Patents

Literature

32results about How to "Good impact and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

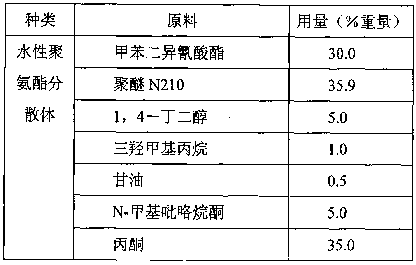

Multiple crosslinking ultraviolet light solidifying water polyurethane dispersoid and its preparation method and application

The invention discloses a multiple crosslink ultraviolet solidification aqueous polyurethane disperser, a relative preparation method and an application. The preparation method comprises synthesizing polyurethane initial polymerized compound I, synthesizing polyurethane prepolymer II, synthesizing polyurethane prepolymer III, synthesizing polyurethane acrylate oligomer and synthesizing ultraviolet solidification aqueous polyurethane disperser. The invention mainly utilizes aromatic diisocyanate, diatomic alcohol prepolymer, polyhydroxy carboxylic acid, epoxy resin and hydroxyl acrylate as raw materials, with better water dispersity and storage stability, which leads in light inducer, levelling agent, defoaming agent and thickener to prepare ultraviolet solidification aqueous wood paint better than solvent ultraviolet solidification photosensitive resin, with stable storage, low fineness, high rigidity, high brightness, better flow leveling property, better water resistance, better solvent resistance, excellent abrasion resistance, environment protection, easy process and fire hazard resistance.

