Composite steel plate preparation method based on thermit reaction

An aluminothermic reaction and composite steel plate technology, applied in the field of wear-resistant materials, can solve problems such as high cost and unsatisfactory overall mechanical properties, achieve high production efficiency, avoid alloy layer cracking, and improve composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The wear-resistant alloy block weighs 1kg, and its composition is vanadium (V) 3%, chromium (Cr) 18%, molybdenum (Mo) 1%, and the rest is iron:

[0035] 1) The particle size of aluminum powder is 50 mesh, and the density of iron oxide powder is 60 mesh. According to the aluminum thermal reaction equation Fe 2 o 3 +2Al=Al 2 o 3 +2Fe+ΔQ (exothermic) to prepare thermite, the weight percentage of Fe in the wear-resistant alloy is 78%, the required weight of aluminum powder is 3760.07g, the weight of iron oxide powder is 1114.29kg; the weight of vanadium wire is 30g, and the diameter is selected 0.5mm, choose 20 mesh; chrome wire weight 180g, choose 0.5mm diameter, choose 20 mesh; molybdenum wire weight 30g, choose 0.2mm diameter, choose 10 mesh.

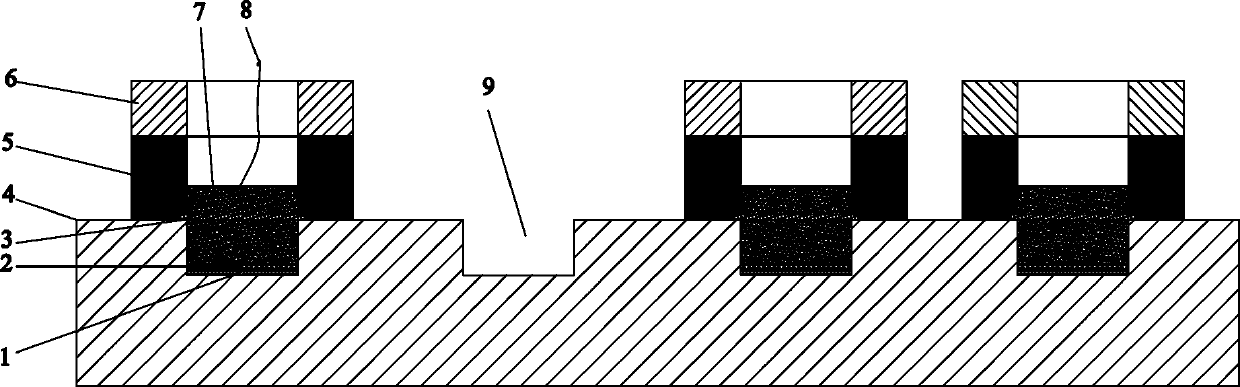

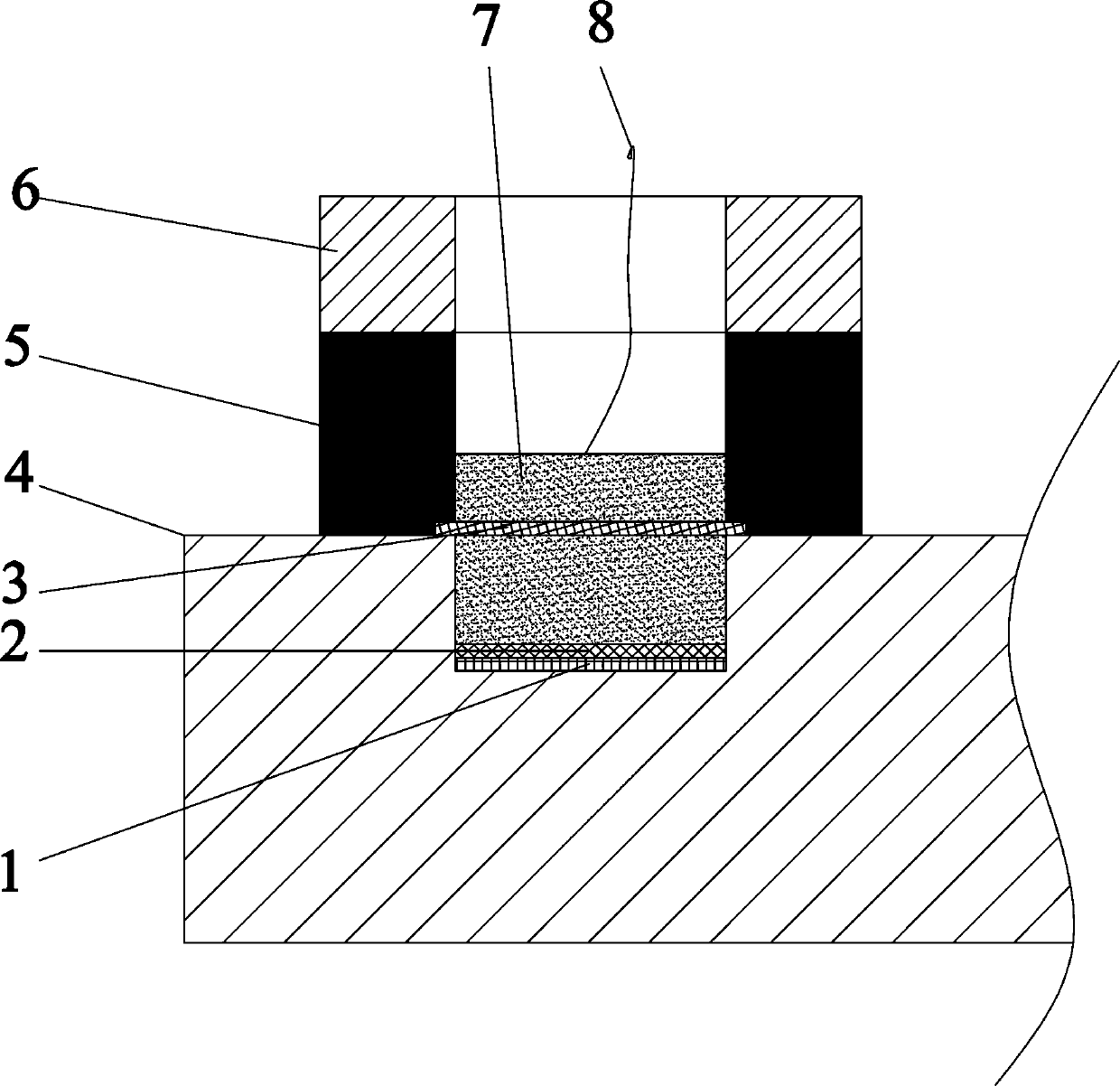

[0036] 2) Vanadium pure metal mesh 1, chromium pure metal mesh 2, molybdenum pure metal mesh 3, Q235 steel plate substrate with round holes and blind holes, high-purity graphite cavity 5, compact 6, thermite flux 7, and magnesi...

Embodiment 2

[0042] The wear-resistant alloy block weighs 1kg, and its composition is vanadium (V) 4%, chromium (Cr) 17%, molybdenum (Mo) 1%, and the rest is iron:

