Patents

Literature

30results about How to "Achieve wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-fog resin lens with hydrophilic factors in surface film layer and preparation method of anti-fog resin lens

ActiveCN104656166AAchieve wear resistanceTo achieve the purpose of long-term anti-fogCoatingsOptical elementsRelease timeHardness

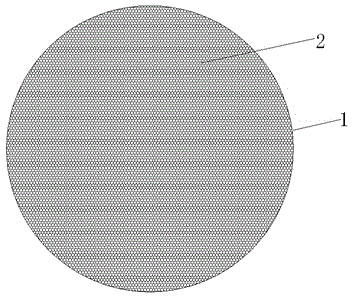

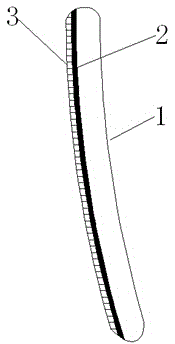

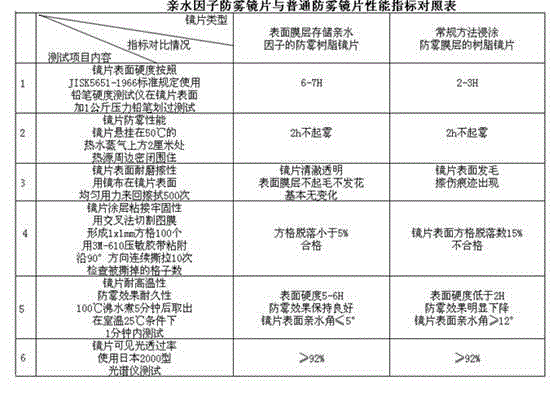

The invention discloses an anti-fog resin lens with hydrophilic factors in a surface film layer. The anti-fog resin lens is composed of a resin substrate, a hardened storage grid film layer and a hydrophilic factor slow-release anti-fog film layer. The anti-fog resin lens is characterized in that the hardened storage grid film layer is printed on the surface of the resin substrate; and the outside of the hardened storage grid film layer is coated with the hydrophilic factor slow-release anti-fog film layer to form a hydrophilic factor slow-release anti-fog film layer. According to the anti-fog resin lens, an anti-fog coating is stored when the hardness of the surface of the resin lens is ensured; the release time of the hydrophilic factors in the anti-fog coating is retarded; and the targets that the lens has friction and scratch resistance and long-acting anti-fog effect are reached.

Owner:WANXIN OPTICAL GRP

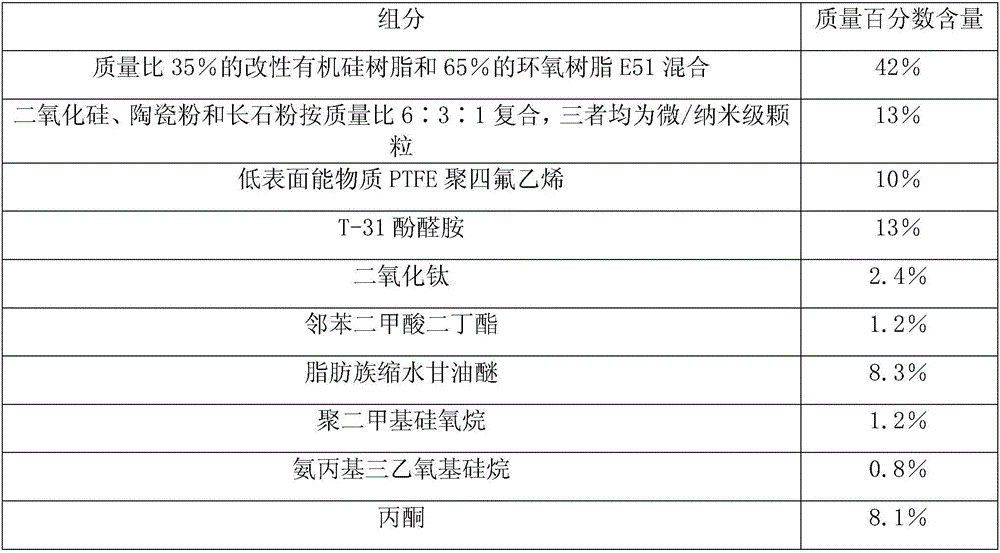

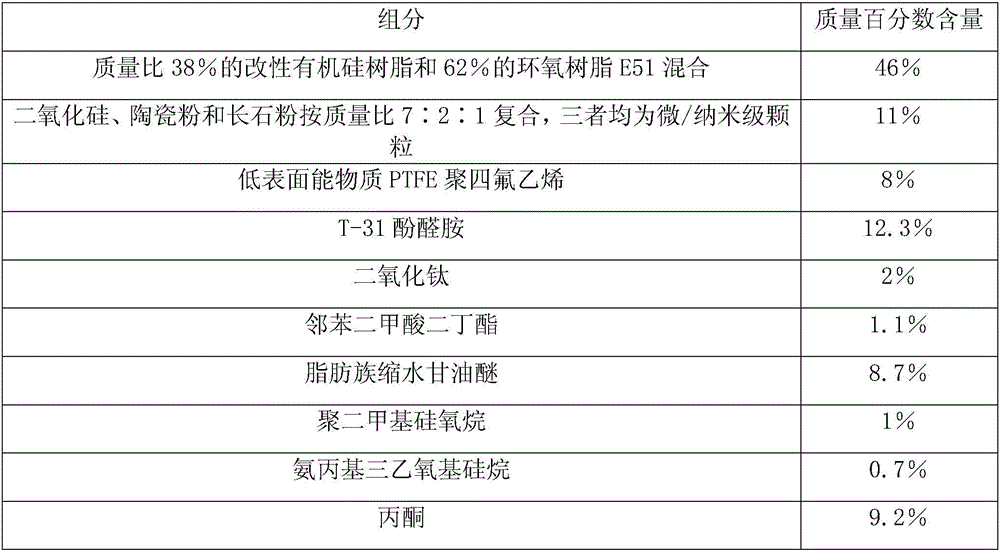

Hydrophobic corrosion-resistant ceramic paint and preparing method thereof

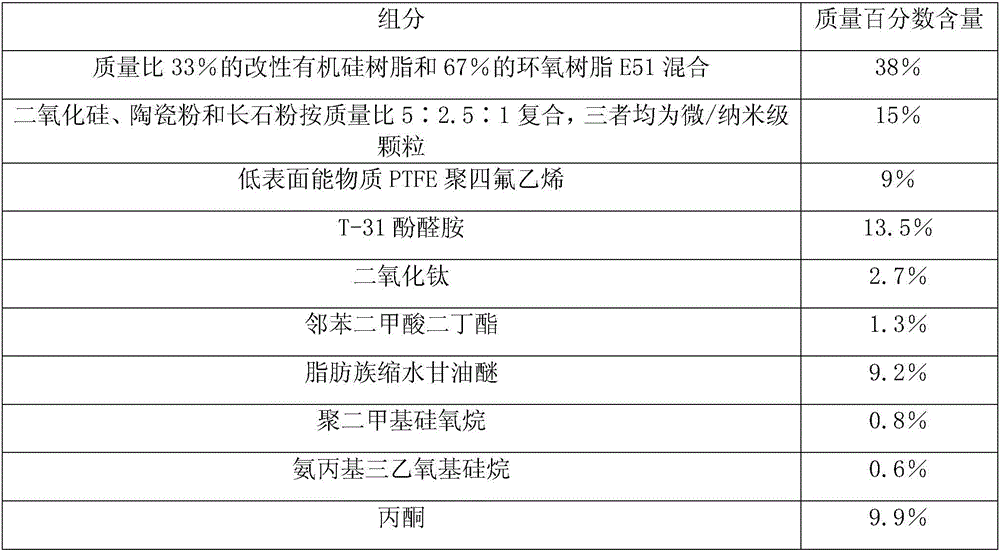

InactiveCN106010122AImprove performanceStrong adhesionAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceEpoxy

The invention discloses a hydrophobic anti-corrosion ceramic coating, which uses epoxy resin and modified silicone resin as a film-forming material, and adds various fillers, auxiliary agents and solvents, including body fillers, pigments and fillers, curing agents, coloring Agent, toughener, diluent, leveling agent, epoxy coupling agent and solvent. The hydrophobic anti-corrosion ceramic coating of the present invention has stable performance, strong adhesion, excellent salt water resistance, strong acid and alkali corrosion resistance, good weather resistance, high hardness, and excellent wear resistance; and it is environmentally friendly and non-toxic (low VOC), and has Good protection, decoration and functional effects, low price of raw materials, simple preparation method, suitable for the surface of metal substrates that need to be protected under harsh corrosion environments.

Owner:GUANGXI UNIV

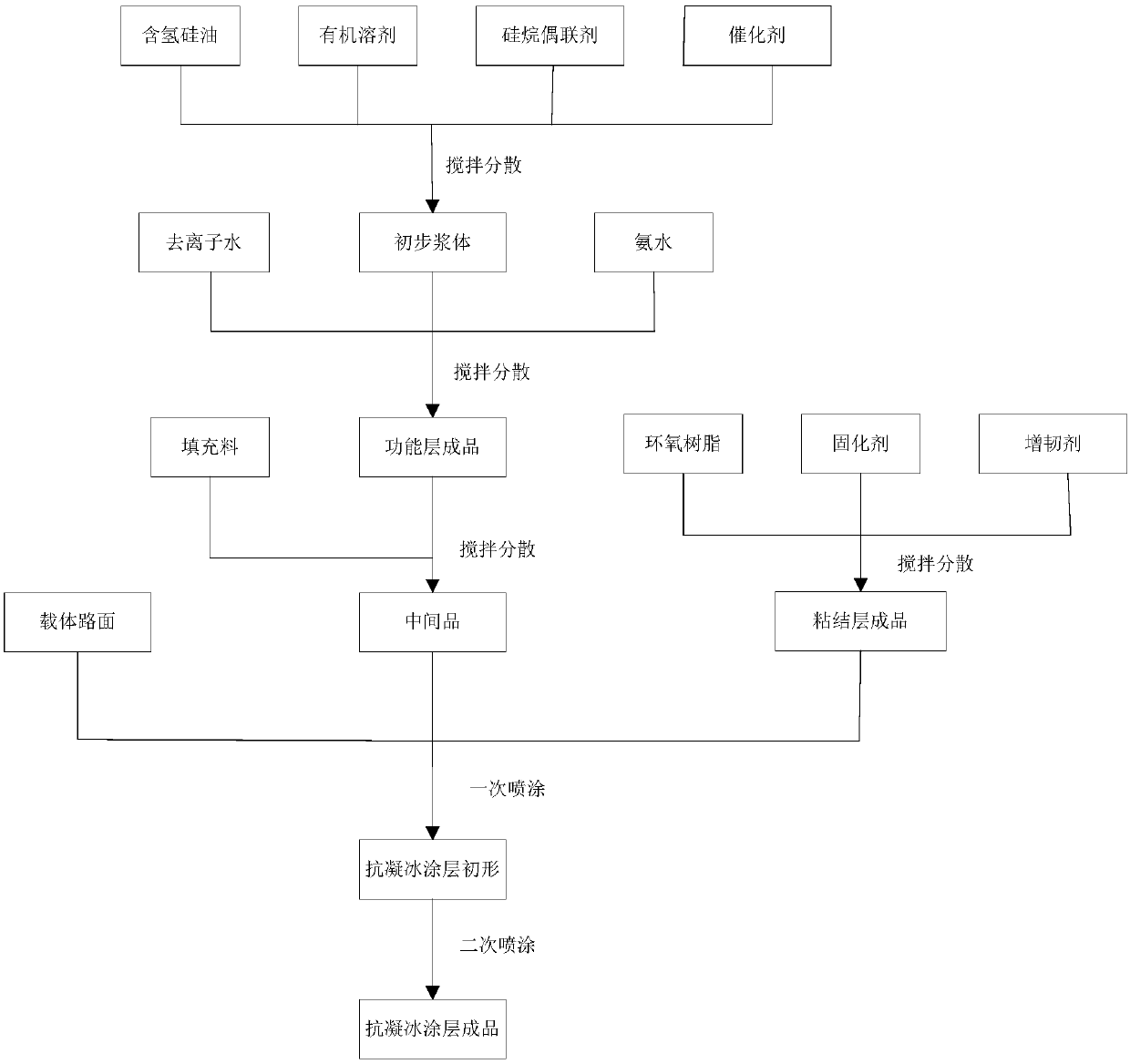

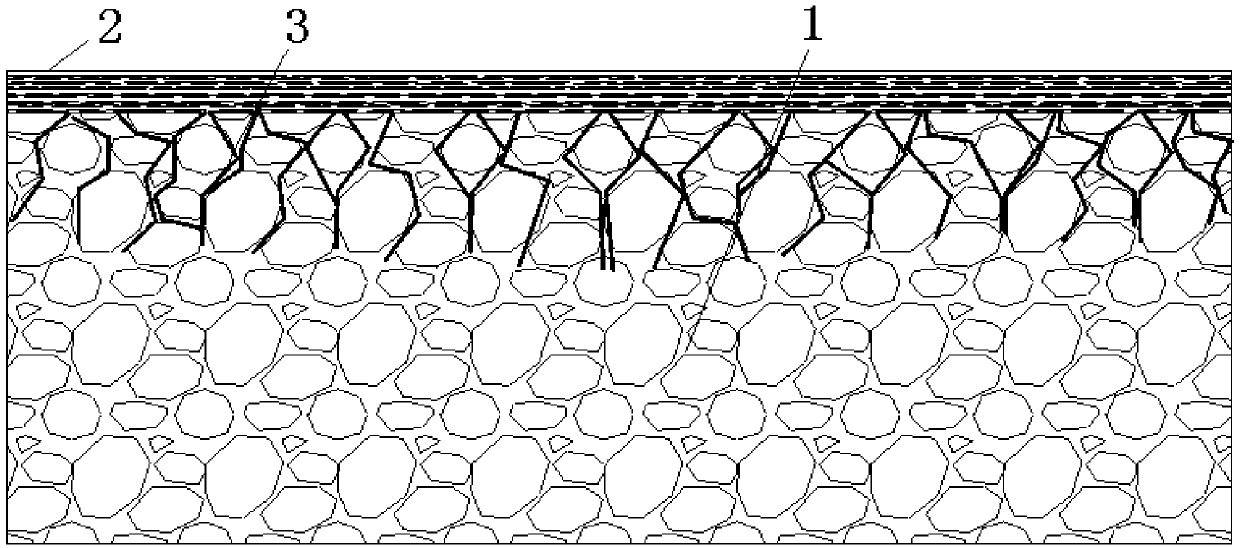

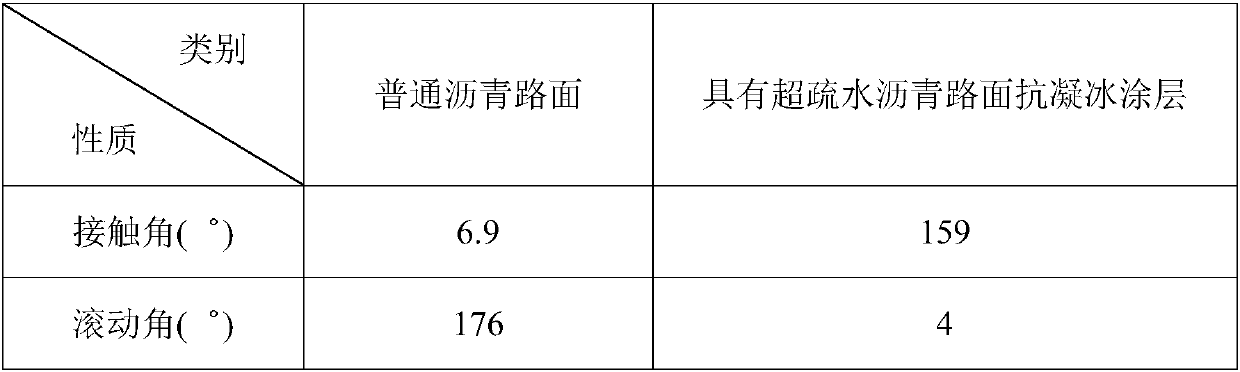

Super-hydrophobic asphalt pavement anti-freezing coating and preparing method thereof

ActiveCN109627974ASuperhydrophobicTo achieve the effect of anti-icingPaving detailsCoatingsEpoxySlurry

The invention belongs to the technical field of the design of asphalt concrete pavement coatings, and relates to a super-hydrophobic asphalt pavement anti-freezing coating and a preparing method thereof. The coating comprises an adhesive layer arranged on the surface of a carrier pavement, a functional layer arranged on the surface of the adhesive layer, and anti-wear filler dispersed in the functional layer. The functional layer is a low-surface-energy material. Slurry of the adhesive layer is formed by mixing epoxy resin 128, an amine curing agent and an epoxy toughening agent 277. Slurry ofthe functional layer is formed by mixing MHX-1107 hydrogen-containing silicone oil, gamma-aminopropyl triethoxysilane, dibutyltin dilaurate, absolute ethyl alcohol, ammonium hydroxide and deionized water. The anti-wear filler is evenly dispersed in the slurry of the functional layer. The performance of the super-hydrophobic asphalt pavement anti-freezing coating can completely meet the requirements for super hydrophobicity, freezing resistance, wear resistance, high friction coefficient and the like.

