Anti-impact wear-resistant concrete for hydraulic engineering and preparation method thereof

A technology for water conservancy engineering and concrete, applied in the fields of hydroelectric power generation, sustainable waste treatment, solid waste management, etc., can solve the problems of difficult implementation and maintenance of underwater engineering, accelerated wear of concrete, etc., to improve anti-drying and anti-erosion performance. , The effect of compactness inside concrete and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

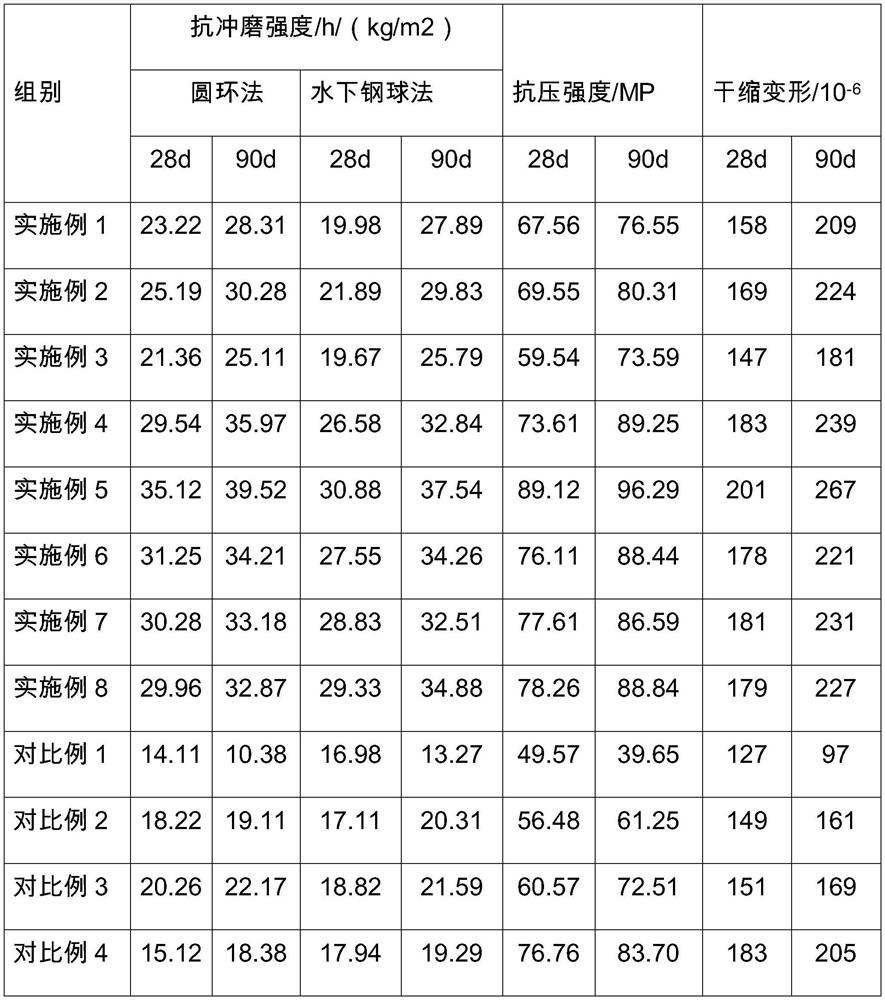

Examples

Embodiment 1

[0027] A kind of impact-resistant and wear-resistant concrete for hydraulic engineering, comprising the following raw materials by weight: 73 parts of Portland cement (Conch brand XK08-001-04054, the same below), 41 parts of yellow phosphorus slag, 20 parts of phosphogypsum powder, 5 parts of alkalophilic Bacillus licheniformis (purchased from Shandong Changsong Biotechnology Co., Ltd., the same below), 15 parts of brown corundum, 0.1 part of polypropylene film split fiber (purchased from Langfang Yuanneng New Building Materials Co., Ltd., the same below), 3 parts Parts of water-reducing agent (ZM-1 aliphatic high-efficiency water-reducing agent, purchased from Xuzhou Xingu Building Materials Technology Co., Ltd.), 113 parts of sand and gravel, its preparation method is:

[0028] S1. Prepare raw materials according to the ratio;

[0029] S2, grind described Portland cement, yellow phosphorus slag, brown corundum and sand to obtain grinding powder A, and the specific surface ar...

Embodiment 2

[0034] An impact-resistant and wear-resistant concrete for water conservancy projects, comprising the following raw materials by weight: 78 parts of Portland cement, 43 parts of yellow phosphorus slag, 21 parts of phosphogypsum powder, 6 parts of alkalophilic Bacillus licheniformis, and 17 parts of brown corundum , 0.2 parts of polypropylene film split fibers, 4 parts of water-reducing agent (ZM-1 aliphatic superplasticizer, purchased from Xuzhou Xingu Building Materials Technology Co., Ltd.), 116 parts of sandstone, its preparation method is:

[0035] S1. Prepare raw materials according to the ratio;

[0036] S2, grind described Portland cement, yellow phosphorus slag, brown corundum and sand to obtain grinding powder A, and the specific surface area of described grinding powder A is 340m 2 / kg;

[0037] S3. Grinding the ground powder A, the phosphogypsum powder, and the polypropylene film split fiber again to obtain a ground powder B, the specific surface area of the gr...

Embodiment 3

[0041] An impact-resistant and wear-resistant concrete for water conservancy projects, comprising the following raw materials by weight: 79 parts of Portland cement, 45 parts of yellow phosphorus slag, 27 parts of phosphogypsum powder, 9 parts of alkalophilic Bacillus licheniformis, and 21 parts of brown corundum , 0.2 parts of polypropylene film split fibers, 5 parts of water-reducing agent (ZM-1 aliphatic superplasticizer, purchased from Xuzhou Xingu Building Materials Technology Co., Ltd.), 123 parts of sand and gravel, its preparation method is:

[0042] S1. Prepare raw materials according to the ratio;

[0043] S2, grind described Portland cement, yellow phosphorus slag, brown corundum and sand to obtain grinding powder A, and the specific surface area of described grinding powder A is 360 m 2 / kg;

[0044] S3. Grinding the ground powder A, the phosphogypsum powder, and the polypropylene film split fiber again to obtain a ground powder B, the specific surface area of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com