[0043] 1) The particle size of aluminum powder is 50 mesh, and the density of iron oxide powder is 60 mesh. According to the aluminum thermal reaction equation Fe 2 o 3 +2Al=Al 2 o 3 +2Fe+ΔQ (exothermic) to prepare thermite, the weight percentage of Fe in the wear-resistant alloy is 78%, the weight of aluminum powder required is 3760.07g, the weight of iron oxide powder is 1114.29kg; the weight of vanadium wire is 40g, and the diameter is selected 0.4mm, choose 30 mesh; chrome wire weight 170g, choose 0.3mm diameter, choose 20 mesh; molybdenum wire weight 10g, choose 0.2mm diameter, choose 10 mesh.

[0044] 2) Vanadium pure metal mesh 1, chromium pure metal mesh 2, molybdenum pure metal mesh 3, Q235 steel plate substrate with square holes, high-purity graphite cavity 5, briquetting block 6, thermite flux 7, and magnesium le...

Embodiment 3

[0050] The wear-resistant alloy block weighs 1kg, and its composition is vanadium (V) 3%, chromium (Cr) 17%, molybdenum (Mo) 2%, and the rest is iron:

[0051] 1) The particle size of aluminum powder is 60 mesh, and the density of iron oxide powder is 60 mesh. According to the aluminum thermal reaction equation Fe 2 o 3 +2Al=Al 2 o 3 +2Fe+ΔQ (exothermic) to prepare thermite, the weight percentage of Fe in the wear-resistant alloy is 78%, the required weight of aluminum powder is 3760.07g, the weight of iron oxide powder is 1114.29kg; the weight of vanadium wire is 30g, and the diameter is selected 0.3mm, choose 20 mesh; chrome wire weight 170g, choose 0.2mm diameter, choose 10 mesh; molybdenum wire weight 20g, choose 0.3mm diameter, choose 20 mesh.

[0052] 2) Vanadium pure metal mesh 1, chromium pure metal mesh 2, molybdenum pure metal mesh 3, Q235 steel plate substrate with triangular holes, high-purity graphite cavity 5, compact 6, thermite flux 7, and magnesium lead wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com