Owner:CHANGAN UNIV

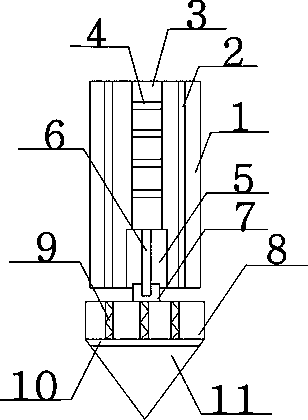

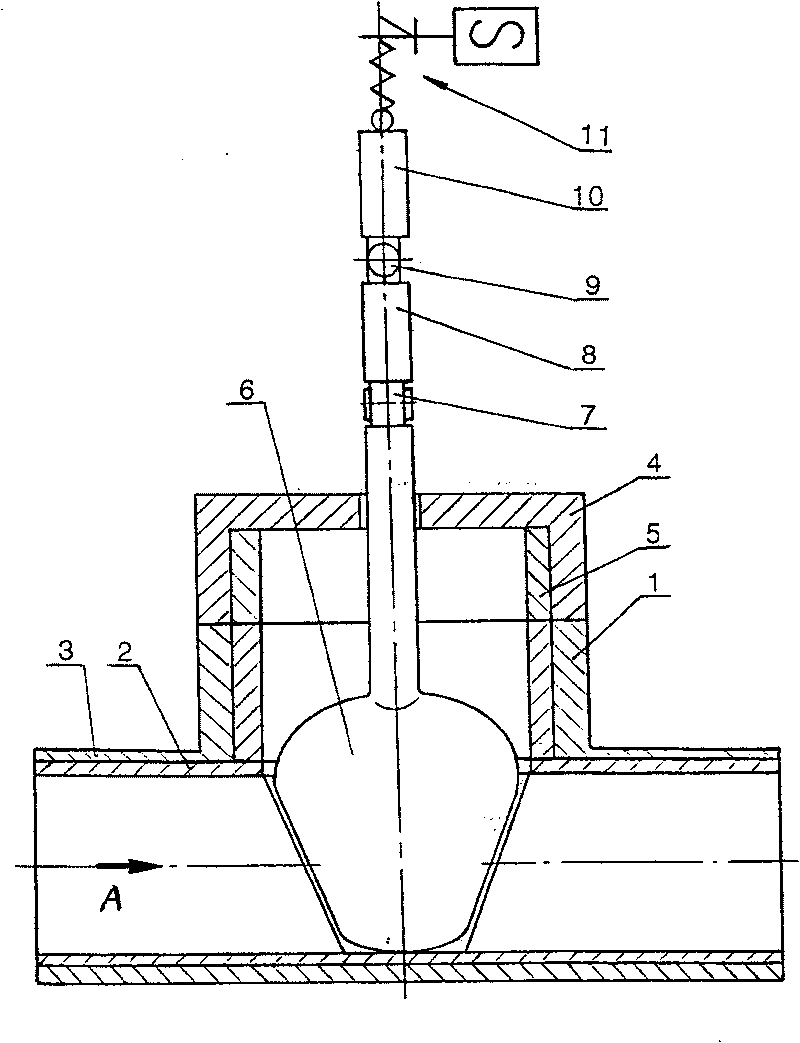

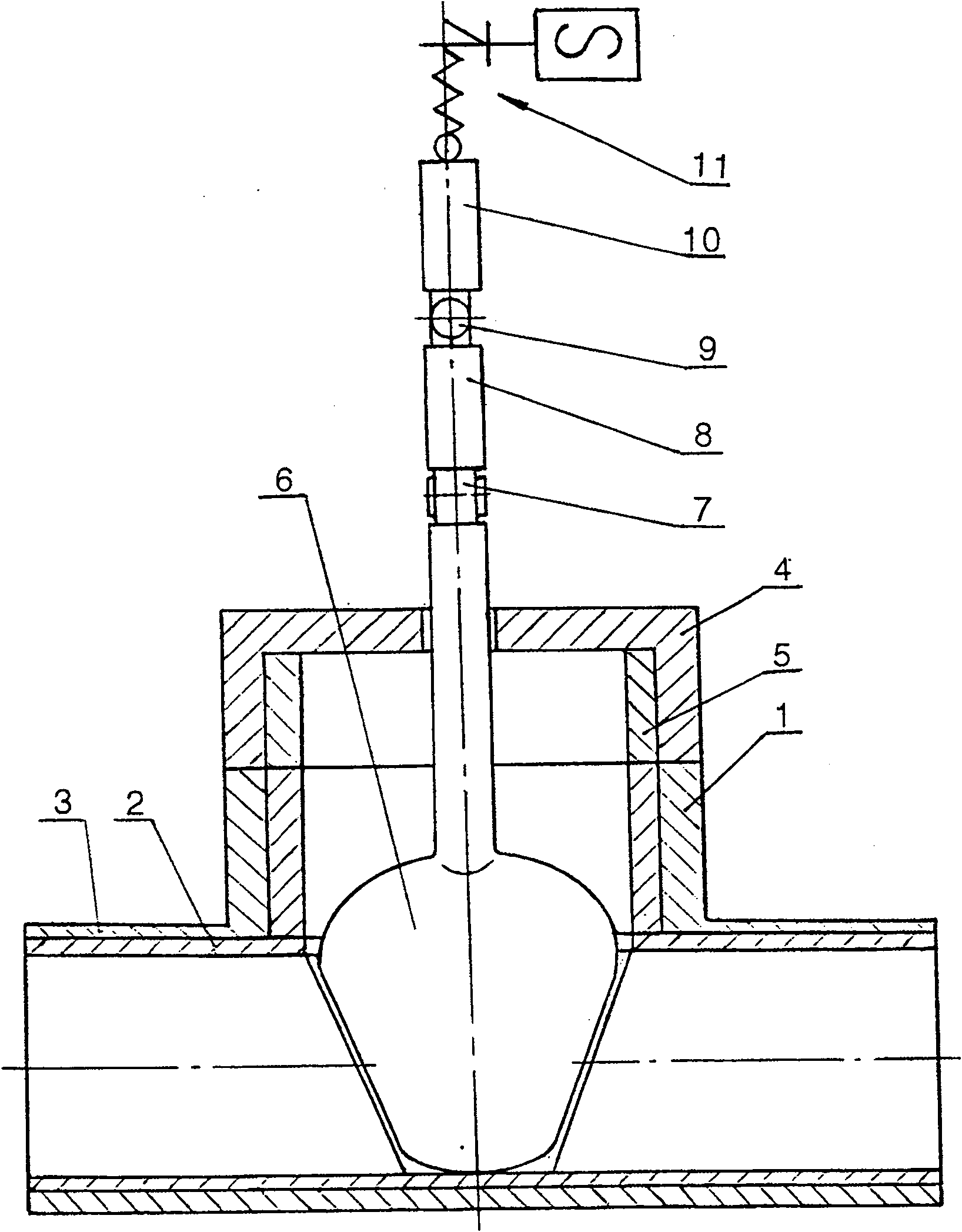

Mechanical punching pile

InactiveCN104213558AEasy to punchGood vibration dampingEarth drilling toolsBulkheads/pilesHydraulic cylinderPunching

The invention discloses a mechanical punching pile. The mechanical punching pile comprises a hole pile barrel, wherein two cement pipelines are vertically arranged in the hole pile barrel; a reinforced rib plate is arranged between the two cement pipelines; a wear-resistant material layer is transversely arranged on the reinforced rib plate; the bottom of the reinforced rib plate is provided with a hydraulic cylinder; the reinforced rib plate is mechanically connected with the hydraulic cylinder; a hydraulic shaft is arranged in the hydraulic cylinder; the top of the hydraulic shaft passes through the hydraulic cylinder, and is mechanically connected with the reinforced rib plate; the bottom of the hydraulic shaft extends into a protection groove; the bottom of the protection groove is positioned on a motor, and is connected with the motor through a mechanical shaft; the motor is movably connected with the hydraulic shaft through a connecting rod; an anti-shock device is arranged in the motor. The mechanical punching pile is convenient for punching, and has a good damping function; when a drill bit is not extracted from a hole, cement slurry is introduced through the cement pipelines to fill the hole; moreover, a certain wear resisting effect can be achieved, and the component replacing frequency is lowered; furthermore, the motor is arranged on the lower part of the hole pile barrel, so that the motor can be protected to a certain degree.

Owner:浙江冶民园林工程有限公司

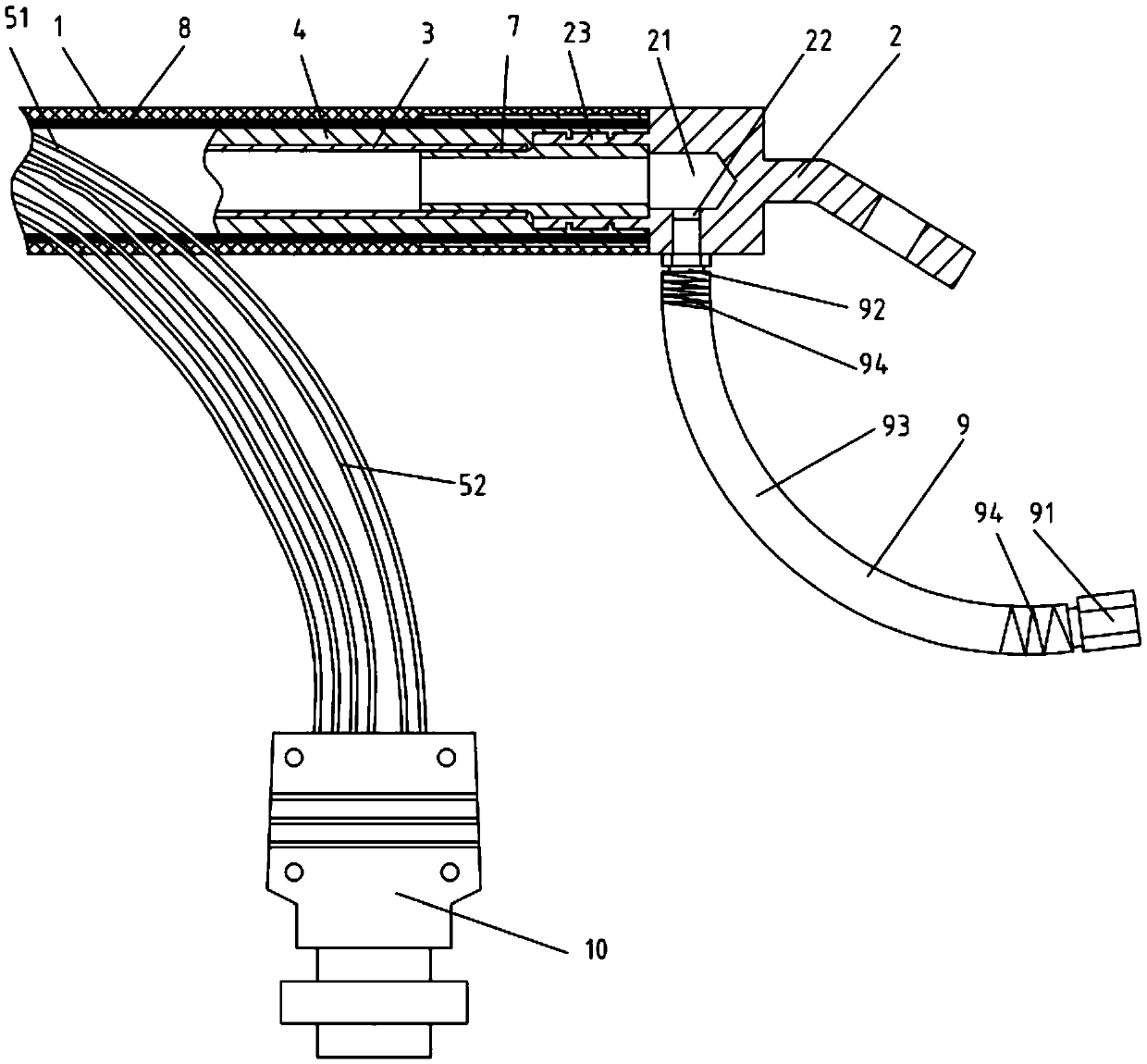

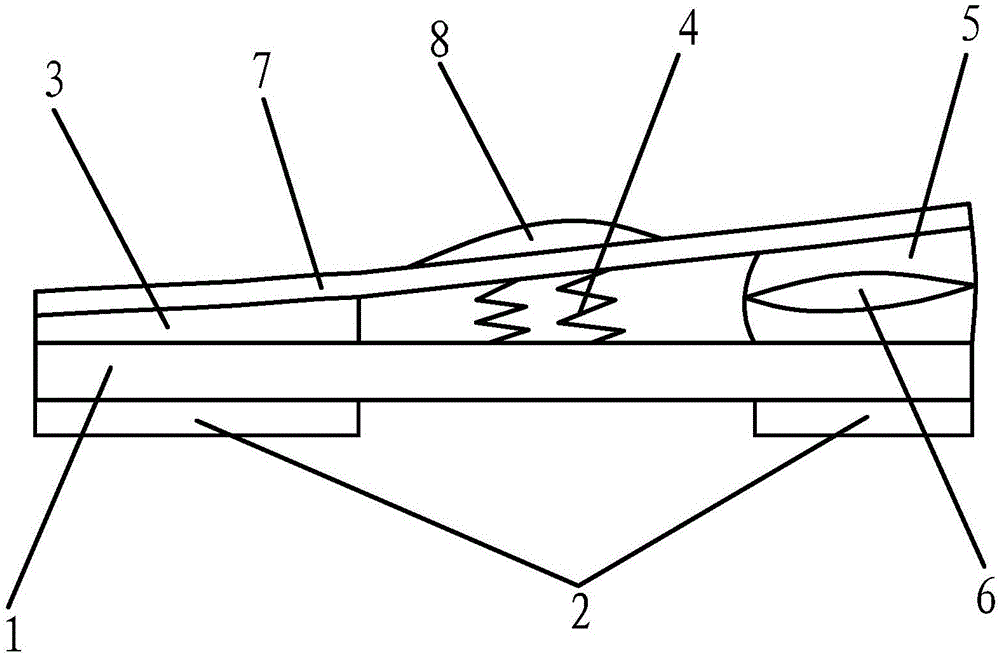

Complex cable special for welding

ActiveCN105514730AFirmly connectedEasy to useSleeve/socket jointsPower cables including communication wiresElectrical conductor

The invention discloses a complex cable special for welding, comprising an outer sheath, a connection terminal internally provided with a gas passage capable of being externally connected with a gas source, a gas pipe wrapped inside the outer sheath and communicated with the gas passage of the connection terminal, a cable conductor filled between the outer sheath and the gas pipe and electrically connected with the connection terminal, and a control wire core group provided with a main body part and an extending connection part, wherein the main body part of the control wire core group fills a place between the outer sheath and the gas pipe, and the extending connection part of the control wire core group extends to be outside the outer sheath. According to the complex cable, the cable conductor, a control wire, the gas pipe and the like are manufactured in an integrated way, so the use requirements on wear resisting and burning resisting are met, the use is very convenient, the appearance is attractive, materials are saved, and the use quality is improved.

Owner:CHANGZHOU WULIAN ELECTRIC WELDING & CUTTING EQUIP

High-toughness wallpaper and method for preparing same

InactiveCN106320093AImprove toughnessImprove toughness and strengthCovering/liningsSpecial paperGlass fiberEpoxy

The invention discloses a method for preparing high-toughness wallpaper. The method includes (1), adding plant fibers into water and grinding and treating the plant fibers to obtain primary pulp; (2), mixing modified glass fibers, phthalocyanine, epoxy resin, phthalate, fatty acid sodium and diluents with one another to obtain auxiliaries; (3), adding the auxiliaries into the primary pulp to obtain mixtures, adding water into the mixtures to dilute the mixtures and then forming and drying the mixtures by the aid of professional equipment to obtain the high-toughness wallpaper. A weight ratio of the auxiliaries to the primary pulp is 1:30-40; the lengths of the modified glass fibers are 80-100 micrometers. The method has the advantages that the high-toughness wallpaper prepared by the aid of the method is high in toughness and tensile strength, and good abrasion-resistant effects can be realized by the high-toughness wallpaper.

Owner:安徽金生金世电子科技有限公司

High-strength wear-resistance steel

The invention discloses high-strength wear-resistance steel. The steel comprises, by weight, 3.9-4.5% of carbon, 0.6-0.8% of tungsten, 1.3-2.5% of copper, 1.2-1.8% of rare earth, 4-6% of manganese, 2.9-3.9% of chromium, 0.7-1.5% of nickel, 0.02-0.04% of sulphur and the balance ferrous. Compared with the prior art, the steel has the advantages that the content of the carbon is reasonably defined, the proportioning between the nickel, the chromium and the carbon is particularly defined, other material components with an appropriate proportion are selected, so that manufactured protecting plateshave extremely high hardness and more importantly have better toughness, the protecting plates have the advantages of wear resistance, impact resistance and the like, all requirements on mechanical performance during the ball blast process are met, the service life is prolonged, the performance of an alloy structure is improved by using strong to perform rapid cooling and reasonable quenching process, finally the hardness of the alloy reaches HRC 150-165, the impacting toughness is good, the comprehensive mechanical performance is good, manufactured products reach the performance requirementsof wear resistance and moderate impact, and the service life of the alloy is 10-12 times longer than Hadfield's manganese steel.

