Self-walking type corn straw recycling and baling combined harvester

A technology for combine harvesters and corn stalks, which is applied to harvesters, agricultural machinery and implements, and packaging. It can solve the problem that the harvested area of corn is less than 15%, and achieve reduced field burning, good air permeability, and reduced smog. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to illustrate the technical solutions of the present invention more clearly, the specific implementation manners of the present invention will be further elaborated in conjunction with the accompanying drawings.

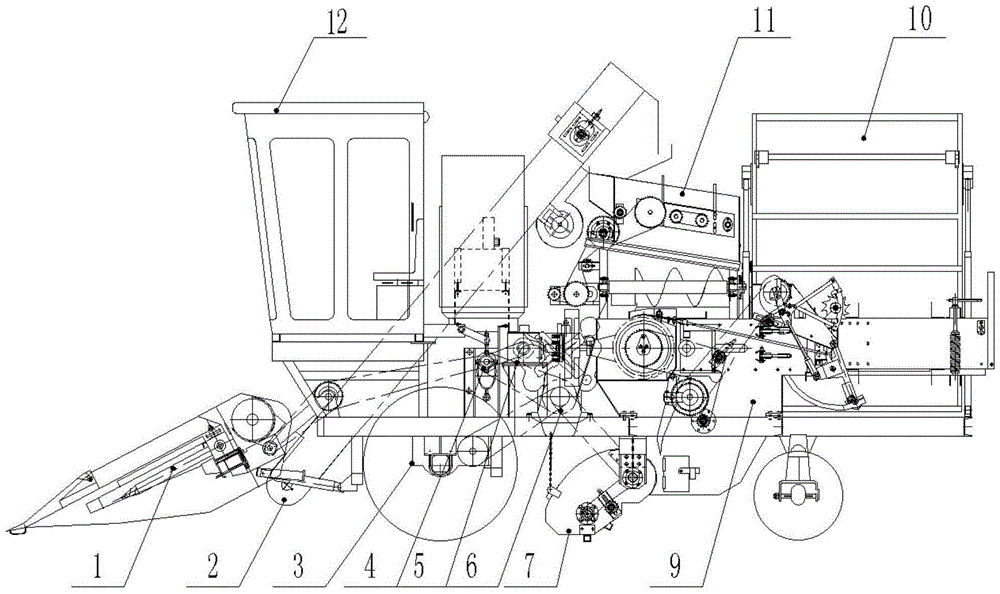

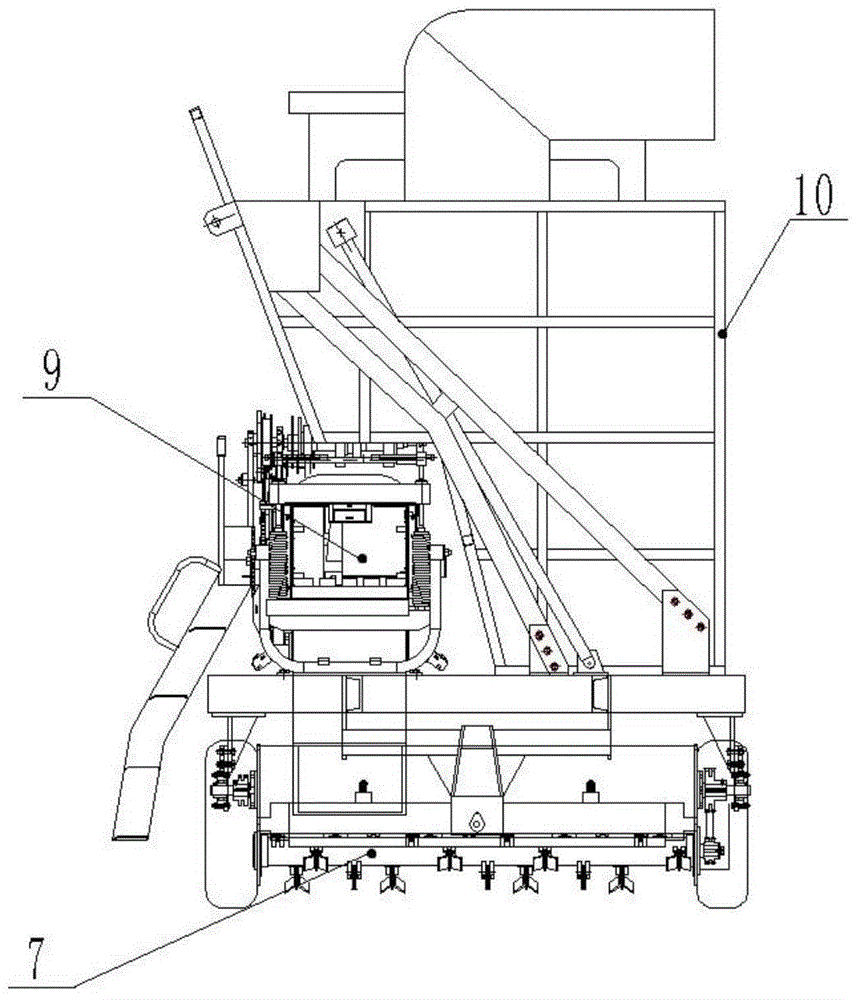

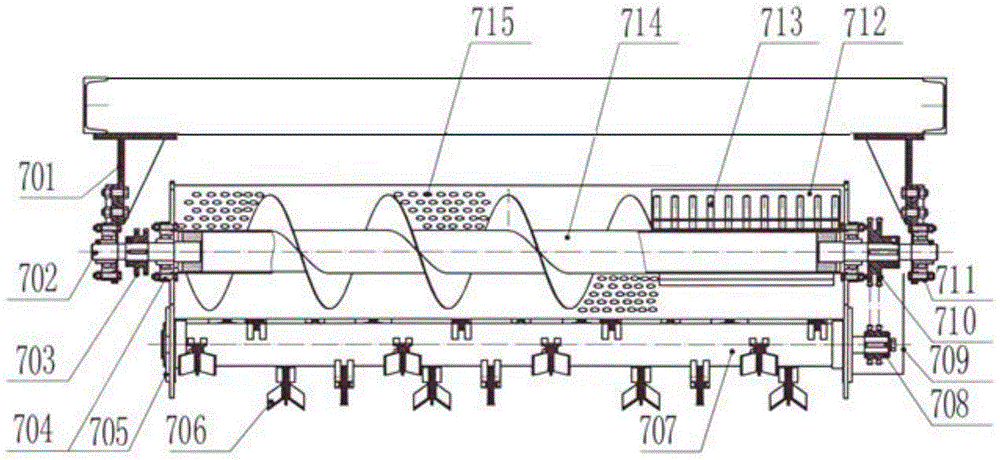

[0031] like figure 1 As shown, the present invention discloses a self-propelled corn stalk recovery and baling combined harvester, the harvester includes a header 1, ear elevator 2, chassis 3, intermediate shaft 4, gearbox 5, engine 6, A straw collector 7, a baler 9, a grain tank 10, an ear peeling mechanism 11 and a driver's cab 12. Described header 1 is installed on chassis 3 front ends, and described driver's cab 12, engine 6, ear peeling mechanism 11, grain tank 10 are all installed on the chassis. Described fruit ear lifter 2 is installed in harvesting platform 1 back, and fruit ear lifter 2 upper ends are fixed on the chassis by fixed mount, and its upper end outlet is facing fruit ear peeling mechanism 11, and its lower end is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com