Owner:SOUTH CHINA UNIV OF TECH

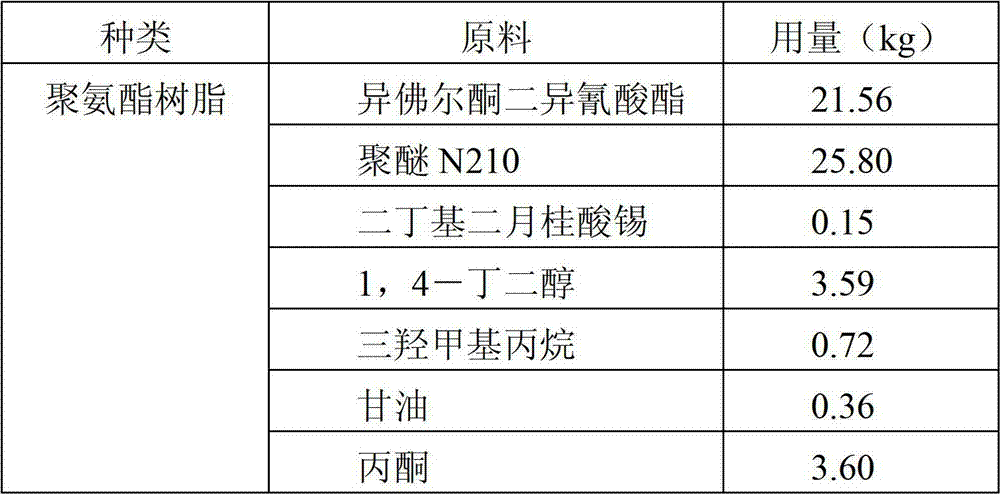

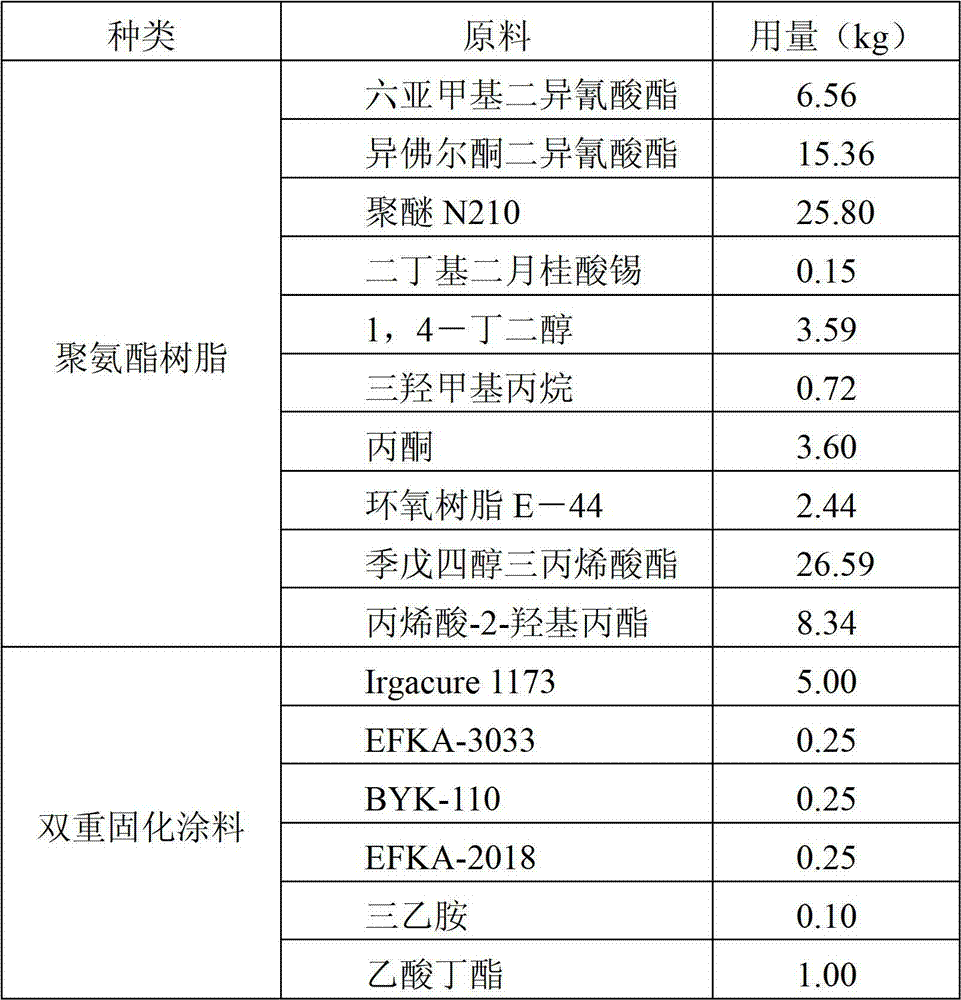

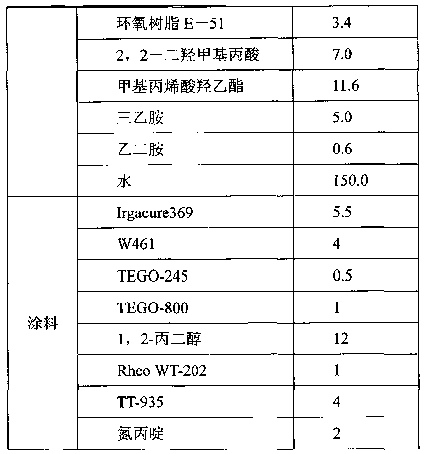

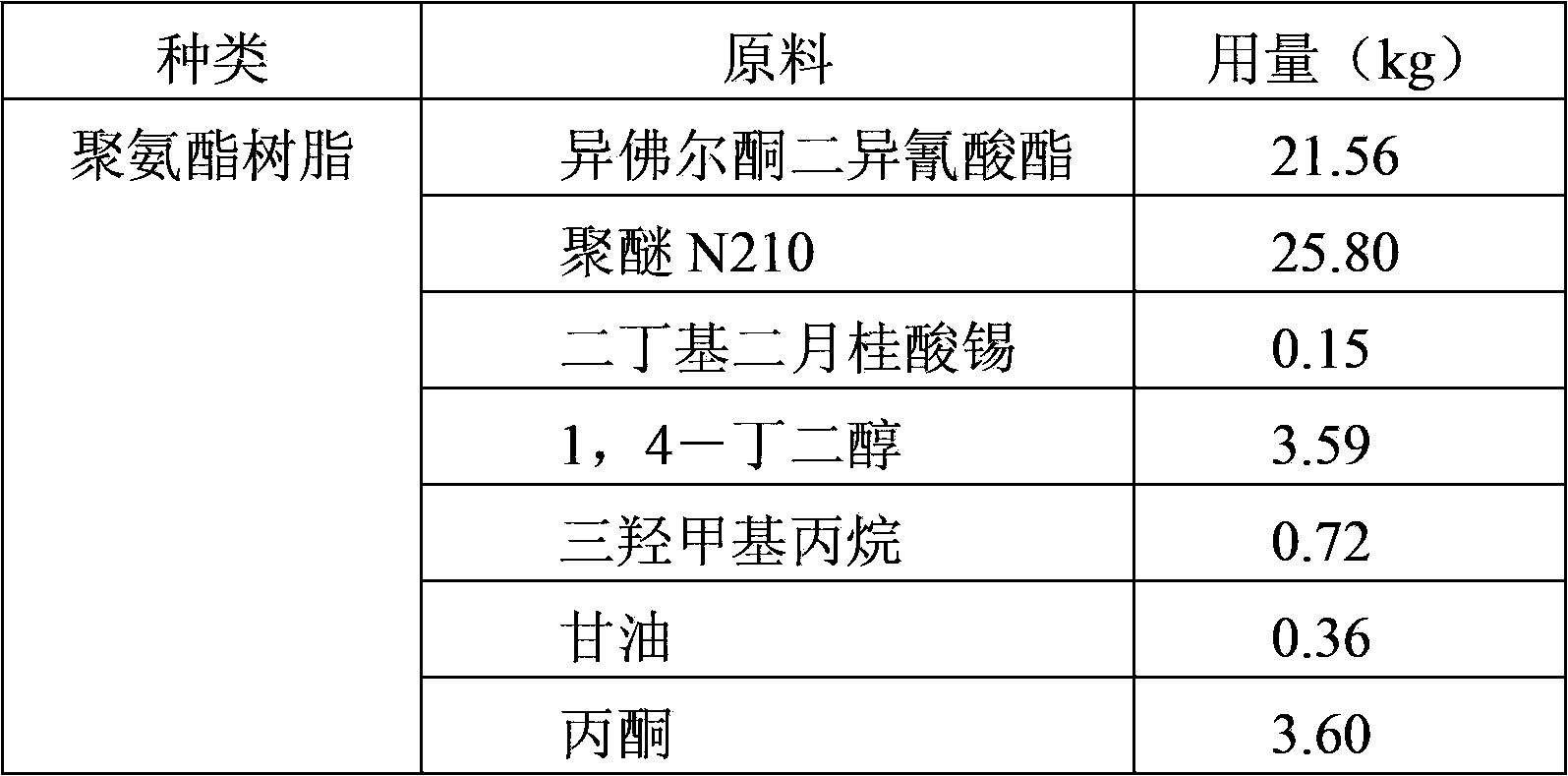

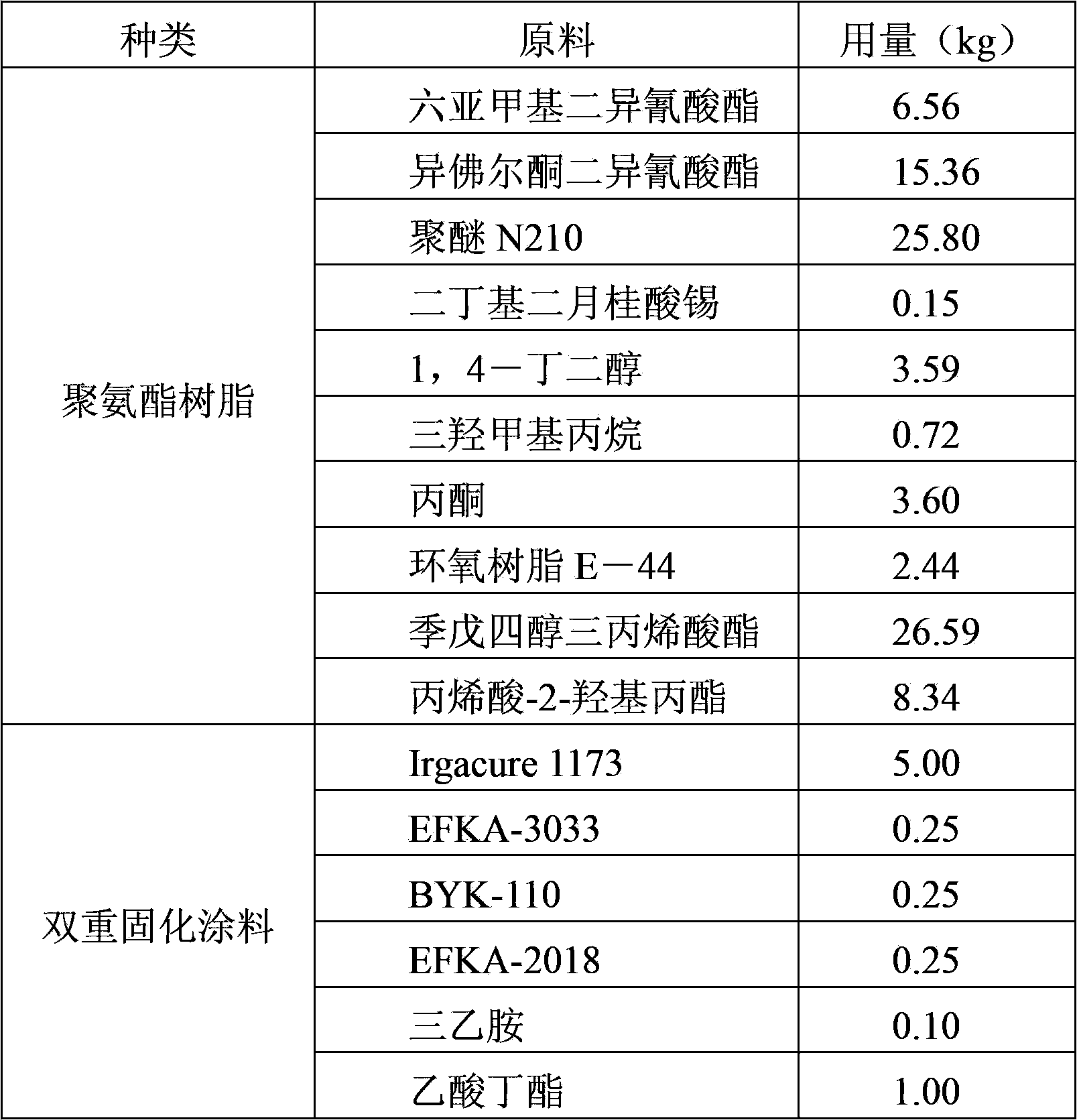

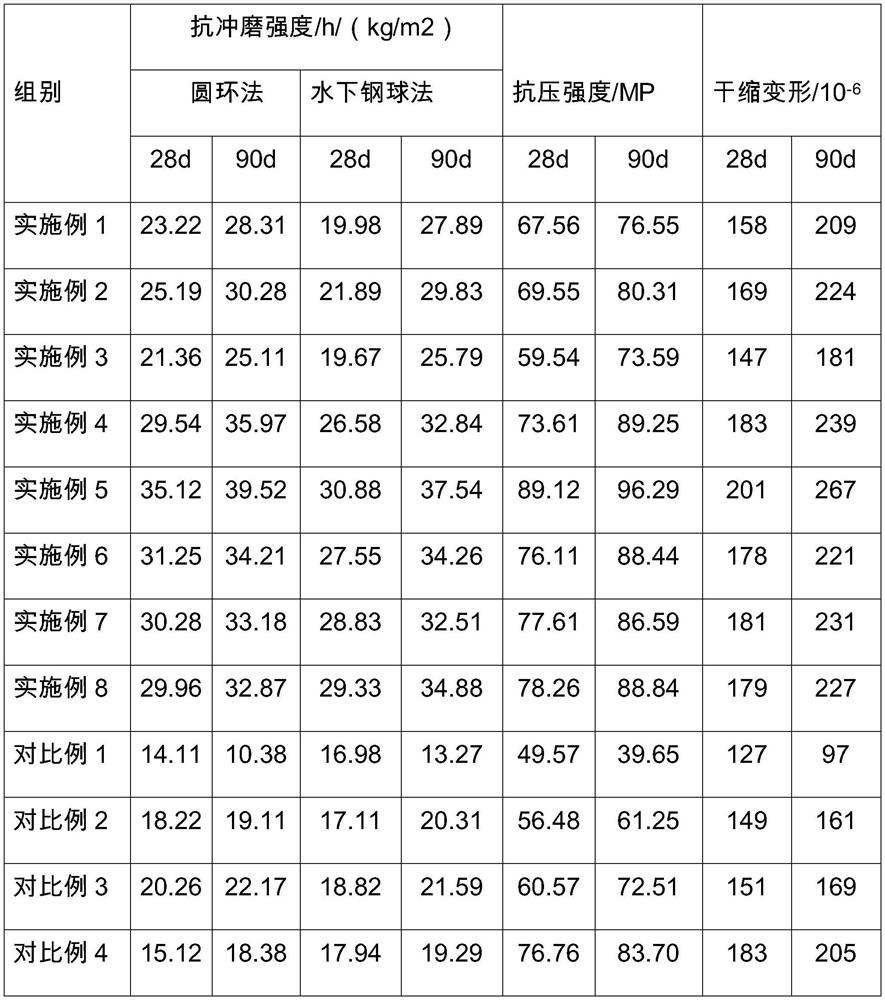

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

Anticorrosion epoxy powder paint used outside marine steel pipe pile

ActiveCN101724331AGood scratch resistanceImprove scratch resistanceAnti-corrosive paintsEpoxy resin coatingsWaxAluminium

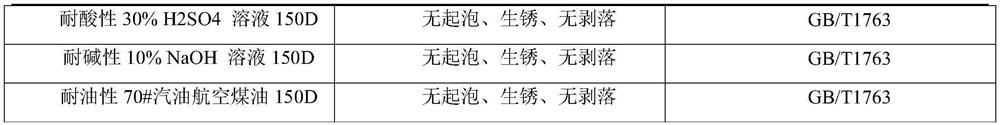

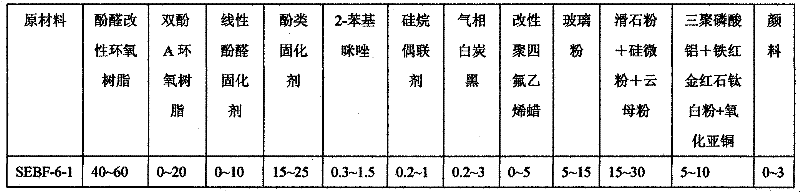

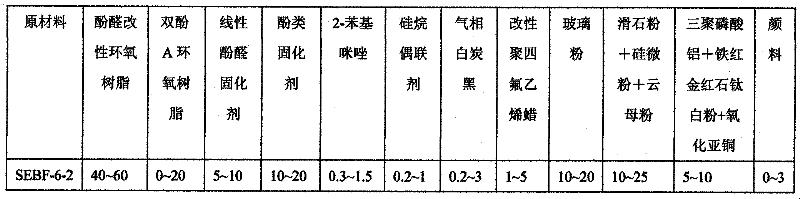

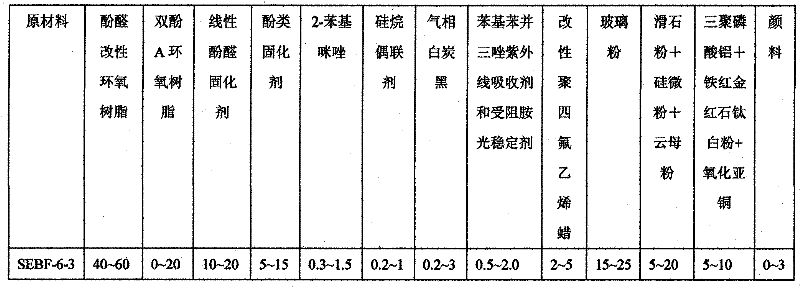

The invention provides an anticorrosion epoxy powder paint used outside a marine steel pipe pile, which is characterized by comprising resin, a curing agent, an accelerant, a coupling agent, an edge covering agent, a special function auxiliary agent, a stuffing, a pigment and the like, and the formula of the anticorrosion epoxy powder paint comprises the following components in percentage by weight: 40-60 percent of phenol-modified epoxy resin, 0-20 percent of bisphenol A epoxy resin, 0-20 percent of linear phenol curing agent, 5-25 percent of phenol curing agent, 0.3-1.5 percent of 2-phenylimidazole, 0.2-1 percent of silane coupling agent, 0.2-3 percent of gas phase white carbon, 0-2 percent of hydroxy-phenyl benzotriazole ultraviolet absorbent and hindered amine light stabilizer, 0-5 percent of modified polyfluortetraethylene wax, 5-25 percent of glass powder, 5-30 percent of talcum powder, silicon powder and mica powder, 5-10 percent of aluminium triphosphate, iron red, rutile titanium pigment and cuprous oxide and 0-3 percent of pigment. The paint SEBF-6 has the advantages that the surface roughness of a coating satisfies the required built-in strength of a steel pile and the marine geological condition of the steel pile, and the paint has the characteristics of excellent scratch resistance, shock resistance, abrasion resistance, marine biological fouling resistance, ageing resistance, ultraviolet irradiation resistance and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High solid content acrylic varnish, and preparation method and application thereof

The invention discloses a high solid content acrylic varnish which comprises the following raw materials in percentage by mass: 50-60% of hydroxy acrylic resin, 20-30% of polyurethane curing agent, 12.6-18% of organic solvent, 0.1-2% of wetting agent, 0.1-2% of flatting agent and 0.1-1% of antifoaming agent. The high solid content acrylic varnish disclosed by the invention can be applied in bamboo and wood tableware, is combined with a high solid content coating technology and technologies of cross-linked film curing and organic solvent removal and is a new development direction for bamboo and wood coatings and coating materials.

