Straw fire-retardant sound-absorbing board

A sound-absorbing board and straw technology, applied in the field of industrial textiles, can solve the problems of human and environmental hazards, high price, high production cost, etc., and achieve the effects of simple and convenient operation, good sound absorption performance, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

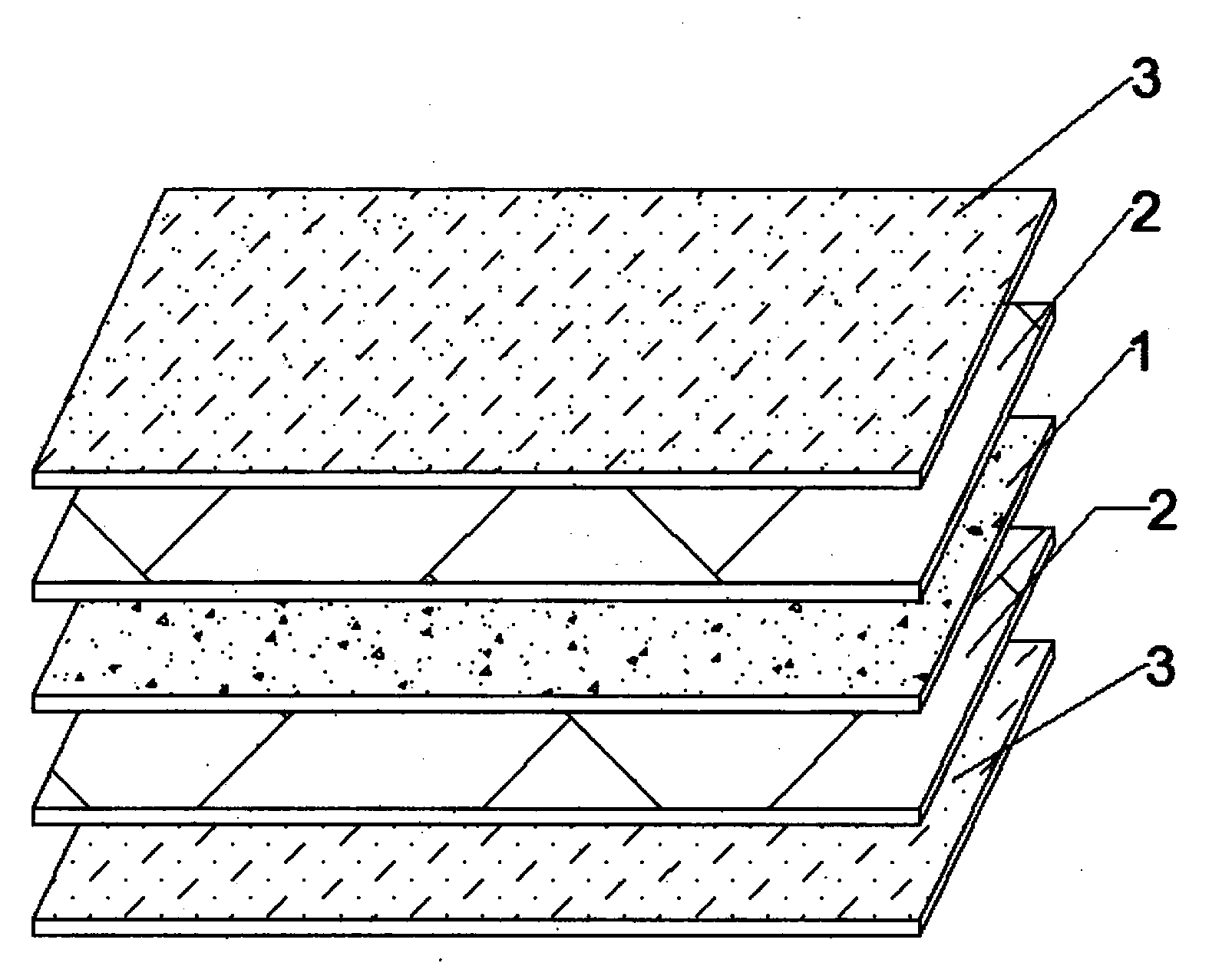

[0018] A straw flame-retardant sound-absorbing panel, the preparation method of which is: mix 4000g corn stalks with 1000g hot-melt fiber 4080, air-laid, and bonded with hot air at 170°C for 90s (length: 30cm; width 30cm; thickness 15mm) sound-absorbing Part 1: arrange the flame retardant part 3, the material connecting part 2, the sound absorbing part 1, the material connecting part 2 and the flame retardant part 3 from top to bottom, wherein each flame retardant part 3 is made of 50g of modified viscose The fibers (1.5d×38mm) are laid flat, and each material connection part 2 is made of 20g polypropylene fibers (1.5d×38mm), molded at a temperature of 185°C and a pressure of 2MPa 300s, the material connecting part 2 is melted, and the flame-retardant part 3 and the sound-absorbing part 1 are connected together to form a straw flame-retardant sound-absorbing panel with a thickness of 4 mm.

[0019] The sound-absorbing performance of the straw flame-retardant sound-absorbing pa...

Embodiment 2

[0021] A straw flame-retardant sound-absorbing panel, the preparation method of which is as follows: 4000g of wheat straw and 1000g of PLA (1.5d × 38mm) are mixed, air-laid, and hot air bonded at 170°C for 90s (length: 30cm; width: 30cm; thickness 15mm) sound-absorbing part 1; the flame-retardant part 3, the material connecting part 2, the sound-absorbing part 1, the material connecting part 2 and the flame-retardant part 3 are arranged sequentially from top to bottom, wherein each flame-retardant part 3 is modified by 50g Viscose fiber (1.5d×38mm) is laid flat, and each material connection part 2 is made of 20g polypropylene fiber (1.5d×38mm). Molding under certain conditions for 300s, so that the material connecting part 2 is melted, and the flame-retardant part 3 and the sound-absorbing part 1 are connected together to form a straw flame-retardant sound-absorbing panel with a thickness of 4 mm.

[0022] The sound-absorbing performance of the straw flame-retardant sound-abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

| Afterburn time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com