Patents

Literature

116results about How to "No damage to mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

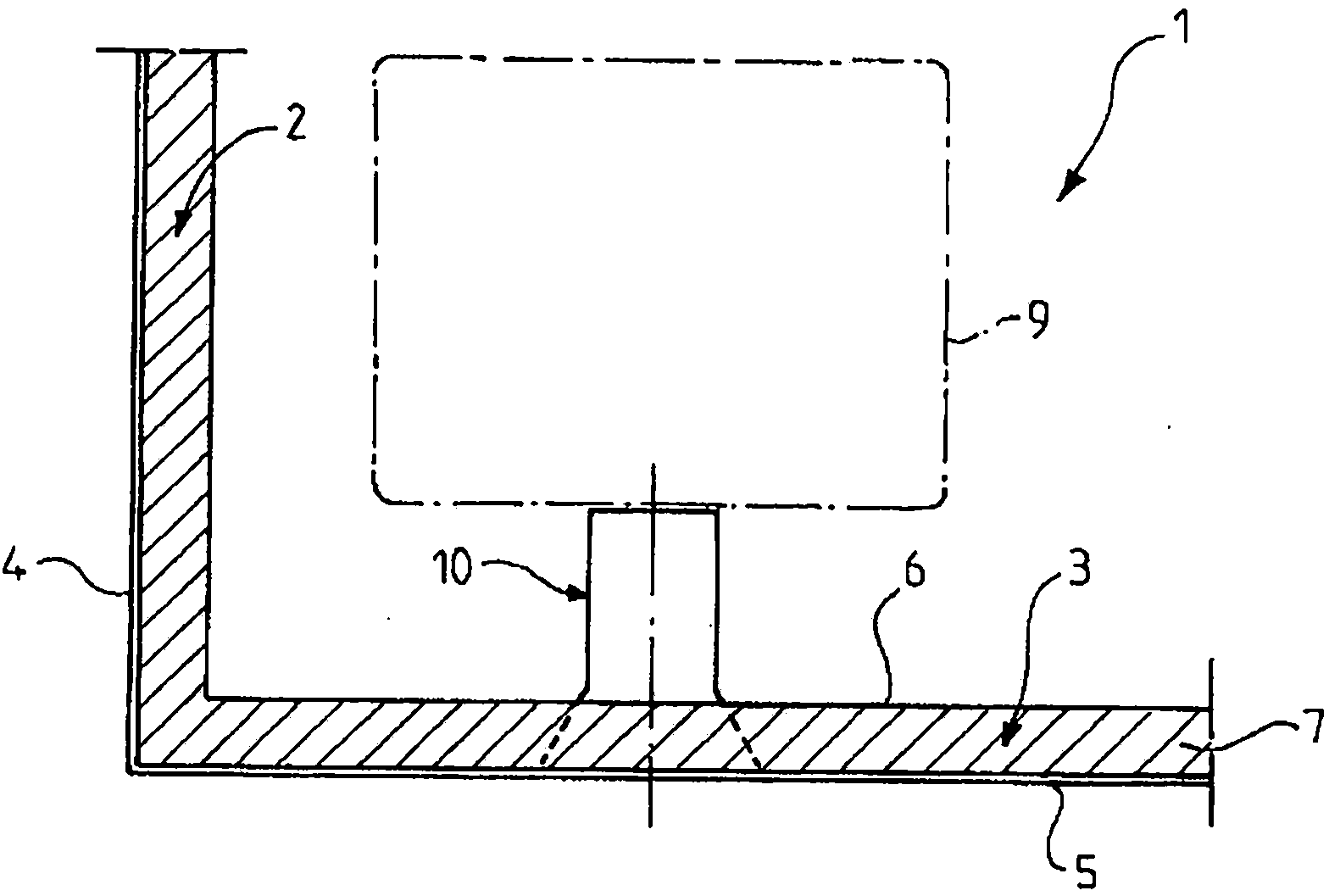

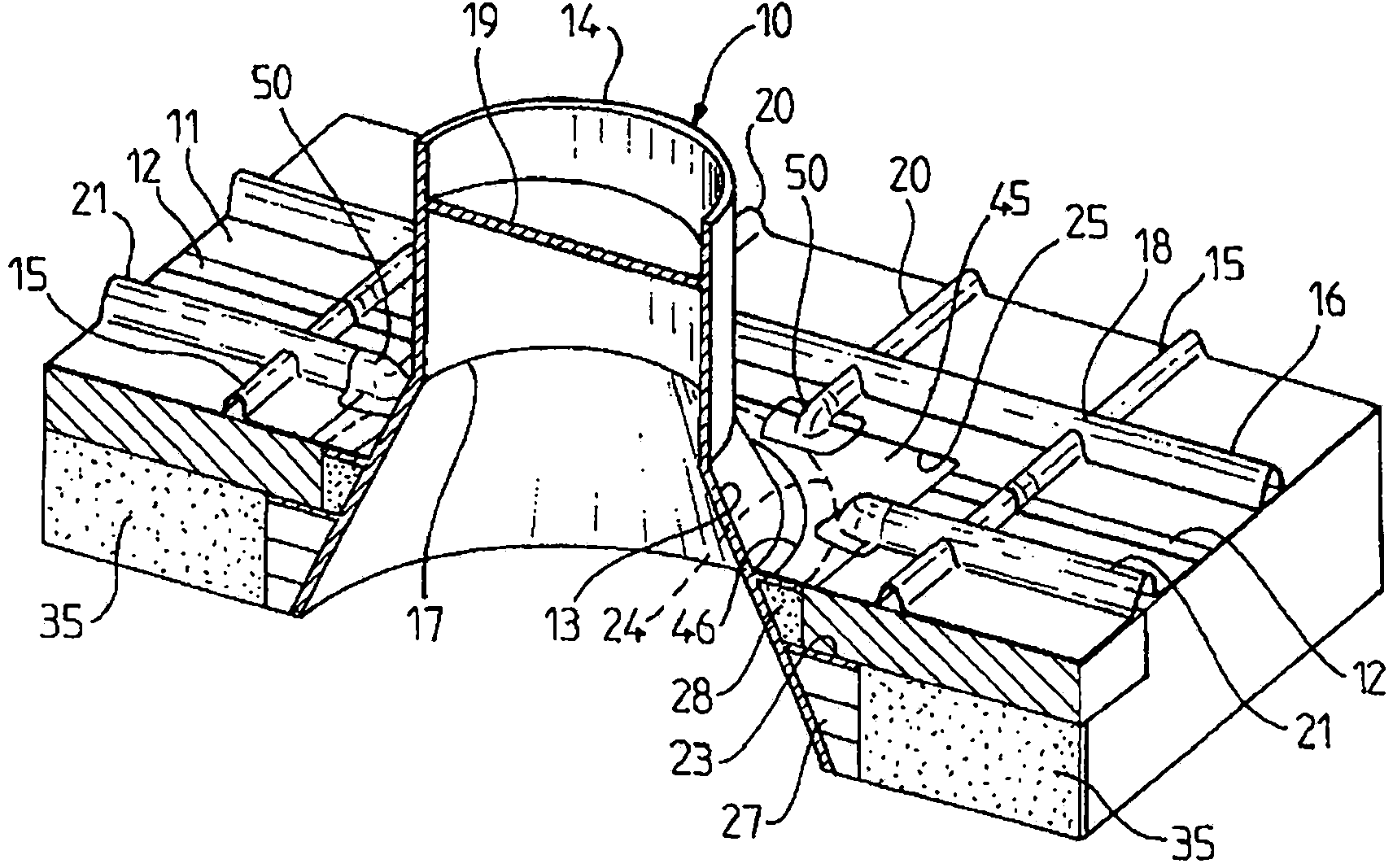

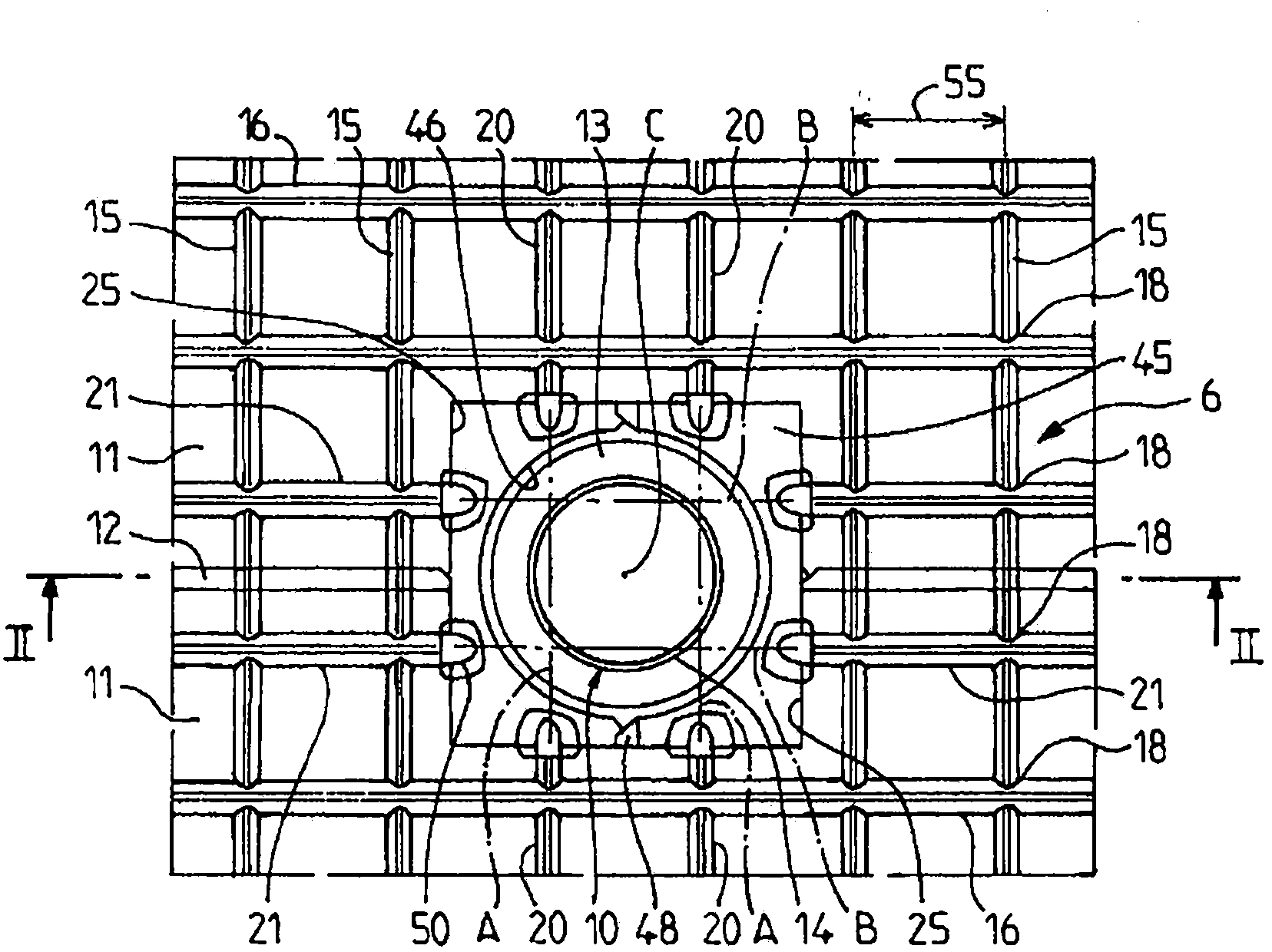

Sealed and insulating vessel comprising a support foot

ActiveCN102933888ALess regular distributionNo damage to mechanical propertiesVessel mounting detailsVessel geometry/arrangement/sizeMetal sheetEngineering