Owner:CARPOLY CHEM GRP

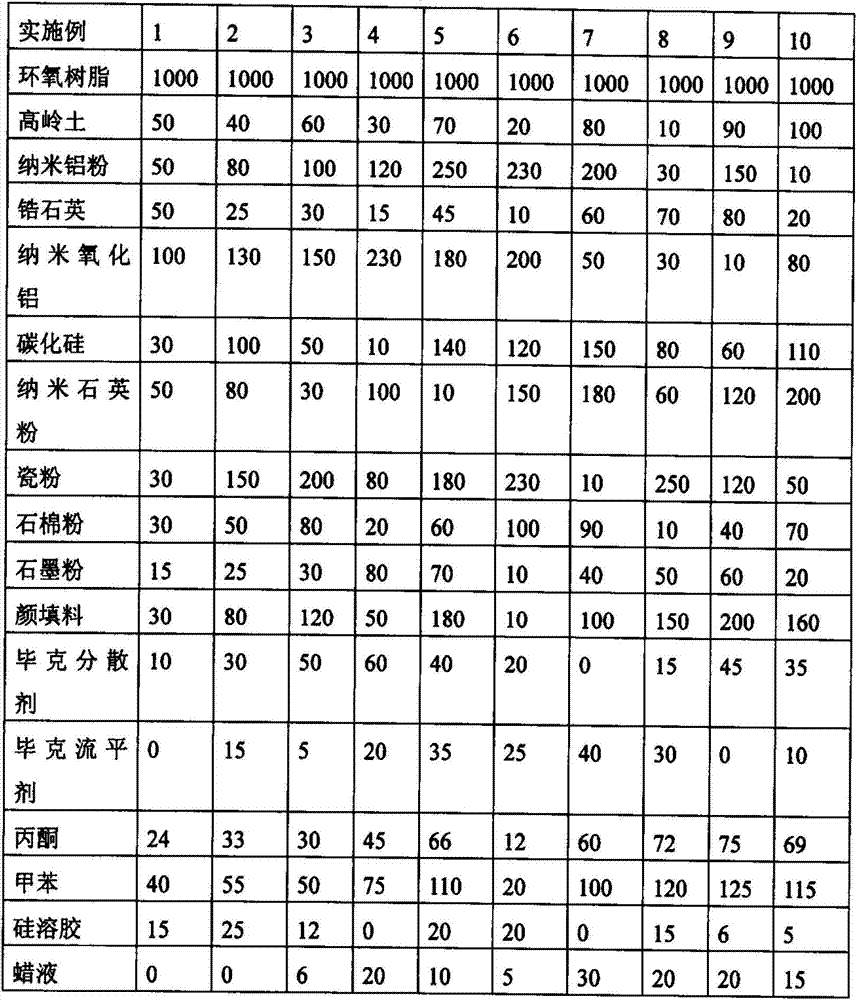

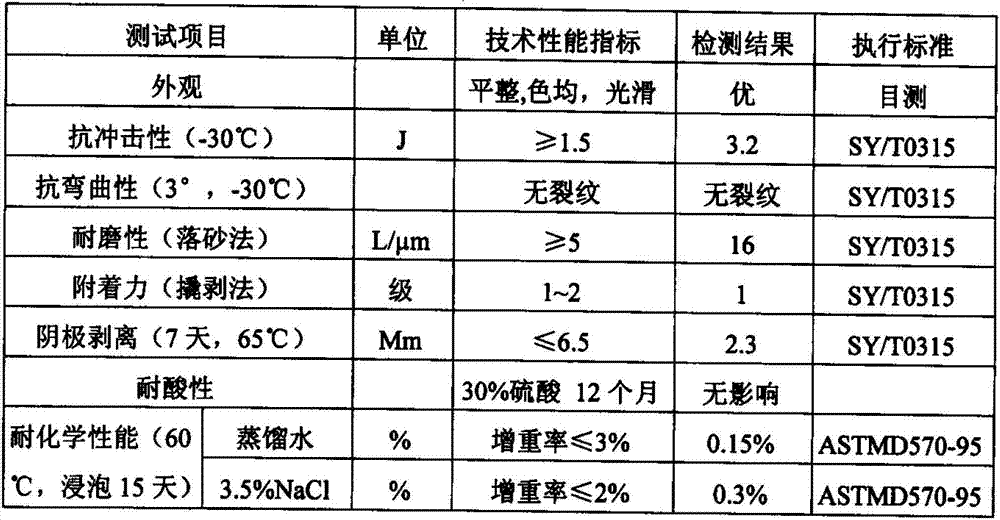

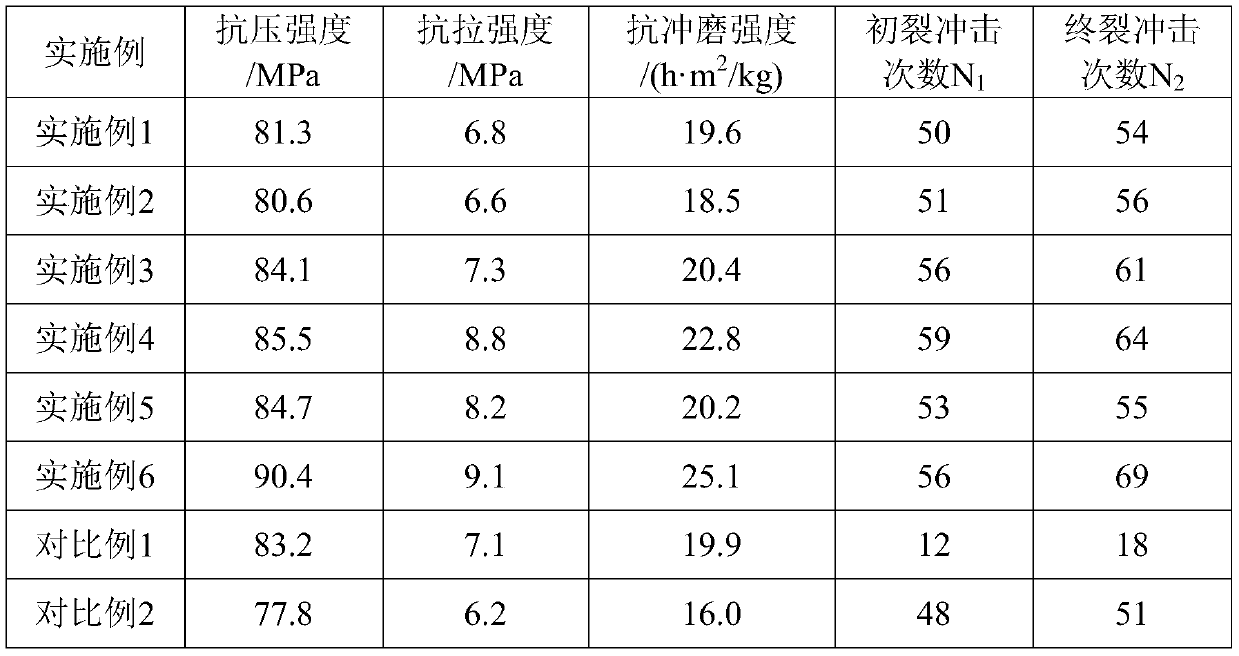

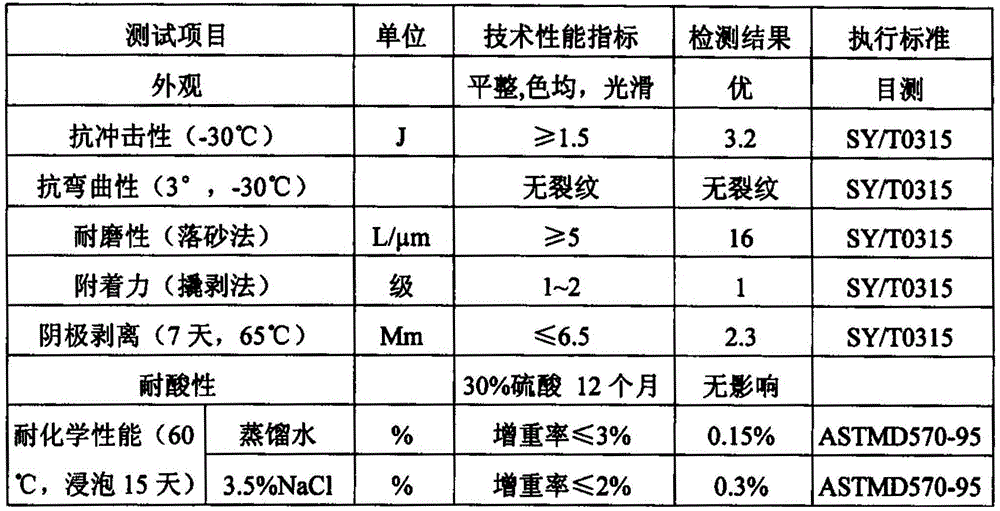

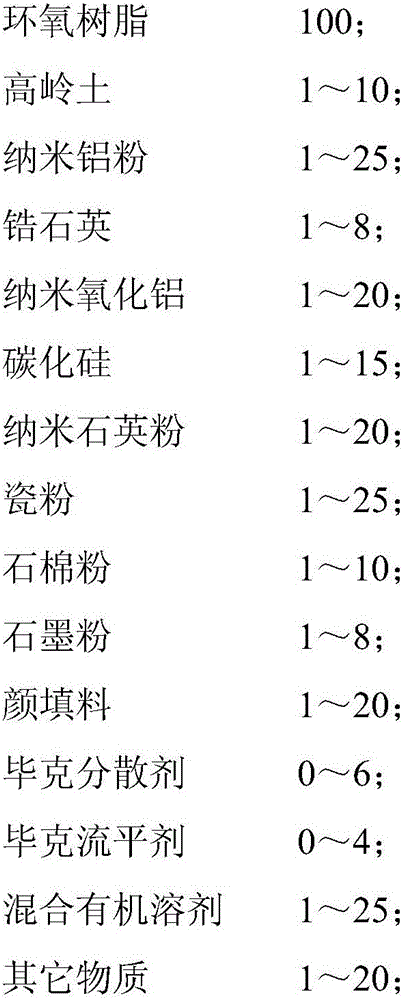

Manufacturing method of metal ceramic anticorrosive paint

ActiveCN103589273AImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyNano al2o3

A metal ceramic anticorrosive paint mainly includes kaolin, nanometer aluminium powder, nano alumina, silicon carbide, nano quartz powder, ceramic powder, asbestos powder, graphite powder, a pigment, a filler, epoxy resin, an additive and a mixed organic solvent. The solid powders are subjected to nano ultrafine treatment to reach a granularity of 20-200 nm. The paint provided by the invention is a single-component paint, which is simple in manufacturing process, economical and environment-friendly. The coating of the paint does not require a primer and can be used alone without adding special finish. The coating has excellent wear resistance, corrosion resistance, impact resistance, stability, strong adhesion, compactness and stability, and can effectively prevent erosion by acid, alkali, salt and seawater. In addition, the paint can be widely applied to oil pipeline, oil storage tank, chemical equipment, ships, bridges, offshore platforms and other steel structure buildings.

Owner:SHANGHAI JIANYE TECH ENG

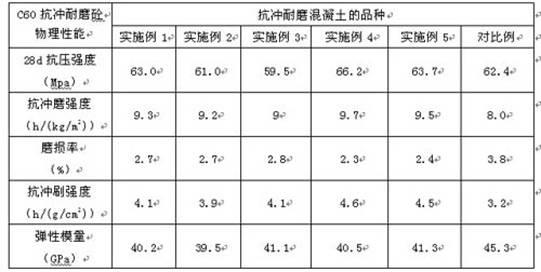

Impact-resistant anti-wear agent for hydraulic concrete

The invention provides an impact-resistant and anti-wear agent for hydraulic concrete, which mainly comprises a nano material, slag, latex powder, rubber powder, a water reducing agent, fibers, an exciting agent and a defoaming agent. The impact-resistant anti-wear agent is suitable for places such as water conservancy projects, roads and airport pavements requiring high impact-resistant and anti-wear concrete, has the functions of resisting crack, reducing water, reinforcing and reducing elasticity, and excellent mixing and constructing properties. The impact-resistant and anti-wear agent has the advantages of increasing concrete impact-resistant and anti-wear properties, prolonging maintenance period and reducing maintenance cost.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE +1

