Filling material used for removing permeable reactive barrier of nitrate and preparation method thereof

A technology for permeable reaction walls and filling materials, which is applied in the field of filling materials for permeable reaction walls and its preparation, can solve problems such as difficult co-precipitation or adsorption, complicated operation of electroosmosis, and difficulty in removing nitrate, etc., achieving simple technology , Restoring a good ecological environment and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

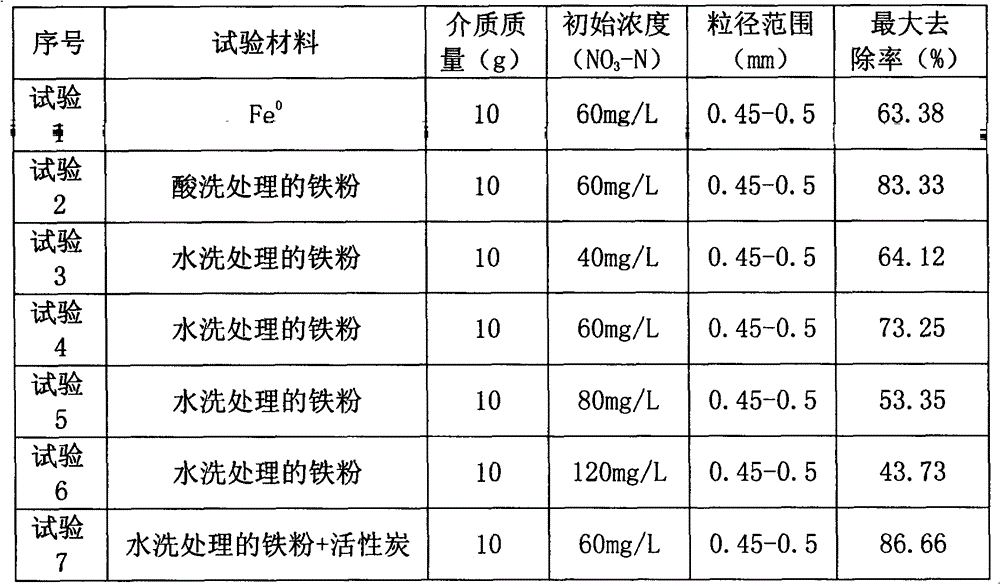

[0022] The filling material (i.e. PRB material) for the permeable reaction wall for removing nitrate in the present invention is composed of pretreated iron powder, non-metallic carrier activated carbon (C) and coarse sand as the basic medium ratio, and the pretreated iron powder, activated carbon And the volume ratio of coarse sand is 3:1:6, the selection of PRB material: the particle size of pretreated iron powder is 0.45-0.5mm, the particle size of activated carbon is 1.7-2mm, and the particle size of coarse sand is 0.25-2mm; The composition content of the iron powder is: 96.5% Fe, 0.05% C, 0.06% S, and the rest are impurities. During the whole reaction process, Fe 0 Poor activity, Fe 2+ Has strong reducibility, with Fe 0 As a reaction material, the removal effect of nitrate is low, Fe 2+ The removal effect on nitrate is obvious, so Fe 0 Requires pretreatment to produce Fe 2+ , Fe 2+ It has the characteristics of strong reducibility, fast reaction speed and high remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com