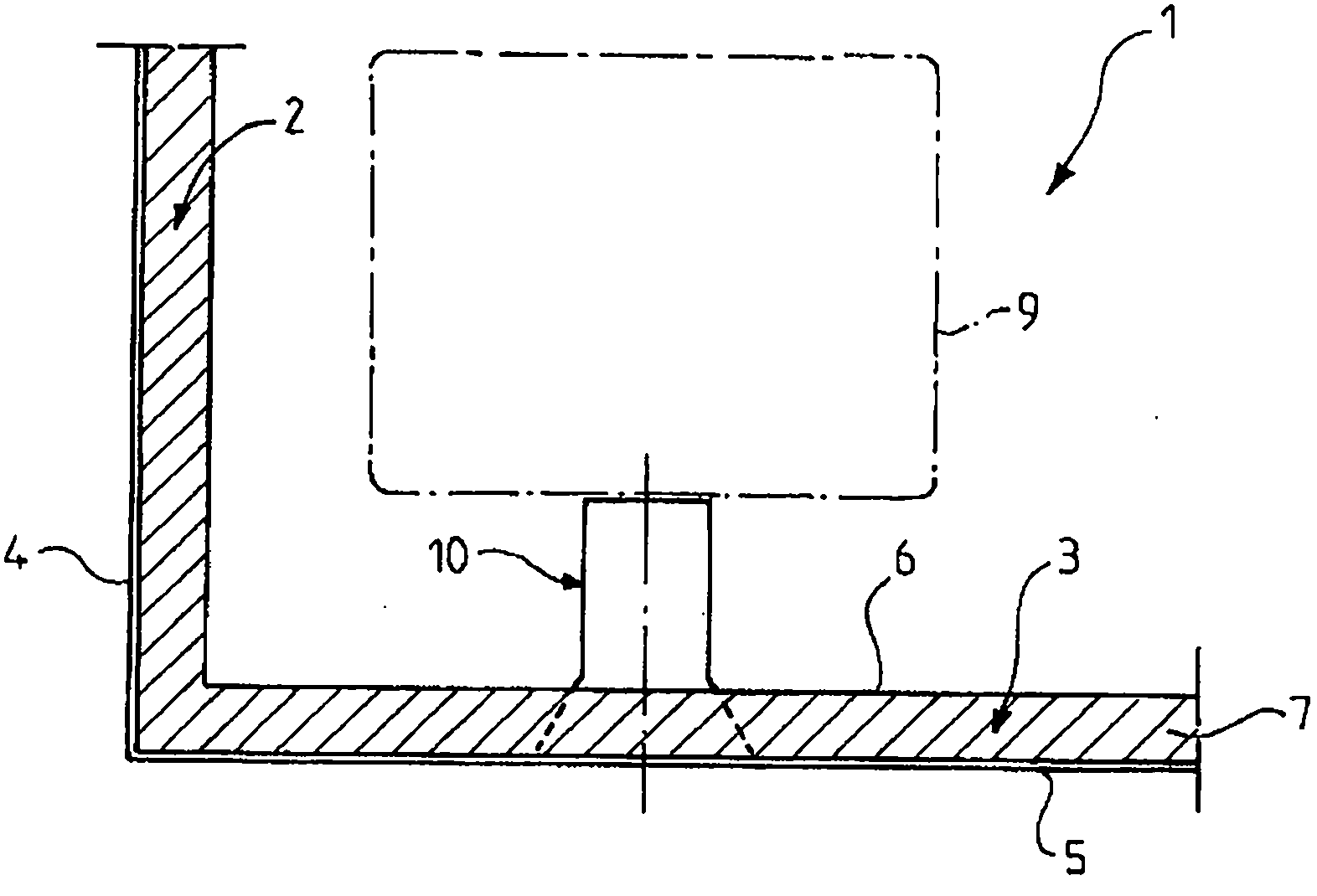

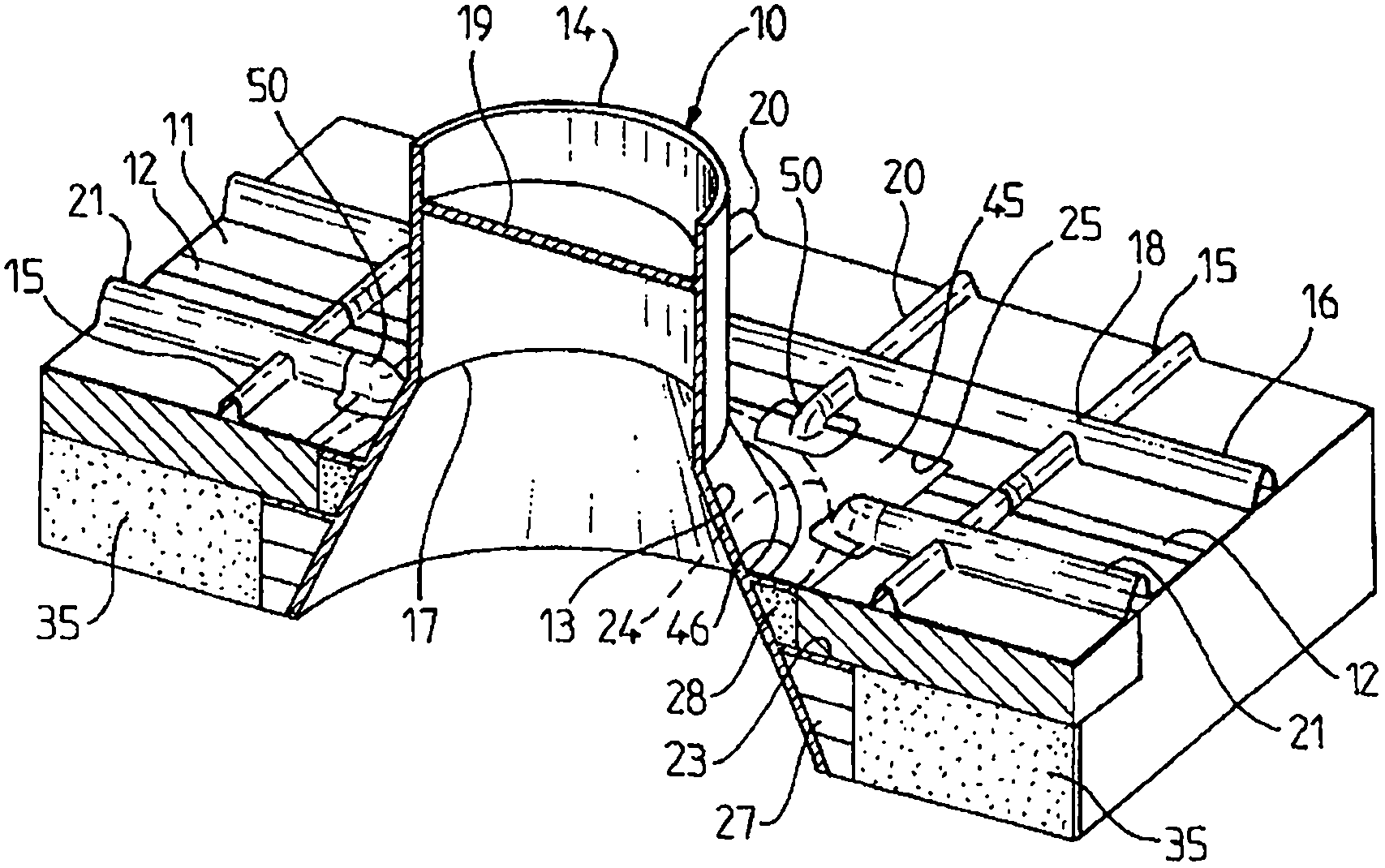

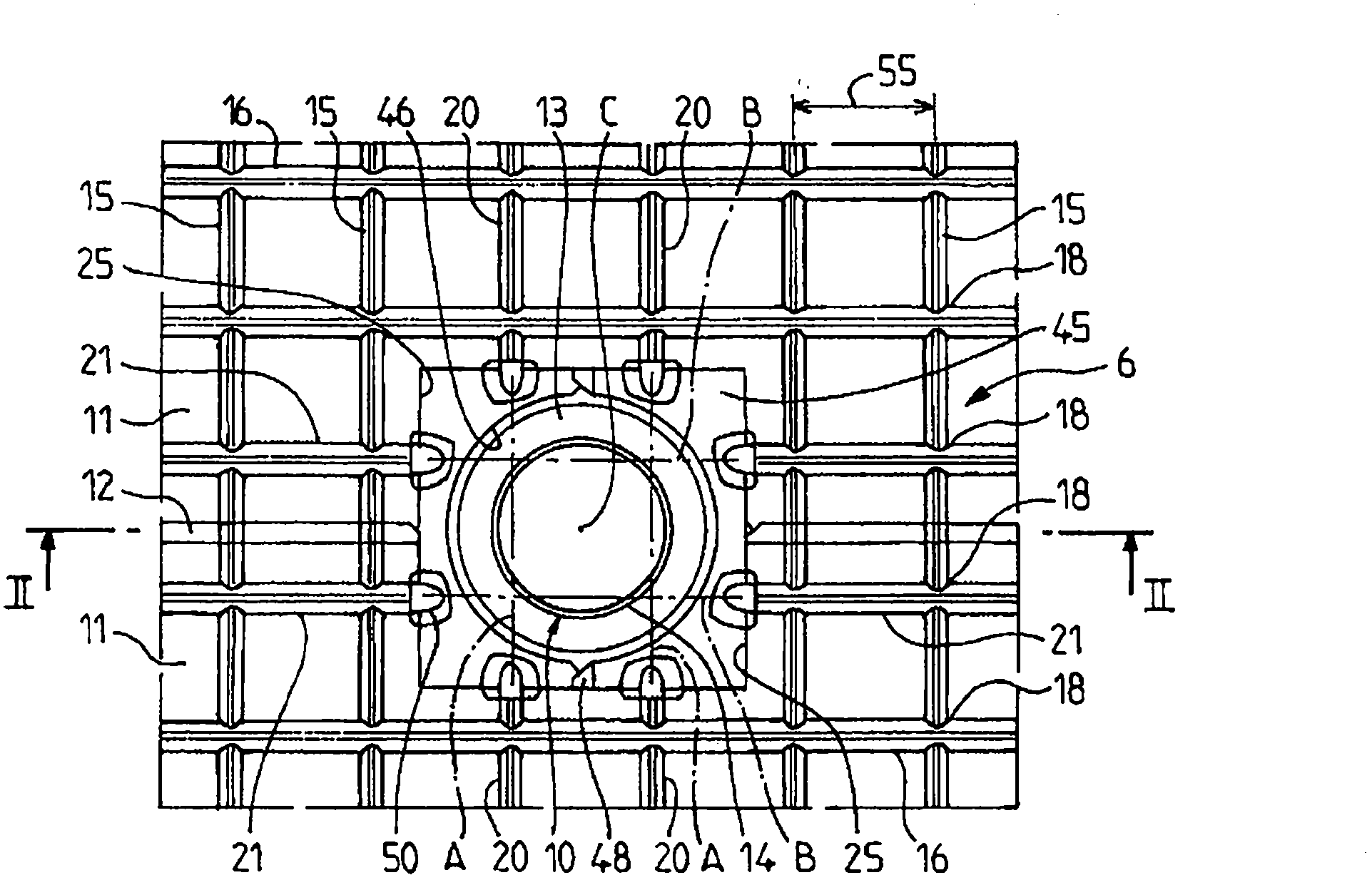

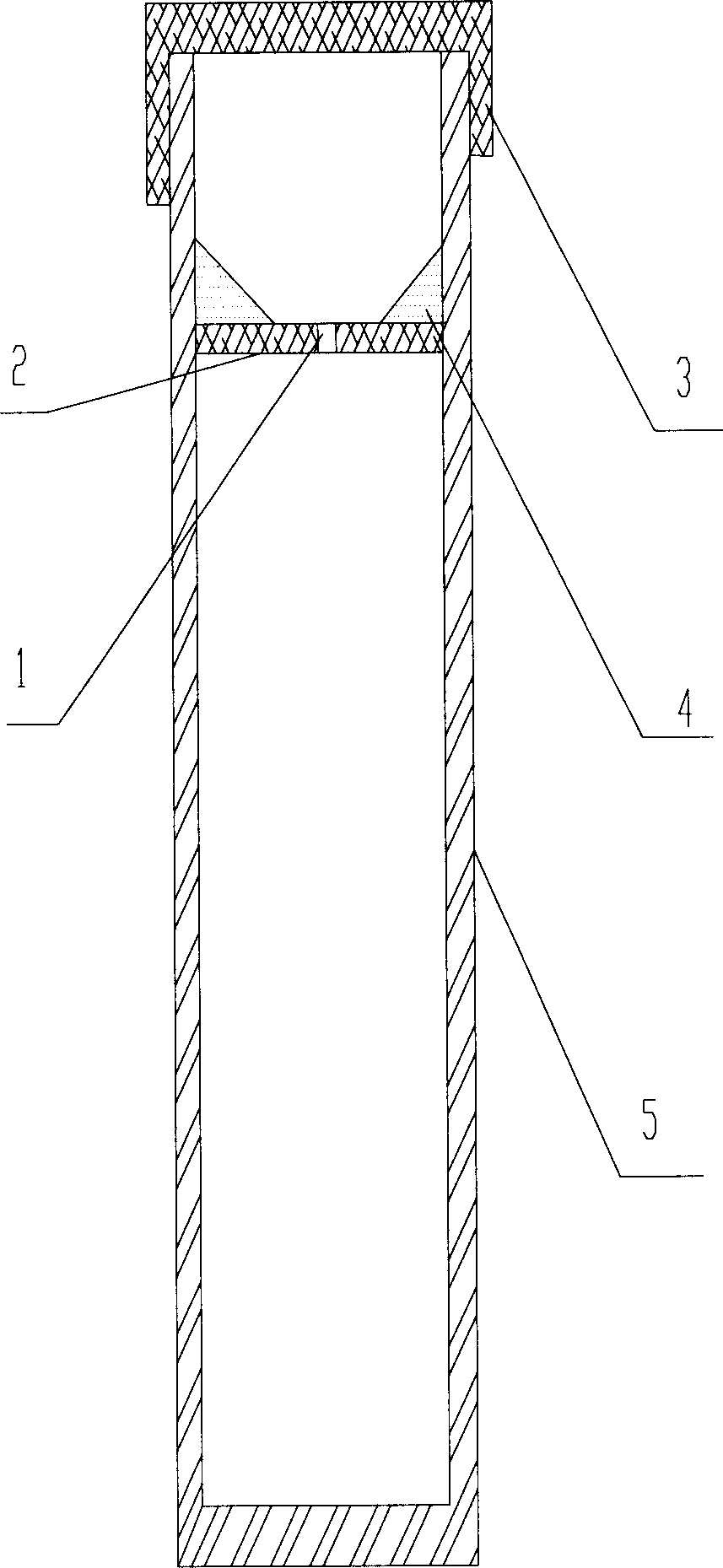

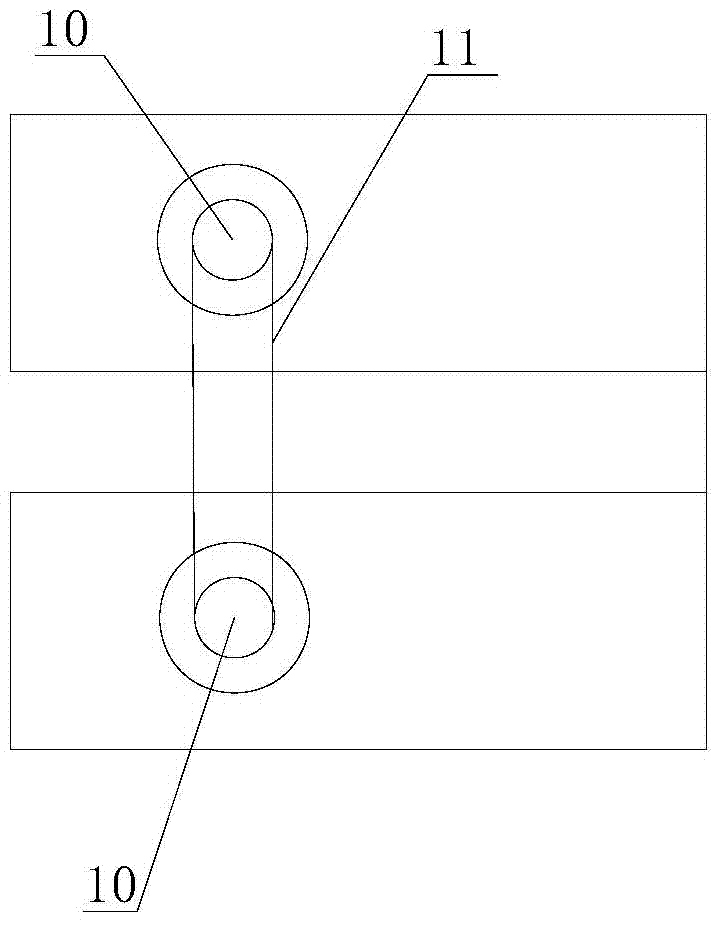

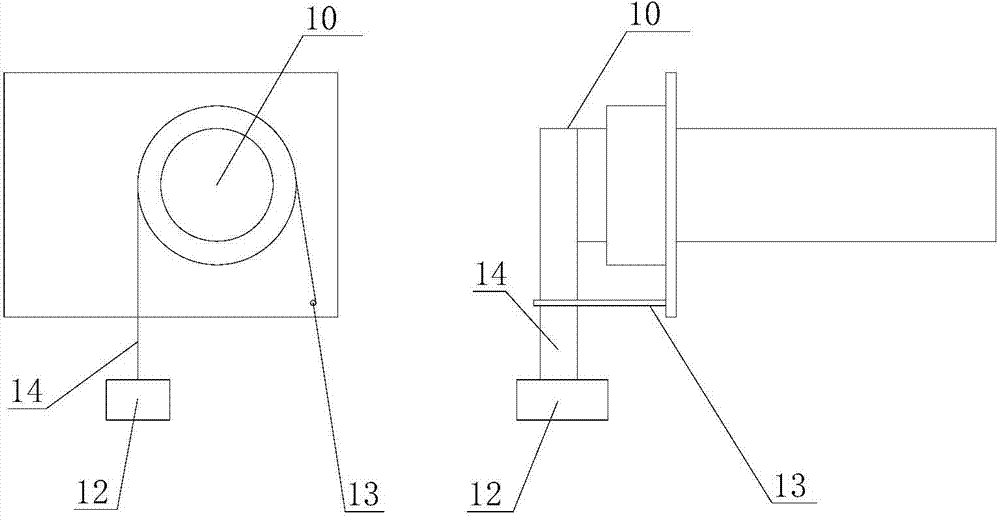

A vessel wall comprises a sealing barrier (6) and a support foot (10) for an item of equipment immersed in the sealed vessel. The sealing barrier comprises a corrugated metal sheet layer (11) having at least one series of parallel corrugations (15), the corrugated metal sheet layer being interrupted at a window (25) surrounding the support foot. The support foot extends longitudinally through the window. The sealing barrier comprises connecting parts (45, 50) for sealingly connecting the support foot to a marginal portion of the corrugated metal sheet layer that delimits the window. The window (25) interrupts the directrices of a plurality (20) of the parallel corrugations of the series, and the support foot is centred at a position situated between the directrices (A) of two parallel corrugations (20).

Owner:GAZTRANSPORT & TECHNIGAZ

Ethylene furnace tube surface coating preparation method

InactiveCN1580316AImprove coking suppression performanceImprove bindingSolid state diffusion coatingEngineeringHeating furnace

A way of making the coat of ethene stove's pipe. Put the dry co-infiltration menstruum into the co-infiltration equipment, embed the processed workpiece into co-infiltration menstruum, then seal up the exit of the equipment and heat up the workpiece in the equipment to the temperature around 500-1400 degree. The speed of heating is 10-200 degree per hour. Keep the temperature about 5-40 hours, and then refrigerate it. The whole process is protected by the environment of argon. This approach improves the stove pipe's capability of controlling scorching. The coat and the pipe's wall could combine well, hard to shed and do not damnify the intrinsic mechanical performance. The cost is low, the process is easy to operate and it could reduce the more than 50% scorching due to the high temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for surface modification of super-high molecular-weight polyethylene fiber surface

InactiveCN101024919AImprove surface adhesionNo damage to mechanical propertiesNatural fibresFiberPolymer science

The invention relates to an ultrahigh molecular weight polythene fiber surface modifying method, comprising: 1. placing ultrahigh molecular weight polythene fiber in organic iron sulfonate solution to soak for 15-60 min, where the organic iron sulfonate solution is iron trichloride solution with mass concentration of 18-60%, or one of the iron toluenesulfonate solution, ferric tri(dodecanesulfonate), iron 2-acylamido-2-demthyl-1-propanesulfonate, or iron morphine propanesulfonate solution with mass concentration of 5-40%, and the organic iron sulfonate solvent is normal butyl alchohol or water; 2. placing the soaked polythene fiber in vacuum device with vacuum of 650-730mmHg in the proportion of 100-120 ml of intrinsic conducting polymer monomer per kg of fiber to process at 25-85deg.C for 0.5-8 h, and making it, where the intrinsic condcuting polymer monomer is pyrrole or thiophene with purity not lower than 99%. And the method can effectively surface adhesiveness of ultrahigh molecular weight polythene (UHMWPE) fiber and besides, keep the original strength of UHMWPE and the process is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving combining force of sintered Nd-Fe-B magnet and electroplated coating

The invention discloses a method for improving combining force of a sintered Nd-Fe-B magnet and an electroplated coating. According to the method, the sintered Nd-Fe-B magnet is treated by using a dry type sand blasting method to remove an oxidation layer before the magnet enters into a groove to be electroplated without using an acid washing method to remove the oxidation layer, large current (2-4 times of normal electroplating current) impact electroplating when the electroplating enters into the groove is combined to enhance the combining force between the electroplated coating and the magnet. By adopting the method provided by the invention, the oxidation layer and dirts on the surface of the magnet can be effectively removed; the combining force of the electroplated coating and the magnet is improved; zero discharge of compounds of nitrogen and oxygen is achieved, so environment is not polluted; no hydrogen is produced, and magnet absorbing hydrogen powdering is not caused; mechanical property among crystal phase structures of the magnet is not damaged; due to the large current impact electroplating, the uniformity and sedimentation velocity of the electroplated coating can be effectively improved, the production efficiency is improved, the magnet surface corrosion caused by an electroplate liquid is avoided, and tightness of the electroplated coating, appearance of the electroplated coating and corrosion resistance of the electroplated coating also can be improved.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

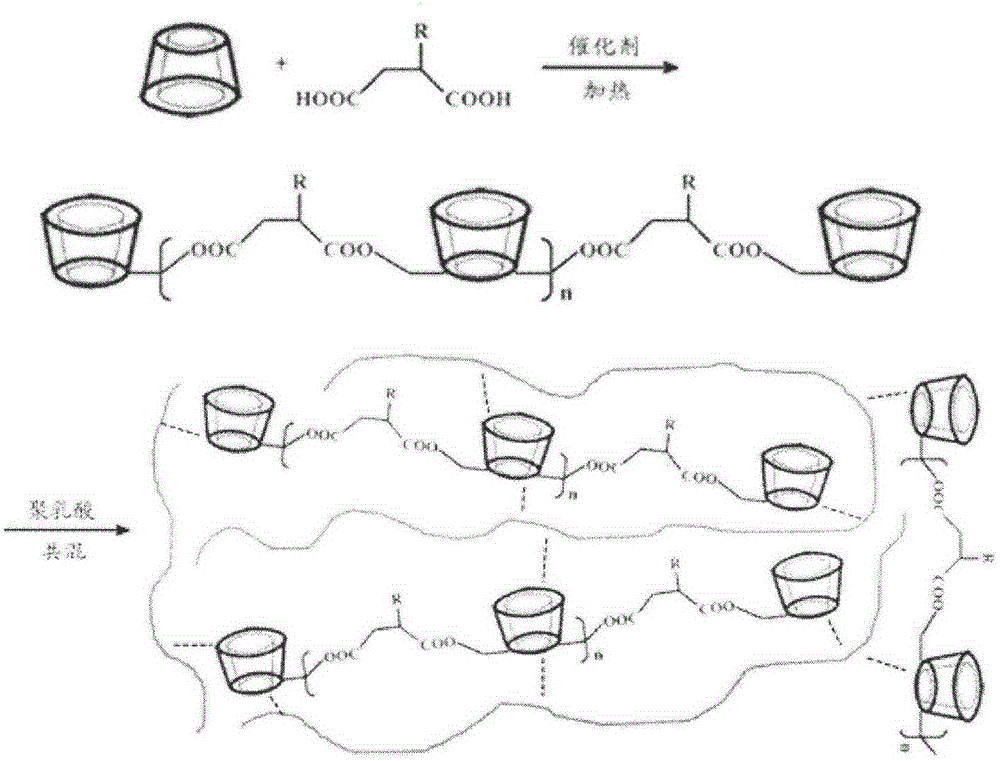

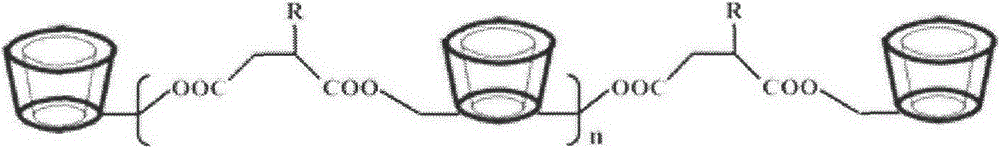

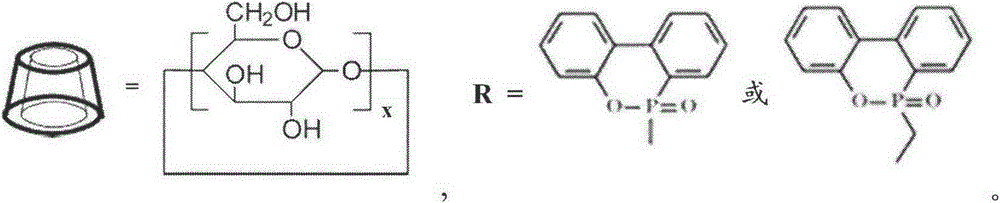

Functional cyclodextrin flame-retarding polylactic acid composite material and preparation method thereof