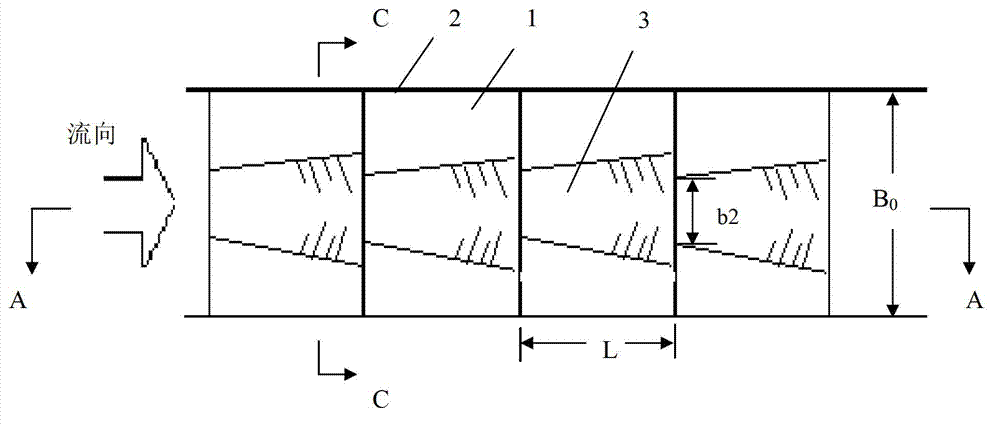

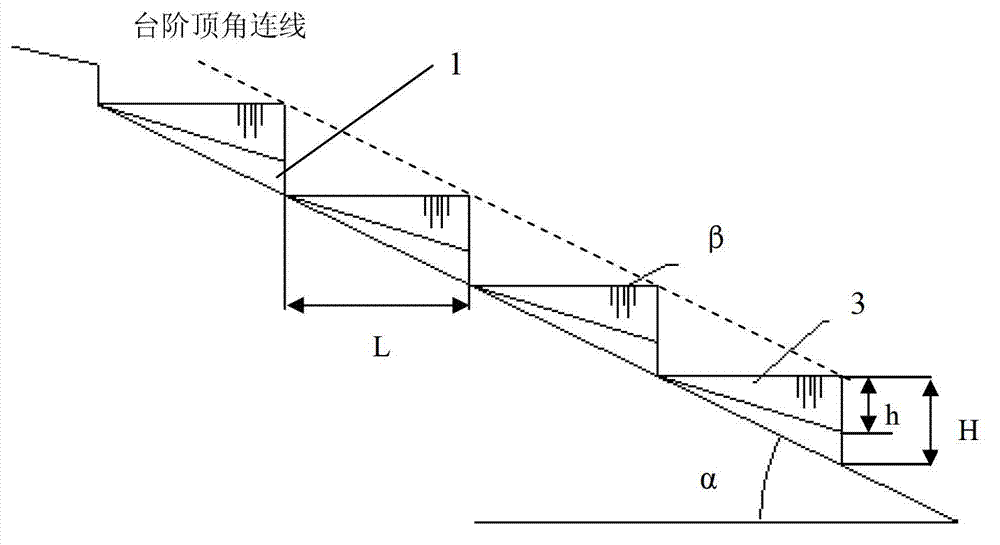

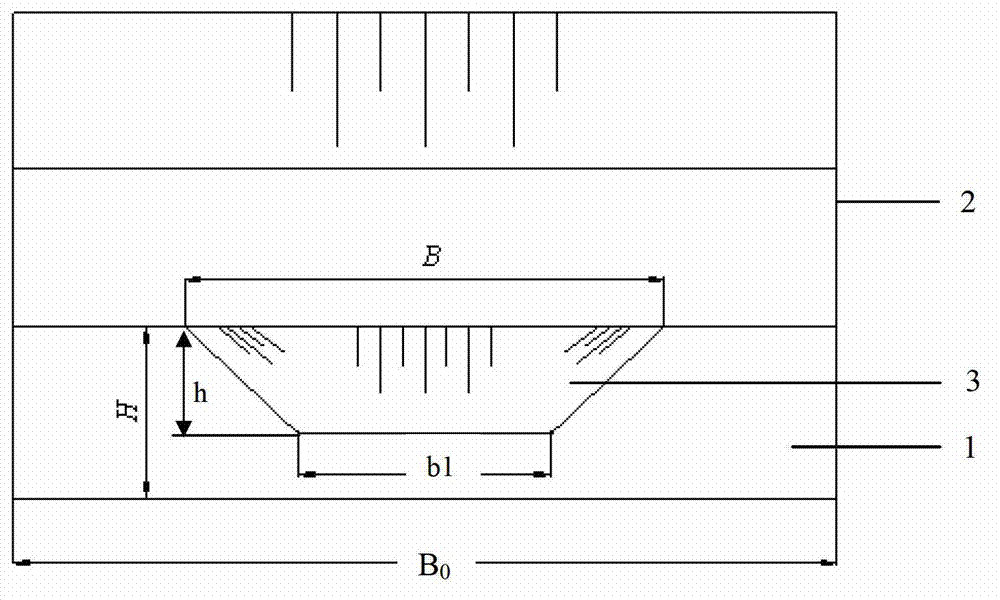

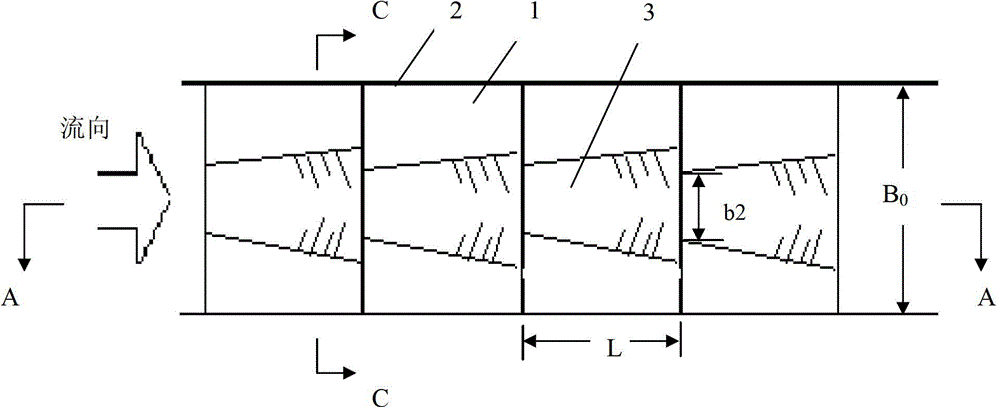

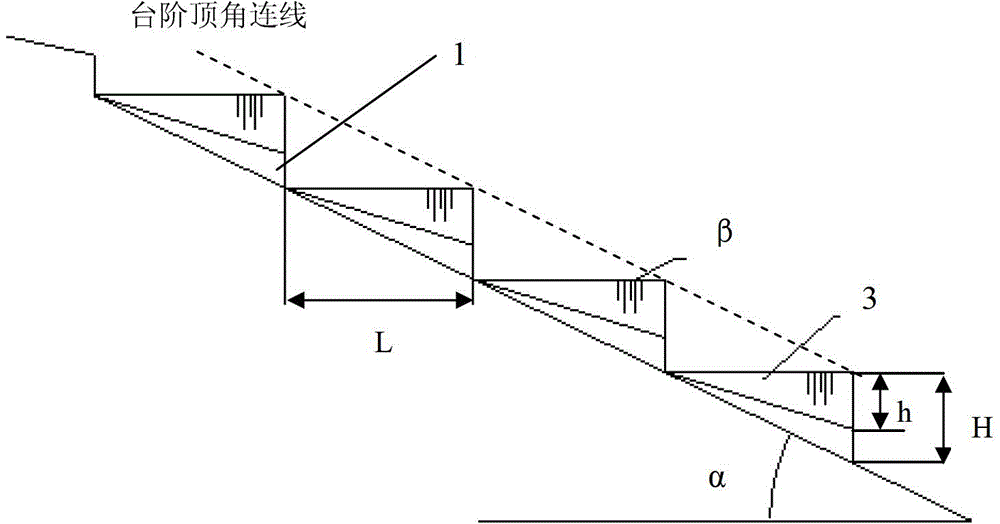

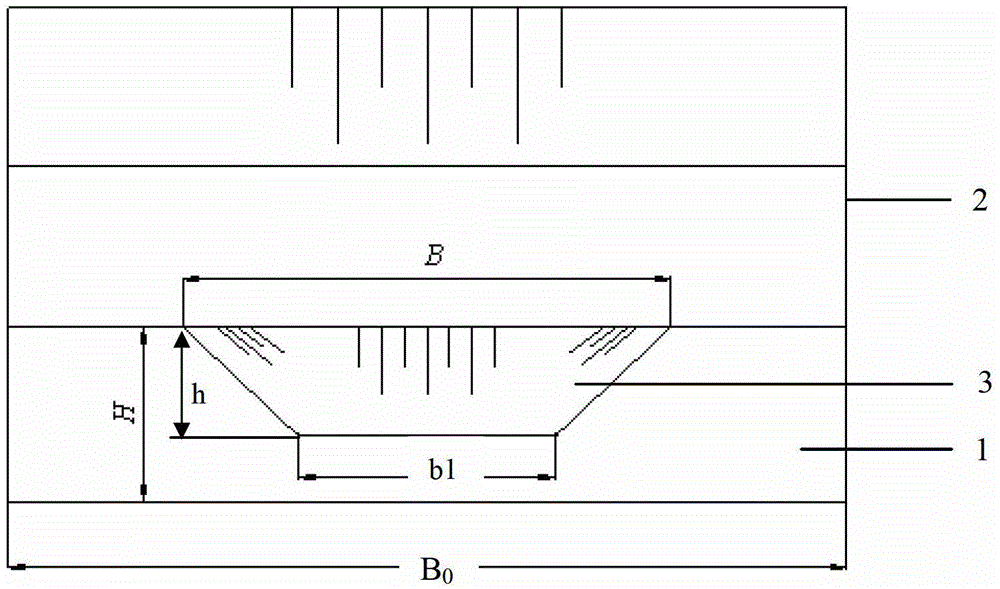

Debris-flow drainage canal with energy dissipation and drainage functions and application thereof

The invention discloses a debris-flow drainage canal with energy dissipation and drainage functions and an application of the debris-flow drainage canal with energy dissipation and drainage functions. The drainage canal comprises a fully-lining drainage canal bottom plate and drainage canal side walls on two sides of the drainage canal bottom plate; the drainage canal bottom plate is in the shape of continuously-connected multiple-stage steps, the steps are provided with grooves; the width of the grooves on the top surfaces of the steps increases gradually along the flow direction of the debris flow, and the width of the grooves on the vertical surfaces of the steps decreases gradually; and the maximum width of the grooves on the top surfaces of the steps coincide with the maximum width B on the vertical surfaces of the steps. Compared wit the prior art, the step shape design is adopted to dissipate the energy of the debris flow all the way and the groove design is adopted to drain the debris flow, so the debris-flow drainage canal disclosed by the invention has high efficiency and good drainage capacity. By adjusting the height and the length of the steps and the size and the shape of grooves, the debris-flow drainagedrainage canal can be used for preventing the debris flow with any gradient and any nature.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Concrete thin-layer repairing polymer mortar and preparation method thereof

ActiveCN107777922AGood wear resistance and repair abilityEasy to adjustPolyurea/polyurethane coatingsPolymer scienceThin layer

The invention provides concrete thin-layer repairing polymer mortar and a preparation method thereof and relates to the field of mortar. The concrete thin-layer repairing polymer mortar is prepared from the following raw materials in weight ratio: two-component slow reaction type polyurea waterproof coating and a sand material, wherein the weight ratio of the two-component slow reaction type polyurea waterproof coating to the sand material is 1:(1-3). By utilizing the concrete thin-layer repairing polymer mortar, the problem that polymer mortar in the prior art cannot well repair a concrete building component can be solved, and the concrete thin-layer repairing polymer mortar has the advantages of good bonding performance, corrosion resistance and scour and wear resistance.

Owner:XINJIANG KENENG WATERPROOF & PROTECTION TECH CO LTD

Antifouling coating as well as use method and application thereof

ActiveCN113881329AImprove wear resistanceImprove adhesionAntifouling/underwater paintsPaints with biocidesCoated surfacePolymer science

The invention belongs to the technical field of marine antifouling coatings, and provides an antifouling coating as well as a use method and application thereof. Polyaspartic acid ester in the antifouling coating is an isocyanate curing agent containing a secondary amine structure, the abrasion resistance of a coating layer can be improved through ester groups and aliphatic series characteristics contained in the structure of the polyaspartic acid ester, and the antifouling coating can be endowed with good toughness and elasticity by combining the polyaspartic acid ester with the prepolymer containing polyisocyanate in a component A, and a formed coating layer has excellent impact resistance and wear resistance. A polydimethylsiloxane structure is introduced into a hydroxypropyl silicone oil type isocyanate prepolymer in the component A, and the polydimethylsiloxane structure can generate a microphase separation effect with a polyurea hard segment and migrate to the surface of the coating layer, so that the surface energy of the coating is reduced, and the adhesive force between fouling organisms and an interface is reduced; and the adhesive force of the coating layer can be increased through hydrogen bonds and chemical bonds by a ureido structure and redundant isocyanate groups migrated to the bottom, so that the cleaning resistance and the wear resistance of the coating are guaranteed.

