Industrial waste treatment technology and device thereof

A technology of industrial waste and treatment process, which is applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems that incineration of sewage cannot be completed at the same time, the amount of treatment is small, and it is not suitable for control. Achieve the effect of solving the problem that solid hazardous waste cannot be disposed of, saving operating costs, and not adding chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

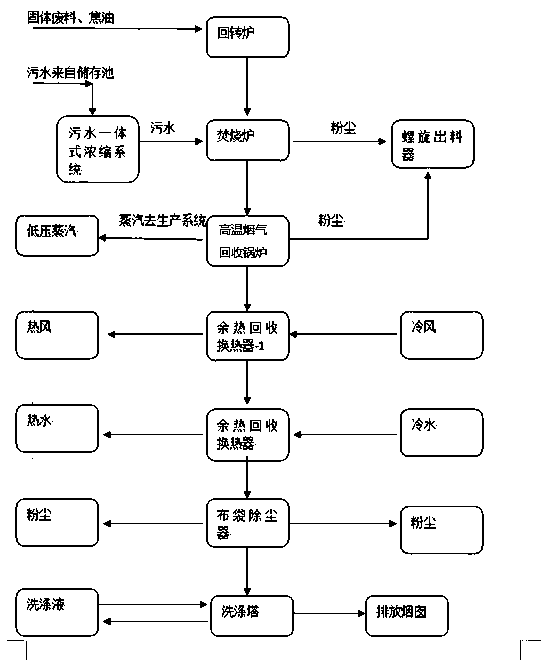

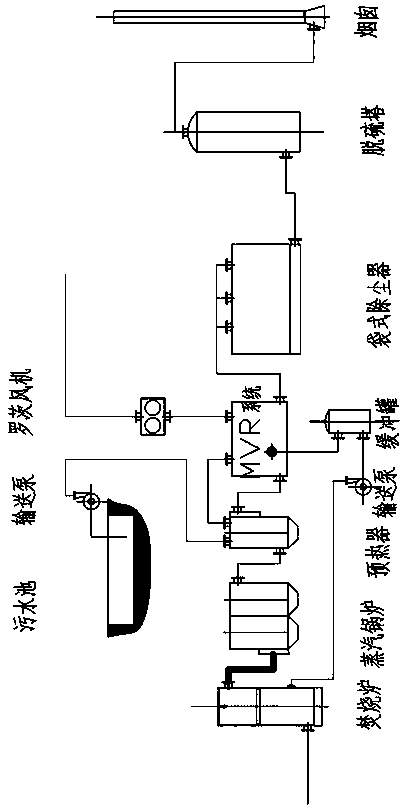

[0059] An industrial waste treatment device, including an integrated sewage concentration system, an incinerator, a high-temperature flue gas recovery boiler, a flue gas waste heat recovery system, and a tail gas treatment system; an integrated sewage concentration system for evaporating high-salt wastewater Concentration, the solid-containing sediment produced by evaporation and concentration enters the incinerator for oxidation and incineration; the integrated sewage concentration system includes an evaporator 11 and a heat exchanger 13, and the cross-sectional area of the evaporator 11 gradually decreases from the middle to the top. Form steam collection chamber 2; The longitudinal section of steam collection chamber 2 is disc-shaped, and the area of the cross section of evaporator 11 gradually reduces from the middle part to bottom end, forms sediment collection chamber 3; The longitudinal section of sediment collection chamber 3 is Disc;

[0060] The top of the steam ...

Embodiment 2

[0069] An industrial waste treatment device, including a rotary furnace, an integrated sewage concentration system, an incinerator, a high-temperature flue gas recovery boiler, a flue gas waste heat recovery system, and a tail gas treatment system; the industrial waste treatment device also includes a rotary kiln , The rotary furnace is used to incinerate industrial solid waste. The flue gas produced by the rotary furnace incineration of industrial solid waste enters the second combustion chamber of the incinerator and is further heated and oxidized to 1000-1100 °C. The integrated sewage concentration system is used to evaporate and concentrate high-salt wastewater, and the solid-containing sediment produced by evaporation and concentration enters the incinerator for oxidation and incineration; the integrated sewage concentration system includes an evaporator 11 and a heat exchanger 13, and the evaporator 11 automatically The area of the cross-section from the middle portion ...

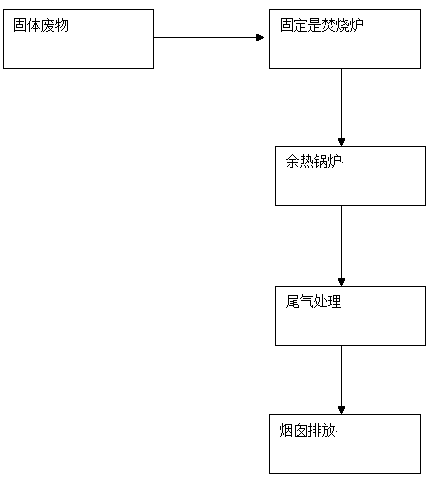

specific Embodiment approach

[0080] Specific embodiments: an industrial waste treatment device, including an incinerator, a natural gas burner, a steam boiler, a generator set, a negative pressure evaporator, an air preheater, a bag filter, a circulating fan, a feeding pump, an absorption tower, and a dust collector desulfurization towers, water softeners and chimneys. The treatment capacity of the device (based on sewage) is 3 tons / hour, the by-product steam is 3 tons / hour, the comprehensive consumption of sewage treatment is 130 yuan / ton, and the process equipment is running stably.

[0081] 1) In actual production, 4 sets of natural gas burners are set up to burn sewage in the incinerator, which generates a high temperature of about 1200°C-1350°C, and the pollutants in the sewage are oxidized and decomposed at high temperature and converted into non-polluting oxides dust;

[0082] 2) The high-temperature flue gas from the incinerator is absorbed by a specially designed steam boiler, and the by-product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com