High-temperature resistant and expediting setting dealcoholized type room temperature vulcanized silicone rubber adhesive and preparation method thereof

A rapid curing and room temperature vulcanization technology, applied in the direction of adhesives, etc., can solve the problems of heat resistance to be improved, and achieve the effects of fast curing speed, excellent bonding performance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

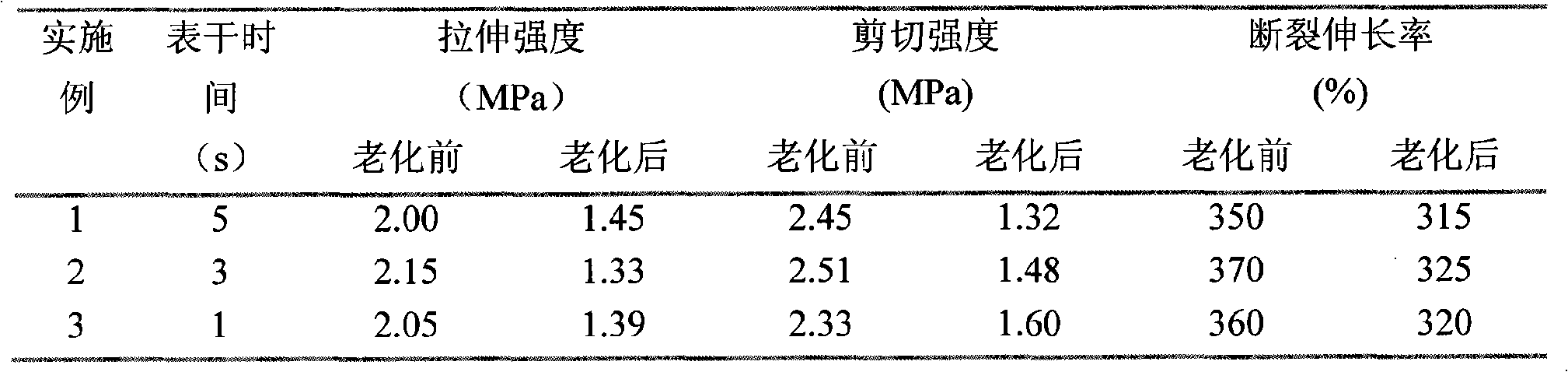

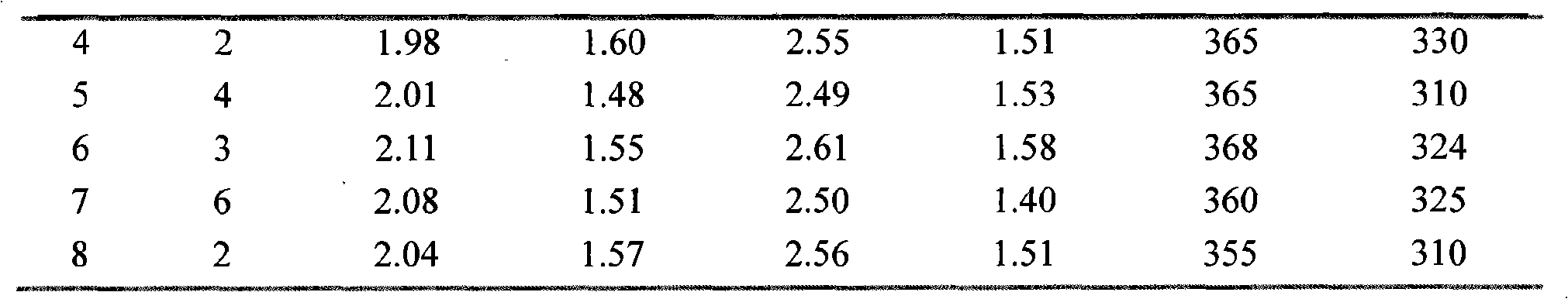

Examples

Embodiment 1

[0036] High temperature resistant rapid curing dealcoholized room temperature vulcanized silicone rubber adhesive, made by the following method:

[0037] (1) 100g of hydroxyl-terminated polydimethylsiloxane (107 glue) with a viscosity of 9100Pa.s, 3g of fumed silica (with a particle size of 10-500nm and a BET specific surface area of 160±25m 2 / g), titanium dioxide 5g (particle size is 15 ~ 500nm, BET specific surface area is 50 ± 15m 2 / g), fully mixed, and the obtained mixture was put into a vacuum oven for drying and defoaming for 2h;

[0038] (2) In a dry environment, to the product obtained in step (1), add 0.1 g of hexamethylcyclotrisilazane, 1 g of trithiocyanuric acid, 0.1 g of dioctyltin dilaurate, 4-amino-3 , 3 dimethylbutyltrimethoxysilane 1g, vacuum stirring at room temperature for 0.5h, that is, a high temperature resistant rapid curing dealcoholized room temperature vulcanized silicone rubber adhesive, poured into a metal hose and sealed for storage.

[0039]...

Embodiment 2

[0041] High temperature resistant rapid curing dealcoholized room temperature vulcanized silicone rubber adhesive, made by the following method:

[0042] (1) 100g of 107 glue with a viscosity of 9100Pa.s, 10g of fumed silica (with a particle size of 10-500nm and a BET specific surface area of 160±25m 2 / g), titanium dioxide 2g (particle size is 15 ~ 500nm, BET specific surface area is 50 ± 15m 2 / g), fully mixed, and the obtained mixture was put into a vacuum oven for drying and defoaming for 1h;

[0043] (2) In a dry environment, to the product obtained in step (1), add 3 g of hexamethylcyclotrisilazane, 2 g of thiocyanuric acid, 0.5 g of dioctyltin dilaurate, and 4-amino-3, 3 Dimethylbutyltrimethoxysilane 4g, vacuum stirring at room temperature for 0.5h, that is, a high temperature resistant rapid curing dealcoholized room temperature vulcanized silicone rubber adhesive, poured into a metal hose and sealed for storage.

[0044] Tested according to the method and conditio...

Embodiment 3

[0046] High temperature resistant rapid curing dealcoholized room temperature vulcanized silicone rubber adhesive, made by the following method:

[0047](1) 100g of 107 glue with a viscosity of 9100Pa.s, 10g of fumed silica (with a particle size of 10-500nm and a BET specific surface area of 160±25m 2 / g), titanium dioxide 8g (particle size is 15 ~ 500nm, BET specific surface area is 50 ± 15m 2 / g), fully mixed, and the obtained mixture was put into a vacuum oven for drying and defoaming for 6h;

[0048] (2) In a dry environment, to the product obtained in step (1), add 5 g of hexamethyldisilazane, 5 g of vinyl triperoxy tert-butyl silane, 1 g of dibutyltin dilaurate, and 1 g of anilinomethyl tris Ethoxysilazane 7g, vacuum stirring at room temperature for 1 hour, that is, a high temperature resistant rapid curing dealcoholized room temperature vulcanized silicone rubber adhesive, poured into a metal hose and sealed for storage.

[0049] Tested according to the method and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com