Owner:HARBIN ENG UNIV

High-strength concrete cementitious composition and high-strength concrete thereof

InactiveCN104743995AHigh strengthEasy constructionSolid waste managementHigh strength concreteSilicon

The invention discloses a high-strength concrete cementitious composition and high-strength concrete thereof. The cementitious composition is formed by mixing water with a cementitious material, wherein the weight ratio of water to the cementitious material is 0.23-0.25; the cementitious material is formed by mixing the following materials in parts by weight: 52.5 parts of common silicate, 445-525 parts of cement, 0-125 parts of coal ash and 30-65 parts of silica fume; the high-strength concrete is formed by mixing the following materials in parts by weight: 720-805 parts of said cementitious composition, 565-660 parts of manufactured sand, 910-1030 parts of rocklets, 4.7-10.0 parts of a super-plasticizing enhancer and 0-1.3 parts of a retarder. According to the high-strength concrete cementitious composition and the high-strength concrete thereof disclosed by the invention, silicate cement, high-quality silicon powder, high-quality coal ash, the high-performance super-plasticizing enhancer and the high-quality retarder are used, coarse and fine aggregates and water are properly cooled, and the prepared concrete has a good construction performance, a higher compressive strength, a low fluidity loss, a higher strength, and a better erosion and abrasion resistance.

Owner:SINOHYDRO BUREAU 7 CO LTD

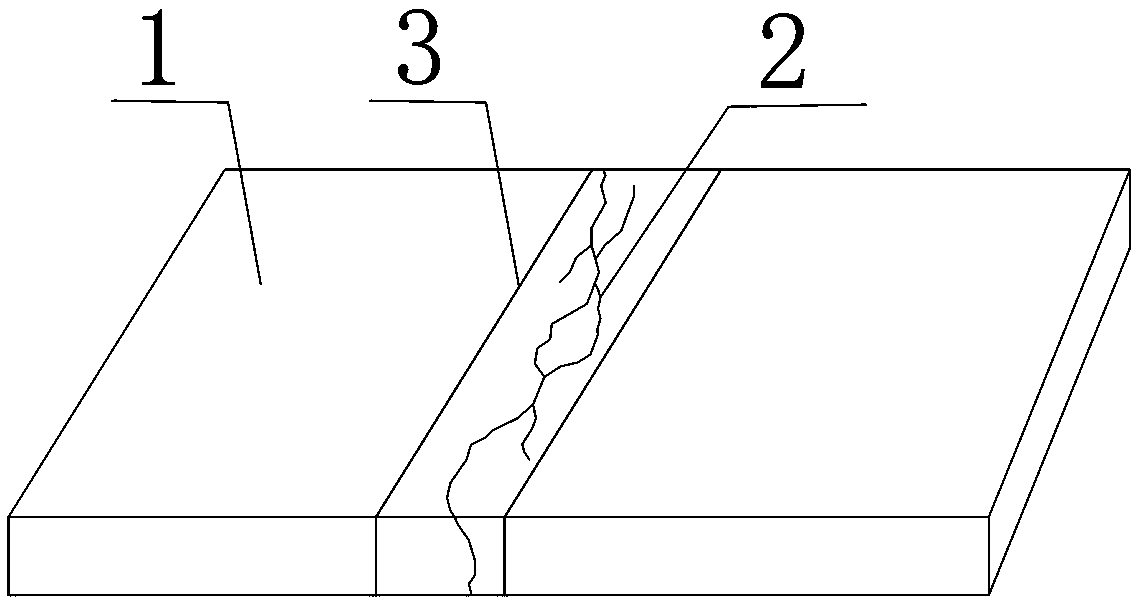

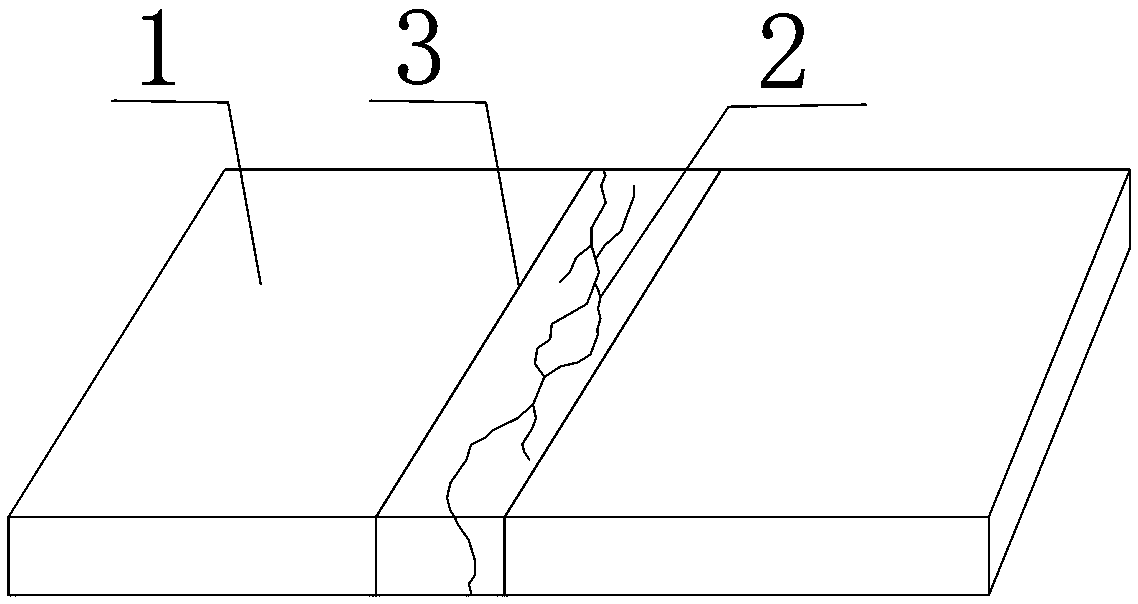

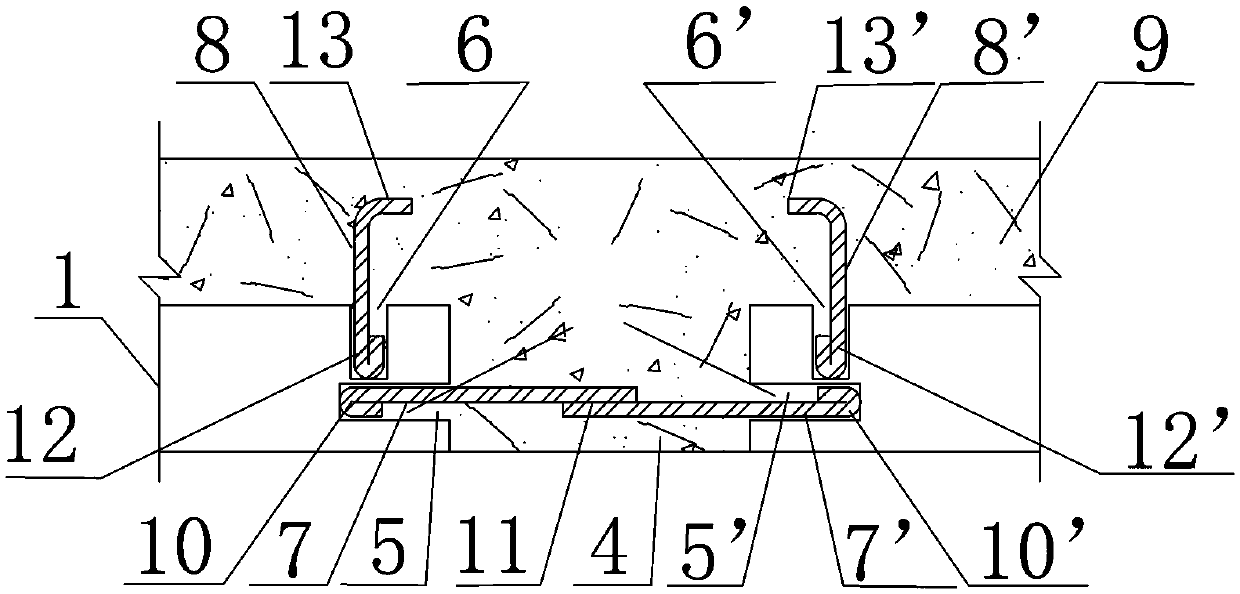

Damaged concrete pavement panel reinforcing structure and method

InactiveCN105507109ASmall shrinkage deformationImprove tensile propertiesPaving detailsWork performanceRoad surface

The invention provides a damaged concrete pavement panel reinforcing structure and method. The structure comprises a concrete pavement panel, the concrete pavement panel is provided with a reinforcing groove, a plurality of pairs of horizontal steel bar embedding holes are formed in the two walls of the reinforcing groove, and horizontal steel bars are fixedly arranged in the horizontal steel bar embedding holes; a steel fiber reinforced concrete blanket is fixedly poured over the concrete pavement panel. The method comprises the steps of 1, conducting surface debristling; 2, making the reinforcing groove and drilling the plurality of pairs of horizontal steel bar embedding holes; 3, embedding the horizontal steel bars; 4, pouring steel fiber reinforced concrete to form the steel fiber reinforced concrete blanket. By combining the horizontal steel bars with steel fiber reinforced concrete, new cement concrete and old cement concrete cooperation work performance is improved, the bearing capacity of the concrete pavement panel reinforcing area is improved, and the service life and maintenance cycle of a road are prolonged.

Owner:ZHENGZHOU UNIV

Reinforcing structure and method for damaged concrete pavement panel

InactiveCN105507110AImprove the anchoring effectEffective anchoringPaving detailsRoad surfaceFace sheet

The invention provides a reinforcing structure and method for a damaged concrete pavement panel. The reinforcing structure for the damaged concrete pavement panel comprises the concrete pavement panel with the planed surface, a reinforcing groove, multiple pairs of horizontal rebar embedding holes, and vertical rebar embedding holes. The horizontal rib embedding holes are formed in the two groove walls of the reinforcing groove, and the vertical rib embedding holes are formed in the concrete pavement panel. Horizontal rebars are fixedly arranged in the horizontal rebar embedding holes, vertical rebars are fixedly arranged in the vertical rebar embedding holes, and a steel fiber reinforced concrete cover is poured and fixed to the concrete pavement panel. The reinforcing method for the damaged concrete pavement panel includes the following steps that 1, surface planing is conducted; 2, the reinforcing groove is formed, and the multiple pairs of horizontal rebar embedding holes and the multiple pairs of vertical rebar embedding holes are drilled; 3, construction glue is poured, and the horizontal rebars and the vertical rebars are embedded; 4, steel fiber reinforced concrete is poured to form the steel fiber reinforced concrete cover. The bearing capacity of the concrete pavement panel is increased, the service life and the maintenance period of a road are prolonged, and the long-term use cost is reduced.