Owner:ZHENJIANG SUBAIXIN CONSTR MACHINERY CO LTD

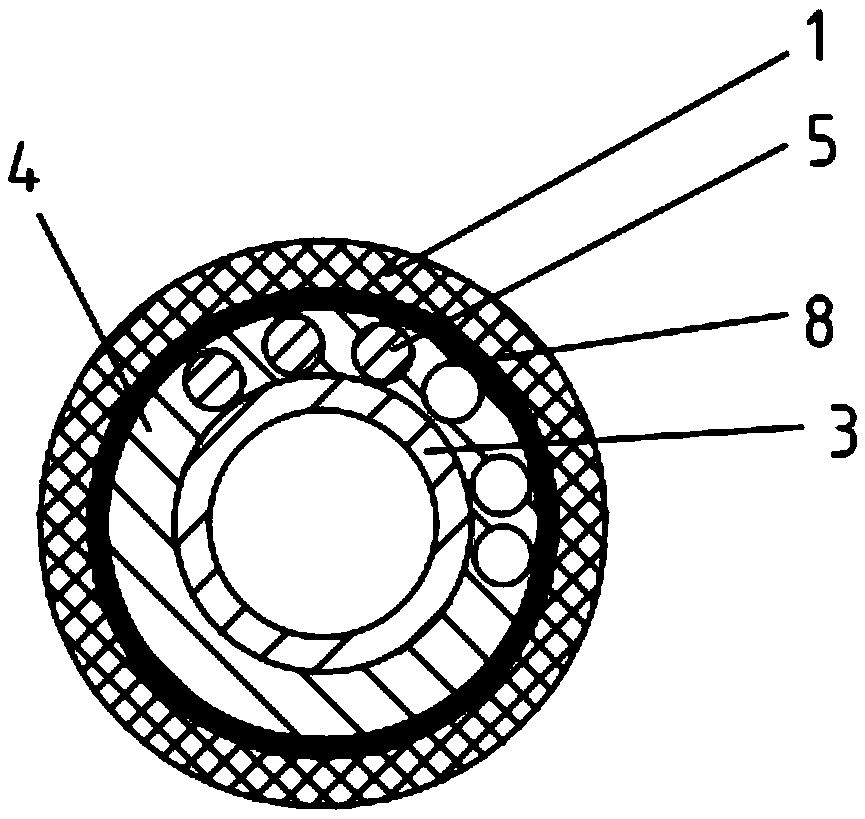

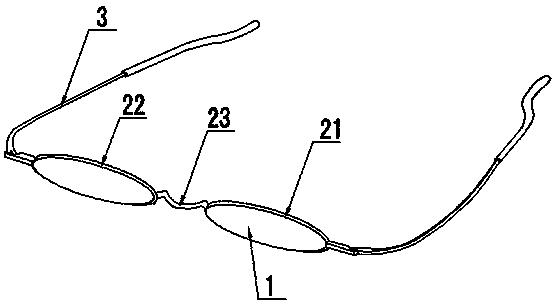

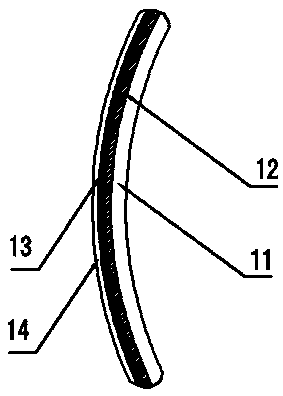

Nasal stent-free discoloration antifogging glasses

InactiveCN108089344AReduce installationAchieve wear resistanceNon-optical partsOptical partsPhysicsProduction rate

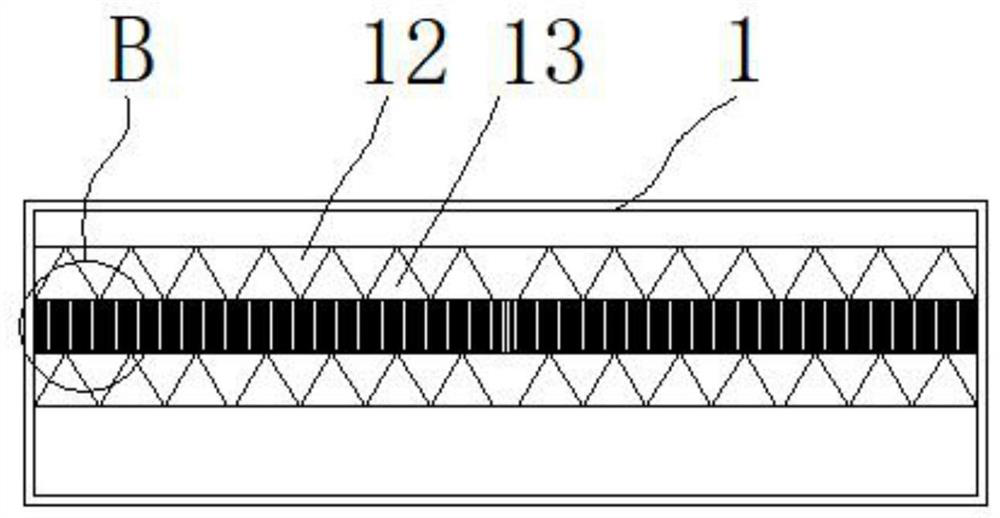

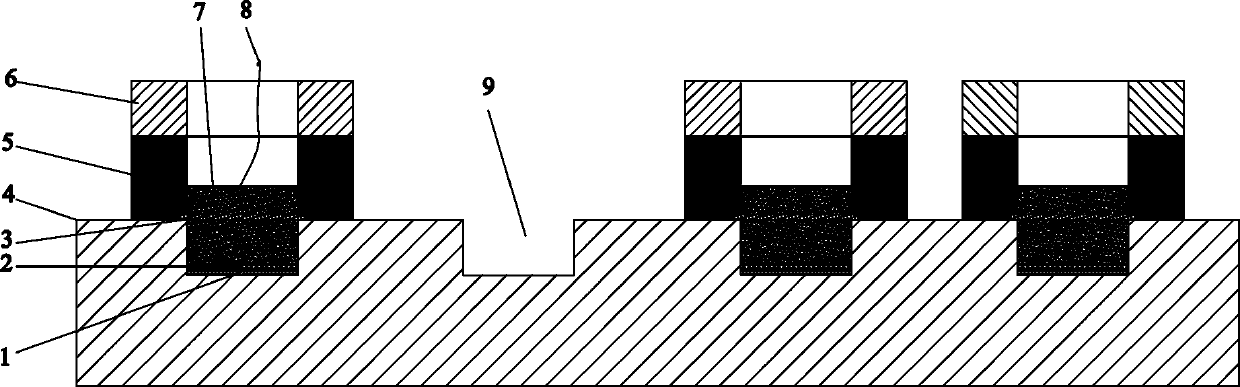

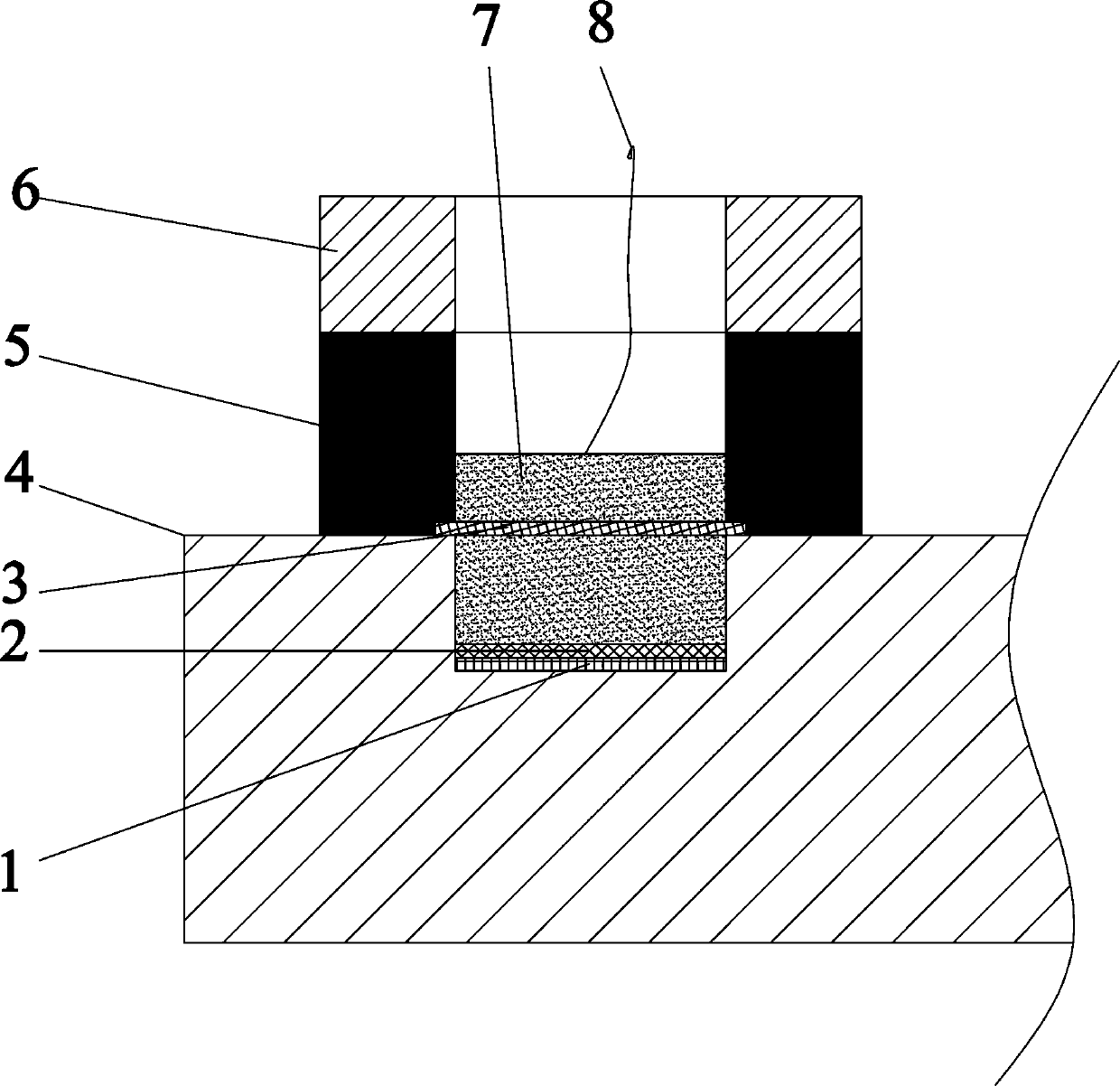

The invention relates to nasal stent-free discoloration antifogging glasses. The glasses includes a W-shaped cross beam (23), the space between the two low points of the W shape is an arc, and the cross beam is supported on a nose bridge through the two low points of the W shape. Each spectacle lens consists of a resin substrate (11), a hardened storage grid film layer (12), an antifogging film layer (13) and a discoloration material film layer (14), the hardened storage grid film layer (12) is printed on the resin substrate (11) surface, the antifogging film layer (13) is dip coated outside the hardened storage grid film layer (12), and the discoloration material film layer (14) is coated outside the antifogging film layer (13). The nasal stent-free discoloration antifogging glasses provided by the invention eliminates nasal stent mounting, improves the productivity, also saves the cost, and has beautiful appearance.

Owner:DANYANG TELUOYI GLASSES CO LTD

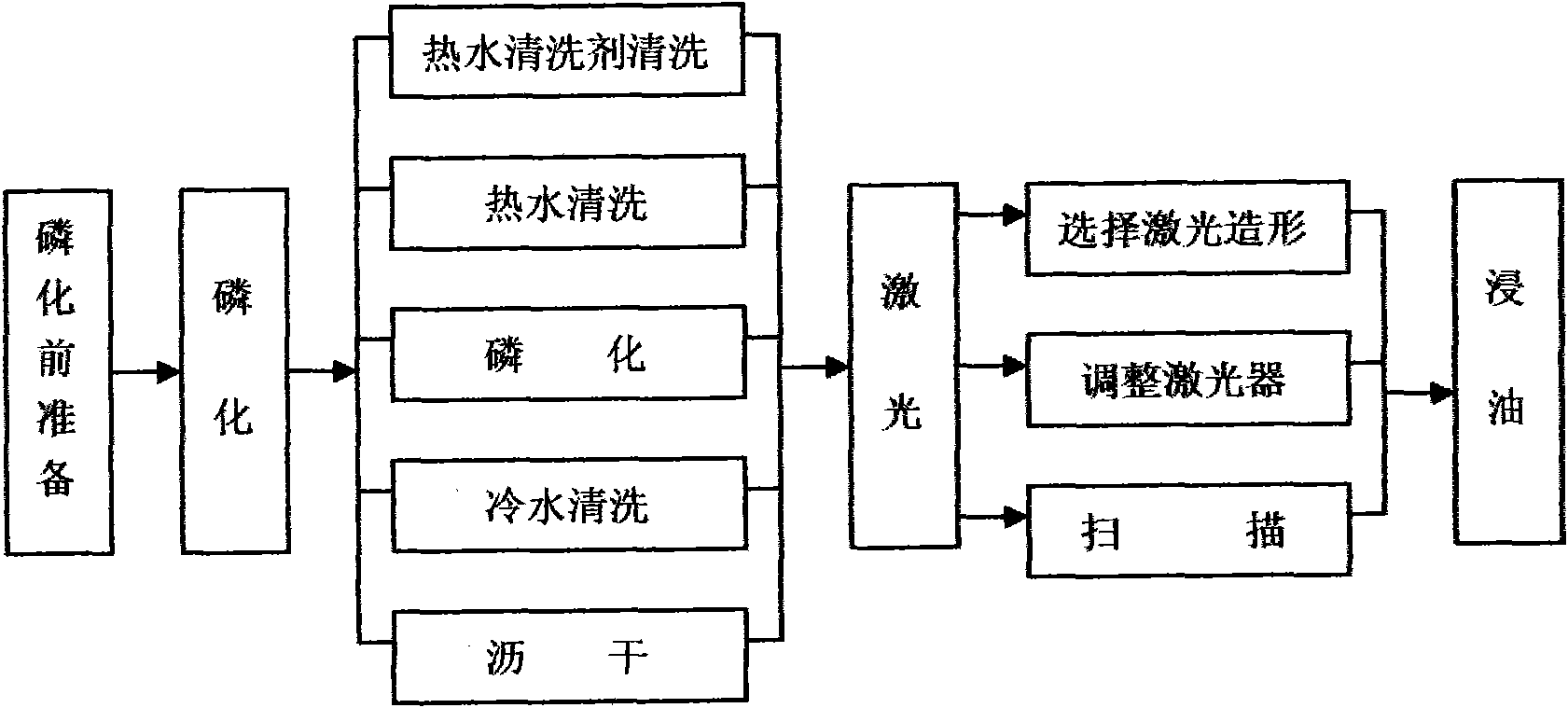

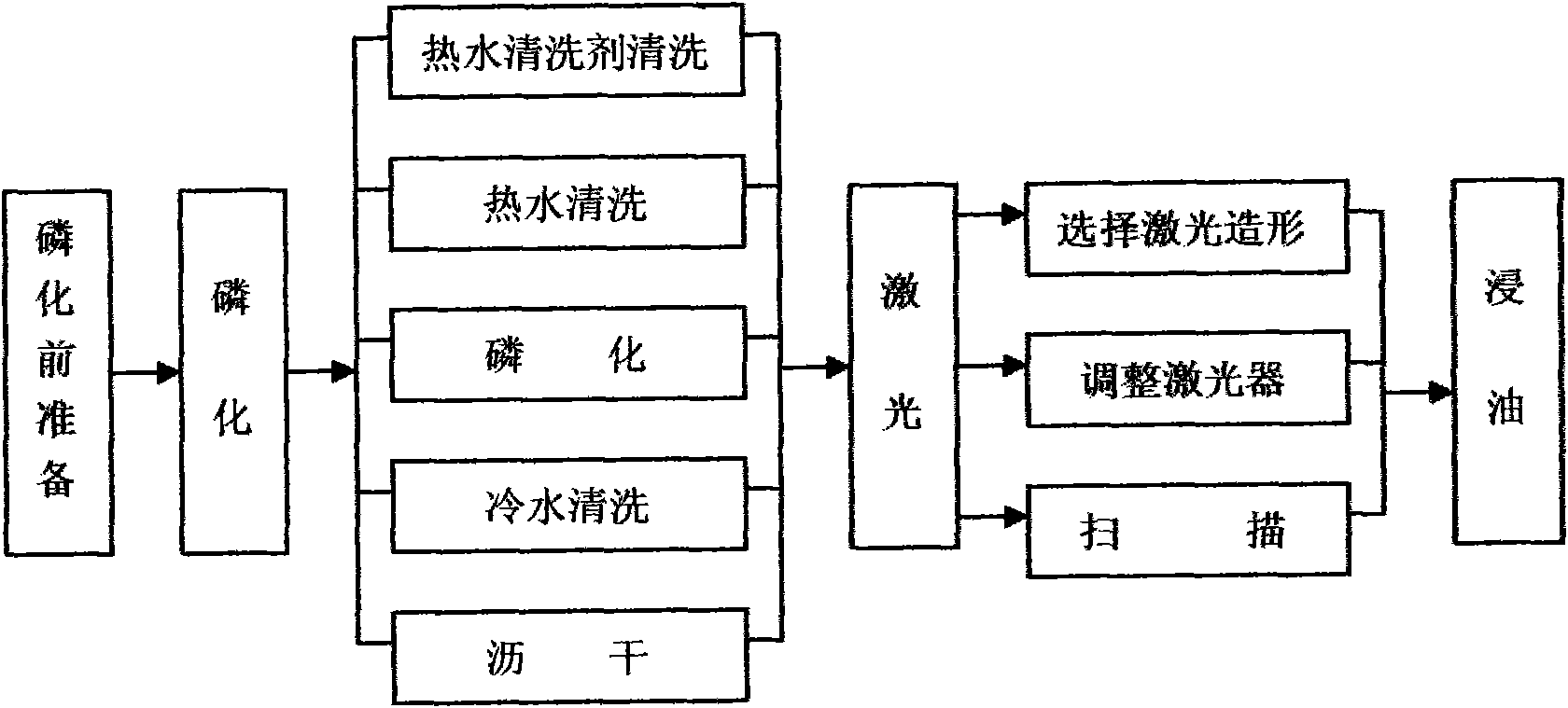

Application of laser honing technology to cylinder sleeve of motorcycle

The invention provides application of a laser honing technology to a cylinder sleeve. Laser and a honing technology are combined, the deformation of laser processing is 1 / 20-1 / 30 of that of the conventional heat treatment, the deformation is very small, the original state of the cylinder sleeve before the laser processing is basically kept, and the cylinder sleeve has good sealing and pairing properties with a piston and a piston ring; metal is heated through laser radiation at a rate of (3-5)*103DEG C / S, the heating rate is improved by tens of times than that of the conventional heating method, the heated cylinder sleeve is cooled by means of self heat conductivity, and the cooling rate is 900DEG C / S and is higher than that of the conventional quenching medium, so that a structure subjected to laser quenching is different from that subjected to the conventional quenching, the temperature of the structure subjected to laser quenching is decreased progressively from the surface to the core, and an ideal structure state is obtained; the maximum hardness number of the laser quenching is HRC66 which is higher than the hardness number of HRC54 of the conventional quenching, and the depth of a quenching layer is 3-3.5 millimeters, so that the inner surface of the cylinder sleeve meets the requirement of high wear resistance; the laser quenching comprises helix laser quenching and network laser quenching; and the width of a hardened zone is greater than that of a softened zone, and the width of the hardened zone is 2-2.5 millimeters generally.