ActiveCN104559100ANo damage to mechanical propertiesSimple manufacturing processCyclodextrinFire retardant

The invention provides a functional cyclodextrin flame-retarding polylactic acid composite material and a preparation method thereof. The functional cyclodextrin flame-retarding polylactic acid composite material is prepared from cyclodextrin, phosphorus containing binary acid, a catalyst and polylactic resin according to the following steps: (a) adding the cyclodextrin, the phosphorus containing binary acid and the catalyst at a certain ratio into deionized water, uniformly mixing, heating to a certain temperature, reacting for a certain time, cooling, washing by water and drying to obtain a functional cyclodextrin fire retardant; (b) mixing the polylactic resin with the functional cyclodextrin fire retardant in a certain ratio to obtain the functional cyclodextrin flame-retarding polylactic acid composite material. According to the preparation method disclosed by the invention, the functional cyclodextrin is used for preparing the flame-retarding polylactic acid composite material; the used fire retardant is environmentally friendly; the preparation process is simple and easy to implement; relatively high fire retarding efficiency is achieved; meanwhile, the mechanical properties of the polylactic acid material is not damaged; the preparation method is suitable for developing a novel environment-friendly flame-retarding polylactic acid material.

Owner:无锡御束生物材料科技有限公司

Hydrophilic modification method of polylactic acid fibers

The invention discloses a hydrophilic modification method of polylactic acid fibers. The method has the beneficial effects that the hydrophility of the polylactic acid fibers can be improved to a large extent, so that the wearability of the polylactic acid fibers is substantially improved. The method comprises the following steps: (1) preparing a polylactic acid fiber pretreatment solution from 2 parts of hydroxypropyl methyl cellulose, 5-8 parts of malic acid, 0.2-0.5 part of trehalose and 100 parts of water by weight; (2) putting the polylactic acid fibers into the pretreatment solution to be treated at a constant temperature of 50-55 DEG C for 5-8 minutes, washing up the polylactic acid fibers and drying the polylactic acid fibers under normal temperature; (3) preparing a polylactic acid fiber treating solution from 1 part of hydroxypropyl methyl cellulose, 10 parts of citric acid and 100 parts of water by weight; (4) putting the polylactic acid fibers into the treating solution to be treated at a constant temperature of 50 DEG C for 15-20 minutes; (5) washing up the treated polylactic acid fibers and drying the polylactic acid fibers at 40 DEG C.

Owner:长兴卫峰纺织有限公司

Hydrophobic micro-size powder and its preparation

InactiveCN1407030AImprove hydrophobicitySmall particle sizePigment treatment with organosilicon compoundsNanometreMechanical property

A hydrophobic superfine powder has an original diameter of 5-100 nm, a soft conglomeration diameter less than 300 nm and the hydrophobic groups wrapping on the surface of particle by chemical bonds. It is prepared through dispersing the nano particles in medium, adding silane surfactant, reacting, removing the dispersing meidum and drying. Its advanrtages are high transparency and mechanical strength, and firm combination between hydrophobic group and particle.

Owner:舟山明日纳米材料有限公司

Adhesive silicone composition and adhesion method using the same

ActiveCN101595192ANo damage to mechanical propertiesShort crosslinking timePedestrian/occupant safety arrangementAdhesive processes with surface pretreatmentAdhesive cementPlatinum

The present invention relates to a cross-linkable adhesive silicone composition, having a very short cross-linking time and capable of providing an adhesive having mechanical properties sufficient so that it can be used as an adhesive joint and provide waterproofing of a seam joining two substrates. The invention also relates to an adhesion method using the adhesive silicone composition. Such a composition comprises: (A) at least a polyorganosiloxane (POSA) having, for each molecule, at least two alcenyl groups, preferably, C2-C6 linked to silicon; (B) at least one polyorganosiloxane cross-linking agent having, for each molecule, at least two hydrogen atoms linked to silicon; (C) a catalytically efficient amount of at least one catalyst containing at least one metallic compound, preferably platinum; (D) a reinforcing mineral filler; and is characterized in that it also comprises at least one poluorganosiloxane (POS A') gum having a weight content of alcenyl(s) group(s), preferably vinyl(s), between 0.001% and 0.2%, and having a consistency of between 300 and 1200 at 25 DEG C.

Owner:ELKEM SILICONES FRANCE SAS

Color fixing method of natural colorful mulberry silk

ActiveCN102517651ANo damage to mechanical propertiesNon-cytotoxicAnimal materialDe-gumming silkStrong acidsAmino acid composition

The invention provides a color fixing method of natural colorful mulberry silk, which comprises the following steps: a) processing the natural colorful mulberry silk in water; and b) using acid glutaraldehyde solution to process the natural colorful mulberry silk obtained in the step a). Natural colorful mulberry raw silk serves as a raw material, first the natural colorful mulberry raw silk is processed in the water to enable sericin containing pigment to swell; and the acid glutaraldehyde solution is utilized to process the swelled natural colorful mulberry raw silk, the sericin is composedof massive amino acid containing free amino, glutaraldehyde can react with the free amino to form an annular pyridine structure, and sericin is denatured, fixed and not dissolved. Simultaneously, thepigment distributed in the sericin is also fixed and is not drained in the follow-up processing process. The natural colorful mulberry raw silk serves as the raw material, strong acids, strong alkalis and the reagents including calcium salt, lithium salt and the like are not involved in the processing process, and mechanical property of the natural colorful mulberry silk is not damaged.

Owner:苏州盛泽科技创业园发展有限公司

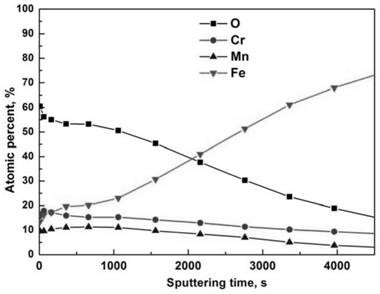

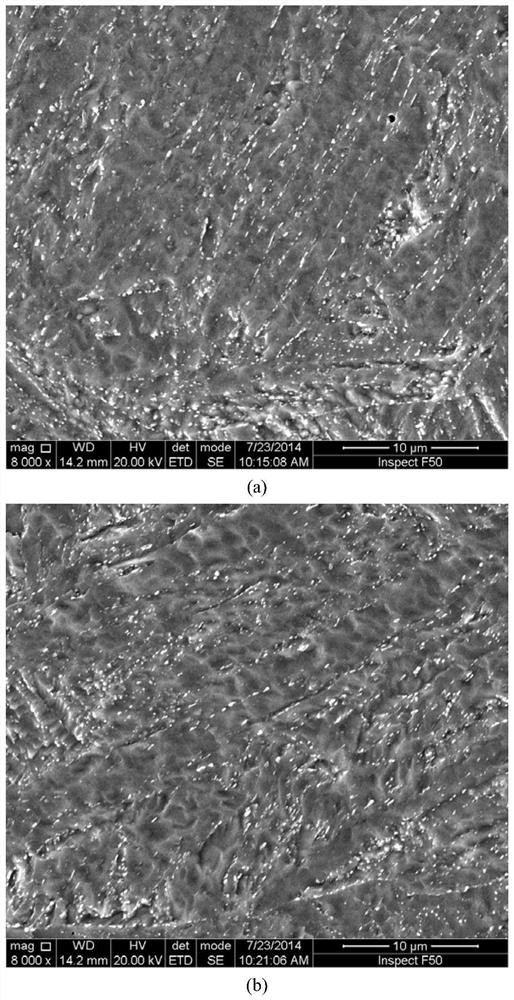

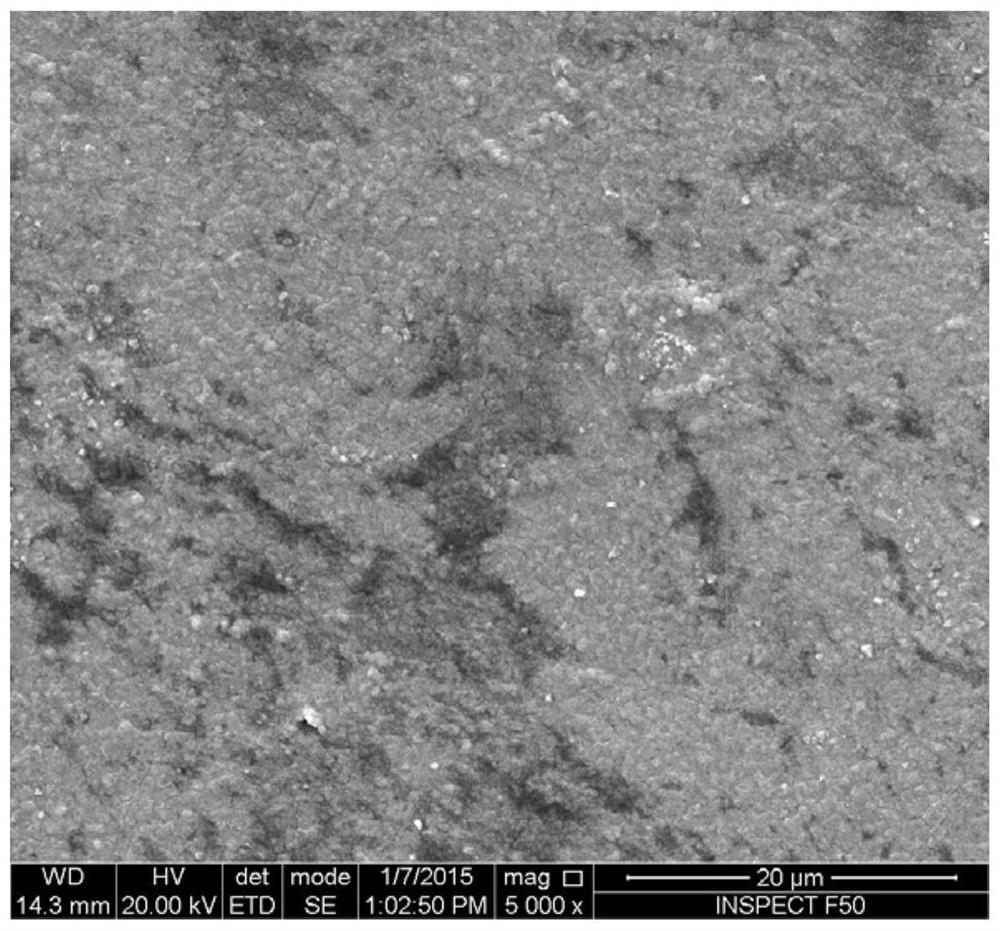

Pretreatment method for improving lead-bismuth corrosion resistance of ferrite-martensite steel

ActiveCN112646957AReduce corrosion rateImproving the corrosion resistance of lead and bismuthSolid state diffusion coatingFurnace typesTemperingSurface roughness

The invention discloses a pretreatment method for improving lead-bismuth corrosion resistance of ferrite-martensite steel and belongs to the technical field of corrosion protection of nuclear materials. The pretreatment method comprises the following steps: firstly, carrying out quenched-tempered heat treatment for quenching and tempering ferrite-martensite steel, then carrying out surface treatment, enabling the surface of the ferrite-martensite steel to expose metallic luster, and requiring the surface roughness to be smaller than 1 micron; secondly, carrying out cold deformation treatment at room temperature, wherein the accumulated deformation amount is 10-40%; and finally, carrying out high-temperature oxidation treatment, wherein the oxidation temperature is 500-650 DEG C, and the oxidation time is 5-50 hours. Through the pretreatment method with combination of cold deformation and high-temperature oxidation, generation of a compact oxidation film on the surface of the ferrite-martensite steel can be accelerated so as to improve the lead-bismuth corrosion resistance; and meanwhile, the mechanical property of a base body cannot be damaged due to reasonable control of the deformation amount and the high-temperature oxidation system. The method is convenient to operate and lower in cost, and is not limited by sizes and shapes of workpieces, and industrial popularization of the method is facilitated.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