Owner:ZHENGZHOU UNIV

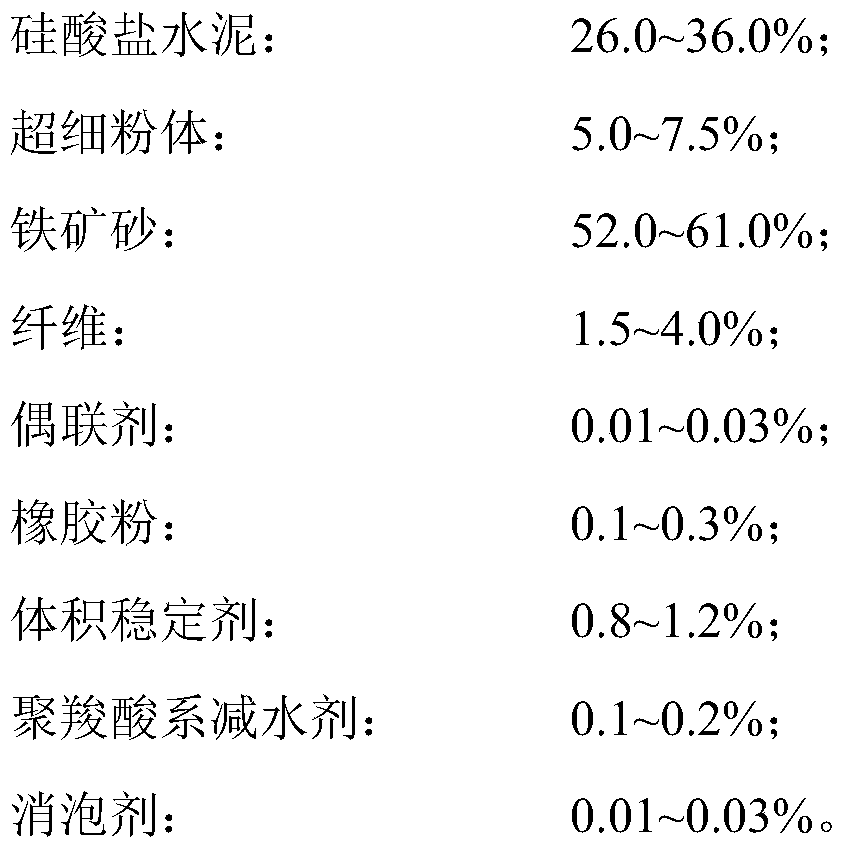

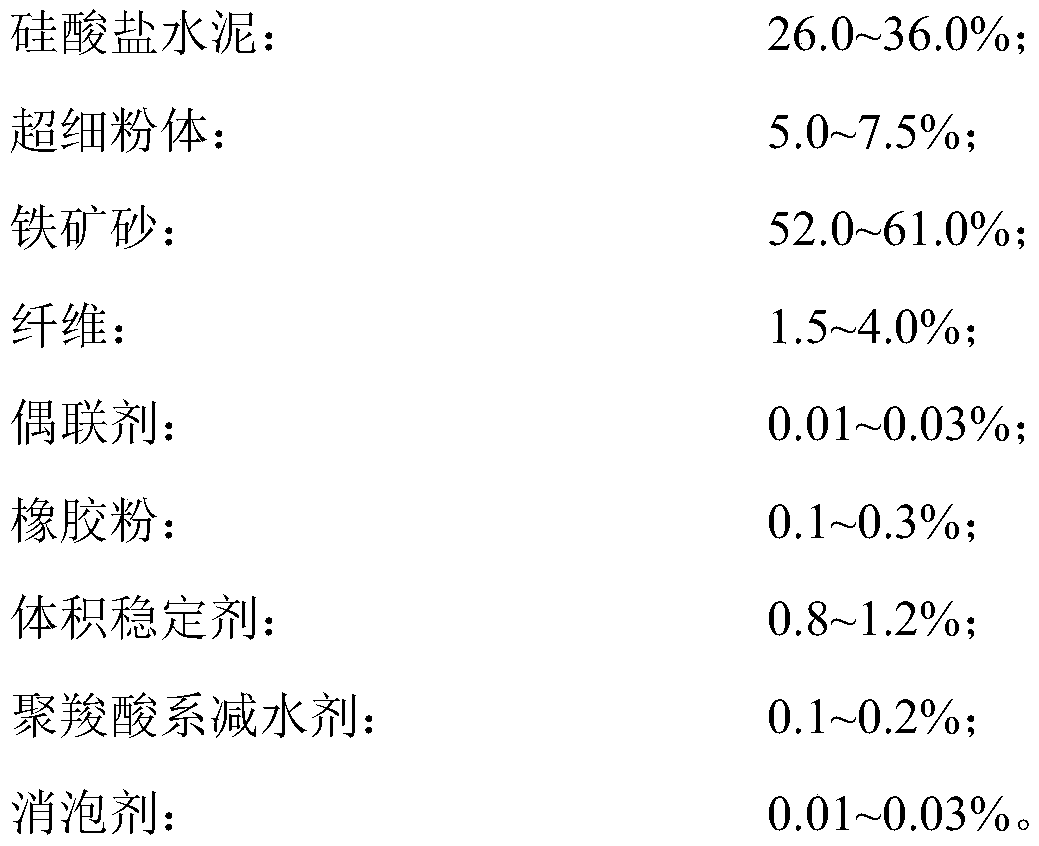

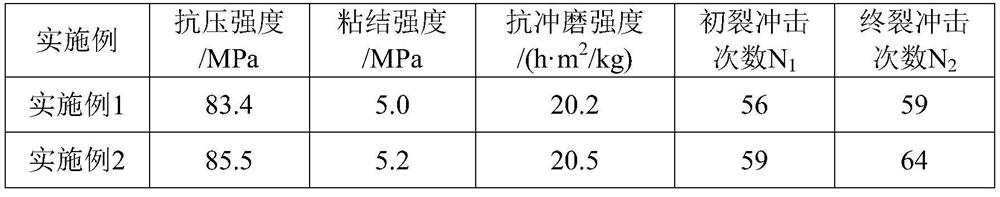

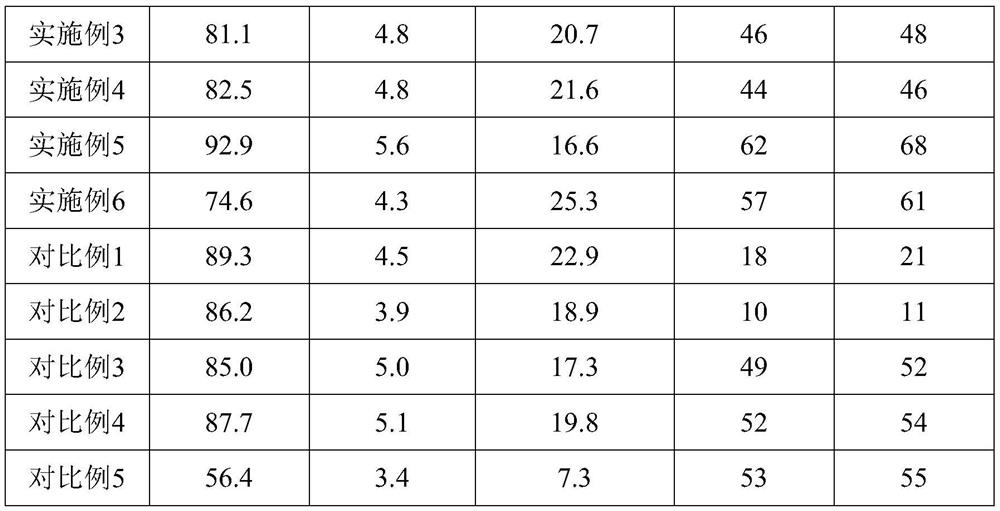

High-toughness impact-resistant and wear-resistant repairing material

The invention provides a high-toughness impact-resistant and wear-resistant repairing material which is mainly prepared from 26.0 to 36.0 percent of portland cement, 5.0 to 7.5 percent of ultrafine powder, 52.0 to 61.0 percent of iron ore, 1.5 to 4.0 percent of fiber, 0.01 to 0.03 percent of a coupling agent, 0.1 to 0.3 percent of rubber powder, 0.8 to 1.2 percent of a volume stabilizer, 0.1 to 0.2 percent of a polycarboxylate water reducing agent, 0.01 to 0.03 percent of a defoaming agent and the like. The high-toughness impact-resistant and wear-resistant repairing material provided by the invention has the advantages of low price, convenient construction, high impact toughness, high impact strength, high bonding strength, low shrinkage and high crack resistance, has a linear expansion coefficient close to that of concrete, cannot fall off from a base material, and can replace organic materials such as epoxy resin mortar and the like.

Owner:安徽瑞和新材料有限公司 +1

Metal-ceramic anticorrosion coating and preparation method thereof

ActiveCN103589273BImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyNano al2o3

A cermet anti-corrosion coating, its formula mainly includes: kaolin, nano-aluminum powder, nano-alumina, silicon carbide, nano-quartz powder, porcelain powder, asbestos powder, graphite powder, pigments and fillers, epoxy resin, additives, mixed organic Solvents, etc., the solid powder is treated by nanometer ultra-fine processing, so that the particle size can reach 20-200nm. The paint of the invention is a one-component paint, and the manufacturing process is simple, economical and environmentally friendly. The paint coating does not need a primer, and can be used alone without a special topcoat. The coating has excellent wear resistance, corrosion resistance, impact resistance and stability. The coating has strong adhesion, dense and stable, and can effectively insulate Acid, alkali, salt, seawater erosion. It can be widely used in oil pipelines, oil storage tanks and chemical equipment, ships, bridges, offshore platforms and other steel structures.

Owner:SHANGHAI JIANYE TECH ENG

High-strength wear-resisting mortar

High-strength wear-resisting mortar is characterized by being prepared from, by mass, 5.0-10.0% of superfine wear-resisting composite micro-powder (micro-sphere), 0.08-0.10% of steel-plastic fiber, 0.10-0.16% of additive, 1.3-2.7% of polymer gelatine powder, 69-74% of fine aggregate and 13.75% of cement through technological combination.The technological process mainly comprises the steps of material drying, pre-dispersion, fiber dispersion and vacuum sealed storage.The high-strength wear-resisting mortar has the excellent bonding property, cracking resistance, freezing resistance, seepage resistance, corrosion resistance, chloride penetration resistance and aging resistance of polymer cement mortar, and also has ultrahigh strength, scour-grind resistance, cracking resistance and gas etching resistance.

