Low-pressure distillation equipment for scallion oil production and use method

A distillation equipment, low-pressure technology, applied in the direction of distillation separation, vacuum distillation, separation methods, etc., can solve the problems of distillation equipment without working table, tools can not be concentrated high-temperature sterilization, pollution of the atmospheric environment, etc., to prevent heat loss and prevent failure , The effect of cleaning the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

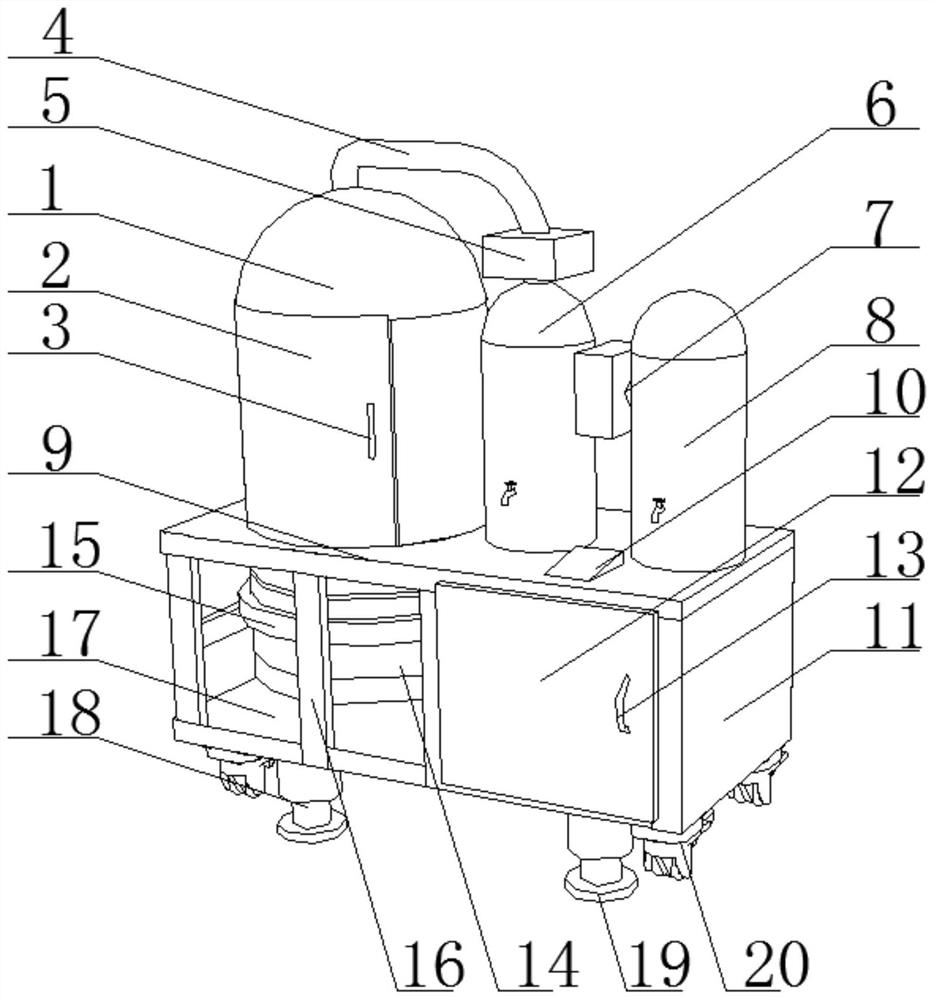

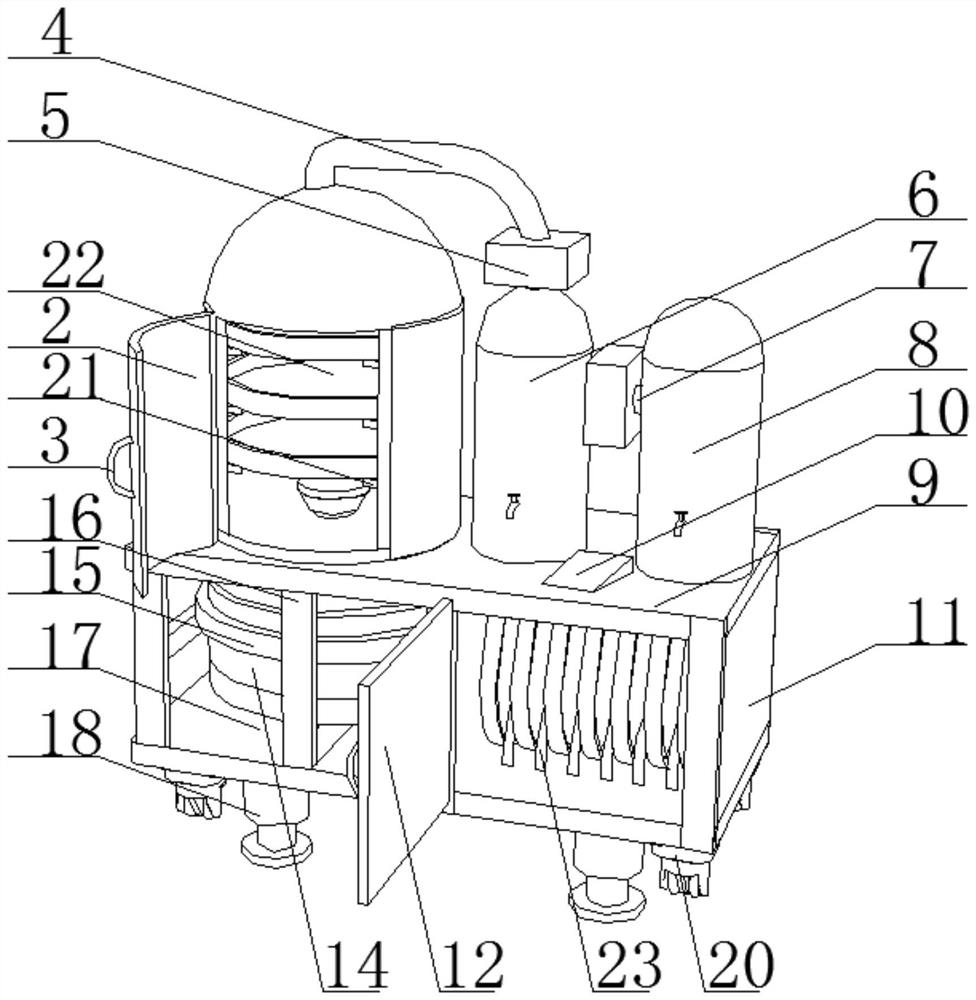

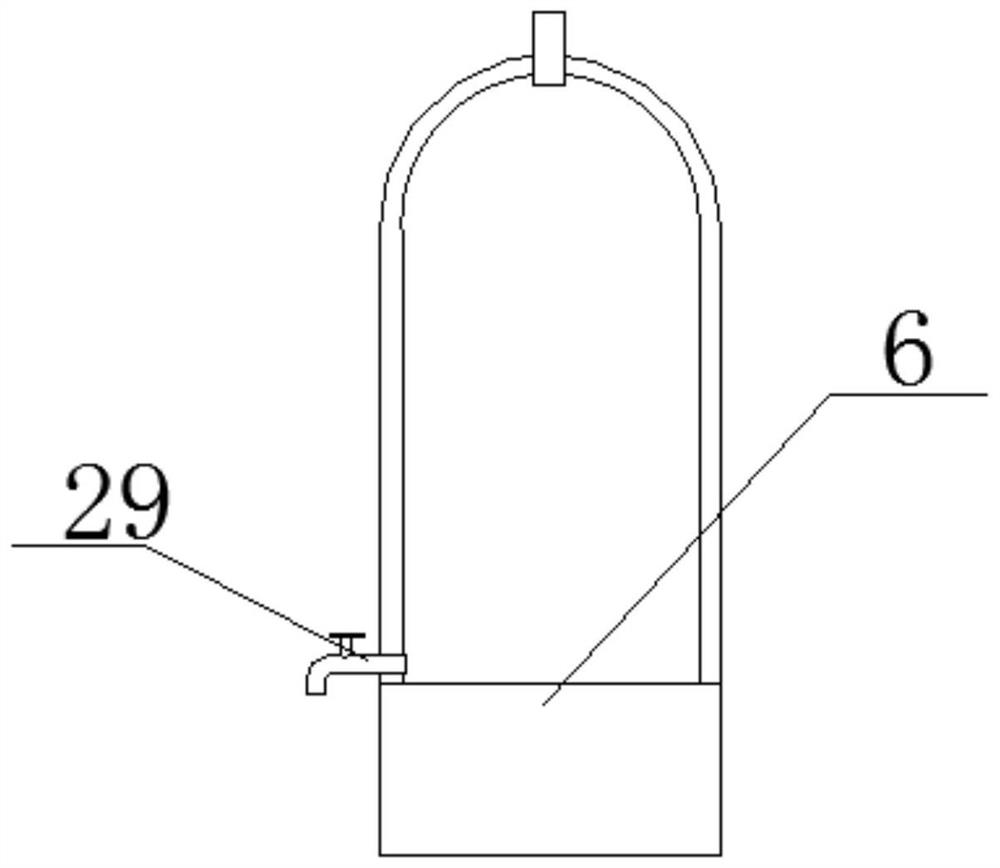

[0032] like figure 1 , 2 , shown in 5, a kind of low-pressure distillation equipment for onion oil production and using method, comprise distillation bin main body 1, the side end outer surface of distillation bin main body 1 is provided with a door 2, the front end outer surface of door 2 A No. 1 handle 3 is provided, a No. 1 pipe 4 is provided on the outer surface of the top of the main body 1 of the distillation bin, a No. 1 extraction tank is provided on the outer surface of the side end of the No. 1 pipe 4, and a No. 1 extraction tank is provided on the outer