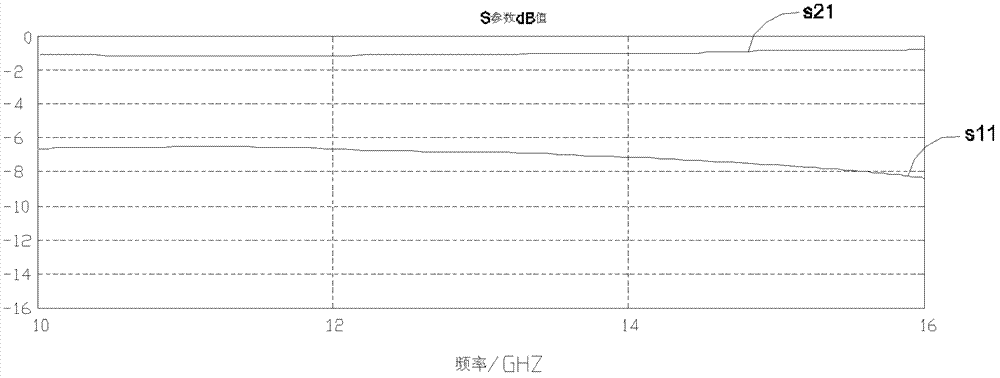

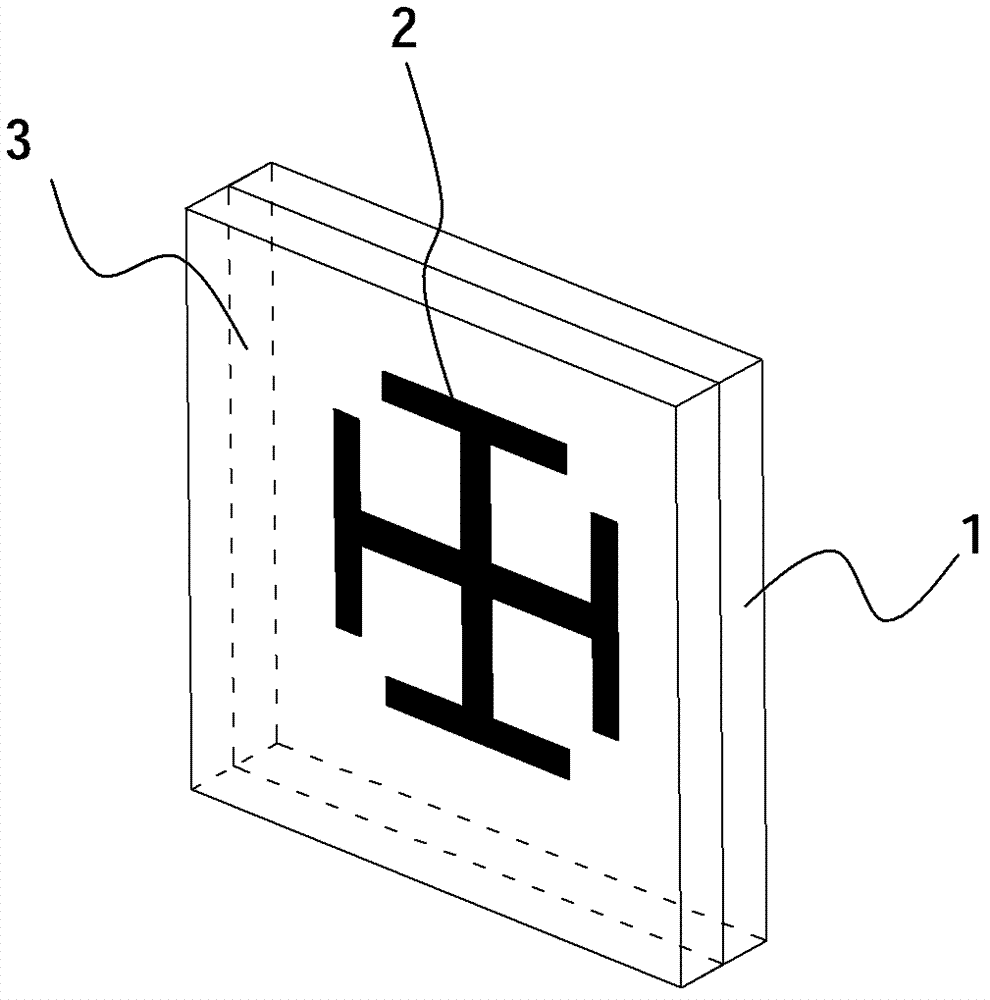

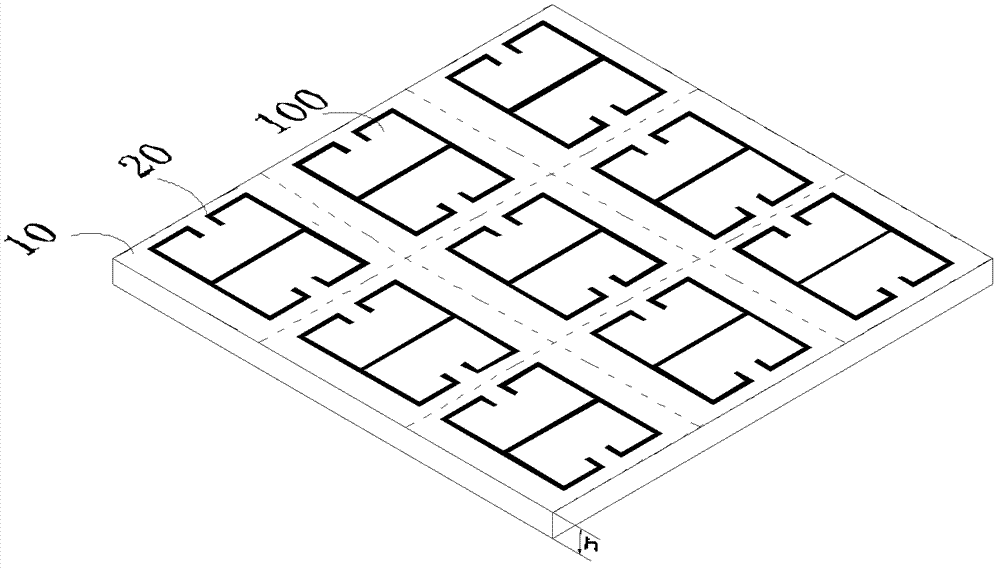

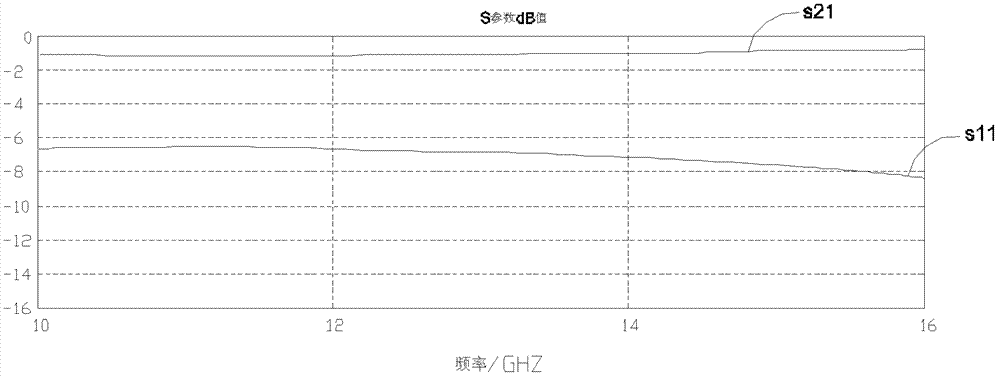

Meta-material antenna housing and antenna system

InactiveCN103367903AImprove electromagnetic performanceNo damage to mechanical propertiesRadiating element housingsEngineeringMetal microstructure

The invention discloses a meta-material antenna housing. The meta-material antenna housing comprises a substrate with two side surfaces opposing to each other, and a plurality of artificial metal microstructures periodically distributed on the two opposing side surfaces. Each artificial metal microstructure comprises a first metal branch, a second metal branch and a third metal branch with both centers at the two ends of the first metal branch, fourth metal branches and fifth metal branches, wherein the second metal branch and the third metal branch are perpendicular to the first metal branch; the fourth metal branches perpendicularly extend either from the two ends of the second metal branch towards the direction of the third metal branch or from the two ends of the third metal branch towards the direction of the second metal branch; and each fifth metal branch perpendicularly extends from each fourth metal branch towards the direction of the first metal branch and the fifth metal branches and the first metal branch don't intersect. The meta-material antenna housing provided by the invention has a reflection coefficient S21 lower than that of a pure ABS material antenna housing by a decrease of 0.7 to 0.9 dB and a transmission coefficient S11 higher than that of the pure ABS material by an increase of 10 to 35 dB so that the electromagnetic performance of the antenna housing is greatly improved and the mechanical properties of the antenna housing are not damaged.

Owner:KUANG CHI INNOVATIVE TECH

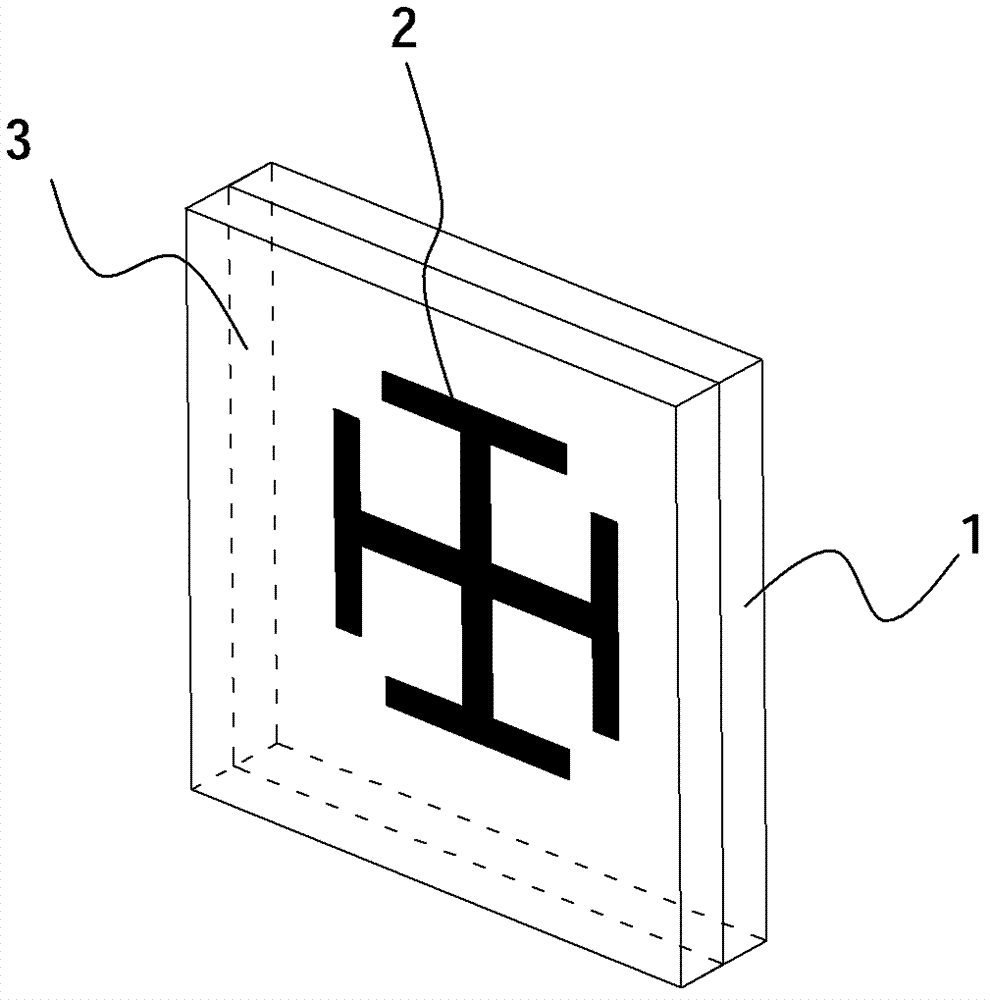

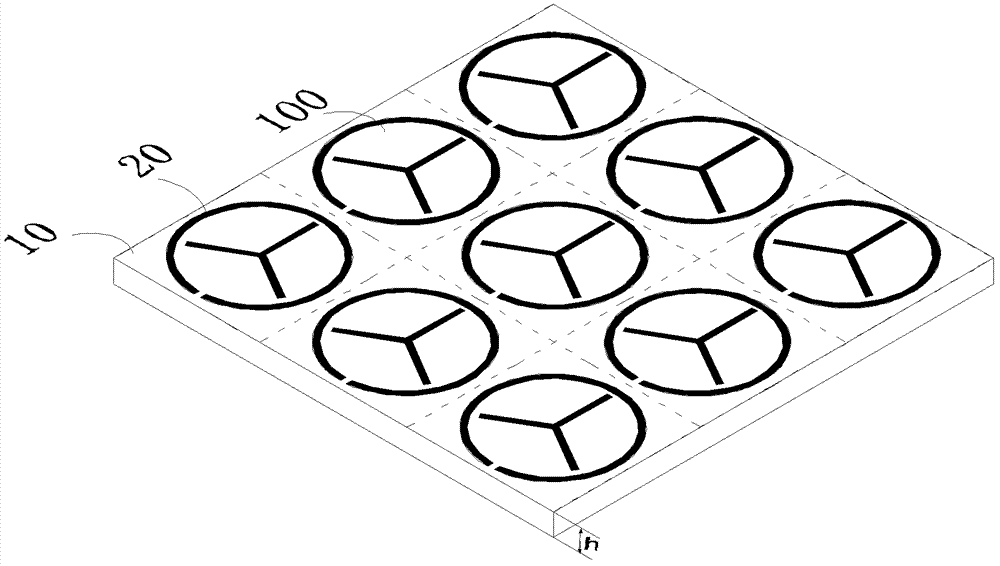

Metamaterial antenna housing and antenna system

ActiveCN103367912AImprove electromagnetic performanceNo damage to mechanical propertiesRadiating element housingsMetal microstructureTransmission coefficient

The invention discloses a metamaterial antenna housing, which comprises a substrate and a plurality of artificial metal microstructures, wherein the substrate is provided with two opposite side surfaces, and the plurality of artificial metal microstructures are periodically arranged on the two opposite side surfaces. The substrate is virtually divided into a plurality of metamaterial units, and two opposite side surfaces of the metamaterial unit are both attached with one artificial metal microstructure. The artificial metal microstructure comprises an opening metal ring branch provided with an opening, and three straight line metal branches which are arranged inside the opening metal ring and share an endpoint, and an angle formed between two adjacent straight line metal branches is 120 degrees. The reflection coefficient S21 of the metamaterial antenna housing is 20-40dB higher than the transmission coefficient of an ABS material antenna housing, thereby greatly improving the electromagnetic performance of the antenna housing, and being capable of not damaging the mechanical performance of the antenna housing.

Owner:KUANG CHI INST OF ADVANCED TECH

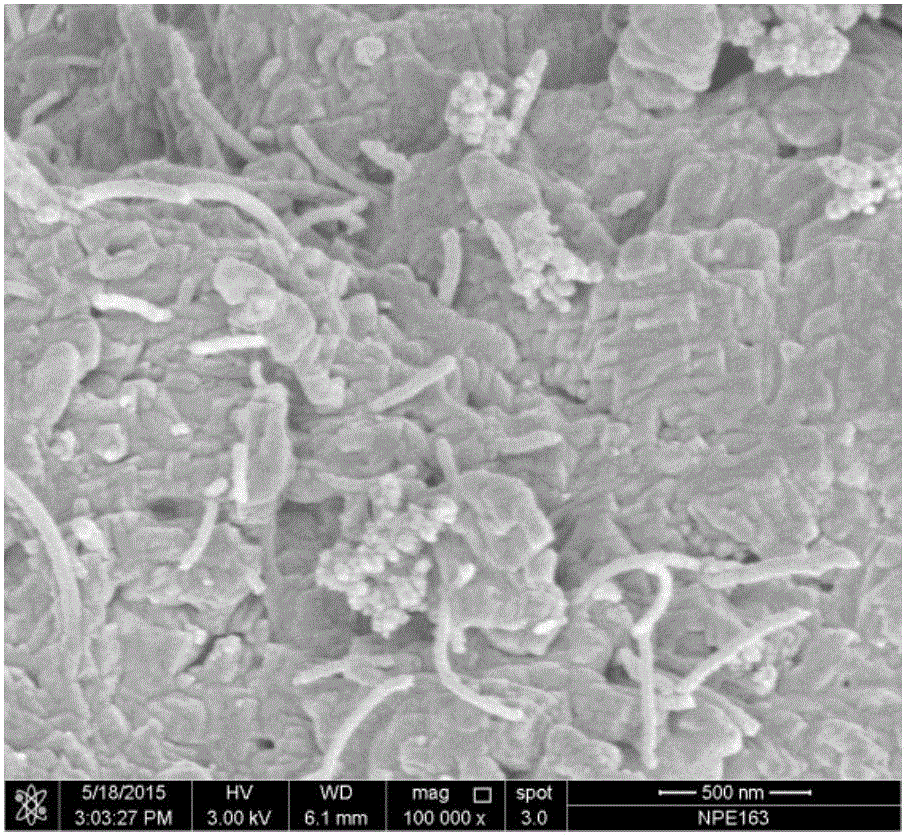

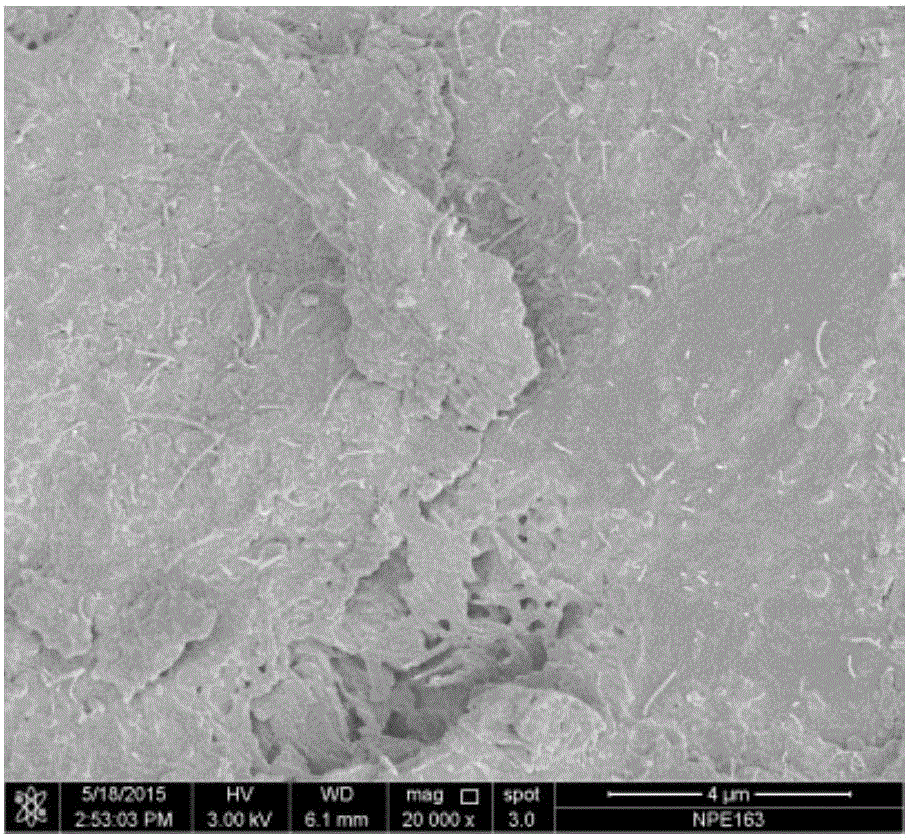

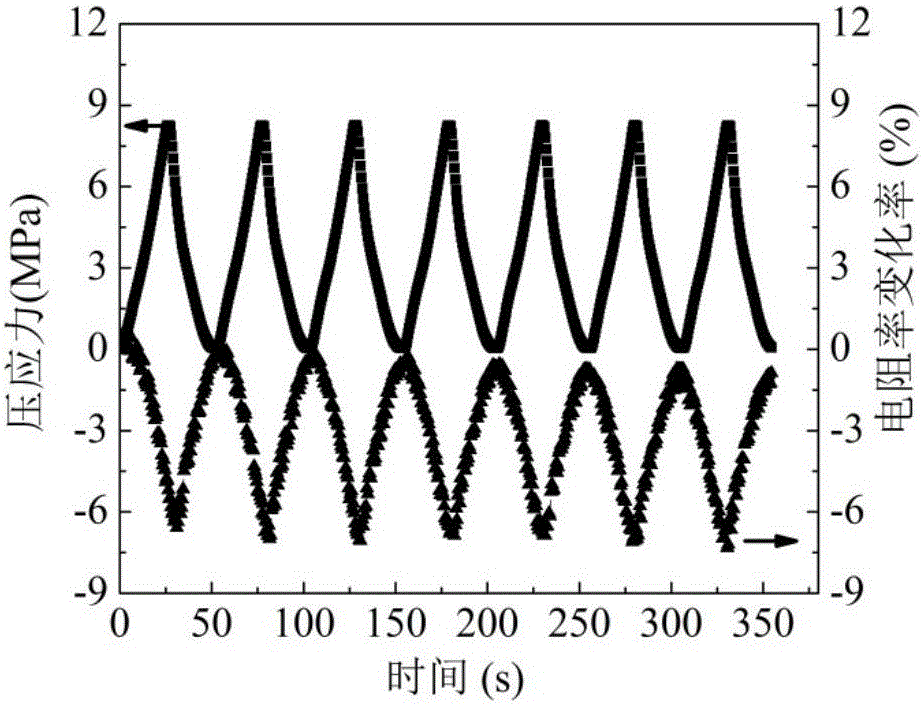

Electrostatic self-assembly carbon nano tube/nano-carbon black composite mortar as well as preparation method and application thereof

The invention discloses electrostatic self-assembly carbon nano tube / nano-carbon black composite mortar. Raw materials of the mortar comprise cement, silica fume, electrostatic self-assembly carbon nano tubes / nano-carbon black, a water reducing agent, sand and water. The minimum static resistivity of the mortar reaches 0.45 omega*m, the range of an absolute value of the resistivity change rate is 3.3%-22.1%, the change range of stress sensitivity is 0.40%-2.69% / MPa, and the change range of the strain sensitivity is 105-704. Compared with the prior art, the electrostatic self-assembly carbon nano tube / nano-carbon black composite mortar and the preparation method thereof solve the problem about dispersion of nanofiller in the mortar very well, and the carbon nano tubes and the nano-carbon black have the collaborative conductive effect, so that the mortar can acquire very low static resistivity and has excellent pressure-sensitivity by the aid of a small mixing amount of electrostatic self-assembly carbon nano tubes / nano-carbon black.