Owner:辽宁省水利水电科学研究院有限责任公司

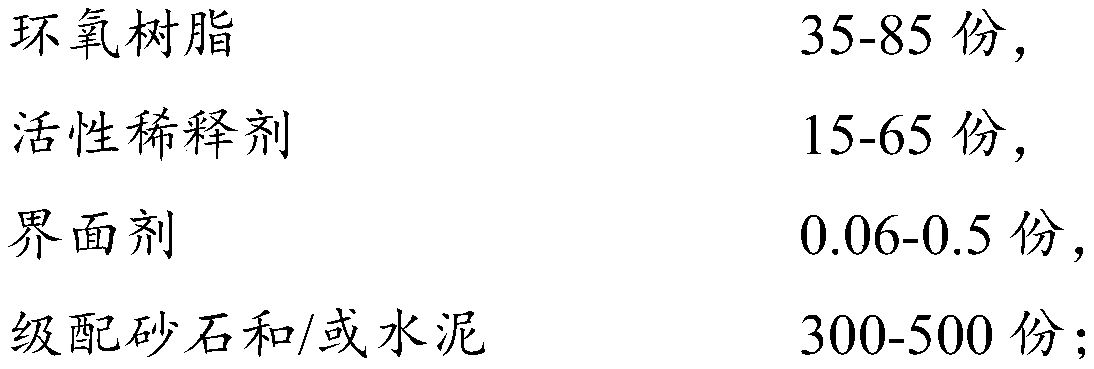

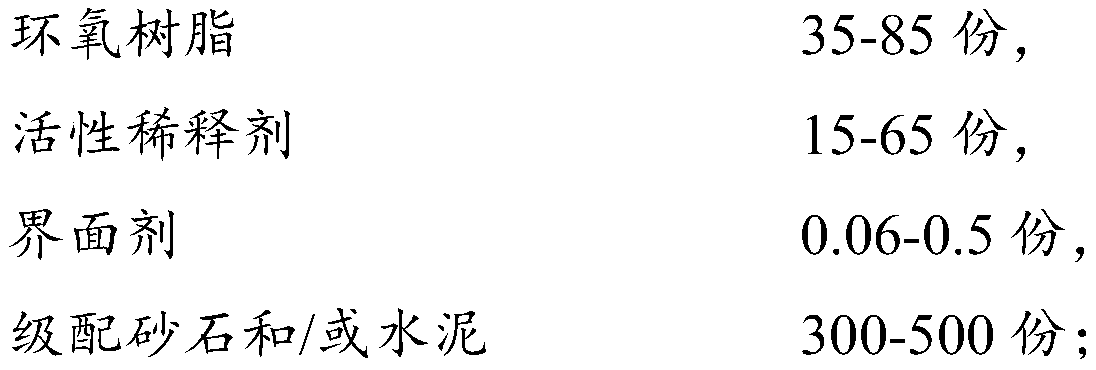

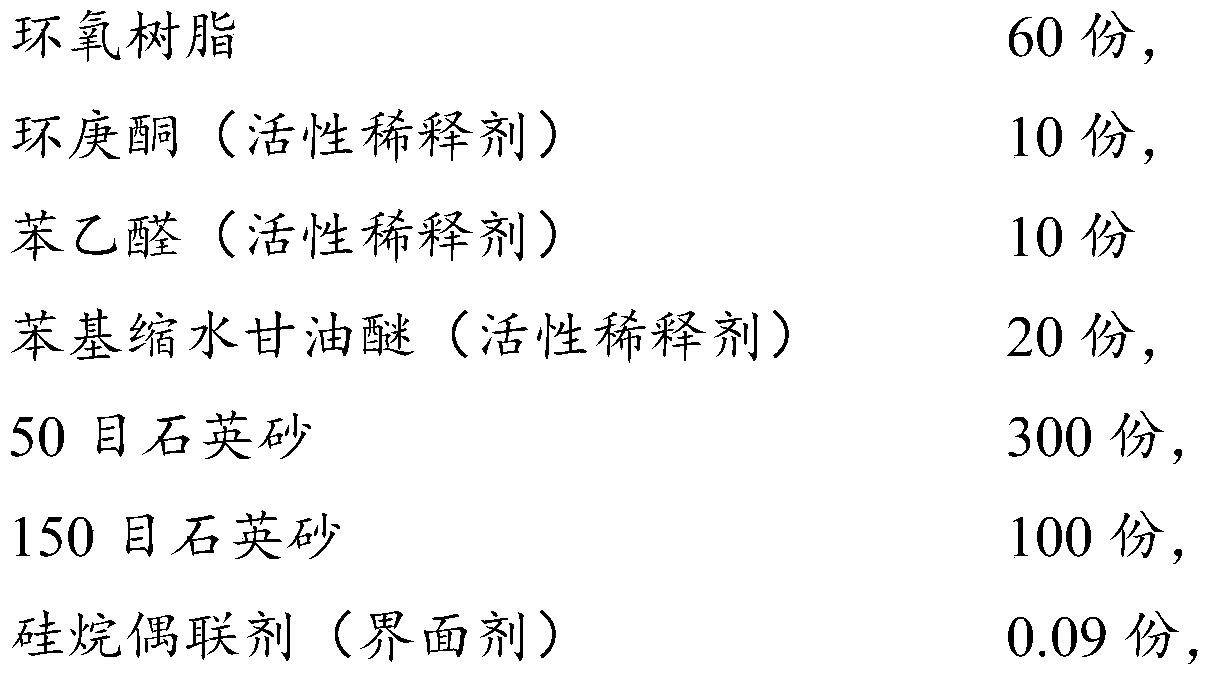

Environment-friendly high-durability epoxy mortar

The invention provides environment-friendly high-durability epoxy mortar, and belongs to the technical field of building materials. The environment-friendly high-durability epoxy mortar is composed ofa component A and a component B. The component A comprises at least one of graded sandstone and cement, epoxy resin, a carbonyl compound, a glycidyl ether compound and an interface agent, and the component B comprises an amine curing agent, a curing accelerator and a humid environment functional curing agent. According to the mortar disclosed by the invention, the carbonyl compound and the glycidyl ether compound are compounded as a diluent, so that the hardness, the flexibility, the adhesive force, the durability and the dilutability of a mortar layer can be synergistically improved, the shrinkage rate and the cost of the mortar layer are reduced, and environmental protection and safety are facilitated; by adding the humid environment functional curing agent, smooth curing in a humid environment can still be ensured, and the construction applicability is higher.

Owner:广州永科新材料科技有限公司

Debris-flow drainage canal with energy dissipation and drainage functions and application thereof

ActiveCN102926356BImprove overall efficiencyGood drainage abilityArtificial water canalsMedicineDrainage canal

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

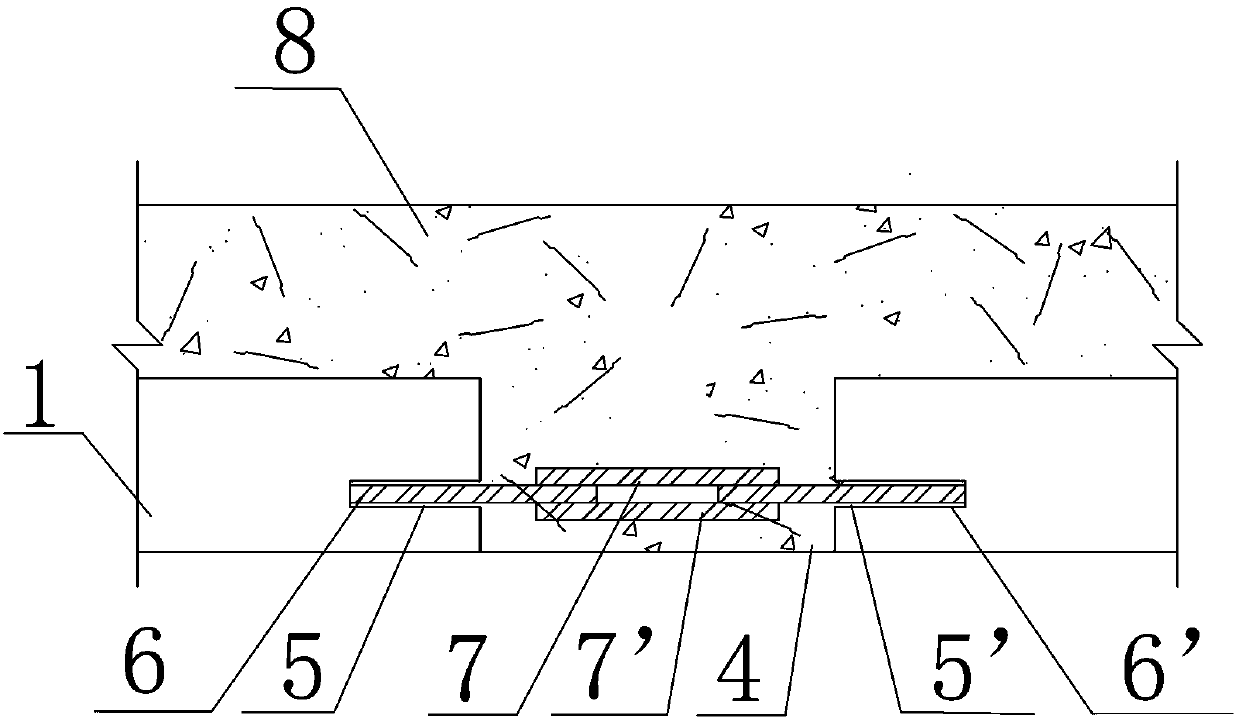

Anti-impact and wear-resistant concrete construction method for bottom plate of hydraulic tunnel

ActiveCN113217033AGood impact and wear resistanceAvoid damageMining devicesUnderground chambersArchitectural engineeringStructural engineering

The invention discloses an anti-impact and wear-resistant concrete construction method for a bottom plate of a hydraulic tunnel. By controlling raw materials in the construction process, excavating and supporting cavities, treating a foundation surface, optimizing a concrete mix proportion, controlling the construction quality of each working procedure on site, performing seepage prevention and cracking limitation of concrete, controlling the temperature, protecting a finished product and controlling on-site construction organization, the anti-impact and wear-resistant performance of high-flow-speed bottom plate concrete of the hydraulic tunnel is improved, and the engineering durability and the operation safety are improved. Through the measures, the anti-impact and wear-resistant performance of the concrete can be improved, the subsequent operation and maintenance work is reduced, the cost is effectively controlled, and the tunnel operation safety is guaranteed.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

A high-strength wear-resistant mortar

High-strength wear-resisting mortar is characterized by being prepared from, by mass, 5.0-10.0% of superfine wear-resisting composite micro-powder (micro-sphere), 0.08-0.10% of steel-plastic fiber, 0.10-0.16% of additive, 1.3-2.7% of polymer gelatine powder, 69-74% of fine aggregate and 13.75% of cement through technological combination.The technological process mainly comprises the steps of material drying, pre-dispersion, fiber dispersion and vacuum sealed storage.The high-strength wear-resisting mortar has the excellent bonding property, cracking resistance, freezing resistance, seepage resistance, corrosion resistance, chloride penetration resistance and aging resistance of polymer cement mortar, and also has ultrahigh strength, scour-grind resistance, cracking resistance and gas etching resistance.

Owner:辽宁省水利水电科学研究院有限责任公司

Multiple crosslinking ultraviolet light solidifying water polyurethane dispersoid and its preparation method and application

InactiveCN101235148BGood water dispersibilityGood storage stabilityPolyurea/polyurethane coatingsDispersityEpoxy

Owner:SOUTH CHINA UNIV OF TECH

Impact-resistant and wear-resistant concrete for civil engineering and preparation method thereof

The invention provides impact-resistant and wear-resistant concrete for civil engineering and a preparation method thereof. The preparation method comprises the following steps: firstly, weighing raw materials in parts by weight, and ultrasonically dispersing the weighed fly ash, silica fume and nano corn starch in water accounting for 1 / 3 of the total water quantity to obtain a suspension A; ultrasonically dispersing the weighed large-aperture mesoporous silica and lithium polysilicate in water accounting for 1 / 3 of the total water amount to obtain a suspension B; then ultrasonically dispersing the weighed igneous rock fiber, nanocrystal cellulose and HF impact-resistant and wear-resistant special water reducing agent into water accounting for 1 / 3 of the total water quantity to obtain a suspension C; and finally, mixing Portland cement and river sand, respectively scattering the obtained suspension C, a graphene oxide solution, the suspension A and the suspension B in a stirring state, uniformly mixing and stirring, conveying the obtained mixed material into a finished product homogenizing bin by using an elevator, and homogenizing by using air generated at the bottom of the homogenizing bin to obtain the product. The concrete provided by the invention has excellent impact resistance and wear resistance, and is not easy to break.

Owner:XIJING UNIV

A kind of antifouling coating and its using method and application

ActiveCN113881329BImprove wear resistanceImprove adhesionAntifouling/underwater paintsPaints with biocidesCoated surfacePolyaspartic acid

The invention belongs to the technical field of marine antifouling coatings and provides an antifouling coating as well as its use method and application. The polyaspartic acid ester in the antifouling coating of the present invention is a kind of isocyanate curing agent containing secondary amine structure, and the ester group and aliphatic characteristic contained in its structure can increase the abrasion resistance of coating, and in A component The combination of the prepolymer containing polyisocyanate can endow the antifouling coating with good toughness and elasticity, so that the formed coating has excellent impact and wear resistance. The hydroxypropyl silicone oil-type isocyanate prepolymer in component A introduces a polydimethylsiloxane structure, which can migrate to the surface of the coating by microphase separation with the polyurea hard segment , reduce the surface energy of the coating, thereby reducing the adhesion between fouling organisms and the interface, and the urea-based structure and excess isocyanate groups that migrate to the bottom can increase the adhesion of the coating through hydrogen bonding and chemical bonding, ensuring its resistance to cleaning and abrasion sex.