Owner:冯娟

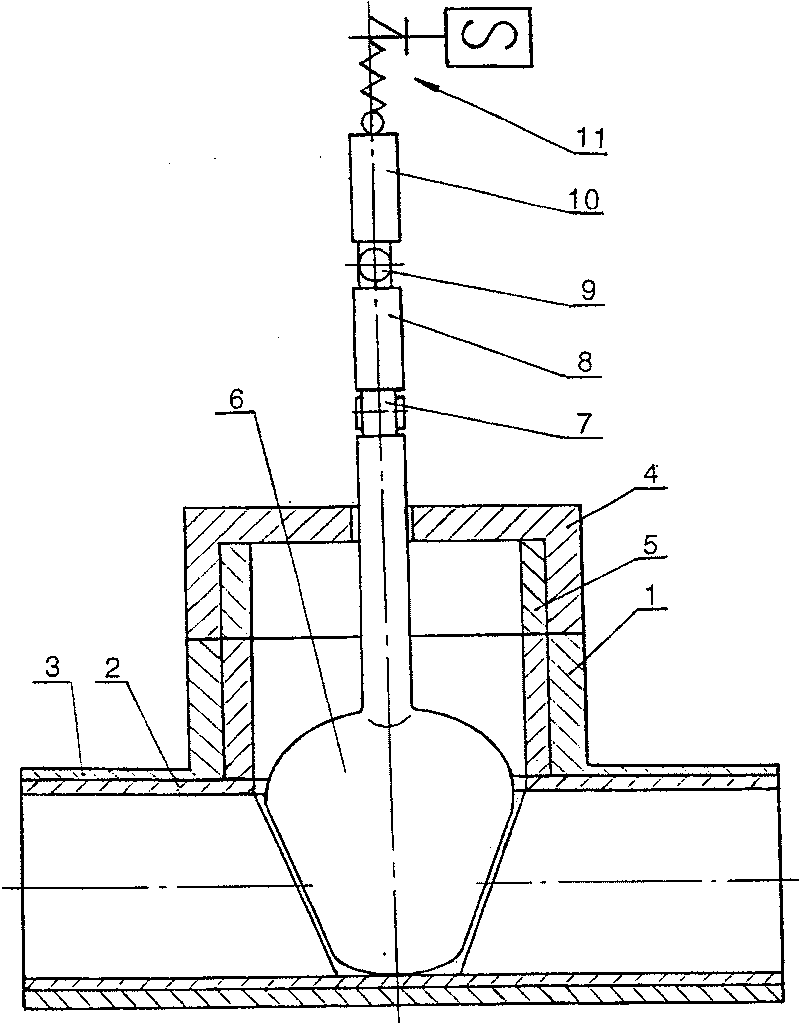

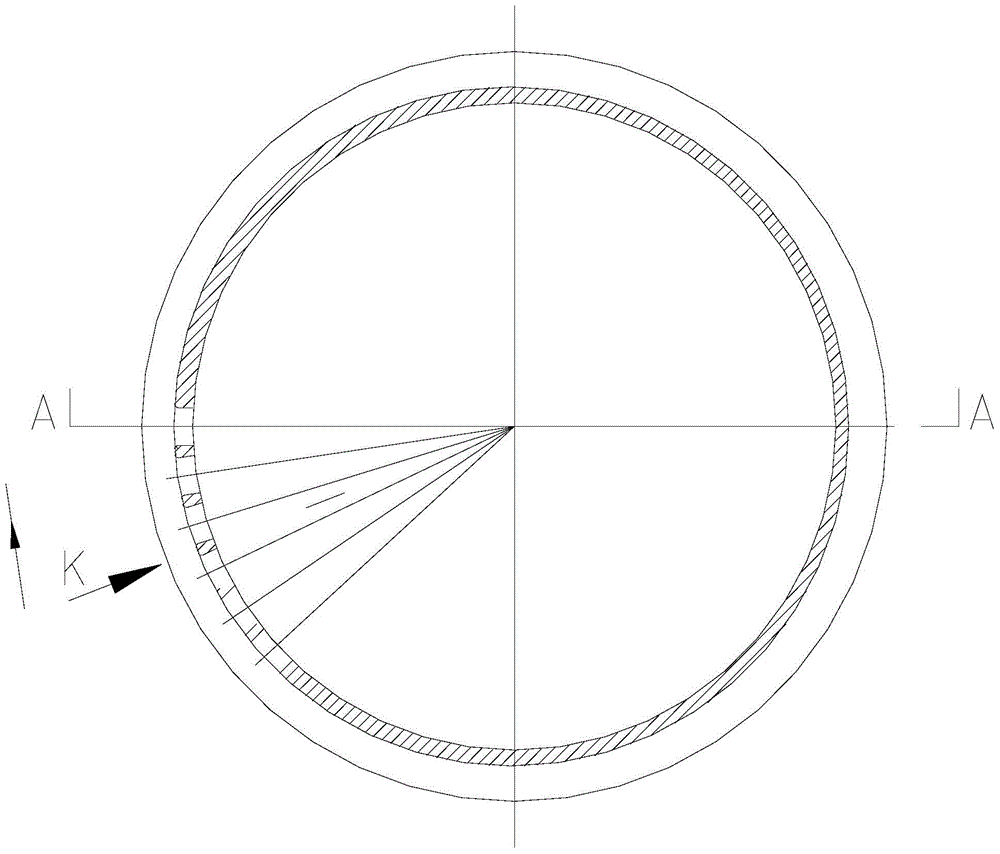

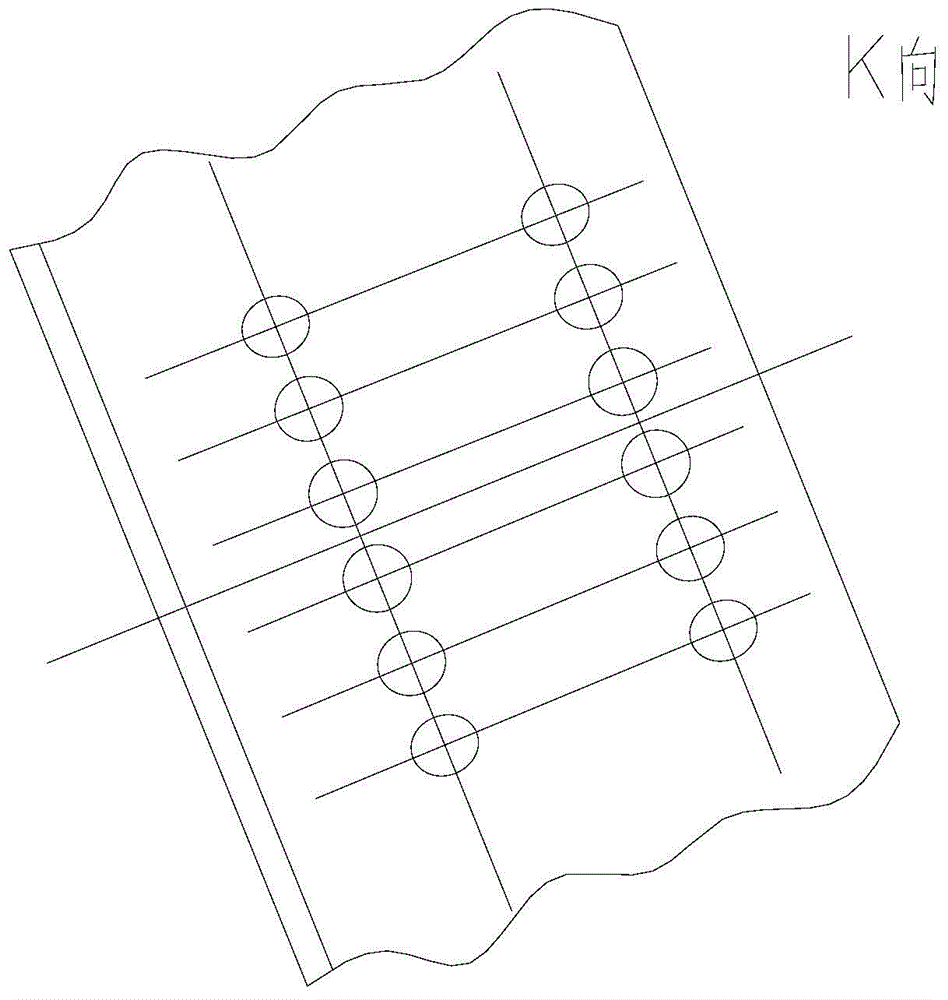

High-temperature slap discharging valves

A high temperature slag discharge valve consists of a body, a cap, a core, heat-expelling levers, and a transmission. The core has an ellipsoidal conic top and connected with the transmission througha universal joint and two heat-expelling levers. The transmission can be screwed up and down. The main parts said above are all made from nonmetal materials, by powder metallurgy and composite materials molded or cast, curing, drying, and sintering, so that all the parts, especially the core, are of high temperature resistance and wear resistance, and reliable to control slag discharge.

Owner:北京水圣木科技有限责任公司

Manufacturing method of oil guide cover for vehicle transmission double clutch

The invention provides a manufacturing method of an oil guide cover for a vehicle transmission double clutch. The manufacturing method comprises the steps of: selection of high-grade carburized bearing steel rod to discharge-forging to a blank-normalization-machining to a roughly machined part-carburization-quenching-whole-diameter correction by a special corrector-tempering and first polishing-pregrinding-first destressed tempering-secondary polishing-rough grinding-secondary destressed tempering-third polishing-fine grinding-demagnetization-cleaning and drying-inspection and warehousing. The method used for manufacturing the oil guide cover for the vehicle transmission double clutch can reduce the cost, and can guarantee the interference press-fit performance, the use working performance and the wear life of the oil guide cover.

Owner:CHANGZHOU DONGFENG BEARING

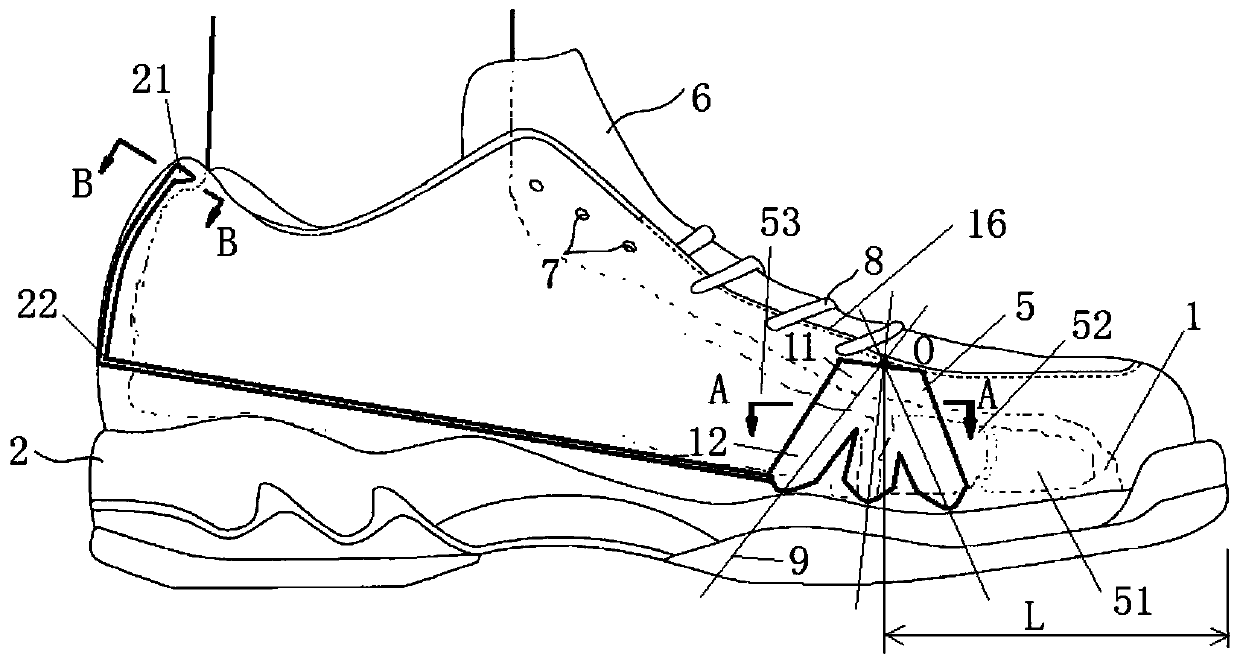

Breathable mesh cloth vamp capable of automatically eliminating shoe marks

The invention discloses a breathable mesh cloth vamp capable of automatically eliminating shoe marks. A fluid component is arranged in the vamp; the fluid component is always in contact with the vamp;bending force generated when a vamp is bent can be absorbed, meanwhile, the fluid component is of a claw-shaped structure, the structure of the fluid component adapts to the stress condition of the vamp when the vamp is bent, the fluid component can well stretch and straighten out the vamp bent when the vamp is bent through expansion deformation, and therefore vamp creases at the position are actively repaired. Meanwhile, bifurcated parts and a main body part are in a communicated state, so that the bifurcated parts and the main body part can cope with complex vamp bending conditions, and thewear resistance and comfort of the vamps are further improved.

Owner:JINJIANG DAYI WARP KNITTING

Preparation method of anti-static silicone rubber O-shaped ring

The invention provides a preparation method of an anti-static silicone rubber O-shaped ring. The method sequentially comprises the following steps: S1, mixing, namely adding 100 parts by mass of methyl vinyl silicone rubber, 3-10 parts by mass of conductive carbon black, 10-15 parts by mass of wear-resistant carbon black, 5-8 parts by mass of iron oxide powder and 2-4 parts by mass of antistatic non-woven fabric fragments into an internal mixer, and mixing for 30 minutes at the temperature of 50-80 DEG C to obtain a rubber compound; and s2, performing forming vulcanization. Two conductive fillers of the conductive carbon black and the iron oxide powder are added into raw materials of a traditional silicone rubber O-shaped ring; and the filling amount of the filler reaches a threshold value, and the volume resistivity and the surface resistivity of the polymer are rapidly reduced, so that the O-shaped ring can simultaneously depend on volume conduction and surface conduction to carry out electrostatic dissipation, and an anti-static effect is achieved.

Owner:宁国天运橡塑制品有限公司

Application of laser boning technology in ship cylinder sleeves

InactiveCN102039485ASmall amount of deformationImprove sealingLaser beam welding apparatusOptoelectronicsPiston

The invention provides application of a laser boning technology in ship cylinder sleeves, achieving the requirements of high wear resistance, low emission and long service life. The deformation of a cylinder sleeve processed by a laser is 1 / 20 and 1 / 30 of conventional thermal treatment deformation, so that the original state of the cylinder sleeve before laser processing and better sealing and matching performance with a piston and a piston ring are basically kept; a temperature for heating metal by laser radiation is (3-5)*103DEG C / S, the heating speed is over ten times of the conventional heating mode, the cylinder sleeve can be cooled down depending on heat conduction per se at a speed of 900 DEG C / S which is faster than the cooling speed of conventional quenching mediums. Because a laser quenching structure is different from a conventional quenching structure, the temperature of the laser quenching structure deceases progressively from the surface to the core part thereof, thereby obtaining an ideal structure state; the maximum hardness value of the laser quenching is HRC66, which is higher than the conventional quenching hardness value of HRC54, and the depth of a quenching layer is between 3mm and 3.5mm, which enables the inner surface of the cylinder sleeve to satisfy the high wear resistance requirement; the laser quenching consists of a spiral form and a reticulated form; and the width of a hardening belt is larger than that of a softening belt, and the width of a common hardening belt is between 2mm and 2.5mm.