surface of one side of the No. 6, the side end outer surface of the No. 1 extraction tank 6 is provided with the No. 2 pipeline 7, the side end outer surface of the No. 2 pipeline 7 is provided with the condenser 5, and the one side outer surface of the No. 2 pipeline 7 is provided with the No. 2 extraction tank 8 , No. 1 extraction tank 6 and No. 2 extraction tank 8 are provided with a discharge valve 29 on the out...

Embodiment 2

[0034] On the basis of Example 1, as figure 2 , 5 As shown, the outer wall of the steam chamber 14 is provided with a thermal insulation layer 28, the thermal insulation layer 28 and the steam chamber 14 are fixedly connected, the material of the thermal insulation layer 28 is aerogel insulation material, and the thermal insulation layer 28 can effectively prevent the steam chamber 14 The internal heat is dissipated, which can improve the thermal efficiency. The heating pipe 26 and the steam chamber 14 are fixedly connected. The heating pipes 26 are arranged in several groups, and the heating pipes 26 are arranged in an array. The production process is cleaner, the pressure reducing valve 25 and the distillation pipe 27 are fixedly connected, and the pressure reducing valve 25 will reduce the atmospheric pressure inside the steam chamber 14, thereby reducing the boiling point of water, reducing the temperature of the water vapor, and the water vaporizes into The process of w...

Embodiment 3

[0036] On the basis of Embodiment 1 and Embodiment 2, as figure 1 As shown, the main body 1 of the distillation bin and the No. 1 door 2 are fixedly connected, the No. 1 door 2 is arc-shaped, the No. 1 door 2 and the No. 1 handle 3 are fixedly connected, and the The connection is provided with a circular groove, and the area of the circular groove is smaller than the area of the bottom surface of the main body 1 of the distillation chamber. The No. 1 pipeline 4 is fixedly connected to the main body of the distillation bin 1 and the No. 1 extraction tank 6, respectively, the No. 1 pipeline 4 is fixedly connected to the condenser 5, and the No. 2 pipeline 7 is respectively connected to the No. 1 extraction tank 6 and No. 2 extraction tank. There is a fixed connection between the extraction tanks 8. The shapes of the No. 1 extraction tank 6 and the No. 2 extraction tank 8 are cylindrical, and the sizes are the same. The No. 2 pipeline 7 and the condenser 5 are fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com