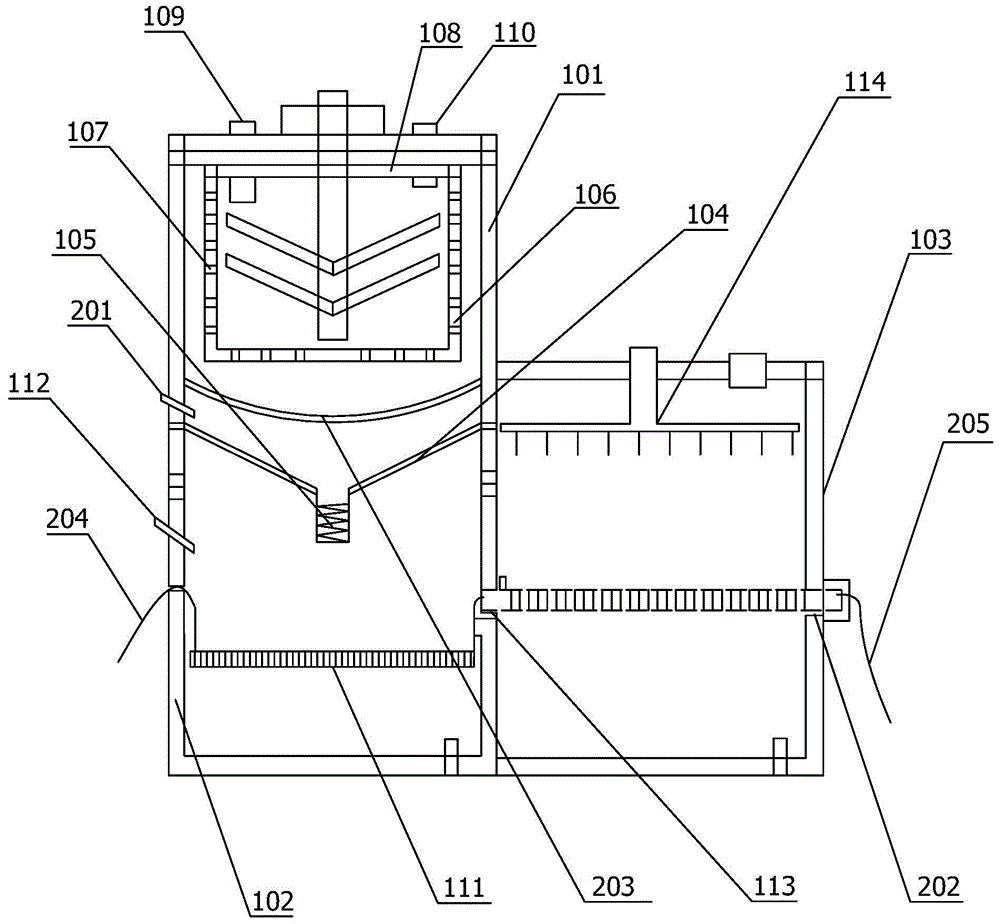

Sludge treatment method and device

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of long time-consuming, high cost, large floor space, etc. To achieve the effect of shortening the degradation time and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The sludge treatment method provided in the embodiment of the present invention comprises the following steps:

[0059] S11: adding a sodium hydroxide solution with a weight of 20% of the sludge to the sludge to be treated, and stirring and reacting to obtain a solid-liquid mixture;

[0060] S12: filter the solid-liquid mixture to obtain a filtrate and a solid portion;

[0061] S13: the filtrate is concentrated and filtered to obtain a solid precipitate;

[0062] S14: the solid precipitate is dried and rinsed with water to obtain a recovery solution and a solid insoluble matter respectively;

[0063] S15: Adjust the pH of the solid part to be neutral, and compress and landfill or incinerate.

Embodiment 2

[0065] The sludge treatment method provided in the embodiment of the present invention comprises the following steps:

[0066] S21: adding a concentrated sulfuric acid solution with a weight of 20% of the sludge to the sludge to be treated, stirring and reacting to obtain a solid-liquid mixture;

[0067] The sludge to be treated is specifically polymerized iron sulfate physicochemical sludge; the sludge mainly contains insoluble iron salts and phosphorus salts, which react with concentrated sulfuric acid to generate soluble iron salts and exist in the filtrate.

[0068] S22: filter the solid-liquid mixture to obtain a filtrate and a solid portion;

[0069] In 100 kilograms of sludge, after adding 10 liters of concentrated sulfuric acid, after stirring reaction and filtration, the weights of the filtrate and solid part obtained are: 68.4 kilograms and 50 kilograms, respectively. Among them, the pH of the filtrate is between 2-3 and contains a certain concentration of ferric su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com