Owner:韦斌

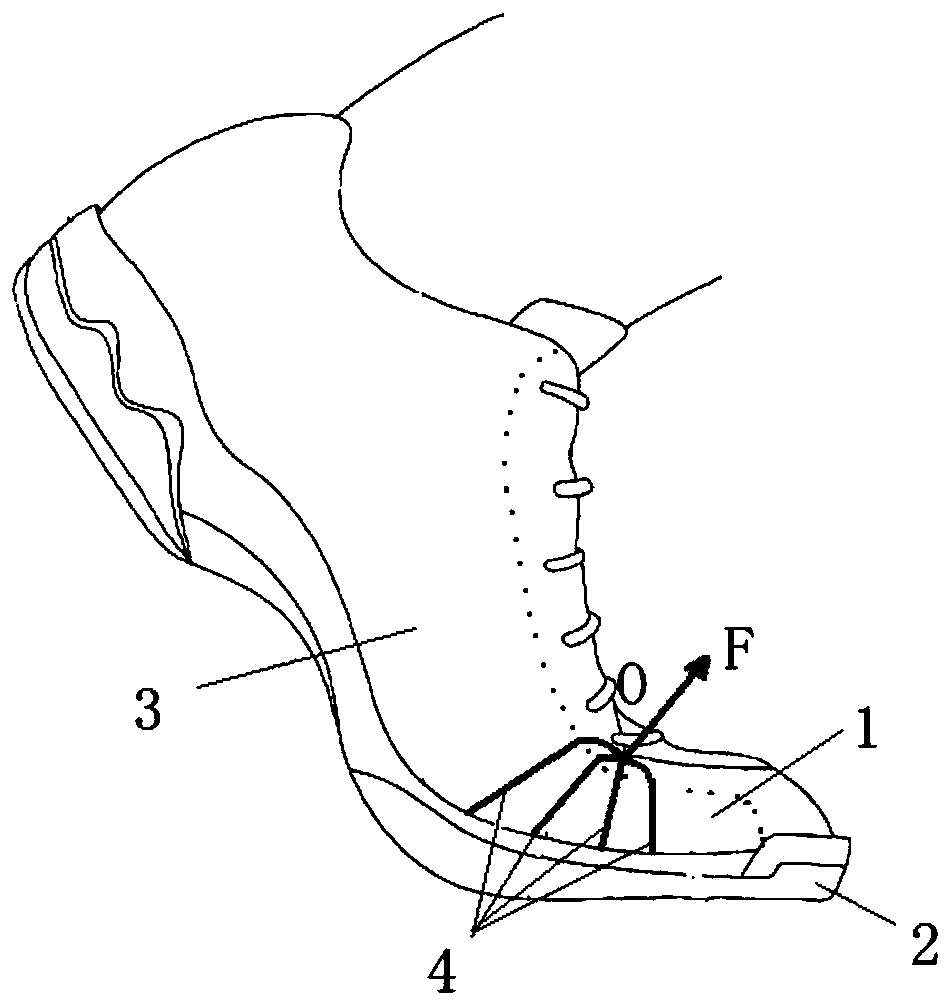

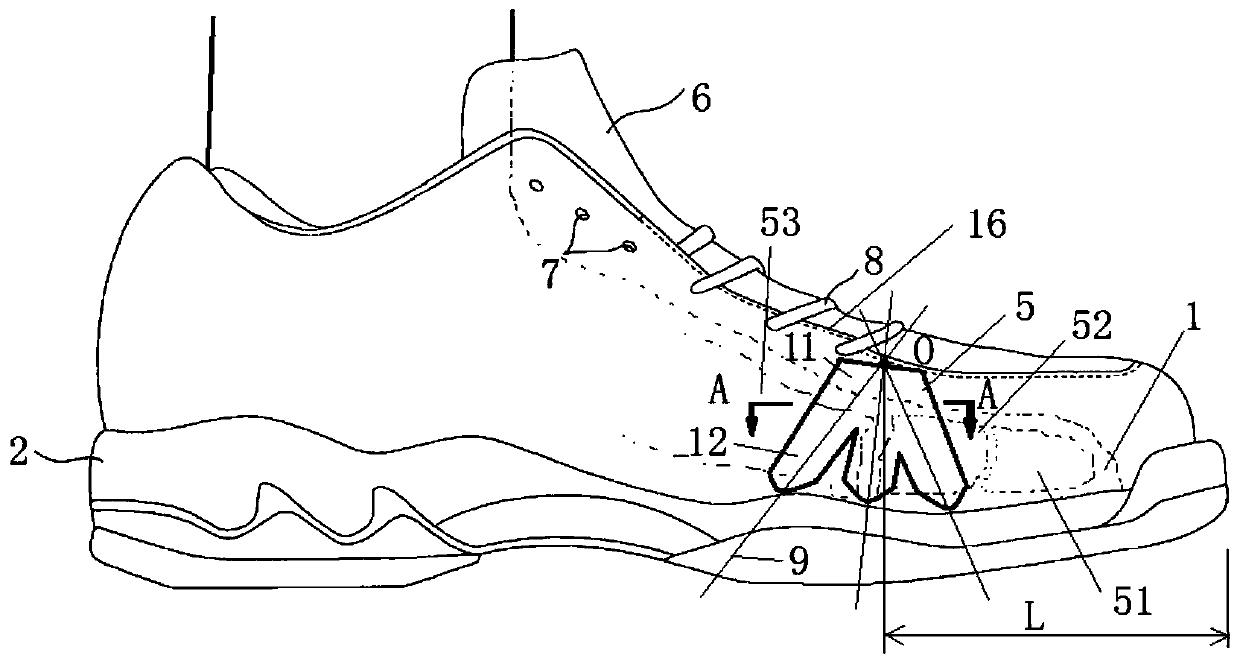

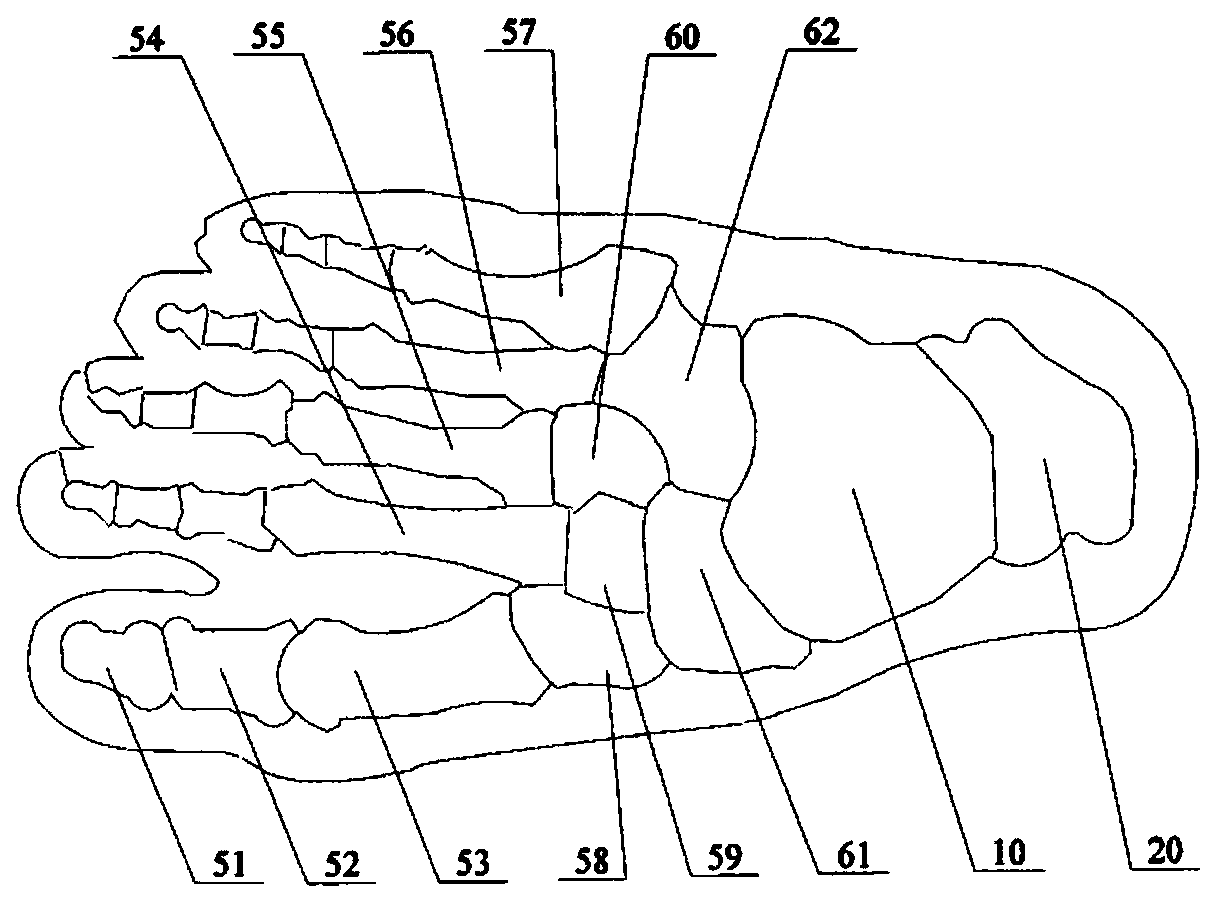

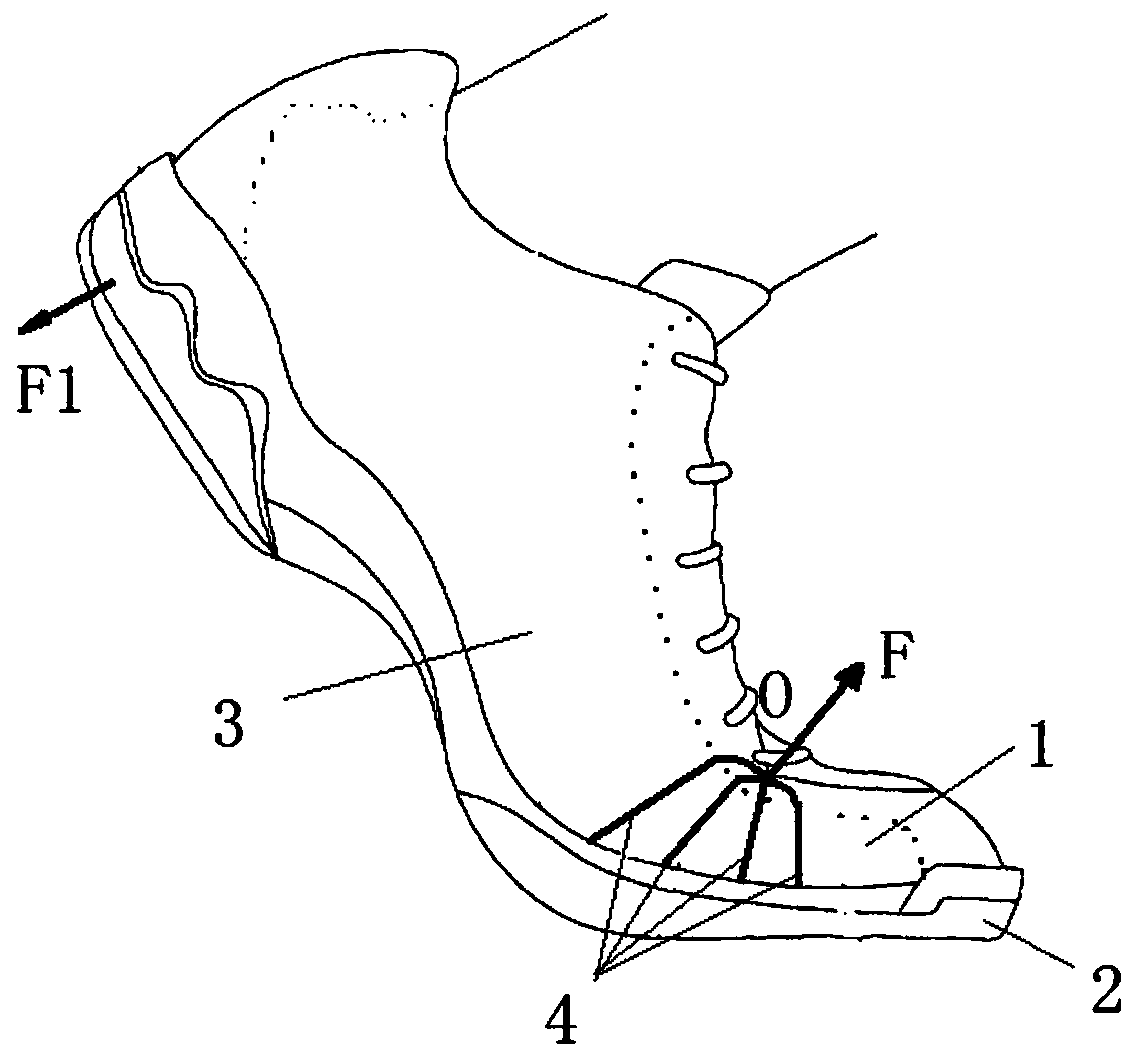

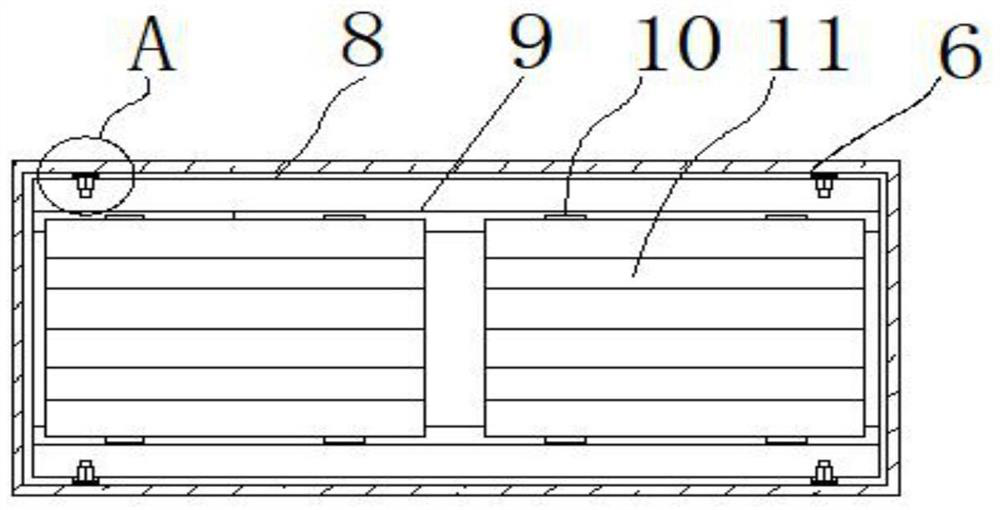

Wear-resisting shock-absorption shoe sole made from composite material and manufacturing method of shoe sole

InactiveCN106307788AExtended service lifeReduce fatigueSolesDomestic footwearSurface layerEngineering

The invention provides a wear-resisting shock-absorption shoe sole made from a composite material and a manufacturing method of the shoe sole. The wear-resisting shock-absorption shoe sole made from the composite material comprises a wear-resisting layer, a shock-absorption layer and a surface layer which are attached mutually from bottom to top; the shock-absorption comprises a sole cushion at the front part, an arch support rib at the middle part and a heel air cushion at the rear part, the bottom face of the sole cushion is bonded with the top face of the wear-resisting layer through an adhesive layer, the sole cushion is gradually thickened from the front end to the rear end, the arch support rib comprises at least one bent elastic strip, the bent vertex angle of the elastic strip is forward, the bent opening is backward, the heel air cushion comprises an air bag, a support cotton body is arranged in the air bag, and the air bag is thickened gradually from the front end to the rear end; the bottom face of the surface layer is bonded with the top face of the sole cushion and the top face of the heel air cushion through adhesive layers, the middle part of the surface layer is provided with an elastic part protruding upwards, the arch support rib is located below the elastic part and is butt against the elastic part. According to the wear-resisting shock-absorption shoe sole made from the composite material and the manufacturing method of the shoe sole, through attaching multiple layers of structures, the functions of wear-resistance, skid resistance and shock absorption are integrated.

Owner:嘉兴宜泰鞋业有限公司

Formula, production process and application method of thermoplastic elastomer surface treatment-free plasticizing material

The invention discloses a formula, production process and application method of a thermoplastic elastomer surface treatment-free plasticizing material. According to the formula, production process andapplication method of the invention, a plurality of materials such as modified polypropylene, polyurethane, nitrile butadiene rubber, a styrene block copolymer, maleic anhydride, an antioxidant and the like are used as raw materials; and the raw materials are uniformly mixed, copolymerization granulation is performed, so that the thermoplastic elastomer surface treatment-free plasticizing material which is stable in property and can be packaged, stored and transported is obtained. Experiments show that various properties of a thermoplastic elastomer can be comprehensively improved only by doping a small amount of thermoplastic elastomer raw material; and therefore, the surface performance of a thermoplastic elastomer molded product is effectively improved, the effects of smoothness, abrasion resistance and scratch resistance are achieved, surface treatment procedures such as paint spraying are omitted, and safety, stability, economy and environmental protection are achieved. The formula, production process and application method provided by the technical schemes are complete and clear, easy to implement and popularize, and have high remarkable advancement and extremely high industrial value and bright application prospects.

