Concrete thin-layer repairing polymer mortar and preparation method thereof

A thin layer of concrete and polymer technology, applied in coatings, polyurea/polyurethane coatings, etc., to achieve the effects of general production and storage conditions, good wear resistance and repairability, superior elastic properties and bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

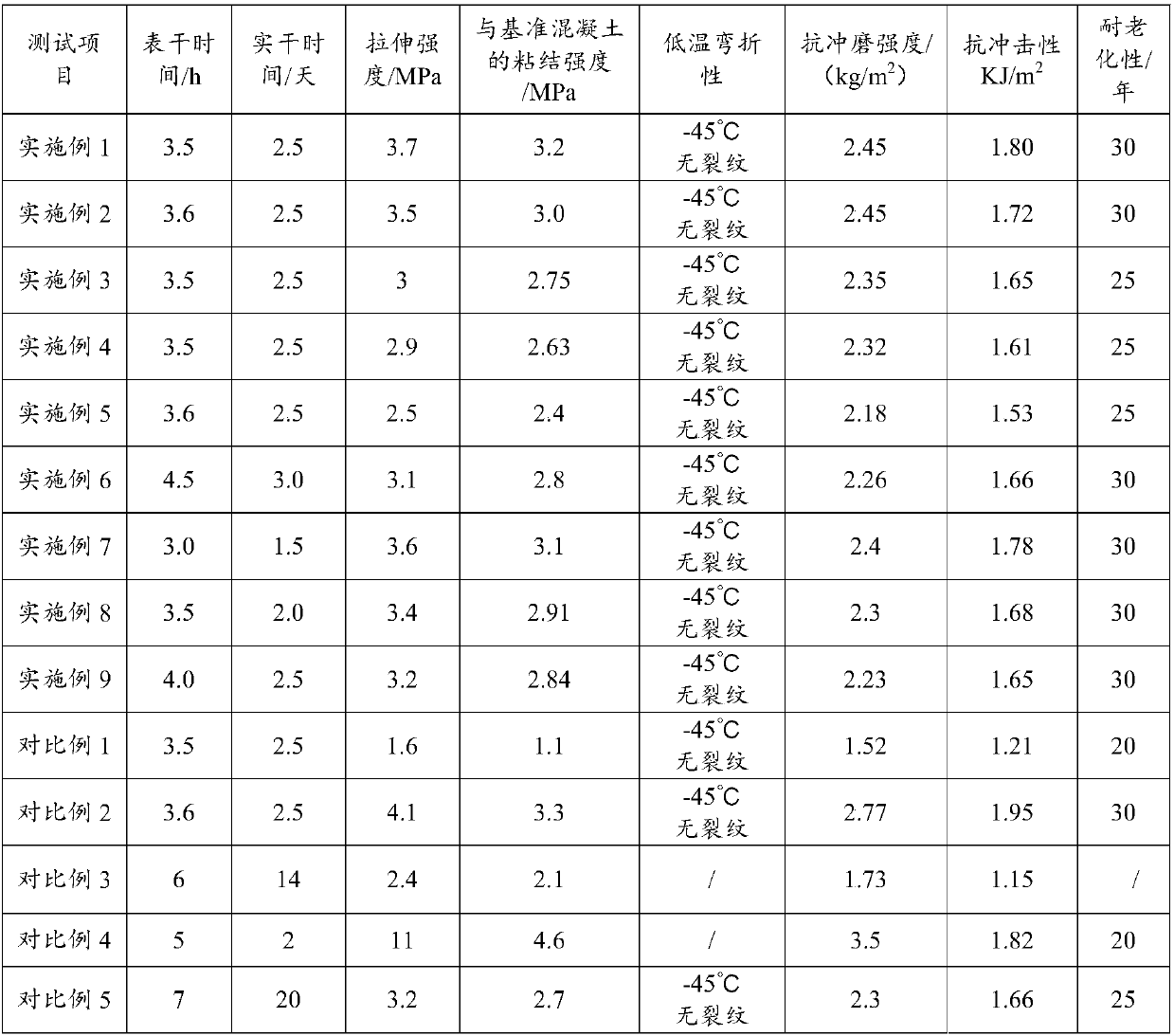

Examples

Embodiment approach

[0036] As a preferred embodiment of the present invention, it includes raw materials in the following weight ratio: two-component slow-response polyurea waterproof coating: sand material = 1: (1-2.5).

[0037] As a further preferred embodiment of the present invention, it includes raw materials in the following weight ratio: two-component slow-response polyurea waterproof coating: sand material = 1: (1-2).

[0038] By further optimizing the ratio of the two-component slow-response polyurea waterproof coating and sand, the cohesiveness, elasticity and aging resistance of the polymer mortar for repairing thin concrete layers can be further improved.

[0039] As a preferred embodiment of the present invention, the two-component slow-response polyurea waterproof coating includes the following raw materials in parts by weight:

[0040]Polyether polyol 2471 200-260 parts, polyether polyol DDL-2000 60-80 parts, polyether polyol DDL-1000 20-30 parts, 4,4'-dicyclohexylmethane diisocyan...

Embodiment 1

[0052] This embodiment is a polymer mortar for repairing a thin concrete layer. The weight ratio of the two-component slow-response polyurea waterproof coating to the sand material in the polymer mortar for repairing a thin concrete layer is 1:1. Among them, the two-component slow-response polyurea waterproof coating includes the following raw materials in parts by weight: 2471 230 parts of polyether polyols, 70 parts of DDL-2000 polyether polyols, 25 parts of DDL-1000 polyether polyols, 4, 90 parts of 4'-dicyclohexylmethane diisocyanate, 40 parts of T5000 polyether amine, 7 parts of amine chain extender, 120 parts of superfine calcium powder, 25 parts of solvent T-305, 13 parts of plasticizer, 65 parts of mica powder 15 parts of titanium dioxide, 7 parts of white carbon black and 4 parts of black carbon black for pigments and fillers.

Embodiment 2

[0054] This embodiment is a polymer mortar for repairing a thin concrete layer. The weight ratio of the two-component slow-response polyurea waterproof coating to the sand material in the polymer mortar for repairing a thin concrete layer is 1:1.5. Wherein, the composition of the two-component slow-response polyurea waterproof coating is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com