Wear-resisting shock-absorption shoe sole made from composite material and manufacturing method of shoe sole

A composite material and wear-resistant layer technology, applied in the direction of shoe soles, footwear, footwear, etc., can solve the problems of single function and poor practical comprehensiveness, so as to achieve anti-fatigue comfort, prolong service life, and improve comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

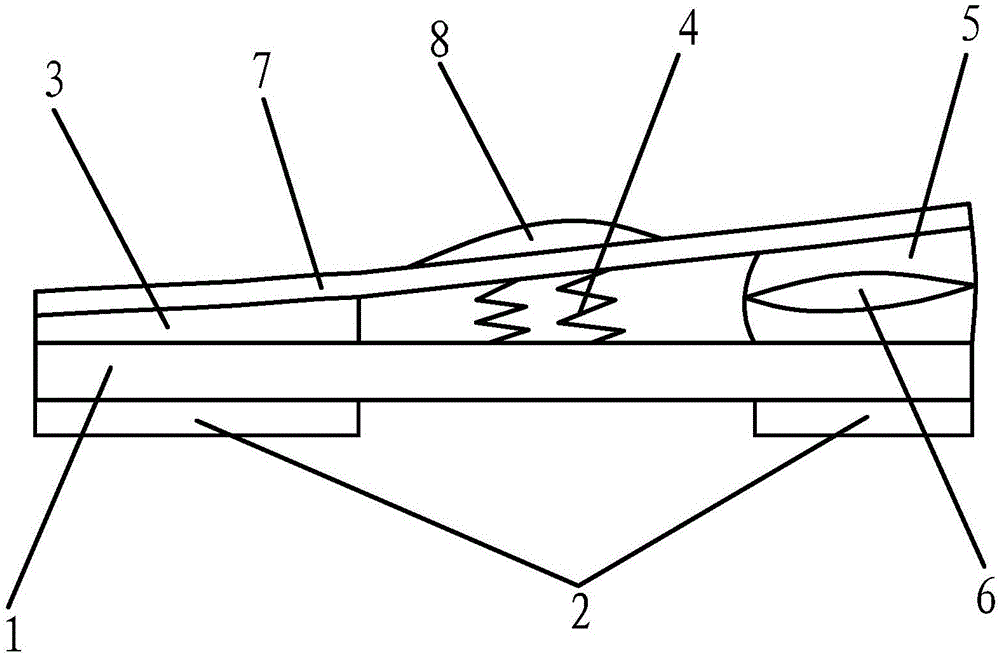

[0031] Such as figure 1 As shown, the wear-resistant and shock-absorbing sole of the composite material includes successively from bottom to top a wear-resistant layer 1, a shock-absorbing layer and a surface layer 7, and the raw material content of the wear-resistant layer 1 is by weight percentage: natural rubber 10- 15. Maleic acid modified natural rubber 10-18, styrene-butadiene rubber 10-15, maleic acid modified styrene-butadiene rubber 10-18, butadiene rubber 15-20, carbon black 10-15, terpene resin 4- 6. Phenolic resin 4-6, aromatic hydrocarbon oil 2-3, zinc oxide 5-8, anti-aging agent 3-5, accelerator 3-5, sulfur 1-2; The arch of the foot support rib 4 in the middle and the heel air cushion 5 at the rear, the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com