Owner:覃珍锋

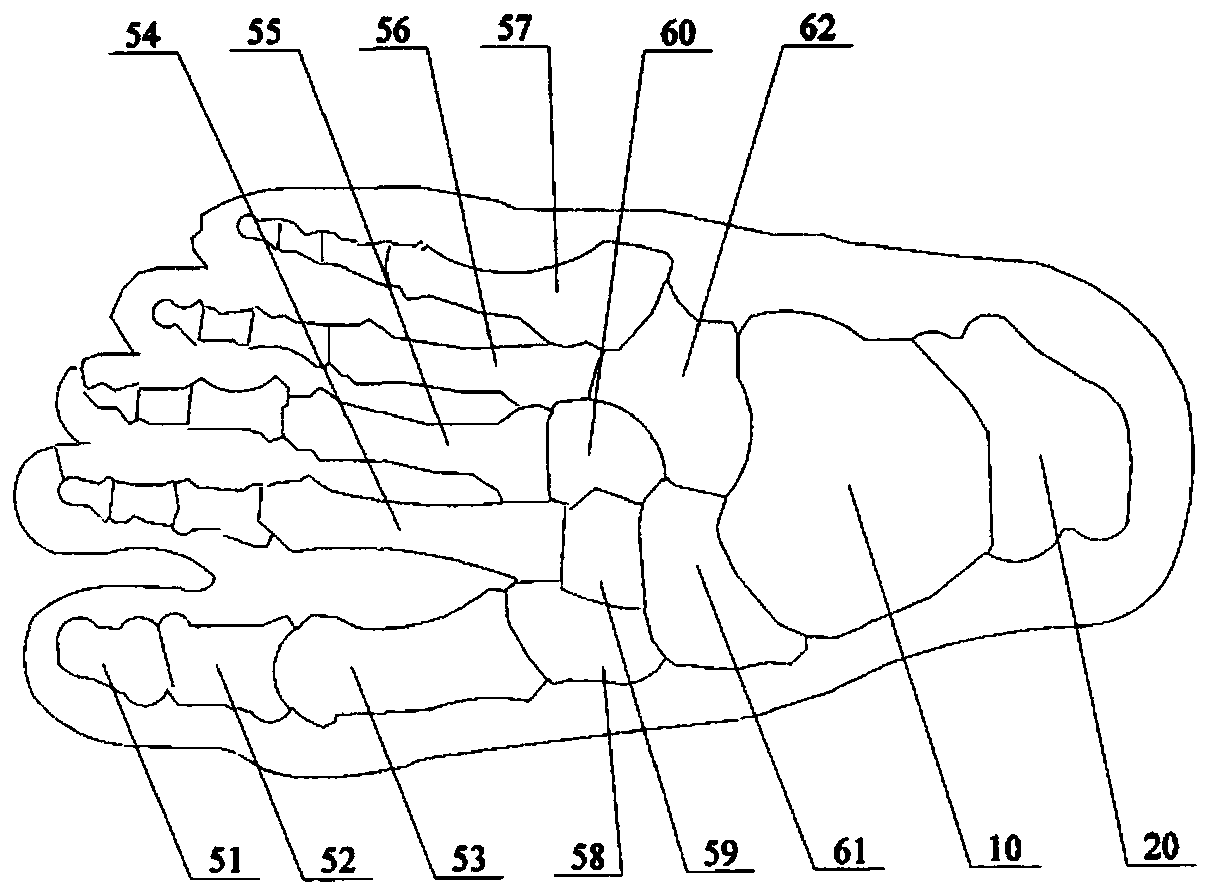

Self-adaptive vamp for fitting foot

The invention discloses a self-adaptive vamp. A fluid component and a fastener are arranged in the vamp. The fluid component is always in contact with the vamp; a bending force generated when the vampis bent can be absorbed; meanwhile, the fluid component is of a claw-shaped structure; the structure adapts to the stress condition of the vamp when the vamp is bent; the fluid component can also beused for well stretching and straightening out the vamp which is bent when the vamp is bent through expansion deformation; therefore, the vamp crease at the position is actively repaired; meanwhile, the fastener also adapt to the bending action of the vamp, fasten the heel bone during bending and prevent the shoe from being separated from the heel so as to be attached to the foot, and meanwhile, the bifurcated part and the main body part are in a communicated state, so that the integrated vamp structure can cope with the complex vamp bending condition, and the wear resistance and comfort of the integrated vamp structure are further improved.

Owner:JINJIANG DAYI WARP KNITTING

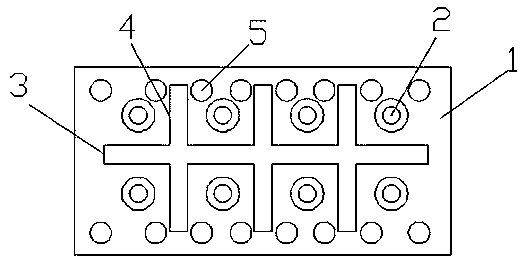

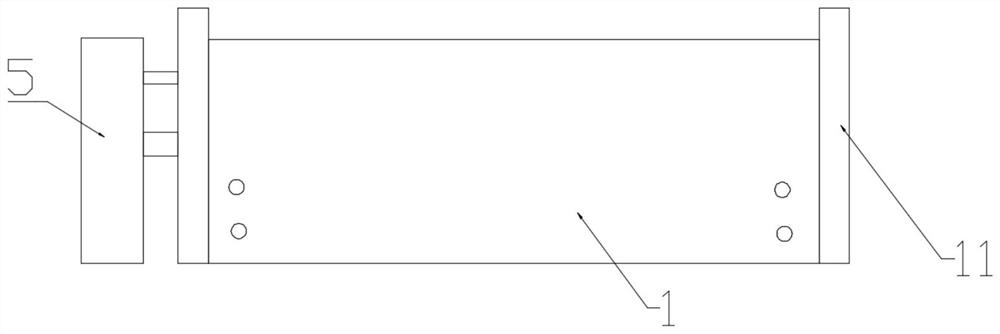

Rolling mill manipulator lining plate

InactiveCN109731923APrevent looseningAchieve wear resistanceGuiding/positioning/aligning arrangementsWear resistantPulp and paper industry

The invention discloses a rolling mill manipulator lining plate. The lining plate comprises a lining plate body, the lining plate body is provided with a plurality of bolt holes, counter bores are formed in the surfaces of the bolt holes, at least one first damping groove is transversely formed in the lining plate body, a plurality of second damping grooves are longitudinally formed in the liningplate body, and a plurality of damping blind holes are formed in the surface of the lining plate body. According to the rolling mill manipulator lining plate, damping grooves are used for damping, sothat the lining plate is prevented from loosening; the contact area between the lining plate and a panel is reduced through the damping grooves and the damping blind holes, so that the wear-resistanteffect is achieved; and the wear-resistant effect of the lining plate is further enhanced through ceramic wear-resistant particles. The rolling mill manipulator lining plate is reasonable in design and suitable for popularization and application.

Owner:FUHUA ZHONGYUAN JIANGSU HEAVY MACHINERY TECH CO LTD

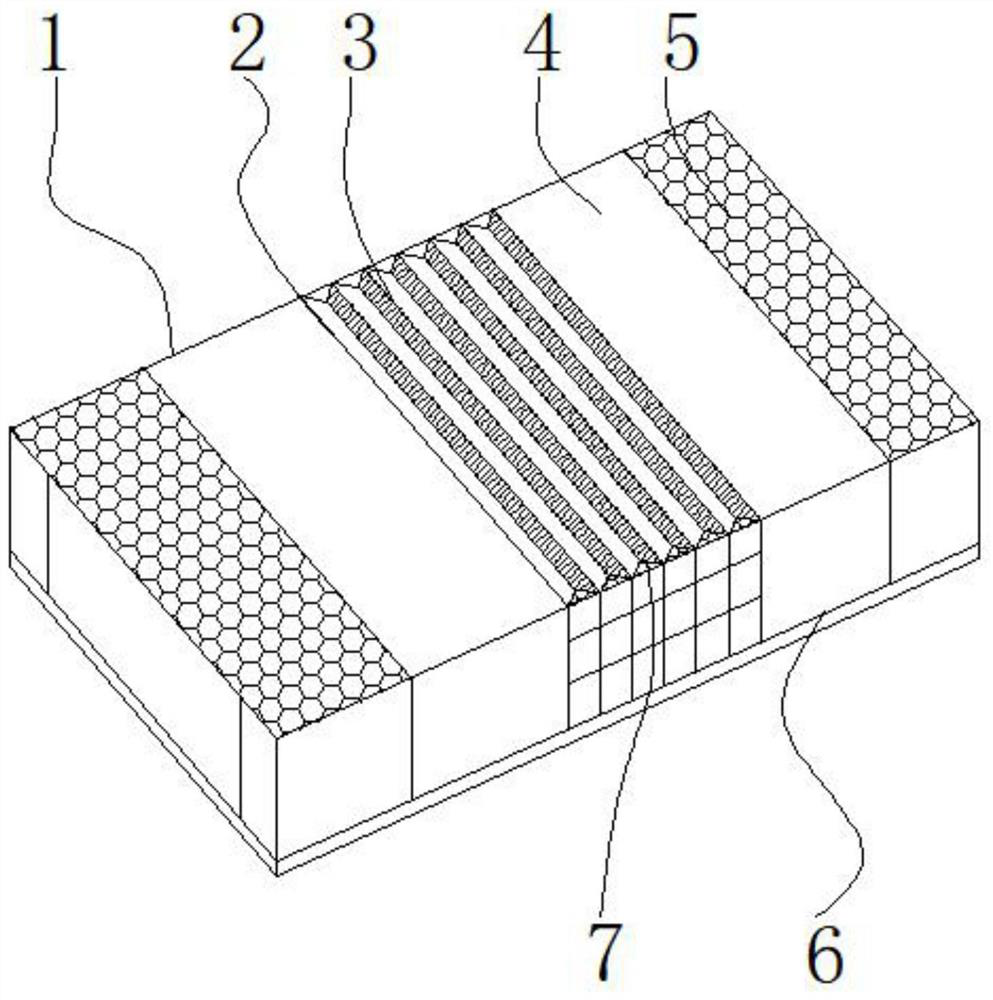

Staggered overlapping type VIP glass fiber core material

ActiveCN112092471AAchieve protectionAchieve wear resistanceInsulation improvementGlass/slag layered productsFiberEngineering

The invention relates to a staggered overlapping type VIP glass fiber core material, which comprises a fiber core material plate, a limiting plate and a soft connecting sleeve, net glass fibers are arranged on the two sides of the top end of the fiber core material plate, supporting glass fibers are arranged on the inner sides of the net glass fibers, and fluctuating plates are arranged on the inner sides of the supporting glass fibers; an inclined plate is arranged on the inner side of the fluctuating plate, a padding plate is arranged in the inclined plate, bottom cover glass fibers are arranged at the bottom end of the fiber core material plate, and grooves are formed in the inner sides of the bottom cover glass fibers. The material has the beneficial effects that when the combined fluctuating plates and inclined plates cover the fiber core material plate in a triangular shape, the multiple sets of fluctuating plates and inclined plates are arranged and folded outside the fiber corematerial plate, the space between the fluctuating plates and the inclined plates can be movably filled with the padding plates, so that the fluctuating plates and the inclined plates with the paddingplates can be installed in a protective mode; therefore, the VIP glass fiber core material can achieve fragile protection effect and wear resistance.

Owner:南通远顺耐纤有限公司

High-toughness wear-resistance steel

The invention discloses high-toughness wear-resistance steel. The steel comprises, by weight, 0.3-0.5% of carbon, 0.6-0.8% of silicon, 0.9-1.2% of tungsten, 2.9-3.9% of chromium, 1.2-1.8% of titanium,2-4% of manganese, 0.9-1.2% of molybdenum, 0.02-0.04% of sulphur and the balance ferrous. The steel has the advantages that the contents of nickel, the chromium and the carbon are defined, other material components with an appropriate proportion are selected, manufactured protecting plates have excellent toughness and more importantly have better hardness, the protecting plates have the advantages of wear resistance, impact resistance and the like, all requirements on mechanical performance during the ball blast process are met, the service life is prolonged, the performance of an alloy structure is improved by rapid cooling and reasonable quenching process, the impacting toughness is good, the comprehensive mechanical performance is good, and therefore manufactured products reach the performance requirements of wear resistance and moderate impact.

Owner:ZHENJIANG SUBAIXIN CONSTR MACHINERY CO LTD

Composite steel plate preparation method based on thermit reaction

The invention provides a composite steel plate preparation method based on a thermit reaction. A preparation device comprises a thermit welding agent consisting of iron oxide powder and aluminum powder, a metal net woven by magnesium leads and such pure metal wires as vanadium, chromium and molybdenum, a high-purity graphite mold cavity and a pressing block. In the preparation process, firstly, the magnesium leads are ignited to trigger the thermit reaction; under the scour effect of high-temperature molten iron, high-density molybdenum is continuously dissolved and sunk, and low-density chromium and vanadium are continuously dissolved and ascended until the mold cavity is uniformly filled; under the effect of heat conduction, the thermit reaction near mold holes is synchronously triggered; wear-resistance alloy blocks uniformly staggered and with uniform components are formed through cooling; and composite wear resisting plates can be formed by turning and grinding. Compared with a composite wear resisting plate prepared by a traditional overlaying method, the composite wear resisting plate has the advantages of uniform alloy components, high production efficiency and no crack inlarge-area wear resisting alloy layers; and when the wear resistance and the impact resistance are achieved, the welding performance of the composite wear resisting plate also can be met.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Alloy material for preparing vehicle air conditioner compressor connecting rod

The invention provides an alloy material for preparing a vehicle air conditioner compressor connecting rod. The alloy material is prepared from the components in parts by mass: 18.0-20.0 parts of Si,0.05-0.5 part of Fe, 4.0-5.5 parts of Cu, 0.02-0.2 part of Mn, 0.8-1.3 parts of Mg, 0.01-0.1 part of Zn, 0.01-0.2 part of Zr and 0.01-0.2 part of an auxiliary material; and the connecting rod is formed through the steps of smelting, degassing, casting, extrusion, blanking, heat treatment and machining. The connecting rod meets requirements of high strength, abrasion resistance and lightweight.

Owner:LOUDI WENCHANG TECH

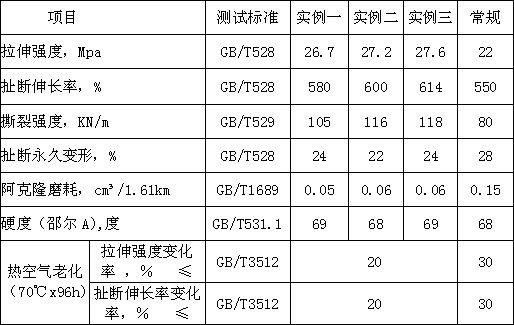

High-wear-resistance tractor rubber track rubber material and manufacturing method thereof

The invention discloses a high-wear-resistance tractor rubber track rubber material and a manufacturing method thereof. The formula comprises the following components in parts by weight: 85-70 parts of polyisoprene, 15-30 parts of rare earth butadiene rubber, 2.7-3.5 parts of a vulcanization accelerator, 3-4 parts of zinc oxide, 1-2 parts of stearic acid, 3-4 parts of an anti-aging agent, 1.5-2.5parts of a homogenizing agent, 1.2-2.2 parts of a flowing exhaust agent, 46-55 parts of carbon black, 5-10 parts of nano silicon dioxide and 0.8-2 part of a coupling agent. The material has the advantages of achieving the advantage of wear resistance, thereby greatly prolonging the service life. According to the invention, the tensile strength can be improved, meanwhile, the prepared rubber trackhas good wear resistance, the strength of a rubber material is improved, the friction coefficient between rubber and the ground is reduced, the phenomenon that the surface of the rubber is prone to foaming is prevented, the smoothness of the contact area is enhanced, the wear resistance is improved, and the problem of better mixing uniformity during blending is solved. In the preparation process,the prepared rubber track has very high wear resistance and tearing strength, and the service life is further prolonged.