Owner:DALIAN UNIV OF TECH

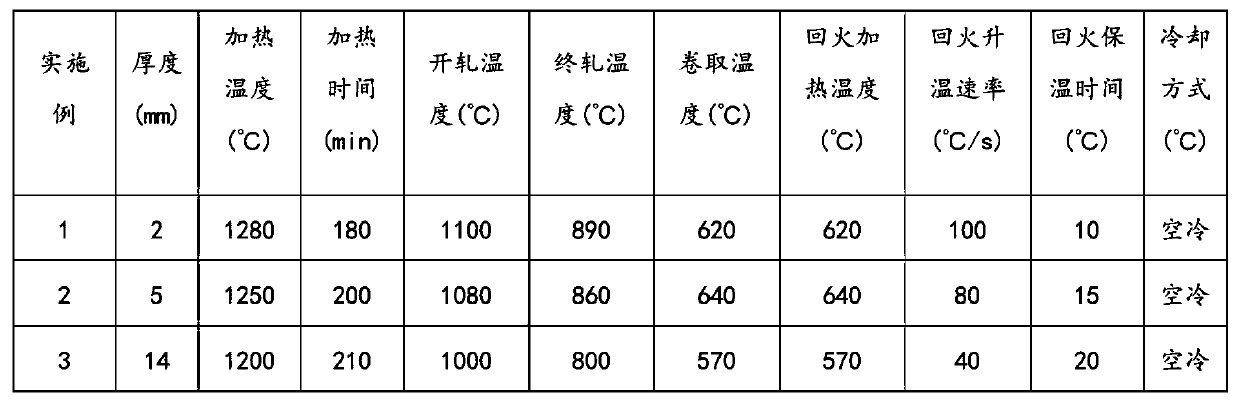

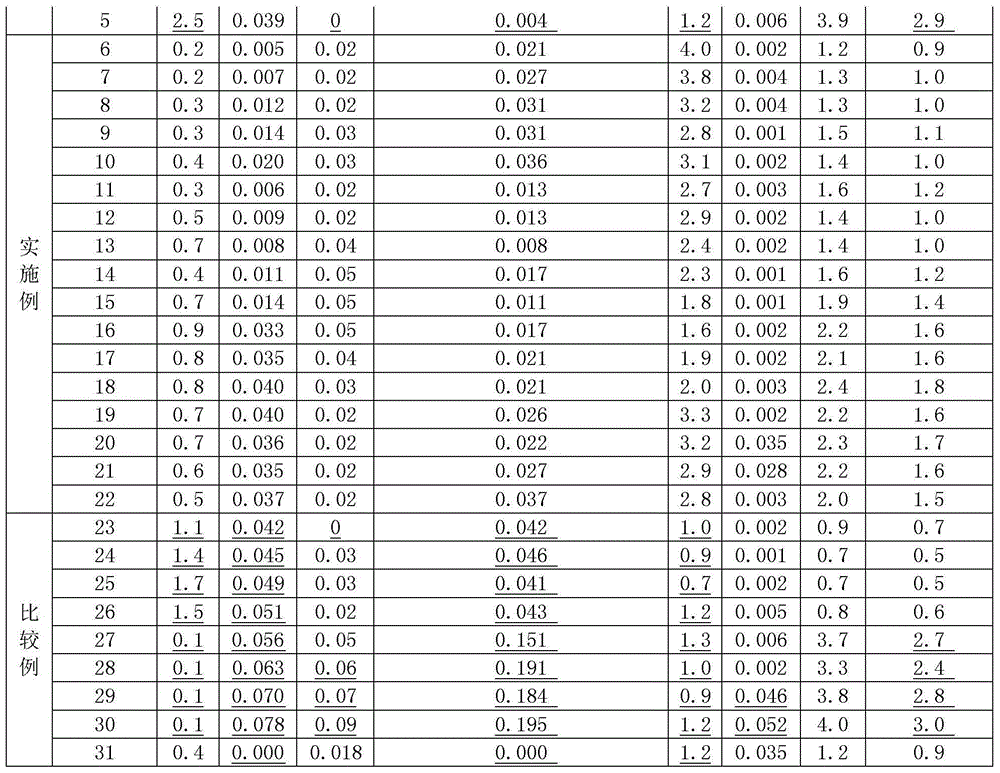

Preparation method of low-alloy high-strength steel plate with low residual stress

InactiveCN110257612AGuaranteed precipitationNo damage to mechanical propertiesProcess efficiency improvementSheet steelChemical composition

The invention relates to a preparation method of a low-alloy high-strength steel plate with low residual stress. The preparation method comprises the following steps: smelting; performing continuous casting; heating; performing rough rolling; performing refined rolling; performing laminar flow cooling; coiling; flattening; straightening; tempering; and performing cross cutting. In the heating step, the heating temperature is more than 1200 DEG C; in the refined rolling step, the final rolling temperature is 800 DEG C to 900 DEG C; in the coiling step, the rolling temperature is 550 DEG C to 650 DEG C; and in the tempering step, the tempering temperature is 550 DEG C to 650 DEG C, and the tempering heat insulation time is 10 minutes to 20 minutes. The method is applied to the steel plate which is prepared from the following chemical components: 0.04 percent to 0.12 percent of C, 0.10 percent to 0.80 percent of Si, 1.3 percent to 2.1 percent of Mn, 0 percent to 0.06 percent of Nb, 0.0 to 0.6 percent of Mo, 0 percent to 0.10 percent of V, 0.02 percent to 0.20 percent of Ti, 0.01 percent to 0.06 percent of Al, less than or equal to 0.003 percent of B, less than or equal to 0.010 percent of P, less than or equal to 0.004 percent of S, less than or equal to 0.008 percent of N, and the balance of Fe and inevitable impurities.

Owner:SHOUGANG CORPORATION +1

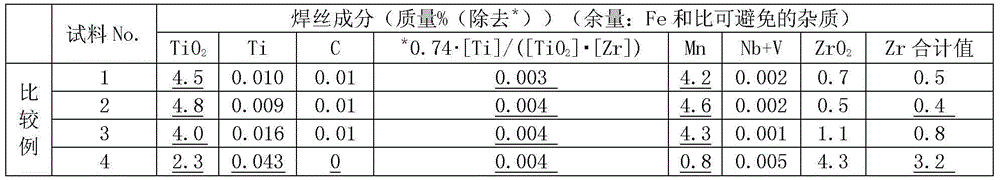

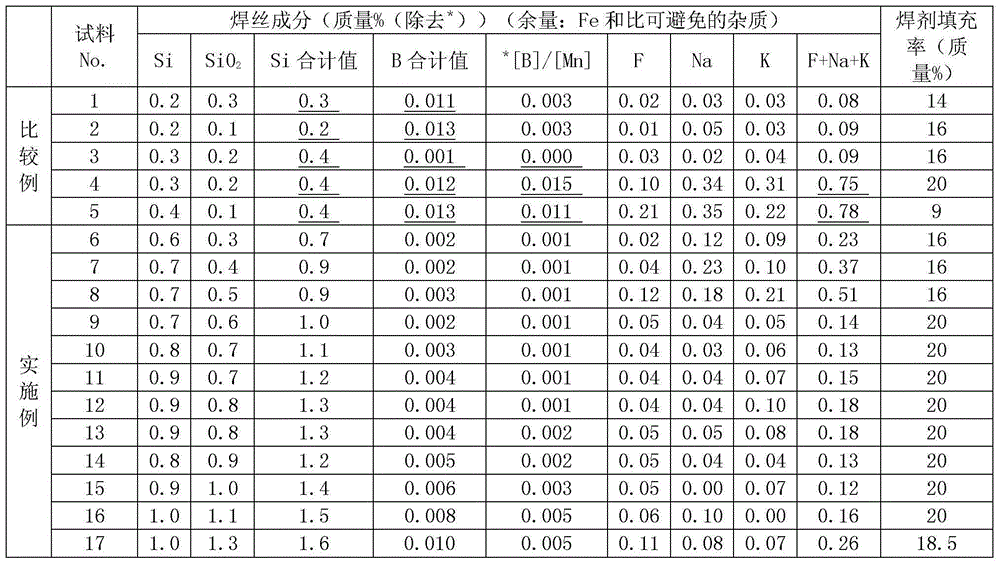

Flux cored wire for gas shielded arc welding

ActiveCN104070298AInhibition of saggingInhibit involvementSolid-state devicesArc welding apparatusArc stabilitySlag

The invention provides a flux cored wire for gas shielded arc welding, and the wire can enable splashing generation to be reduced, cannot damage the arc stability and the mechanical property of a welding metal, inhibits the sinking of a welding bead, and irons out the defect that the welding slags are carried secretly. The wire is characterized in that the wire is formed by that the interior of a steel sheath contains flux; according to the total mass of the wire, the content of TiO2 is 0.2-0.9 % of the total mass of the wire, the content of Ti is 0.005-0.040% of the total mass of the wire, the content of C is 0.01-0.05% of the total mass of the wire, the content of Mn is 1.5-4.0% of the total mass of the wire, the content of the sum of a Zr compound, the Zr equivalent value of a Zr oxide and metal Zr is from 0.5-2.0% of the total mass of the wire, the content of the sum of an Si compound, the Si equivalent value of an Si oxide and metal Si is from 0.5-2.0% of the total mass of the wire, the content of the sum of a B compound, the B equivalent value of a B oxide and metal B is from 0.002-0.010% of the total mass of the wire, and 0.74.[Ti] / ([TiO2].[Zr]) is within the range from 0.005 to 0.040, wherein the [Zr] is the sum of the Zr compound, the Zr equivalent value of the Zr oxide and metal Zr, [B] / [Mn] is within the range from 0.001 to 0.005, and [B] is the sum of the B compound, the B equivalent value of the B oxide and metal B.

Owner:KOBE STEEL LTD

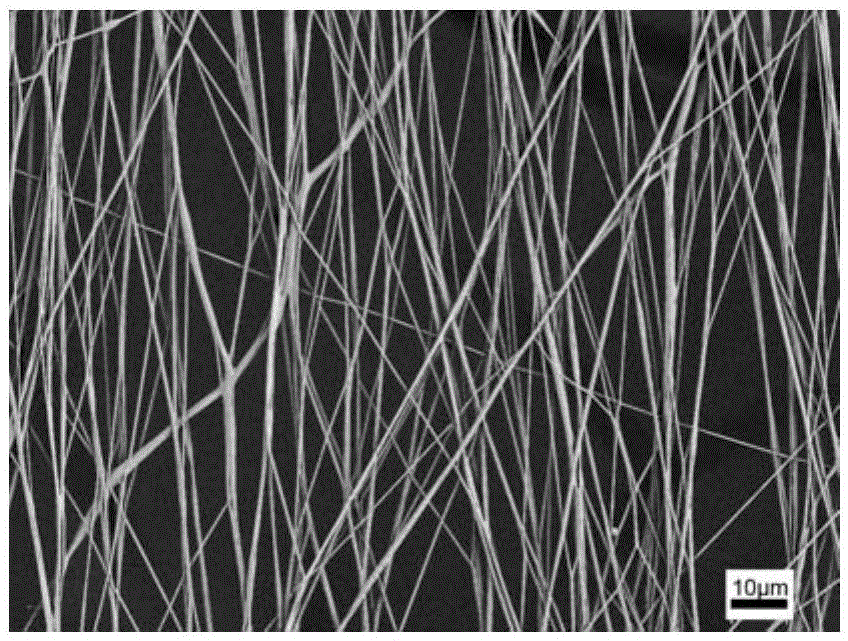

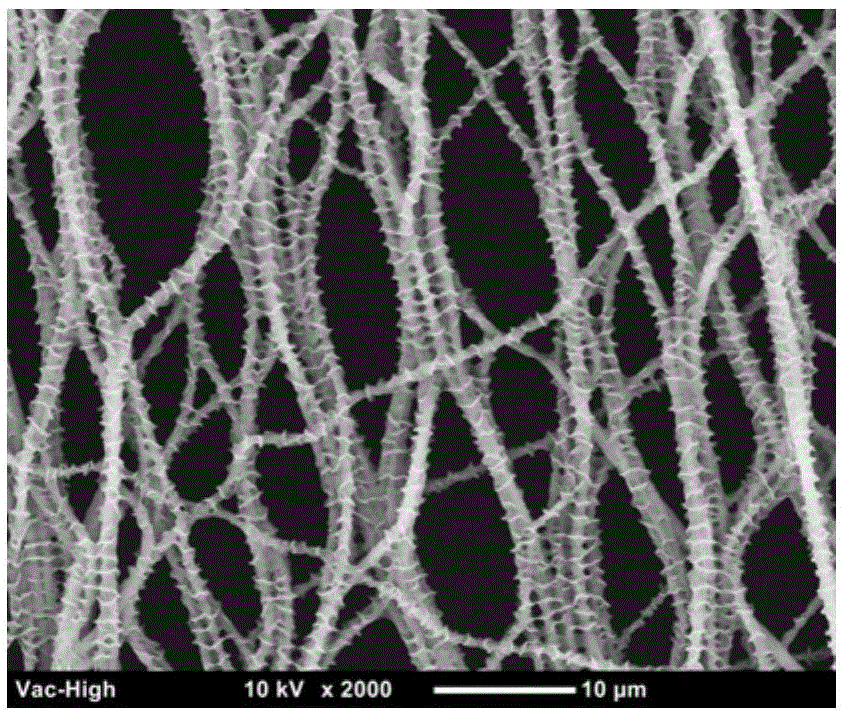

Preparation method of oriented shish-kebab fiber

InactiveCN105463848AEasy to fixImprove hydrophilicityFibre typesPharmaceutical delivery mechanismFiberBone tissue

The invention relates to a preparation method of an oriented shish-kebab fiber and belongs to the technical field of biomedical tissue engineering. The preparation method includes the following steps that oriented nanofibers are obtained through an electrostatic spinning method, grafted copolymer is obtained through a graft copolymerization method, and finally the oriented shish-kebab fiber is obtained through the method that the nanofibers obtained through an electrostatic spinning method induce the grafted copolymer to conduct crystallization. Through the special structure, performance of different polymers can be combined to improve the hydrophilia and the cytocompatibility of electrostatic spinning fibers, and the purpose of stimulating a bone tissue structure on the microscopic scale can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

Carbonated electrode composition for a supercapacitor, electrode, its fabrication process and cell thereof

InactiveCN103198930AImprove adhesionDifficult to control ruptureHybrid capacitor electrodesVehicular energy storageCapacitanceSupercapacitor

A carbonaceous composition usable to constitute a supercapacitor cell electrode, a porous electrode usable to equip such a cell, a process for manufacturing this electrode and one such cell incorporating at least one such electrode, for example in order to equip an electric vehicle. This composition is usable to be in contact with an aqueous ionic electrolyte, is based on a carbonaceous powder and comprises a hydrophilic binder-forming system. The system may include between 3% and 10% by weight a first crosslinked polymer having a number-average molecular weight Mn of greater than 1000 g / mol and having alcohol groups, and between 0.3% and 3% by weight a second polymer of at least one acid and which has a pKa of between 0 and 6 and a number-average molecular weight Mn of greater than 500 g / mol, the first polymer being crosslinked thermally in the presence of the second polymer.

Owner:HUTCHINSON SA

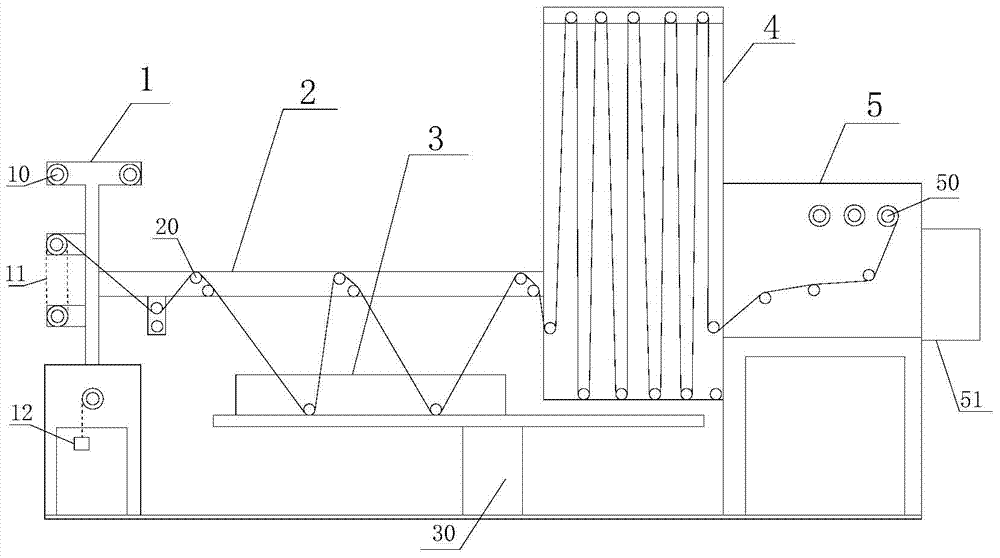

Surface modification processing device for poly(p-phenylene benzobisoxazole) fiber and use method of surface modification processing device

ActiveCN104328610AImprove surface propertiesNo damage to mechanical propertiesTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentYarnFiber

The invention relates to a surface modification processing device for poly(p-phenylene benzobisoxazole) fiber and a use method of the surface modification processing device. The surface modification processing device partially comprises a tension providing device, a yarn guide device, a surface modification processing groove, a drying device and a coiling device. Through the device provided by the invention, the poly(p-phenylene benzobisoxazole) fiber is subjected to surface modification, the poly(p-phenylene benzobisoxazole) fiber can be continuously subjected to surface processing in real time, the surface performance is improved, meanwhile, the original mechanical property of the PBO fiber is not damaged, and in addition, the processing effect is good. The device provided by the invention has the advantages that the structure is simple, the operation is simple and convenient, and the continuous and industrial production can be realized.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

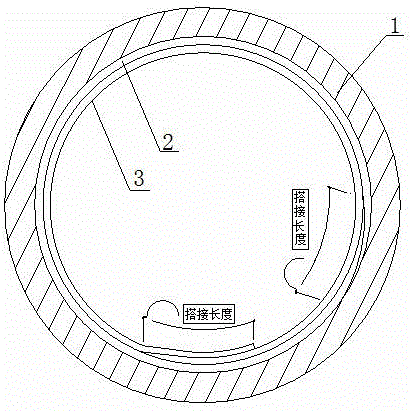

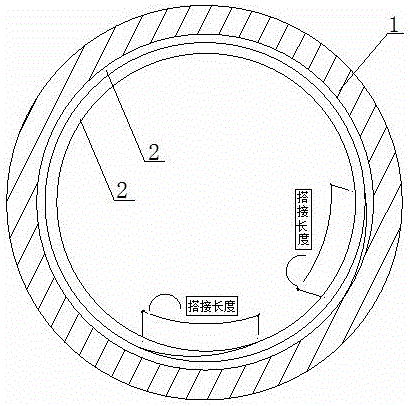

Strengthening method of pasting carbon fiber sheet on inner wall of large-diameter pipeline

InactiveCN106427072ATo achieve reinforcementDoes not destroy the materialLaminationLamination apparatusFiberArid

Disclosed is a method of pasting a carbon fiber sheet on an inner wall of a large-diameter pipeline. The first tier of the carbon fiber sheet is pasted by a carbon fiber cloth (2), and the pasting of the carbon fiber cloth (2) comprises the steps of rubbing down an inner wall of a pipeline (1), keeping the surface of the inner wall of the pipeline (1) clean and arid, smearing uniformly a subbing glue on the inner wall of the pipeline (1), and using hands to gently press and paste the carbon fiber cloth (2) on a pasting area after the surface of the subbing glue is dry to touch or the surface of a leveling glue is dry to touch, installing a support device, dismantling the support device, adopting an angle grinder to grind carbon fiber cohesive glue which is squeezed out by the carbon fiber cloth (2), thus guaranteeing levelness of an entire structure plane. The method of pasting the carbon fiber sheet on the inner wall of the large-diameter pipeline realizes reinforcing of the inner wall of the large-diameter pipeline (1) which is buried underground, thus solving the problem of reinforcing the large-diameter pipeline buried underground.