Owner:HARBIN ENG UNIV

A crack-resistant high-impact and wear-resistant repair material

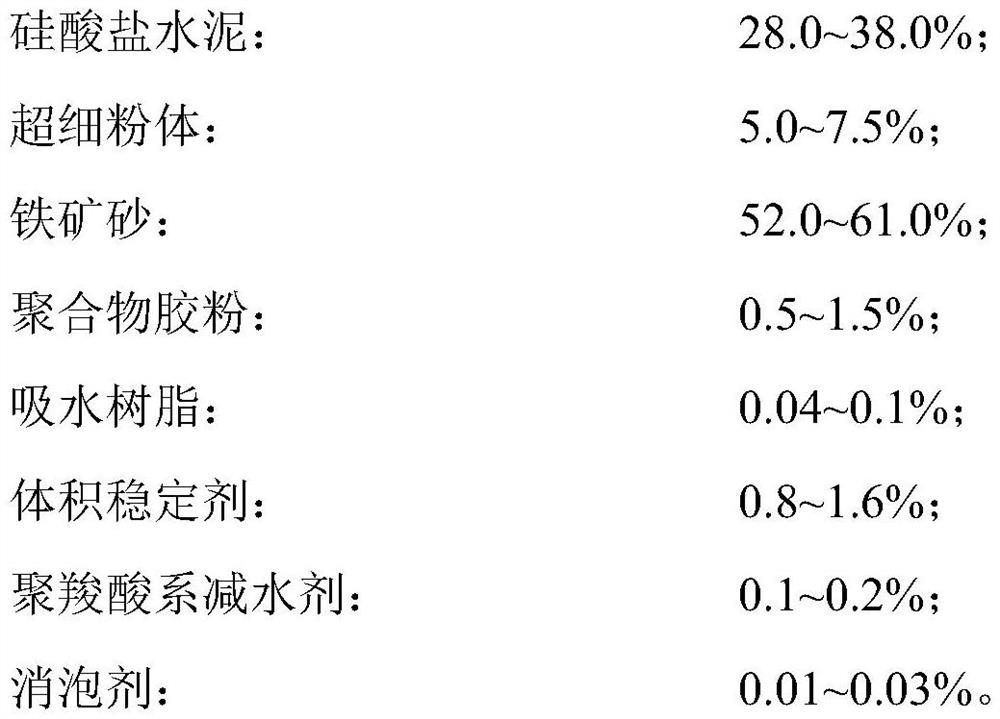

The invention proposes a crack-resistant high-impact and wear-resistant repair material, which mainly consists of 28.0-38.0% of Portland cement, 5.0-7.5% of ultra-fine powder, 52.0-61.0% of iron ore, and 0.5% of polymer rubber powder. ~1.5%, water-absorbent resin 0.04-0.1%, volume stabilizer 0.8-1.6%, polycarboxylate water reducer 0.1-0.3%, defoamer 0.01-0.03% and other raw materials mixed. The repair material has the advantages of low price, convenient construction, high abrasion resistance, high bonding strength, low shrinkage, high crack resistance, linear expansion coefficient close to that of concrete, and will not fall off from the base material. It can replace epoxy resin Organic materials such as mortar.

Owner:安徽瑞和新材料有限公司 +1

A double-mixed grouting material for pavement repair and its preparation method

The invention relates to a double-mixed grouting material for pavement restoration and a preparation method thereof, comprising 50-70 parts of Portland cement, 20-30 parts of aluminate cement, and 5-8 parts of silica fume in terms of parts by mass , 10-15 parts of fly ash, 8-12 parts of barite powder, 1-3 parts of retarder, 10-15 parts of water-based epoxy resin, 3-8 parts of polyurethane, 0.5-0.8 parts of antioxidant, stable defoaming 0.1-0.3 parts of agent, 1-4 parts of coupling agent, 0.3-0.5 parts of surfactant, 3-8 parts of waste rubber powder, 0.05-0.2 parts of cement strengthening agent, and 0.1-0.3 parts of water-retaining agent. The material prepared by the invention has high permeability, impact resistance and wear resistance, high strength, high toughness, high temperature resistance and good durability, can consolidate loose particles and has good bonding performance with the original pavement concrete, and is suitable for many A road repair.

Owner:CHANGAN UNIV

Concrete thin-layer repair polymer mortar and preparation method thereof

ActiveCN107777922BGood wear resistance and repair abilityEasy to adjustPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

The invention provides concrete thin-layer repairing polymer mortar and a preparation method thereof and relates to the field of mortar. The concrete thin-layer repairing polymer mortar is prepared from the following raw materials in weight ratio: two-component slow reaction type polyurea waterproof coating and a sand material, wherein the weight ratio of the two-component slow reaction type polyurea waterproof coating to the sand material is 1:(1-3). By utilizing the concrete thin-layer repairing polymer mortar, the problem that polymer mortar in the prior art cannot well repair a concrete building component can be solved, and the concrete thin-layer repairing polymer mortar has the advantages of good bonding performance, corrosion resistance and scour and wear resistance.

Owner:XINJIANG KENENG WATERPROOF & PROTECTION TECH CO LTD

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

Anti-impact wear-resistant concrete for hydraulic engineering and preparation method thereof

InactiveCN114702283AChange the acid-base environmentReduce adverse effectsSolid waste managementBacillus licheniformisFiber

The invention discloses impact-resistant and wear-resistant concrete for a water conservancy project. The impact-resistant and wear-resistant concrete is prepared from the following raw materials in parts by weight: 73-81 parts of Portland cement, 41-49 parts of yellow phosphorus slag, 20-30 parts of ardealite powder, 5-10 parts of basophilic bacillus licheniformis, 15-22 parts of brown aluminum oxide, 0.1-0.3 part of polypropylene split film fibers, 3-6 parts of a water reducing agent and 113-129 parts of gravel. The preparation method comprises the following steps: grinding the Portland cement, the yellow phosphorus slag, the brown aluminum oxide and the sandstone to obtain ground powder A; grinding the ground powder A, ardealite powder and polypropylene split film fibers again to obtain ground powder B; calcining the ground powder B at the temperature of 610-630 DEG C to obtain calcined powder; and cooling the calcined powder to normal temperature, doping the basophilic bacillus licheniformis and the water reducing agent, and uniformly stirring. The concrete prepared by the invention is impact-resistant, wear-resistant and long in service life.

Owner:吕书波

High-performance aluminum profile for color sorter rice channel

InactiveCN109772668AFlat surfaceSimple processPretreated surfacesEpoxy resin coatingsGasolineWear resistance

The invention discloses a high-performance aluminum profile for a color sorter rice channel. The high-performance aluminum profile for the color sorter rice channel comprises an aluminum profile matrix and a high-performance coating applied to the surface of the aluminum profile matrix. A technology comprises the following steps that firstly, the aluminum profile matrix is degreased with gasoline,washed with deionized water, then subjected to passivating treatment by adopting a chromizing agent and washed with the deionized water; and secondly, the aluminum profile matrix is dried to have theconstant weight, polished to be smooth with abrasive paper, coated with the high-performance coating, cured and cooled, and the high-performance aluminum profile for the color sorter rice channel isobtained. According to the high-performance aluminum profile for the color sorter rice channel, the aluminum profile matrix is treated through the two processes of degreasing through the gasoline andpassivating through the chromizing agent, the aluminum profile matrix obtains the smooth treated surface after being polished before coating is conducted, then the aluminum profile matrix is coated with the high-performance coating, the wear resistance is good, the technology is simple and easy to operate, and the cost is low.

Owner:安徽鑫铂铝业股份有限公司

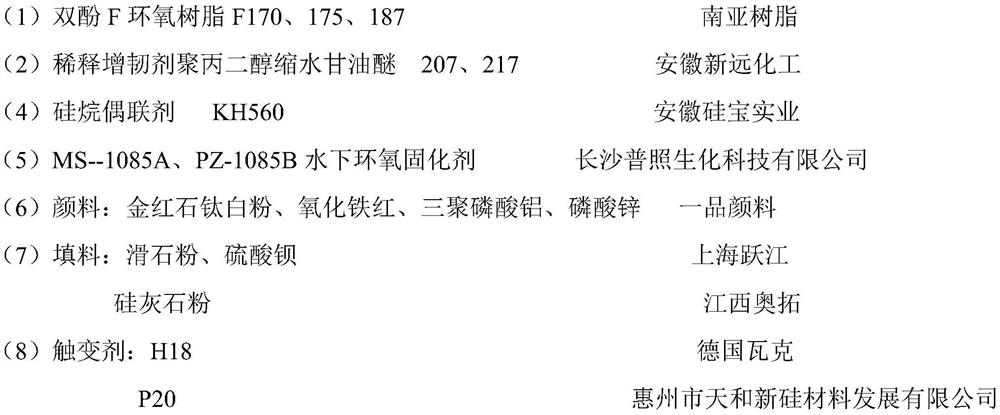

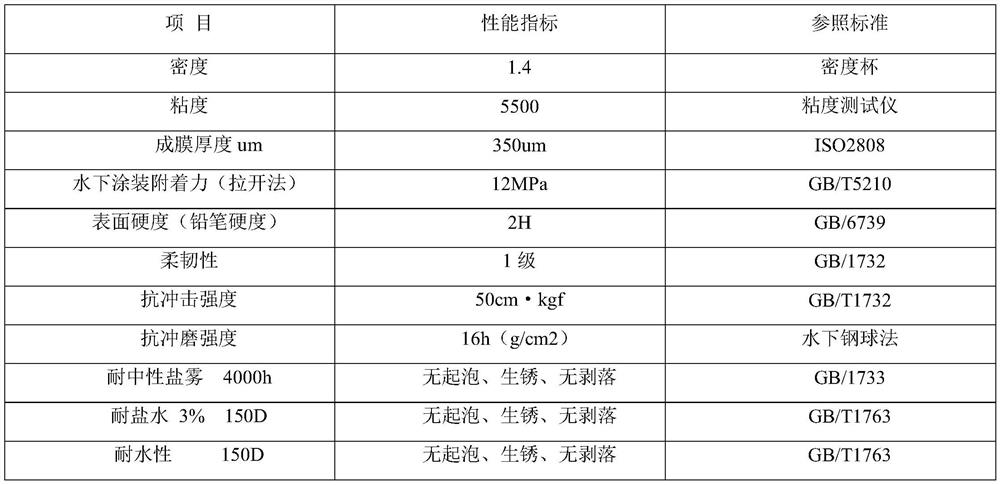

A kind of underwater composite anti-corrosion coating and preparation method thereof

ActiveCN110172288BNo pollution in the processNon-irritatingAnti-corrosive paintsEpoxy resin coatingsTitanium coatingCeramic coating

The invention relates to an anti-corrosion coating for underwater coating, which belongs to the field of protection engineering, and is especially suitable for the inner wall of water diversion pressure steel pipes, the fixed guide vanes of generator sets, gates and other facility metal structural parts, as well as stilling pools, overflow spillways, pickets, etc. Concrete structure facilities such as runnose width are repaired and maintained with water, and double protection against corrosion and abrasion is provided. The epoxy nano-titanium coating comprises epoxy resin, auxiliary agent, milling medium solution, titanium powder, underwater epoxy curing agent and thixotropic agent. The ceramic resin paint comprises a flexible liquid ceramic resin, a diluent, an underwater curing agent for surface coating, and a thixotropic agent. The present invention adopts a unique composite coating combined with underwater nano-titanium epoxy anti-corrosion coating and liquid flexible anti-abrasion ceramic coating. superior to existing technologies.

Owner:长沙普照材料科技有限责任公司

Anticorrosion epoxy powder paint used outside marine steel pipe pile

ActiveCN101724331BImprove scratch resistanceGood resistance to cathodic disbondmentAnti-corrosive paintsEpoxy resin coatingsGas phaseUltraviolet

The invention provides an anticorrosion epoxy powder paint used outside a marine steel pipe pile, which is characterized in that, the formula of the anticorrosion epoxy powder paint comprises the following components in percentage by weight: 40-60 percent of phenol-modified epoxy resin, 0-20 percent of bisphenol A epoxy resin, 0-20 percent of linear phenol curing agent, 5-25 percent of phenol curing agent, 0.3-1.5 percent of 2-phenylimidazole, 0.2-1 percent of silane coupling agent, 0.2-3 percent of gas phase white carbon, 0-2 percent of hydroxy-phenyl benzotriazole ultraviolet absorbent and hindered amine light stabilizer, 0-5 percent of modified polyfluortetraethylene wax, 5-25 percent of glass powder, 5-30 percent of talcum powder, silicon powder and mica powder, 5-10 percent of aluminium triphosphate, iron red, rutile titanium pigment and cuprous oxide and 0-3 percent of pigment. The paint provided by the inventon has the advantages that the surface roughness of a coating satisfies the required built-in strength of a steel pile and the marine geological condition of the steel pile, and the paint has the characteristics of excellent scratch resistance, shock resistance, abrasion resistance, marine biological fouling resistance, ageing resistance, ultraviolet irradiation resistance and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com