Owner:镇江同立橡胶有限公司

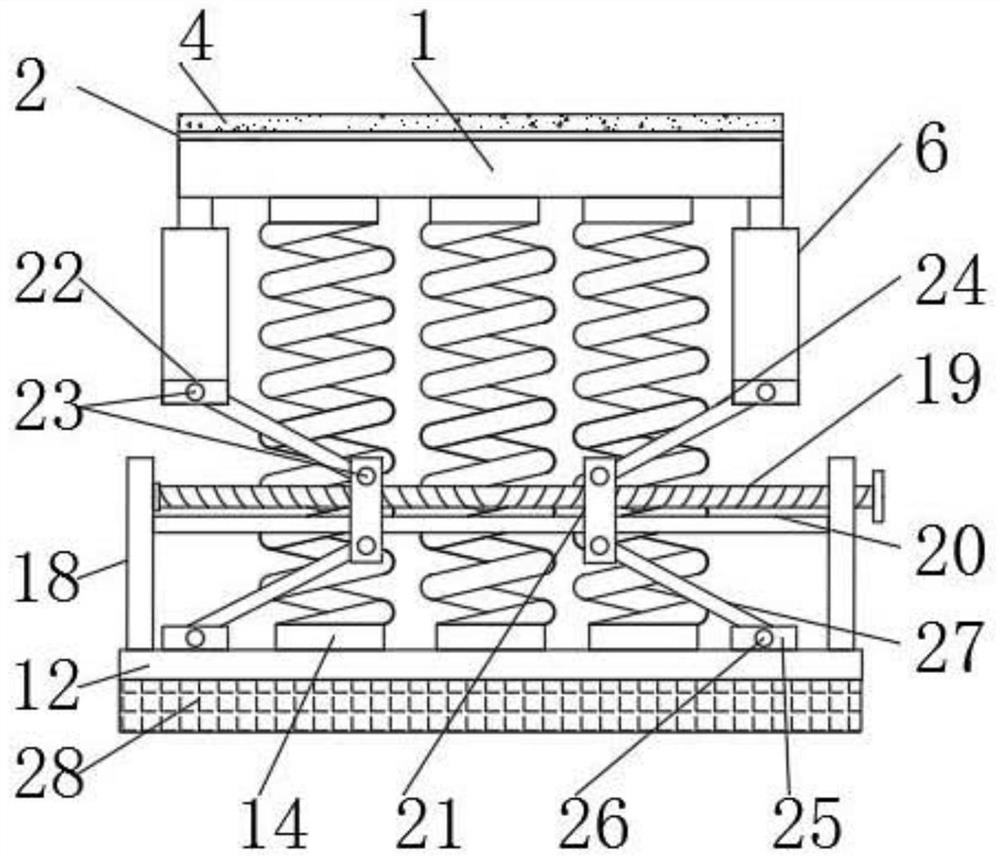

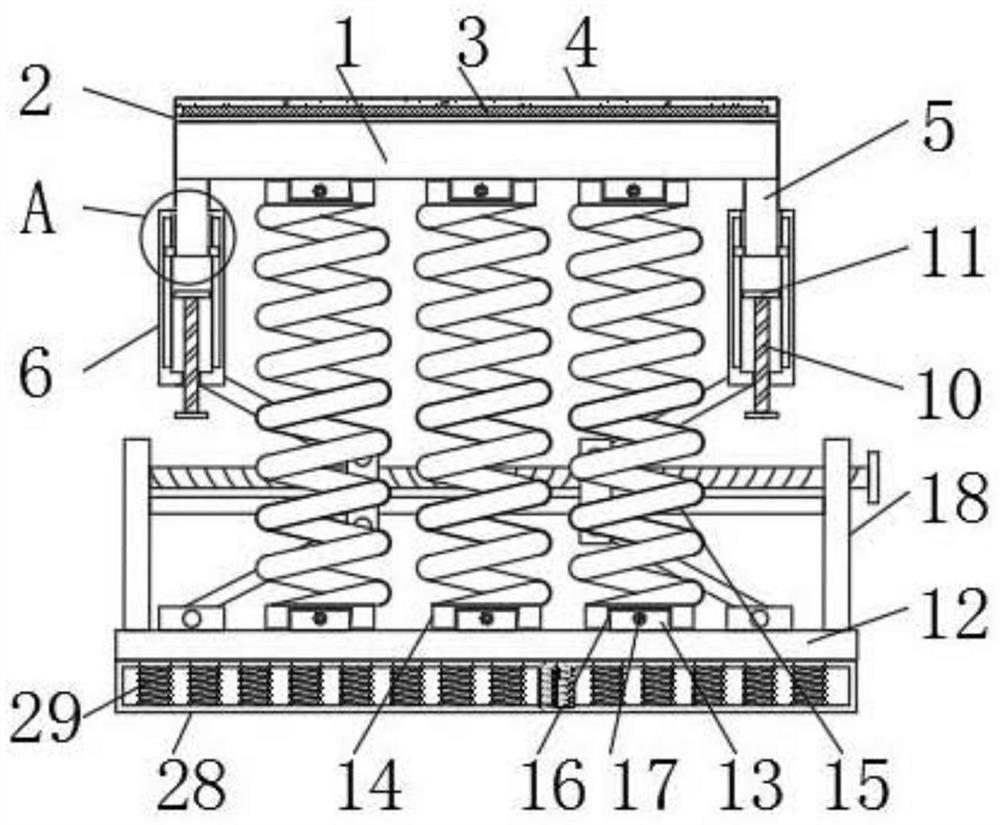

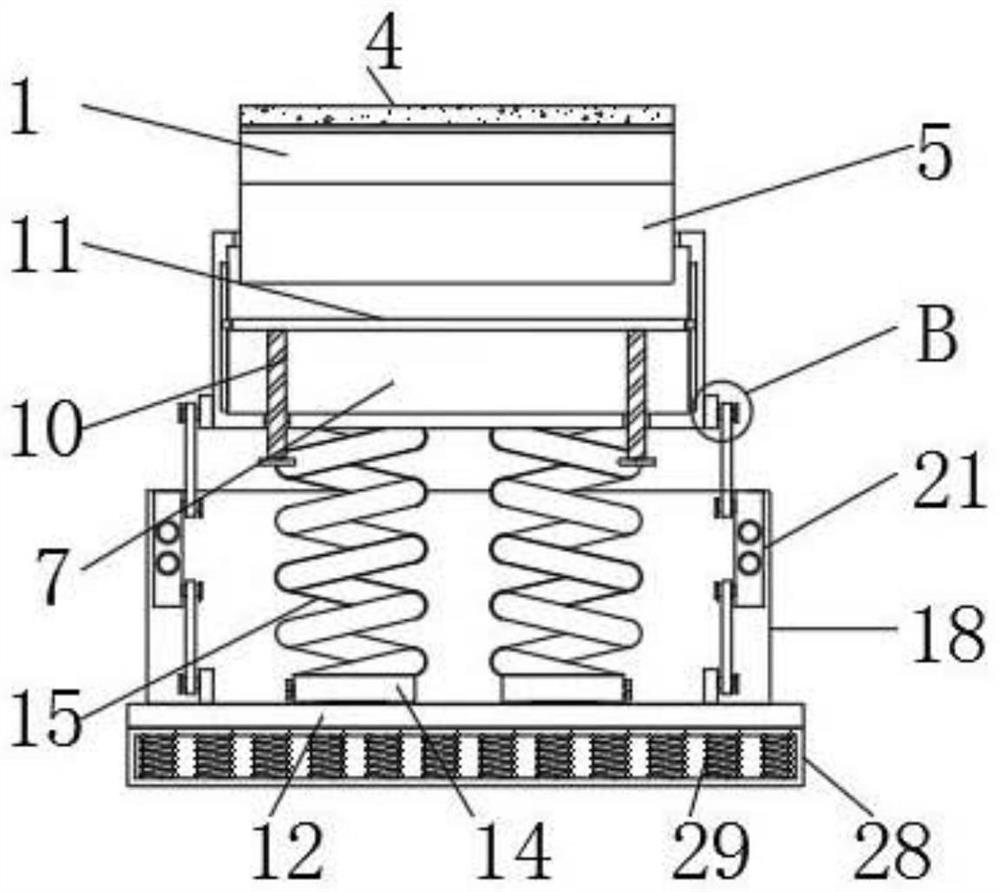

Spring vibration isolator with height fine adjustment function

ActiveCN113007252AWith height fine-tuning functionHeight adjustableLow internal friction springsAdhesiveStress point

The invention discloses a spring vibration isolator with a height fine adjustment function. The spring vibration isolator with the height fine adjustment function comprises a top plate and force equalizing springs, the top of the top plate is coated with an adhesive, and an anti-skid pad is bonded to the top of the adhesive. The top of the anti-skid pad is coated with a wear-resistant layer, the bottom of the top plate is connected with telescopic plates, connecting plates are arranged on one sides of the telescopic plates, and operation grooves is formed in the portions, close to the telescopic plates, of the interiors of the connecting plates. The spring vibration isolator with the height fine adjustment function is provided with first connecting rods and second connecting rods, sliding blocks can drive first connecting shafts and second connecting shafts to move, the first connecting shafts can pull the first connecting rods, and the angle of the first connecting rods can be adjusted through the other set of first connecting shafts. Meanwhile, the second connecting shafts can pull the second connecting rods, the angle of the second connecting rods can be adjusted through the other set of second connecting shafts, the first connecting rods and the second connecting rods are expanded outwards, the telescopic plate is jacked up through the stress points of first fixing blocks, and therefore the top plate can be driven to adjust the height.

Owner:道尔道科技股份有限公司

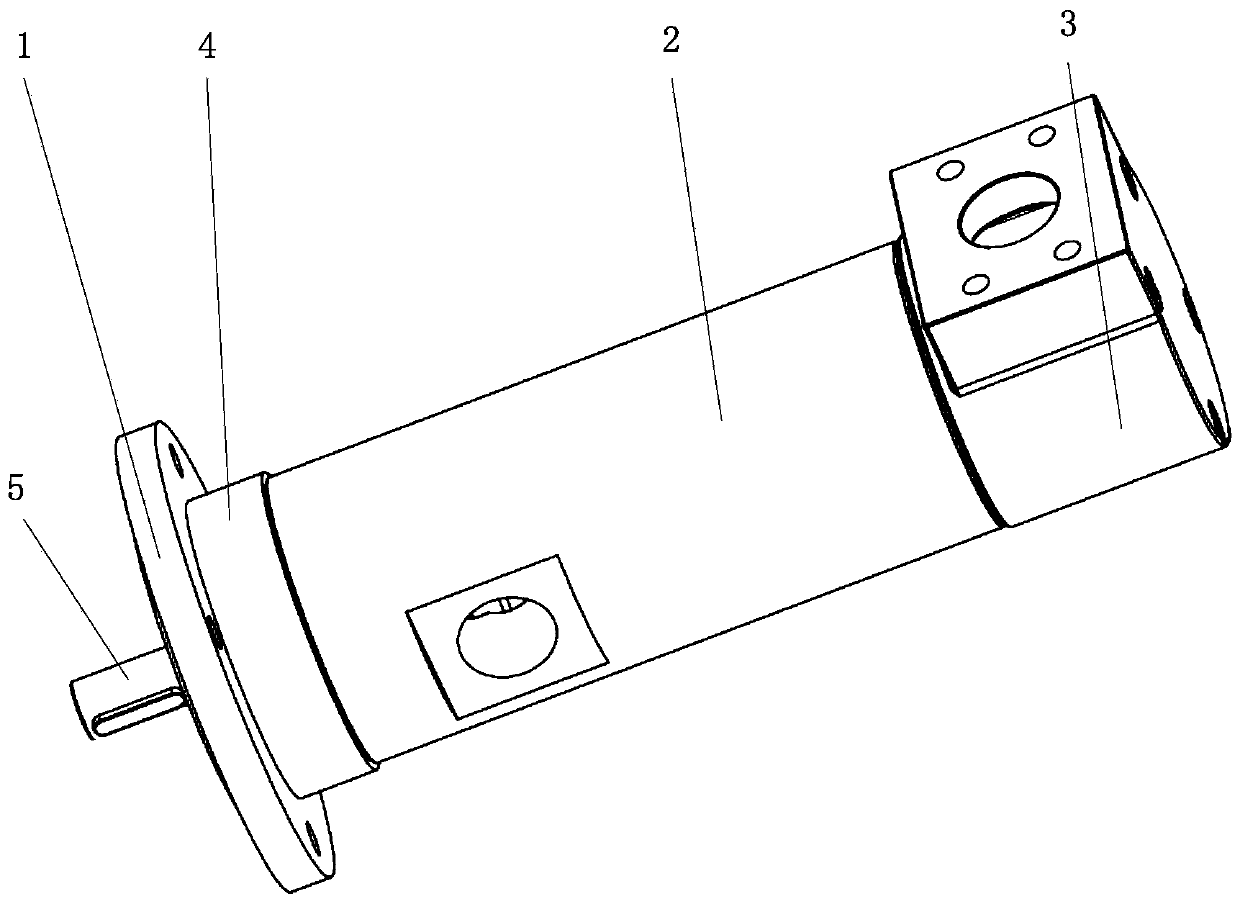

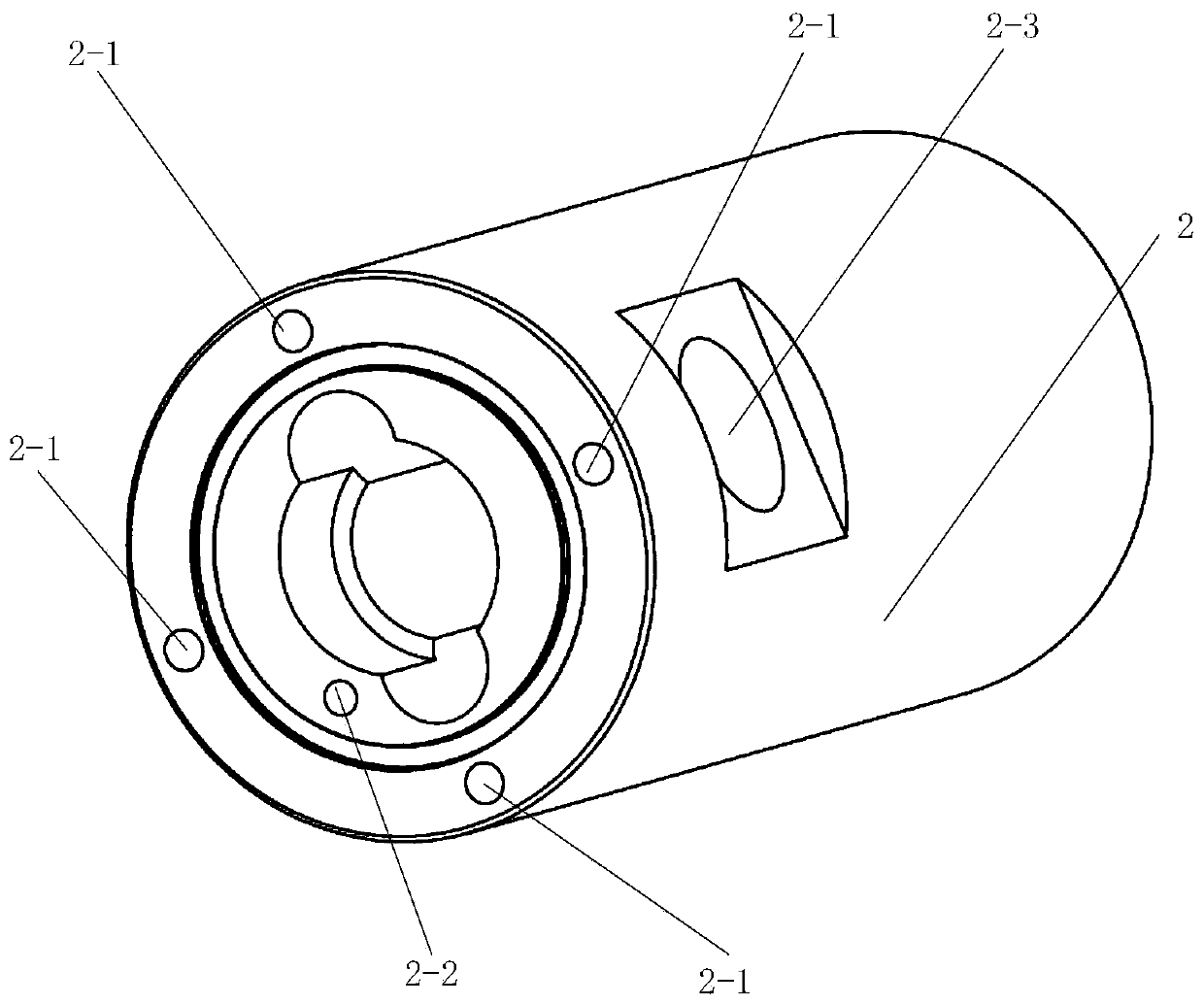

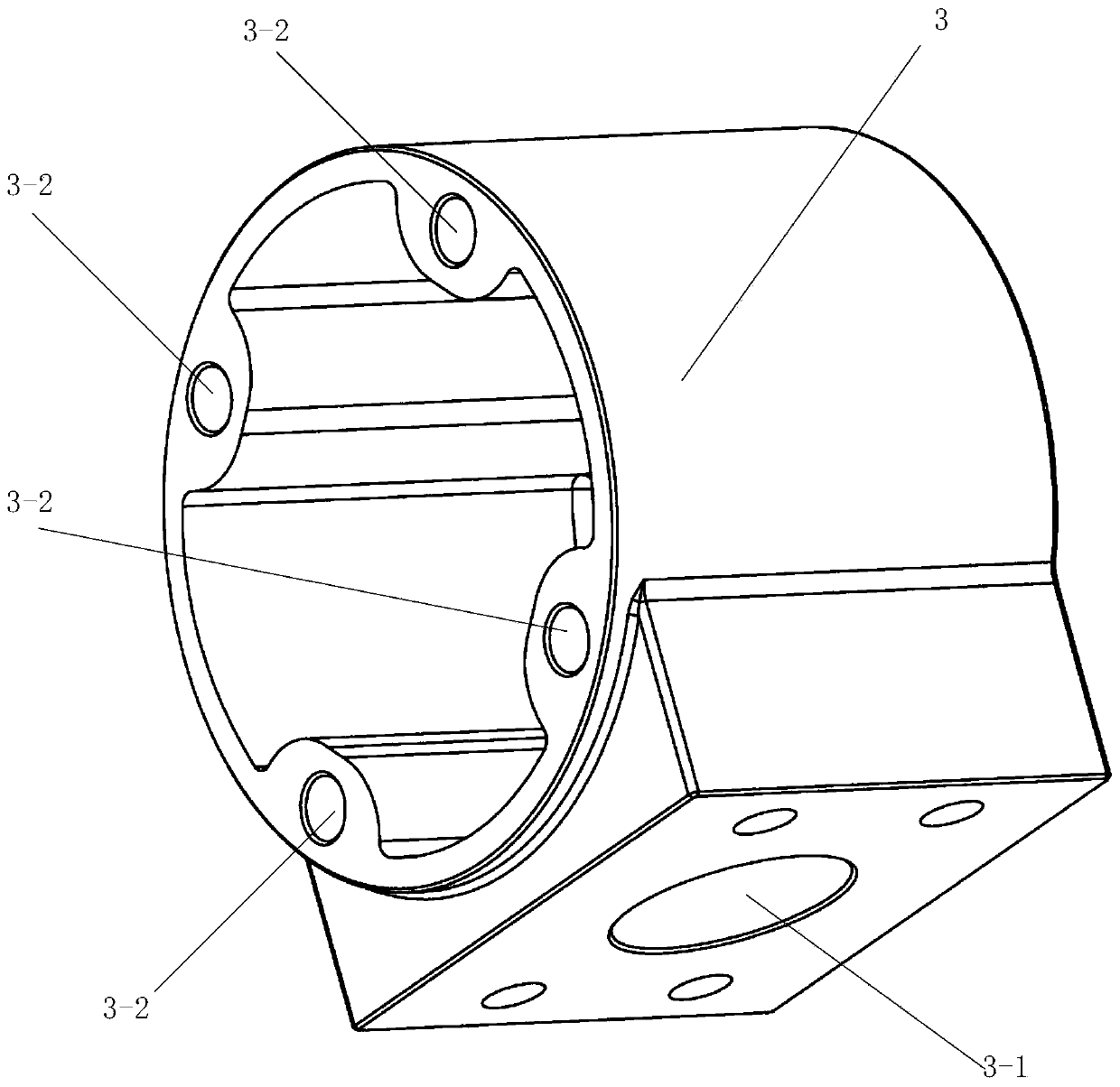

Three-screw labyrinth seal cutting liquid pump

ActiveCN109854497AIncrease the lengthIncrease resistanceRotary piston pumpsRotary piston liquid enginesEngineeringFlange