Owner:WUDA JUCHENG STRUCTURE CO LTD

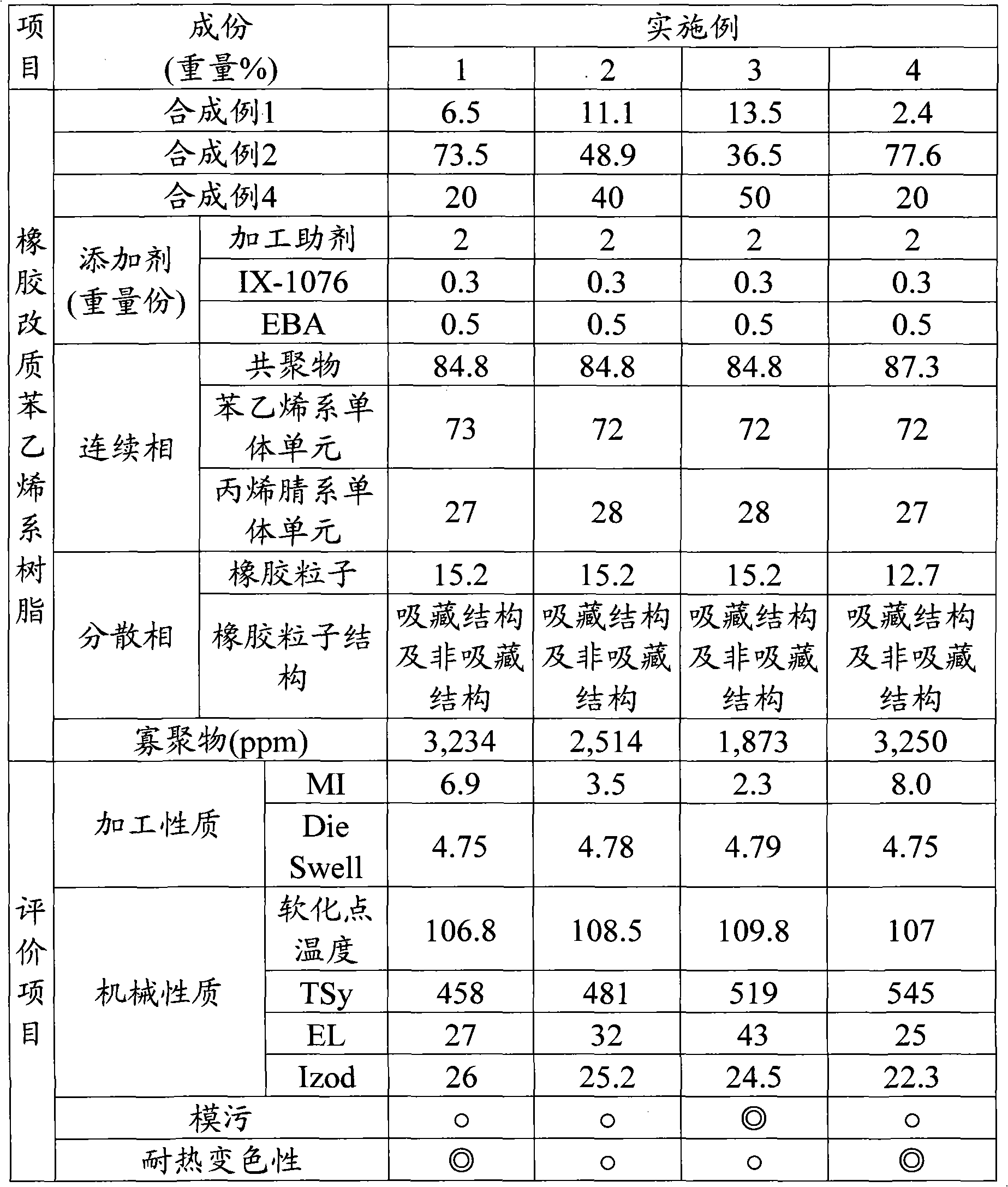

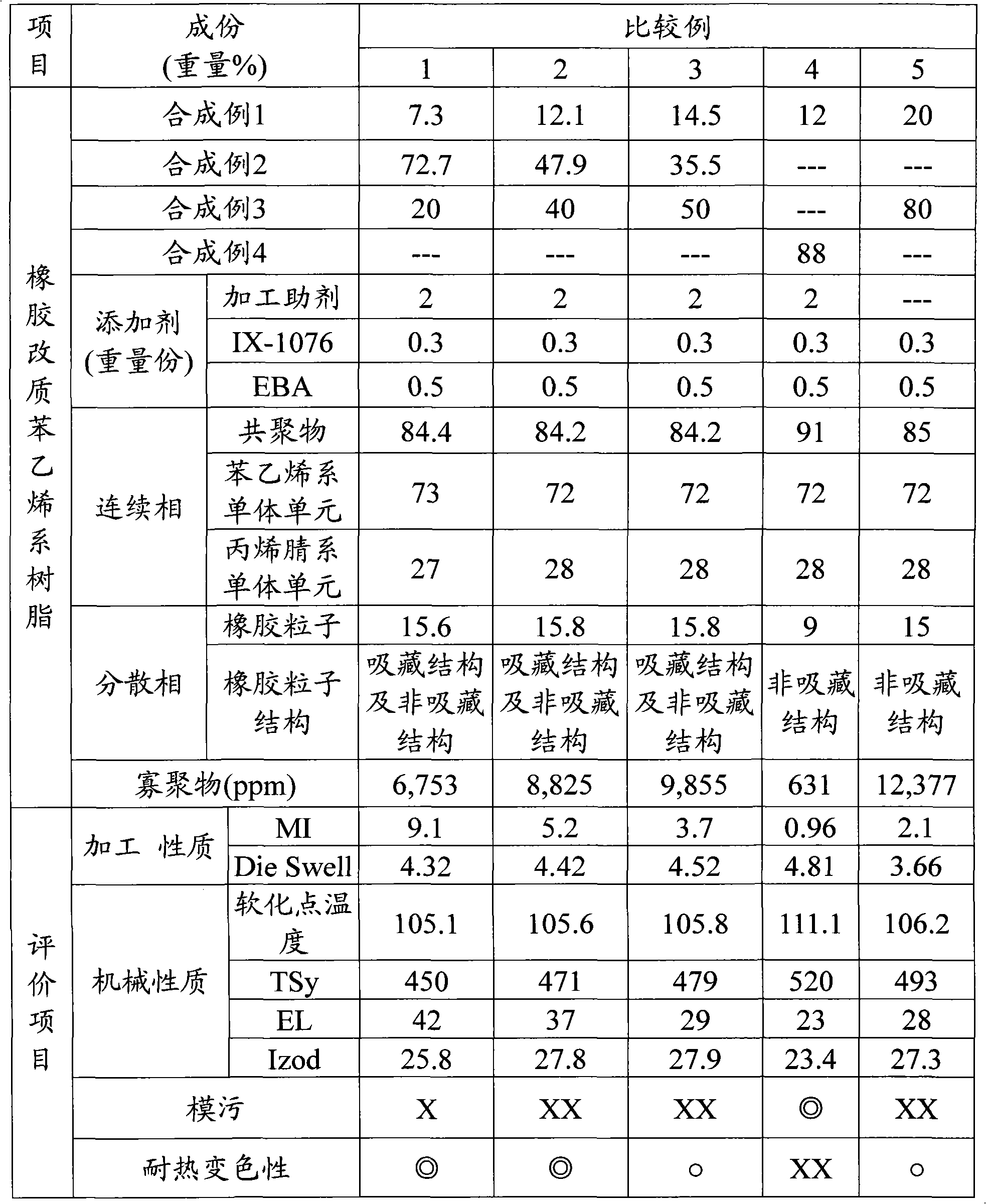

Rubber reforming styrene resin and molded product made by the rubber reforming styrene resin

InactiveCN102977539AImprove processing propertiesNo damage to mechanical propertiesPolymer scienceHeat resistance

The invention relates to rubber reforming styrene resin and a molded product made by the rubber reforming styrene resin, and the rubber reforming styrene resin comprises: 50% in weight-90% in weight of continuous phase formed by copolymer; and 10% in weight-50% in weight of dispersion phase formed by rubber particles, wherein the copolymers comprise 50% in weight-90% in weight of styrene monomeric units and 10%-50% in weight of acrylonitrile monomeric units; the rubber particle has a non-occlusion structure and an occlusion structure; and total content of dimers or trimers derived from the styrene monomeric units and the acrylonitrile monomeric units of the rubber reforming styrene resin occupies under 5,000 ppm of 100 parts in weight of the rubber reforming styrene resin. The resin has a relatively good processing property, non molding pollution will be generated in making process, and the molded product with relatively good heat resistance and color changing property and machinery property is formed.

