hours, boil it for 40 minutes, wash it with deionized water for 3 times, dry it in vacuum and crush it with 40 mesh Sieve through a sieve to obtain pretreated bagasse;

[0027](2) Bagasse alkalization treatment: Soak pretreated bagasse in 5% NaOH aqueous solution for 24 hours, boil for 0.5 hours, wash with deionized water to neutral after cooling, and dry after suction filtration. Obtain alkalized bagasse;

[0028] (3) Preparation of mercapto-bagasse biosorbent: In a stoppered Erlenmeyer flask, add 50mL of thioglycolic acid and 25mL of tetrahydrofuran, add 6 drops of concentrated sulfuric acid, mix well, add 25g of alkalized bagasse, seal at room temperature and react for 3 hours, then Add 30mL of 50% sodium sulfide aqueous solution, stopper, and react at 40°C for 60 h, then wash with deionized water, filter with suction until the filtrate is neutr...

Embodiment 3

[0030] (1) Bagasse pretreatment: Wash the squeezed bagasse with water to remove soil and impurities, put it in a container for 48 hours, boil it for 50 minutes, wash it with deionized water for 3 times, dry it in vacuum and crush it with 40 mesh Sieve through a sieve to obtain pretreated bagasse;

[0031] (2) Bagasse alkalization treatment: Soak pretreated bagasse in 12% NaOH aqueous solution for 28 hours, boil for 0.5 hours, wash with deionized water to neutral after cooling, filter with suction, and dry. Obtain alkalized bagasse;

[0032] (3) Preparation of mercapto-bagasse biosorbent: In a stoppered Erlenmeyer flask, add 20 mL of thioglycolic acid and 10 mL of tetrahydrofuran, add 2 drops of concentrated sulfuric acid, mix well, add 10 g of alkalized bagasse, seal at room temperature and react for 2 h, then Add 15mL of 50% sodium sulfide aqueous solution, stopper, and react at 45°C for 55 hours, then wash with deionized water, filter with suction until the filtrate is neut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com