The invention discloses a three-screw labyrinth seal cutting liquid pump. The three-screw labyrinth seal cutting liquid pump comprises end covers at two ends, and a shell in middle; one of the end covers at two ends is a general flange end cover connected with a motor, and the other one is a radial oil sucking end cover far from the motor; and a rotating shaft is axially distributed in the centerof the shell. The three-screw labyrinth seal cutting liquid pump is characterized in that cutting liquid consists of 95% of water and 5% of oil; the rotating shaft axially distributed in the center ofthe shell is a profiled three-screw rotor; a lengthened labyrinth seal groove is arranged on a driving screw of the profiled three-screw rotor; and a labyrinth seal flange end cover matched with thelengthened labyrinth seal groove is arranged between the general flange end cover and the shell. Through change of the position of the labyrinth seal groove, increment of the length of the labyrinth seal groove, rust resisting and wear resisting treatment of a three-screw material, organic combination and mutual dependence of the three, the difficulty of incapability of further improving the capacity efficiency of the cutting liquid pump for a long time is solved; the capacity efficiency of the cutting liquid pump is improved from 40%-50% to 70%; and the three-screw labyrinth seal cutting liquid pump creates the history at home and abroad, and fills the blank at home and abroad.

Owner:海林柯液压技术(天津)有限责任公司

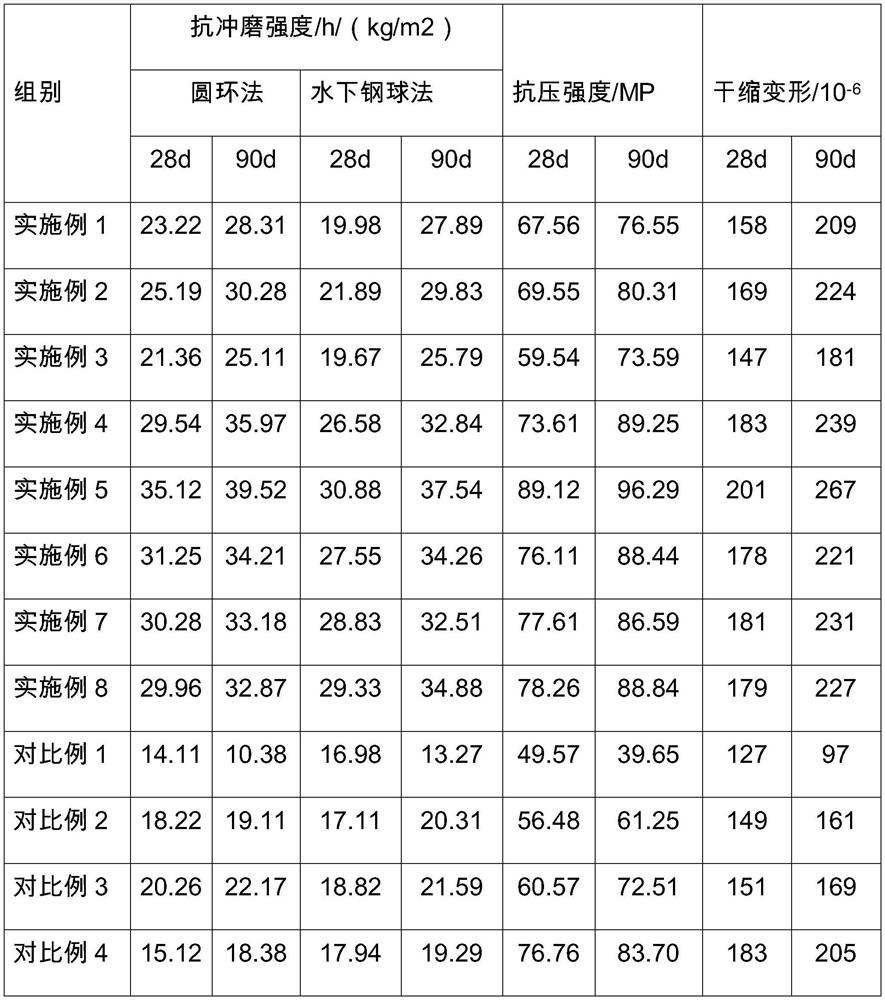

Anti-impact wear-resistant concrete for hydraulic engineering and preparation method thereof

InactiveCN114702283AChange the acid-base environmentReduce adverse effectsSolid waste managementBacillus licheniformisFiber

The invention discloses impact-resistant and wear-resistant concrete for a water conservancy project. The impact-resistant and wear-resistant concrete is prepared from the following raw materials in parts by weight: 73-81 parts of Portland cement, 41-49 parts of yellow phosphorus slag, 20-30 parts of ardealite powder, 5-10 parts of basophilic bacillus licheniformis, 15-22 parts of brown aluminum oxide, 0.1-0.3 part of polypropylene split film fibers, 3-6 parts of a water reducing agent and 113-129 parts of gravel. The preparation method comprises the following steps: grinding the Portland cement, the yellow phosphorus slag, the brown aluminum oxide and the sandstone to obtain ground powder A; grinding the ground powder A, ardealite powder and polypropylene split film fibers again to obtain ground powder B; calcining the ground powder B at the temperature of 610-630 DEG C to obtain calcined powder; and cooling the calcined powder to normal temperature, doping the basophilic bacillus licheniformis and the water reducing agent, and uniformly stirring. The concrete prepared by the invention is impact-resistant, wear-resistant and long in service life.

Owner:吕书波

Manufacturing method of low-carbon alloy steel

The invention discloses a sheath for a shot blasting chamber, and particularly relates to a sheath made of low-carbon alloy steel. The sheath is prepared from, by weight, 0.20-0.23% of carbon, 1.30-1.50% of silicon, 0.6-0.8% of manganese, 1.5-1.8% of chromium, 1.5-1.8% of nickel, 0.6-0.7% of molybdenum, 0.25-0.35% of copper, 1-2% of silicon and the balance iron. Compared with the prior art, the sheath has the following advantages that since the content of carbon is reasonably defined, the proportion of chromium to nickel to carbon is specifically defined, and meanwhile the other material components with the proper proportion are selected, a manufactured protection plate has high rigidity, more importantly, the protection plate has high tenacity, so that the protection plate has performancelike wear resistance and shock resistance, all requirements for mechanical performance in a shot blasting process are met, and the service life is prolonged; moreover, by means of a processing technology, the integration of various components is good, and the alloy structure performance is improved, so that the manufactured product has wear resistance and shock resistance.

Owner:ZHENJIANG SUBAIXIN CONSTR MACHINERY CO LTD

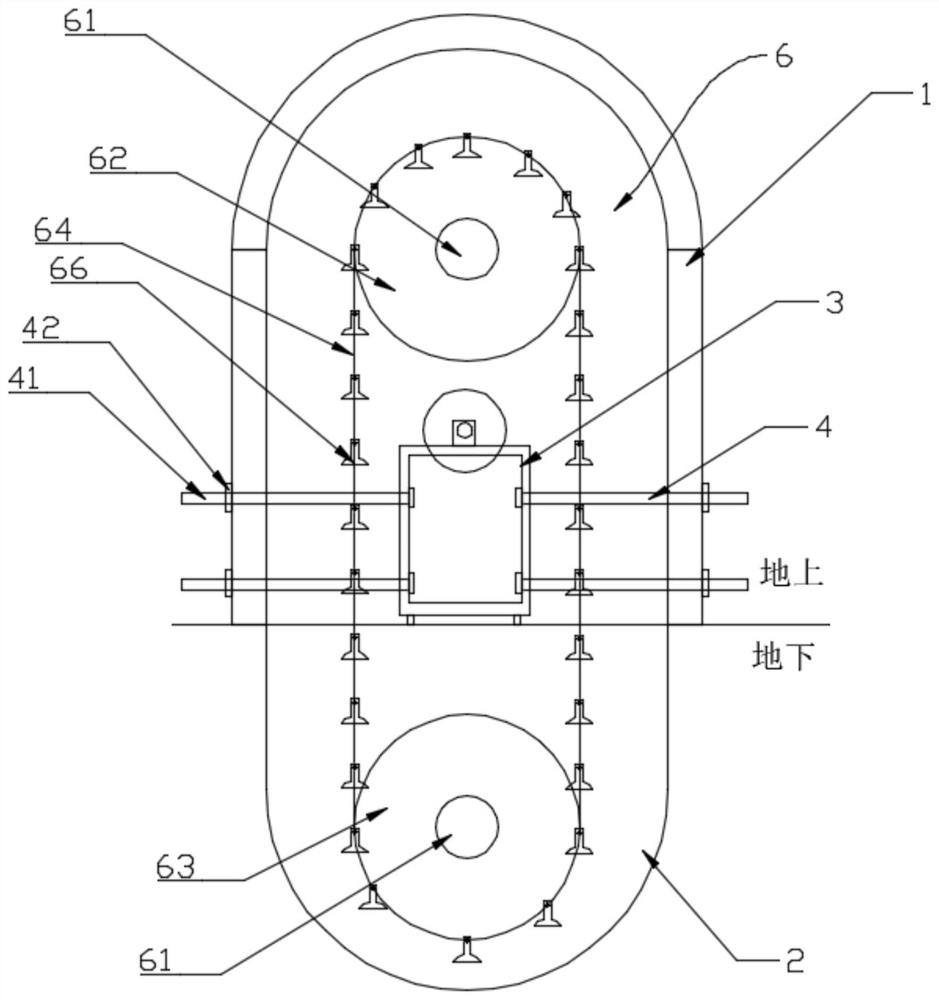

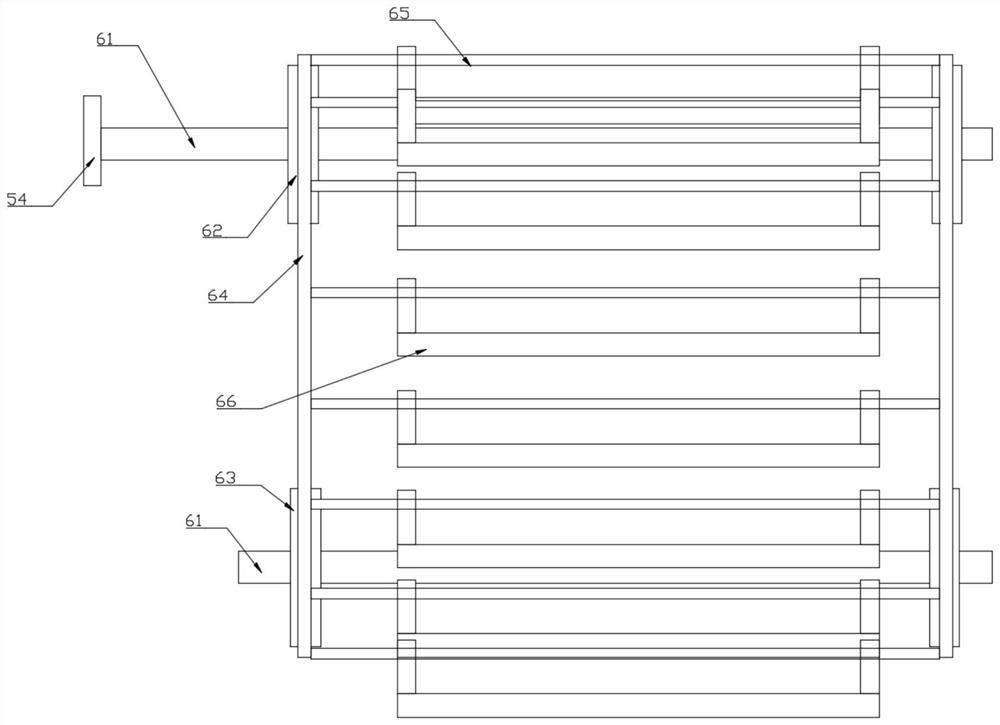

Roller manufacturing method for lithium battery pole piece rolling mill

PendingCN113832328AAchieve strengthAchieve wear resistanceFurnace typesRollsGear wheelLiquid storage tank

The invention discloses a roller manufacturing method for a lithium battery pole piece rolling mill. The method includes the steps that a roller is subjected to cryogenic treatment after quenching, a matched cryogenic device is used, and a transverse feeding mode is adopted, so that the roller feeding is made more convenient, and the feeding time is greatly saved. A rotary cold air conveying mode is adopted, and meanwhile, the roller rotates by itself, so that the roller is cooled more uniformly, and partial excessive cooling of the surface of the roller by direct injection of liquid nitrogen is avoided. Each liquid dipping strip is ingeniously provided with a thin liquid storage tank to store a small amount of liquid nitrogen, so that the cold source amount carried by each liquid dipping strip entering the liquid storage tank each time is ensured, and the refrigeration effect is also guaranteed. And meanwhile, the phenomenon that the liquid nitrogen is thrown out to directly fall off onto the roller due to operation shaking of a cold source conveying mechanism is effectively prevented. And the driving mechanism adopts chain gear transmission and is matched with a tensioning gear, so that the roller is conveniently connected into the driving mechanism, and the equipment cost is further reduced.

Owner:JIANGSU RUNFU MECHANICAL ROLL MFG

Manufacturing method of low-alloy wear-resistance steel

The invention discloses a manufacturing method of low-alloy wear-resistance steel. The manufacturing method comprises the following steps of A, preparing, B, smelting, wherein a smelting furnace is vacuumized, and prepared materials are put in a vacuum smelting furnace for smelting; C, pouring; D, cooling, wherein after being subjected to air cooling, castings are subjected to water cooling, and acondensing device is adopted for condensing; E, annealing, wherein the castings are subjected to heating and heat preservation after being grinded, then temperature rising and heat preservation are conducted, and afterwards, quick water cooling is conducted; F, quenching, wherein the castings are heated, quenched, and timely tempered after being quenched. The manufacturing method has the following advantages that the content of carbon and the proportion of chromium to nickel to carbon are reasonably limited, other material components with a proper proportion are selected, and smelting is conducted after vacuumizing; so that the dissolving uniformity of a solution of the steel is good, cooling is conducted after casting, and the low-alloy wear-resistance steel is stepwise cooled in three modes after being poured; the casting quality is guaranteed, a manufactured protection plate has high hardness, tenacity, wear resistance, shock resistance and other performance, and meets all requirements for the mechanical performance in a shot blasting process, and the service life is prolonged.

Owner:ZHENJIANG SUBAIXIN CONSTR MACHINERY CO LTD

Alloy powder and method for repairing hard surface of heavy-duty gear by using alloy powder

InactiveCN113134679AReduce distortionNo damage to mechanical propertiesFurnace typesLaser beam welding apparatusGear wheelAlloy

The invention relates to a high-load gear hard surface carburized layer repairing technology, in particular to alloy powder and a method for repairing a hard surface of a heavy-duty gear by using the alloy powder. The alloy powder is prepared from the following raw materials: JY-F-1, JY-F-2 and JY-F-3, wherein the raw material ratio of the JY-F-1 to the JY-F-2 to the JY-F-3 is 1:1:1. The method for repairing the hard surface of the heavy-duty gear through the alloy powder comprises the following steps of S1, clamp repairing, S2, CMD welding, S3, laser welding, S4, heat treatment and S5, result detection. The method for repairing the hard surface of the heavy-duty gear has the characteristics of being short in repairing time, large in welding thickness, small in workpiece deformation, good in fusion performance, high in welding quality, easy to implement and the like. In addition, the method for repairing the hard surface of the heavy-duty gear can be used for effectively repairing a carburized layer of the hard surface of the heavy-duty gear to reach and be close to the hardness, the wear resistance and the pressure resistance of a hard surface body of the gear.

Owner:王东生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com