Owner:CHI MEI CORP

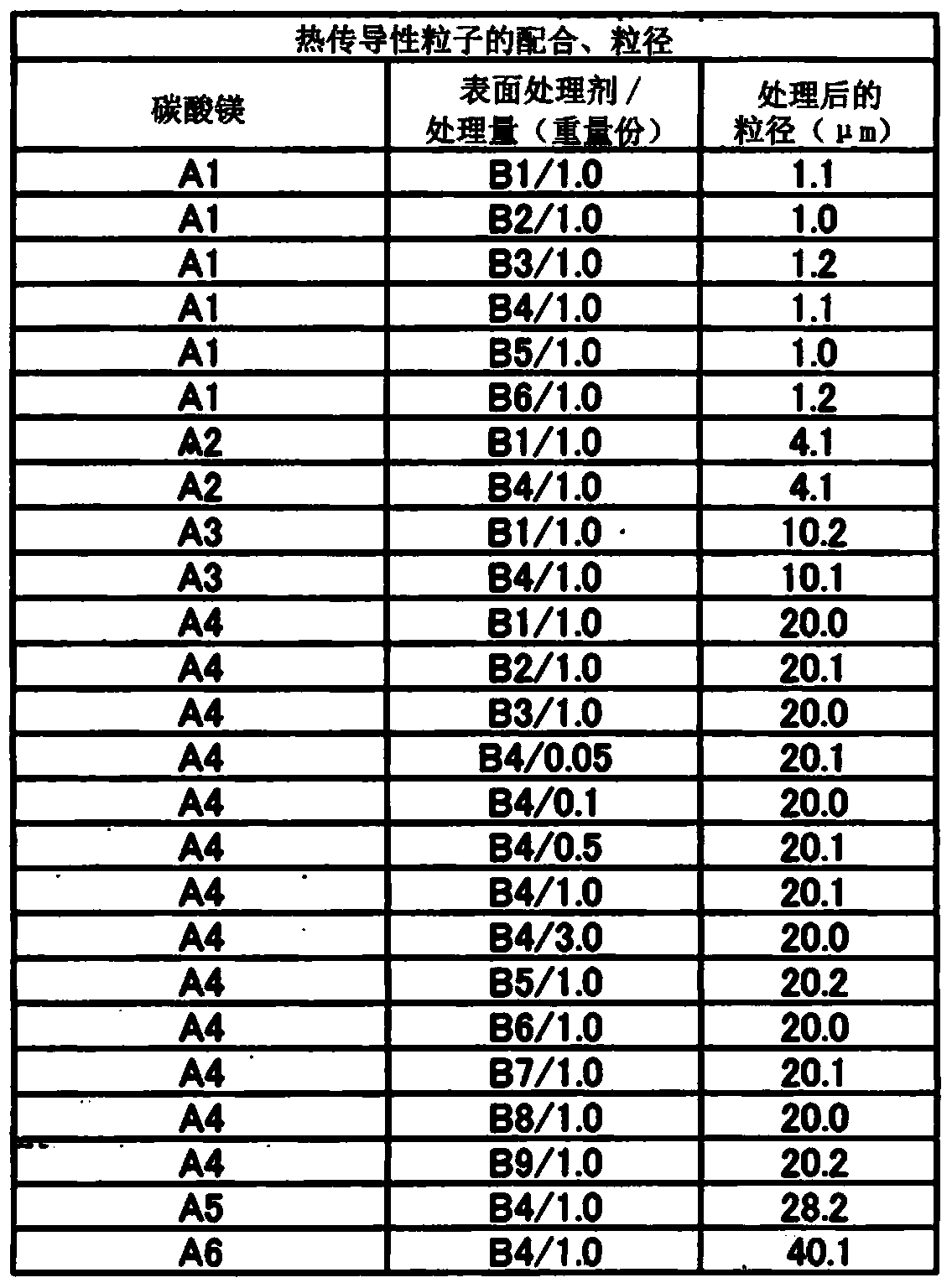

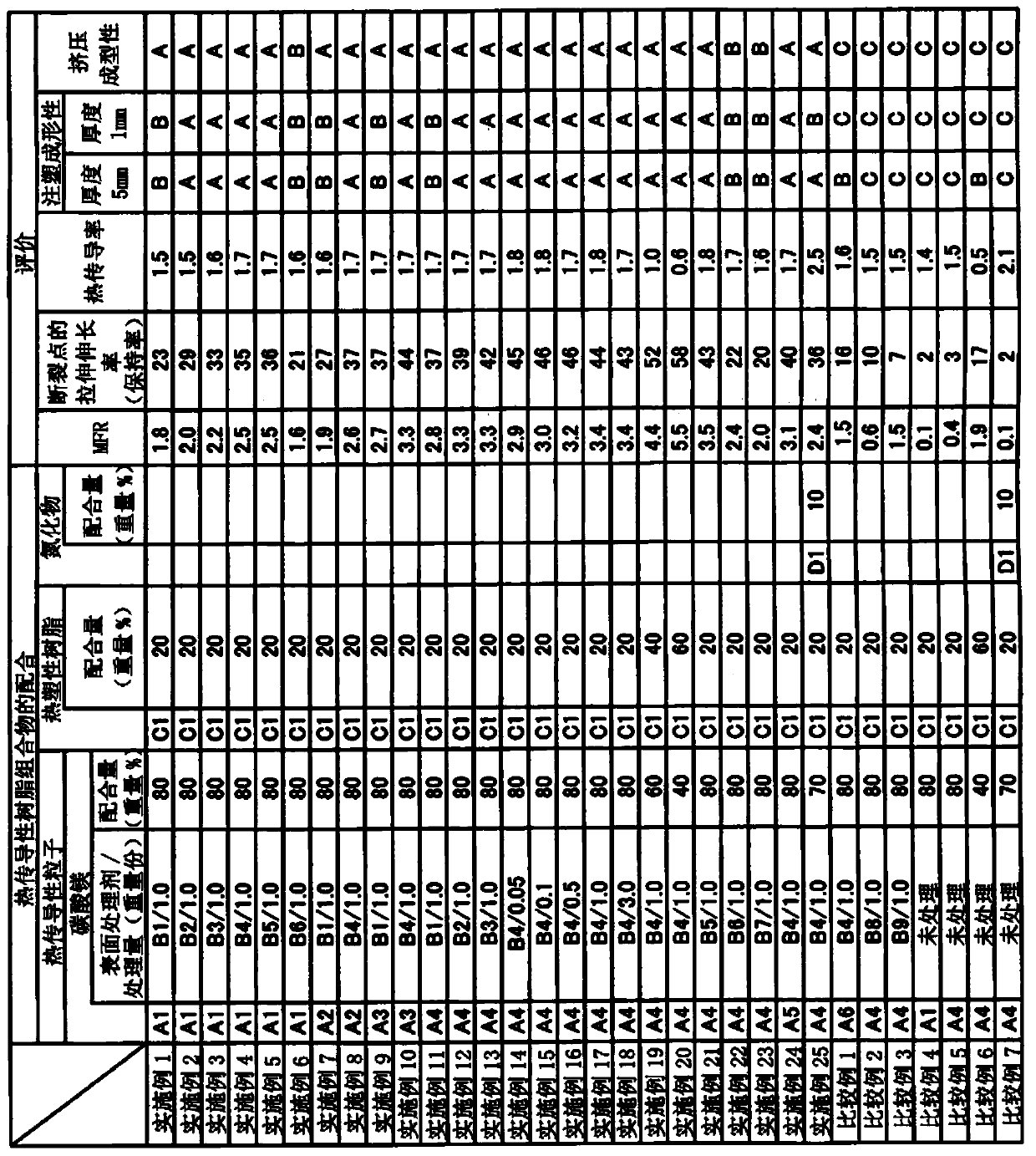

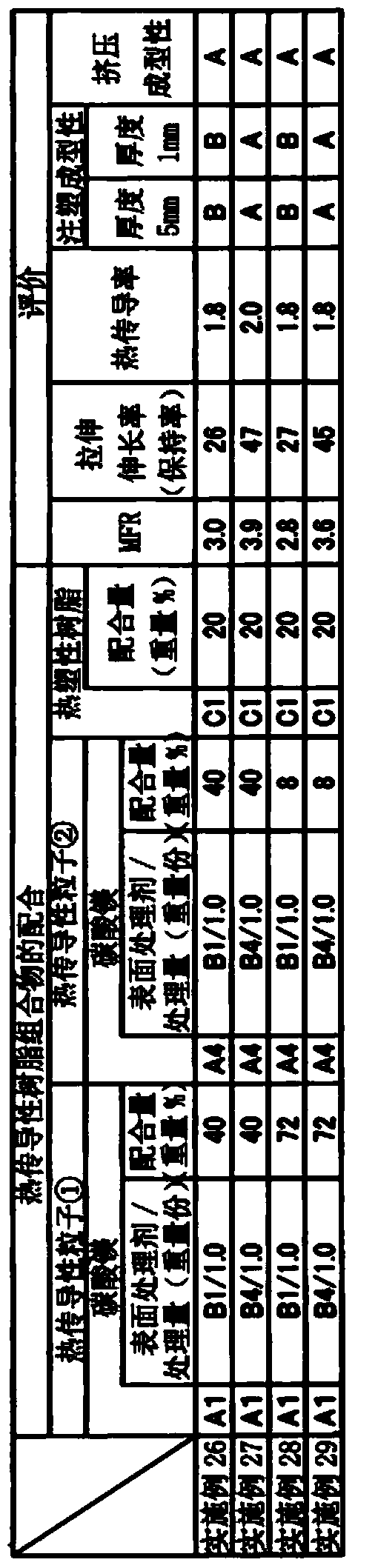

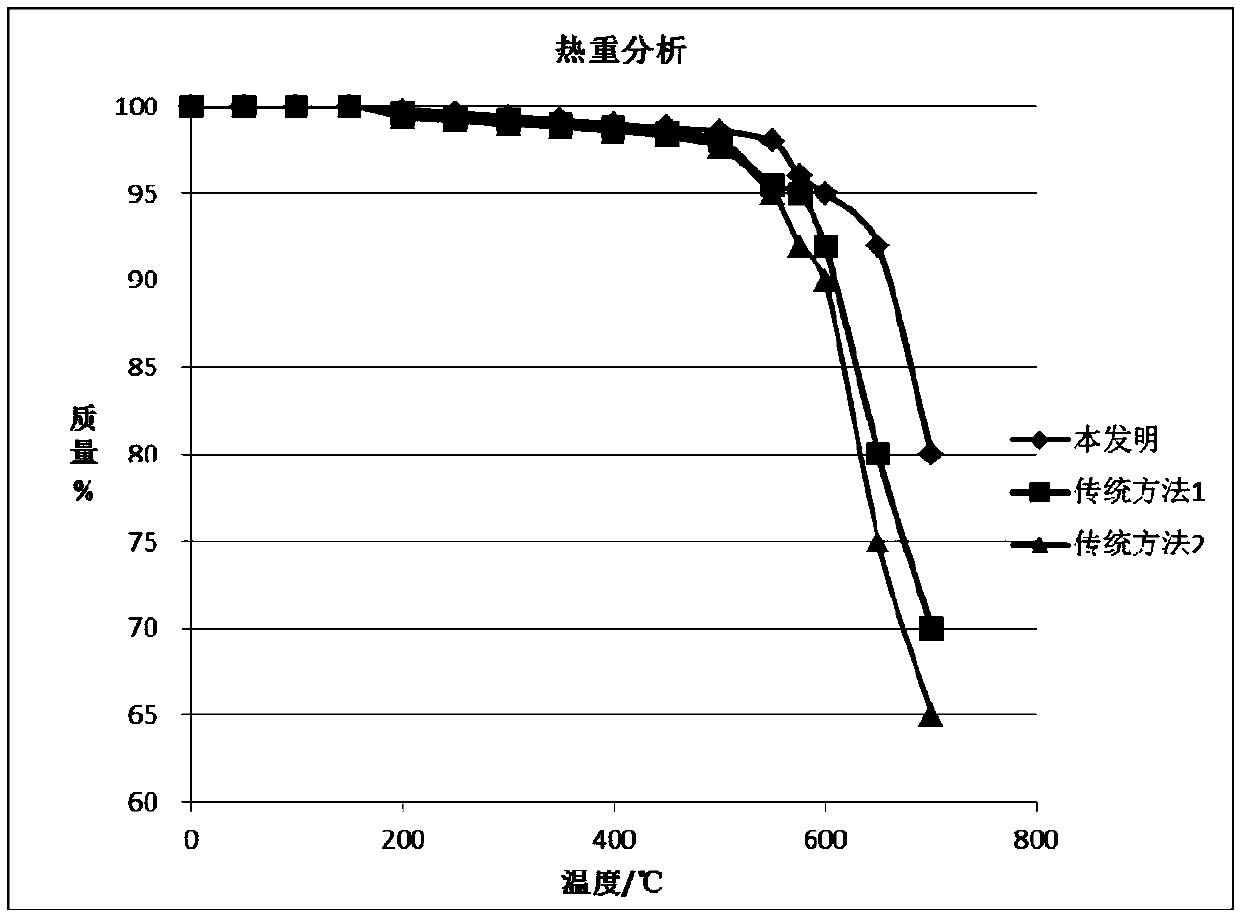

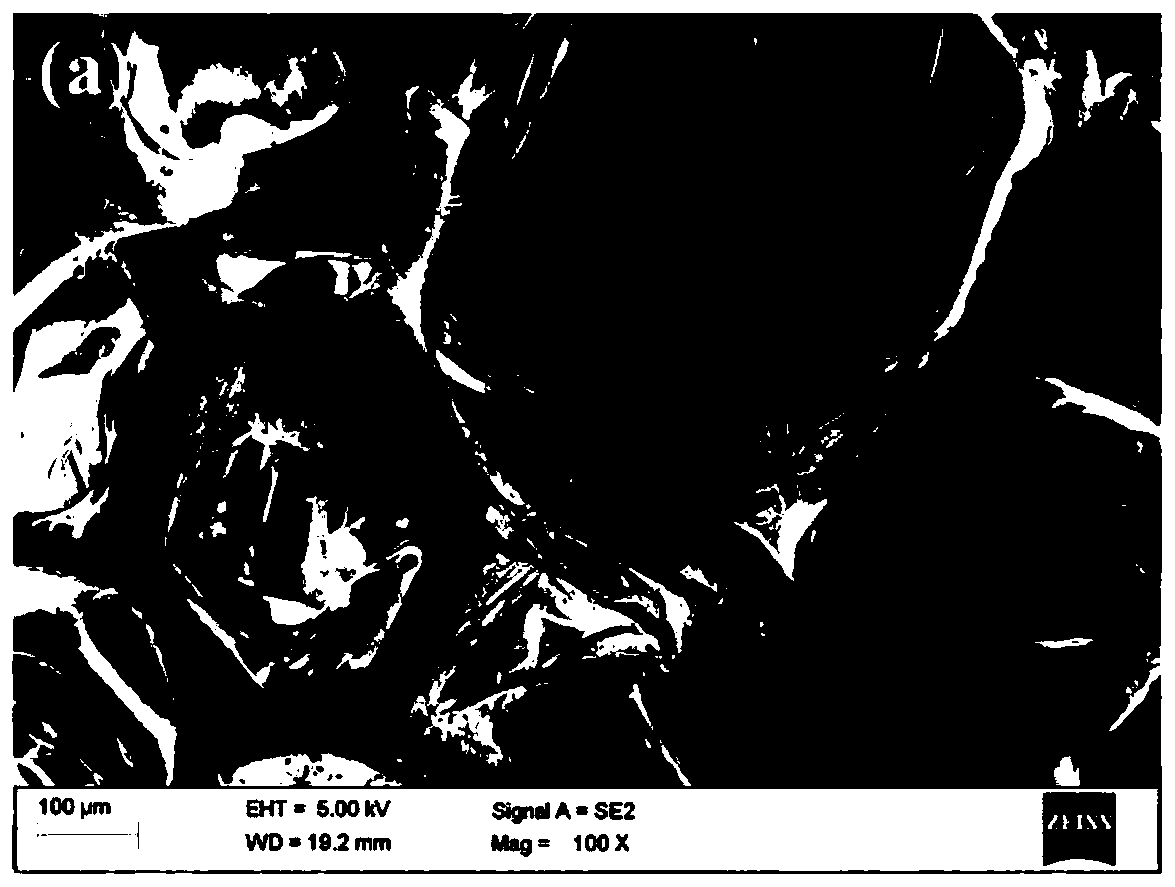

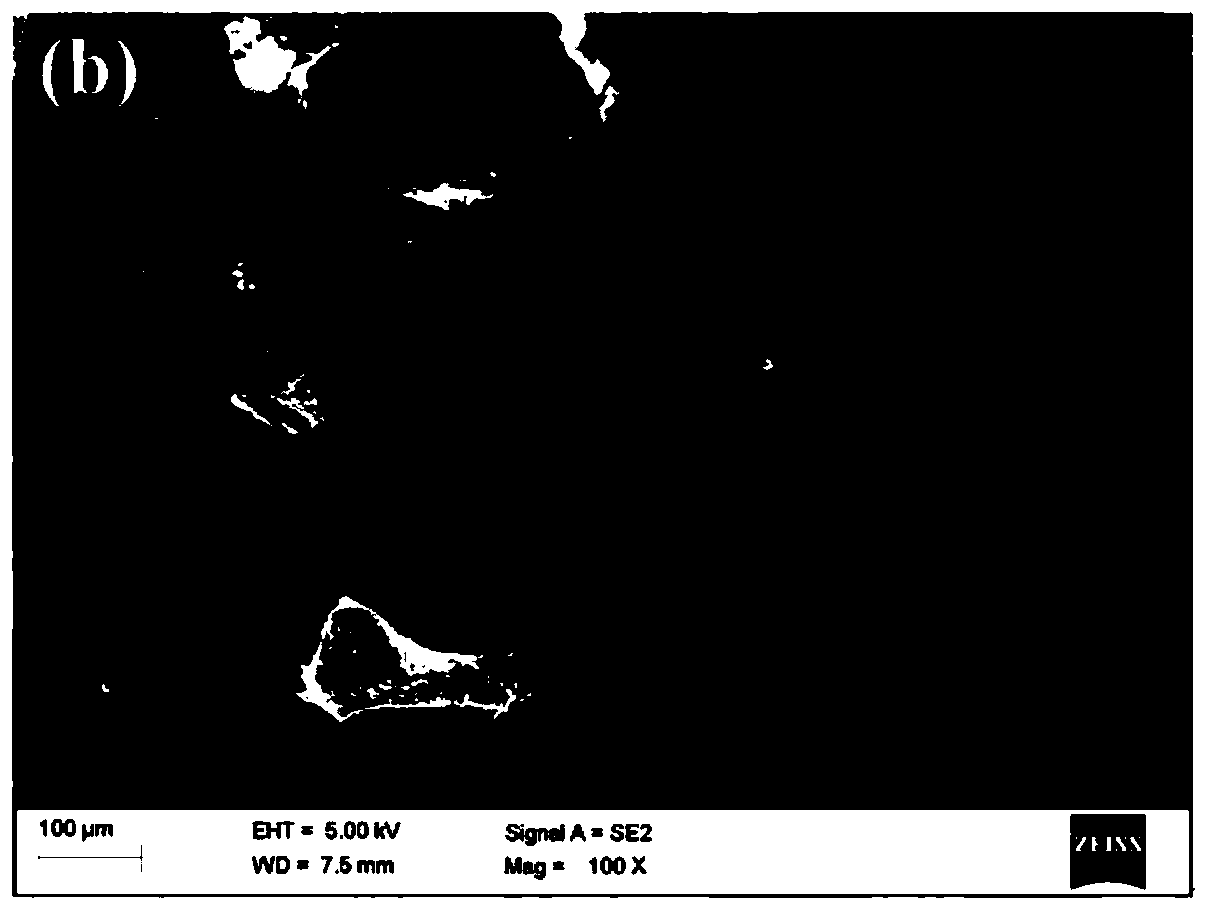

Thermal conductive resin composition and molded body

InactiveCN103937078AGood dimensional stabilityImprove smoothnessInsulated cablesNon-conductive material with dispersed conductive materialInjection mouldingMechanical property

The invention provides a thermal conductive resin composition and a molded body formed by using the thermal conductive resin composition. The thermal conductive resin composition, although containing large amount of thermal conductive particles, has excellent molding processability, and can be used for obtaining, for example in injection molding, a molded body with excellent size stability, or in extrusion molding, a molded body with excellent smoothness and good mechanical properties. The thermal conductive resin composition provided by the invention contains terminal conductive particles with an average primary particle size of 0.1-30[mu]m, and thermoplastic resin. The terminal conductive particle includes a magnesium carbonate particle and a coating which is formed through a surface treating agent including methoxysilyl and alkyl.

Owner:TOYO INK SC HOLD CO LTD +1

PBO fiber reinforced resin-based composite material and preparation method thereof

The invention discloses a PBO fiber reinforced resin-based composite material and a preparation method thereof. According to the method, PBO high-strength and high-modulus fibers are used as a reinforcing material, polyimide resin is used as a matrix, modified phenyl imide silane is used as a coupling agent to carry out surface modification on the PBO fibers, and then the PBO fiber reinforced resin-based composite material is obtained through compression molding of the PBO fibers and the polyimide resin. The composite material prepared by the method has the performance characteristics of lightweight, high temperature resistance, high strength and high modulus.

Owner:CHINA PETROLEUM & CHEM CORP +1

Long-effect anti-bacterial pain-alleviating and heeling-promoting medical cotton swab

InactiveCN106729943AAddress inherent flawsReduce manufacturing costAbsorbent padsBandagesFiberWound healing

The invention discloses a long-effect anti-bacterial pain-alleviating and heeling-promoting medical cotton swab, which consists of a cotton stick and composite fiber cotton covering the end part of the cotton swab. The cotton swab uses reproducible and degradable composite polylactic acid fiber cotton for replacing a conventional absorbent ball; the production cost is reduced; the inherent defects of the absorbent cotton are overcome; no adverse influence exists on the wounded surface. The composite fiber overcomes the defect of poor hydrophilicity of the pure polylactic acid fiber; meanwhile, the mechanical performance is not damaged; the long-effect and durable antibacterial capability can be realized; a grafted polydopamine-carboxymethyl chitosan composite film layer is adhered onto the surface, so that the skin-friendly performance, the water absorption capability and the adsorption capability of the composite fiber are further improved; in addition, the introduced carboxymethyl chitosan also has certain effects of alleviating pain and promoting wound heeling. The cotton swab provided by the invention has the advantages that the production process is simple and efficient; the materials in each kink can be cyclically utilized; no adverse influence is caused on the environment.

Owner:阜阳市汇康医疗器械有限公司

Flame-retardant polyurethane flexible foam plastic and preparation method thereof

InactiveCN110922632AInhibited DiffusionReduce spreadFireproof paintsAlginic acid coatingsPolymer scienceFire safety

The invention discloses a flame-retardant polyurethane flexible foam plastic and a preparation method thereof, and belongs to the technical field of flame-retardant polymer materials. A C60 / guar gum dispersion and a MoS2 / sodium alginate dispersion are prepared, and MoS2 nanosheets and C60 are deposited on the surface of a polyurethane flexible foam matrix by adopting a layer-by-layer assembling process in order to exert the synergistic flame-retardant effects of the MoS2 nanosheets and the C60. The flame-retardant polyurethane flexible foam prepared in the invention has a high fire safety performance.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

