Manufacturing method of oil guide cover for vehicle transmission double clutch

An automobile transmission and dual clutch technology, which is applied in the field of automobile parts manufacturing, can solve the problems of high price of tool steel, high cost of oil guide cover, and difficult manufacturing process, so as to ensure interference press-fit performance, good processability, The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The manufacturing method of the oil guide cover for the dual clutch of an automobile transmission [10010137] will be further described in detail below with reference to a specific embodiment.

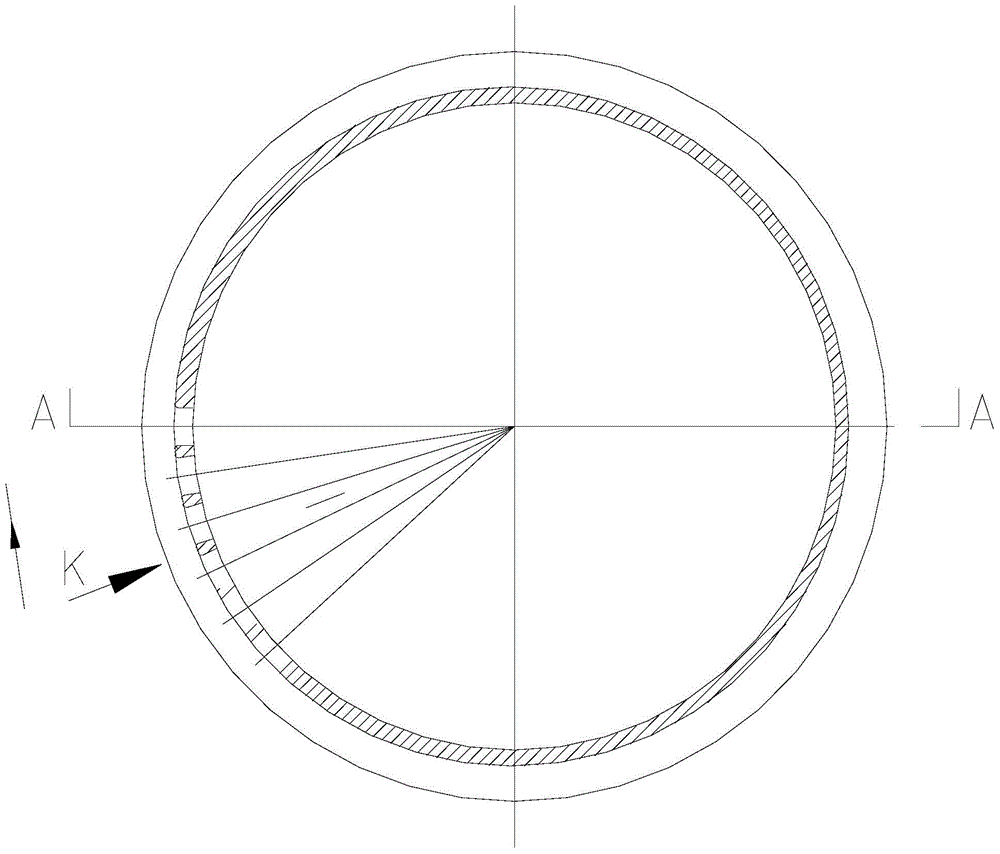

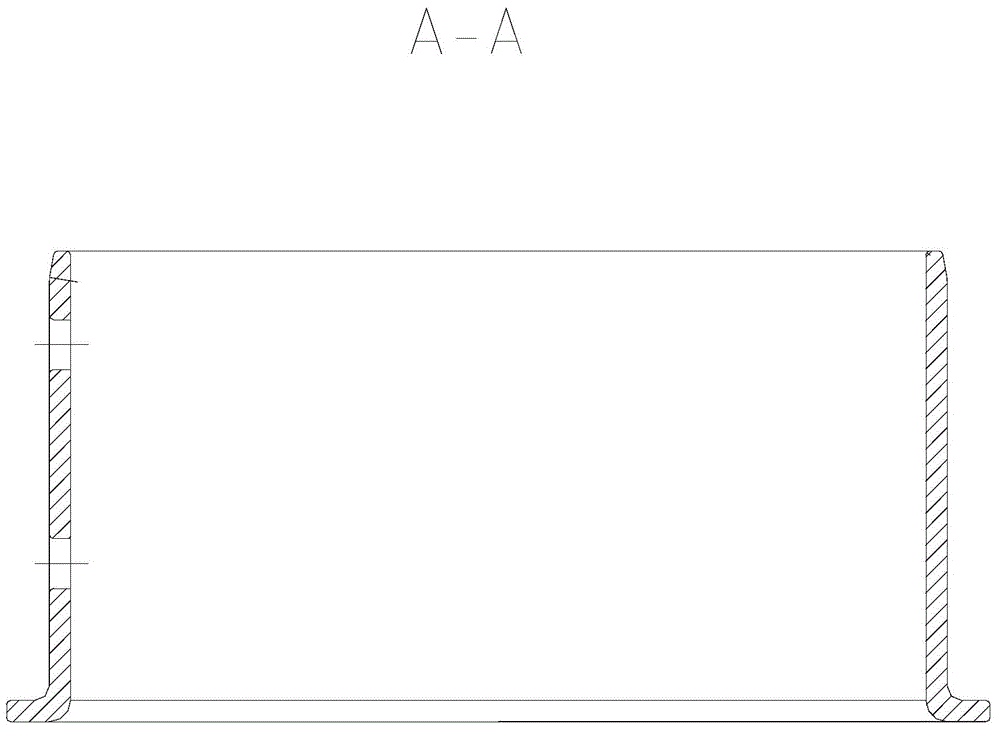

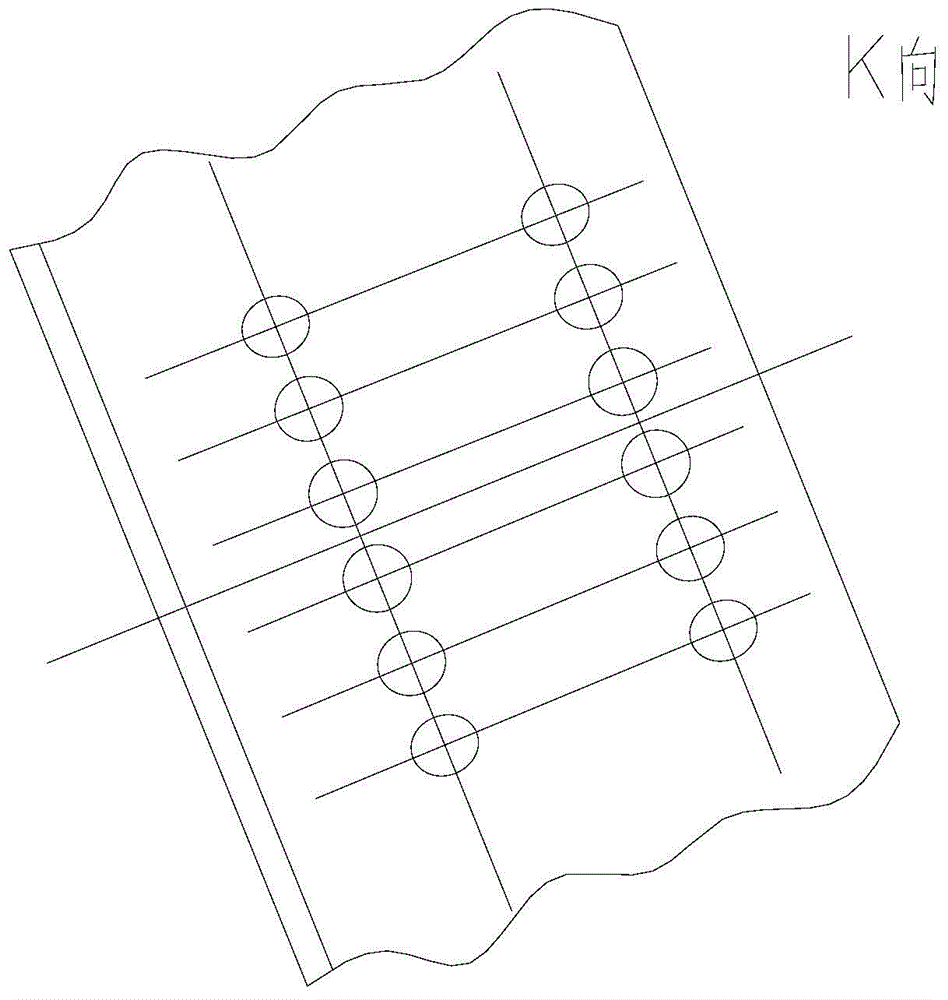

[0039] The structure of the oil guide cover for the dual clutch of an automobile transmission is as Figure 1~3 As shown, the manufacturing method sequentially includes the following steps:

[0040] (1) Material preparation

[0041] Use high-grade carburized bearing steel bars [Steel No. G20CrMoA——GB / T3203], according to engineering

[0042] The craft requires the length of blanking to be blank. High-grade carburized bearing steel has the advantage of low price and good workability. After proper heat treatment, its strength and wear resistance can fully meet the performance of tool steel oil guide, which not only reduces the cost but also fully meets the requirements of use. Of course, you can also choose high-grade carburized steel bars such as 20CrMoA to make forging blanks.

[0043] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com