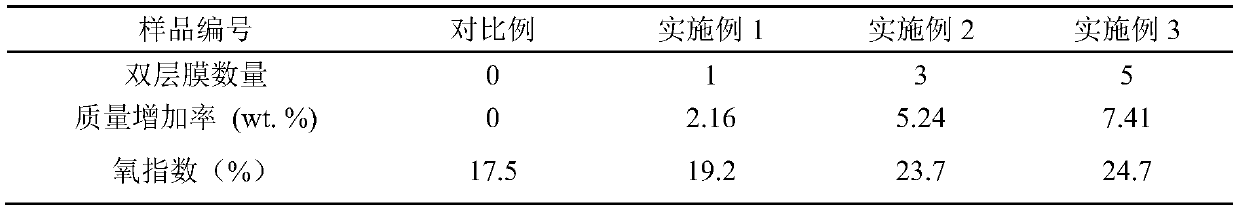

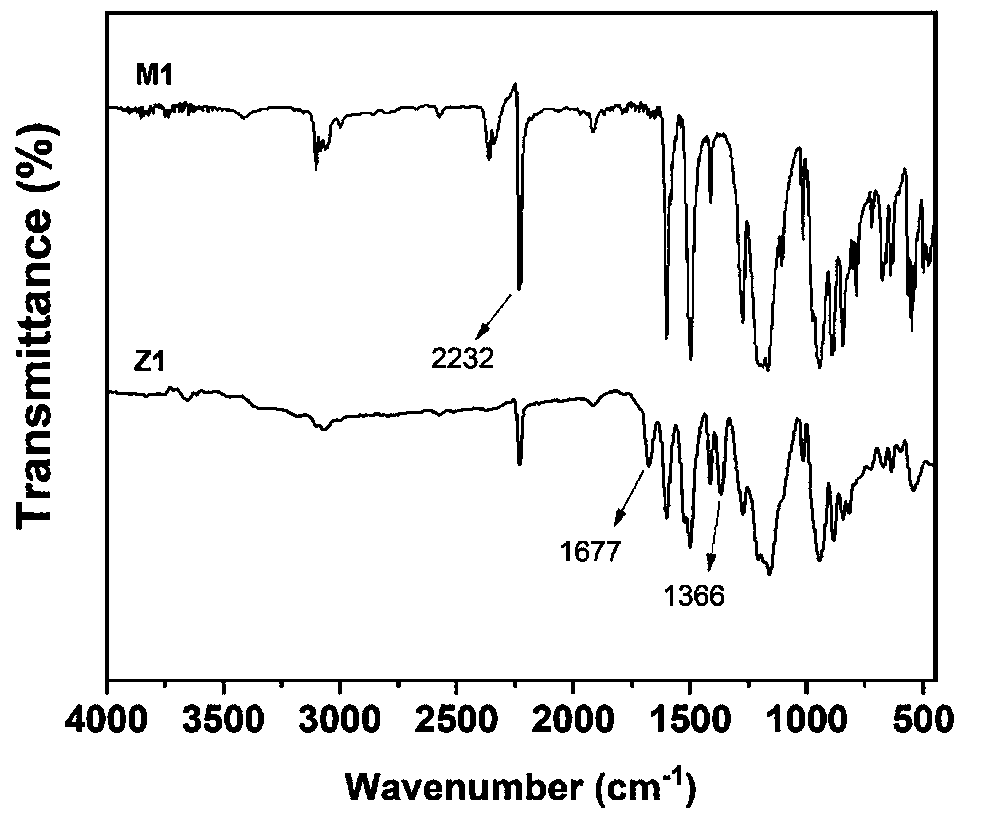

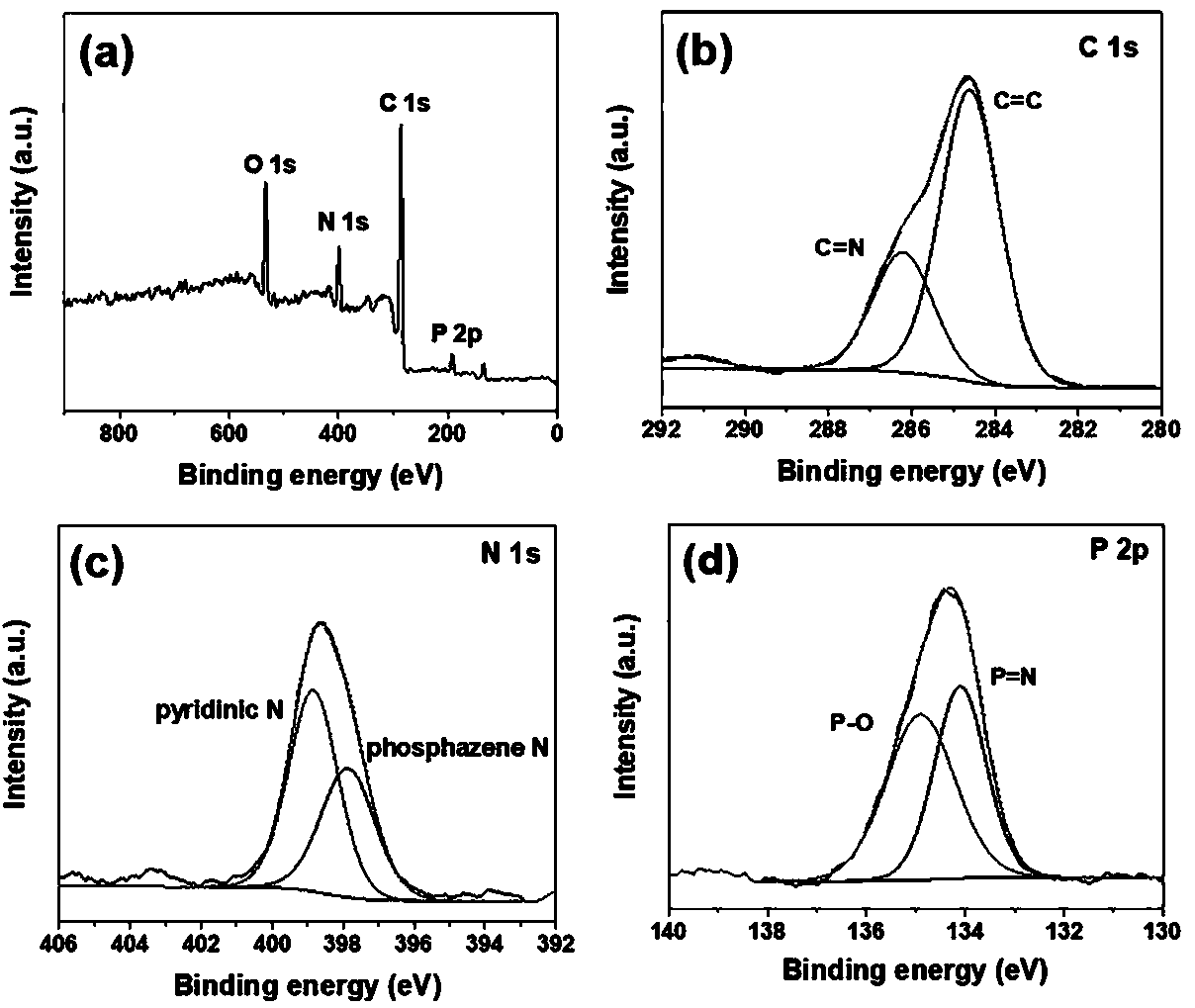

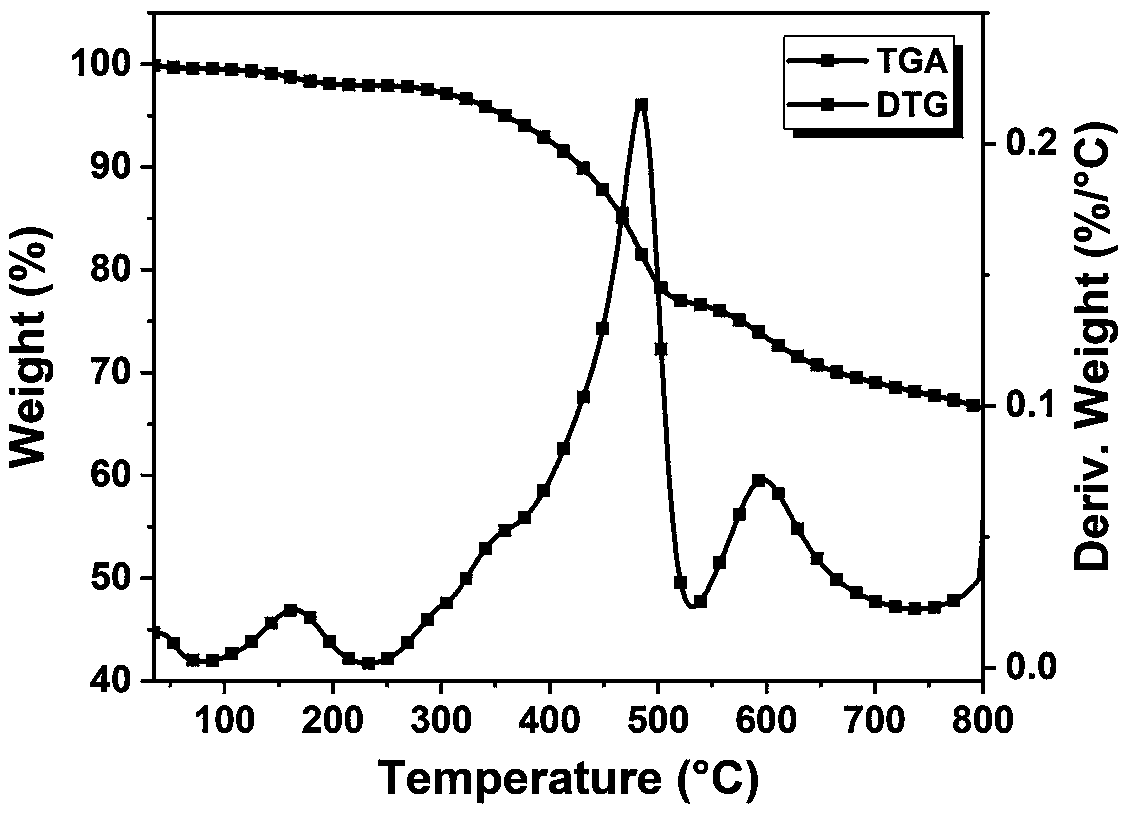

Polyphosphazene covalent triazine polymer and preparation method and application thereof

The invention discloses a polyphosphazene covalent triazine polymer and a preparation method and application thereof. According to the invention, a phosphazene derivative containing a cyano group at an end group is used as a precursor, and a cyclotrimerization reaction is carried out under the catalysis of protonic acid to prepare the covalent triazine polymer containing a phosphazene structure. The polyphosphazene covalent triazine polymer prepared by using the method has the characteristics of simple preparation process, mild reaction conditions, good thermal stability and the like. When theprepared polyphosphazene covalent triazine polymer is applied to flame retardance of epoxy resin, a synergistic flame-retardant effect is obtained, and the polyphosphazene covalent triazine polymer is high in flame-retardant efficiency, does not damage the mechanical properties of the epoxy resin and has great practical application value.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for toughening heat-resistant modified polylactic acid with plant-base composite environment-friendly modifier

The invention relates to a method for toughening heat-resistant modified polylactic acid with a plant-base composite environment-friendly modifier, which comprises the following steps: removing water from the raw material vegetable oil; proportionally adding polybasic acid / acid anhydride and a nucleating agent, and heating to 140-160 DEG C in an N2 atmosphere to react for 2-8 hours; adding a certain amount of dehydrated lactic acid or lactide, continuing reacting at 140-160 DEG C in the N2 atmosphere for 1-2 hours, heating to 170-190 DEG C to react for 2-10 hours, and vacuumizing the system; and extruding the prepared plant-base environment-friendly modifier polymer and polylactic acid by an equidirectional double screw extruder, blending, drawing, cooling with water, granulating, and drying to obtain the modified polylactic acid granules. Compared with the prior art, the modified polylactic acid granules have the advantages of no toxicity or harm, no harm to the environment and human health and favorable compatibility, and can be completely biodegraded. Besides, the polylactic acid modified by the modifier has favorable heat resistance.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing black para-aramid fibers

ActiveCN105696104ANo significant change in fiber propertiesNo damage to mechanical propertiesMonocomponent copolyamides artificial filamentPolymer scienceMechanical property

The invention belongs to the field of technologies for synthesizing macromolecules, and particularly relates to a method for preparing black para-aramid fibers. The method has the advantages that a little oxidized p-phenylenediamine is added into PPTA (poly-p-phenylene terephthamide) to stain the PPTA by the aid of a characteristic that p-phenylenediamine is easy to oxidize and turn black, other auxiliaries are omitted, accordingly, processes for producing the black para-aramid fibers can be simplified, and the mechanical properties of the para-aramid fibers can be guaranteed against being obviously damaged; the addition amount of the oxidized p-phenylenediamine can be adjusted, so that the para-aramid fibers with colors from black, brown and even coffee colors can be prepared by the aid of the method.

Owner:AFCHINA CORP CO LTD +1

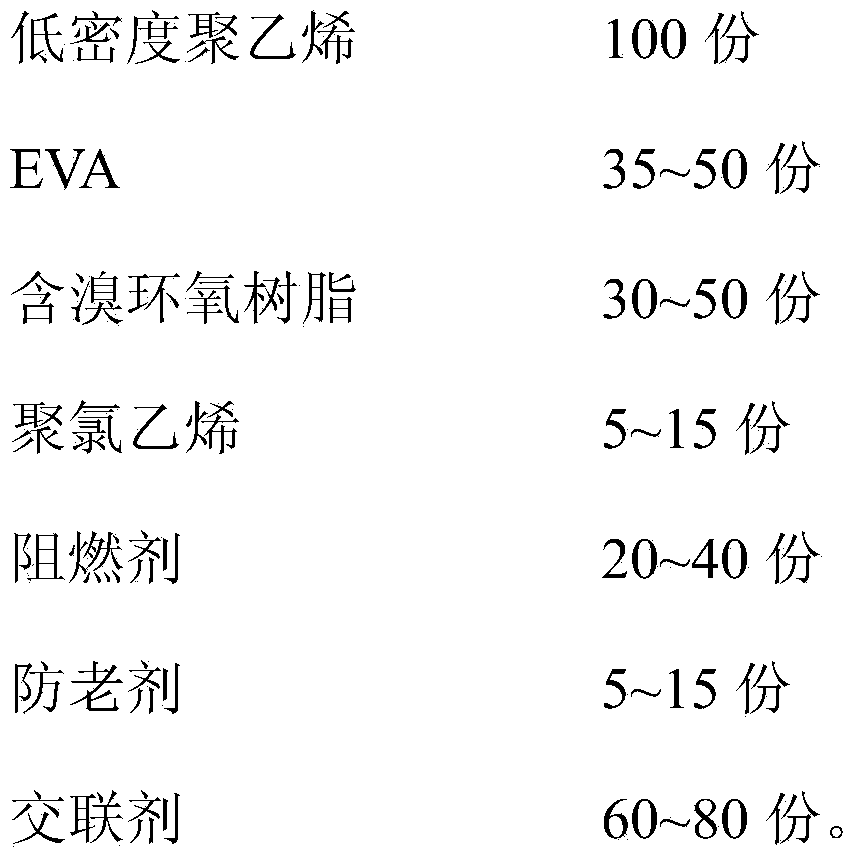

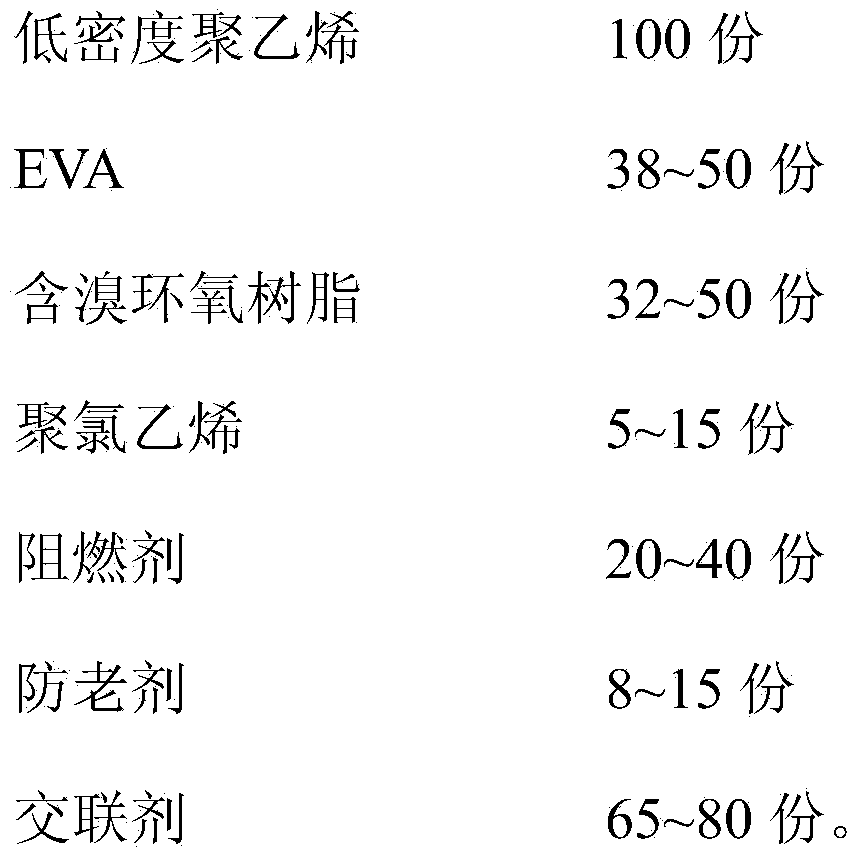

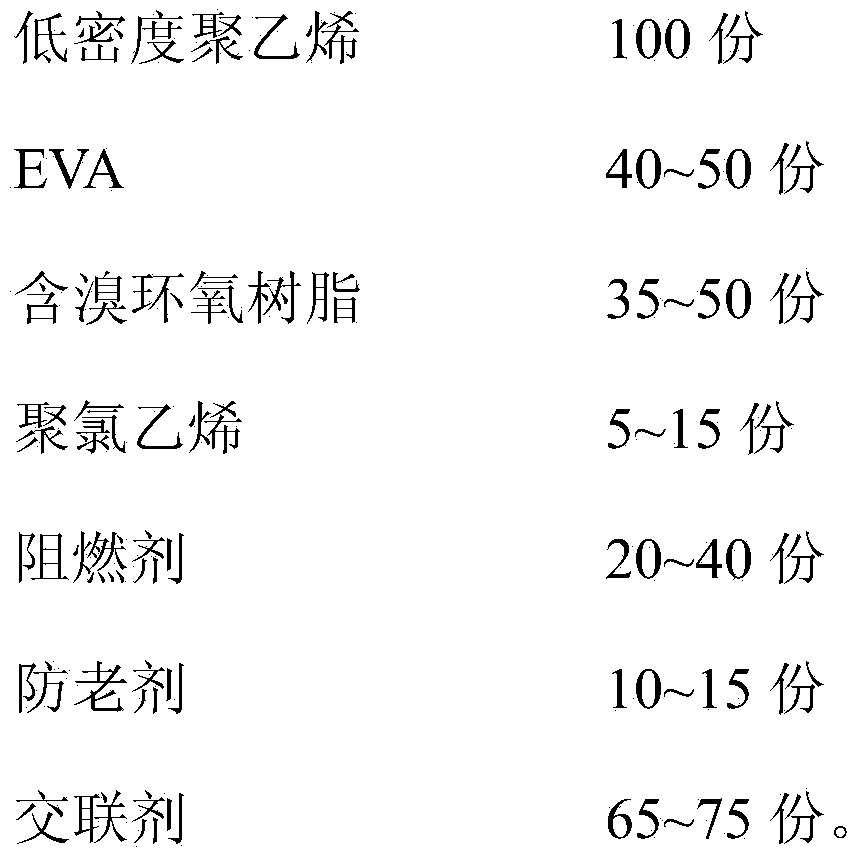

Flame-retardant wire and cable material and preparation method thereof

InactiveCN104231397AImprove flame retardant performanceNo damage to mechanical propertiesInsulatorsLow-density polyethyleneEpoxy

The invention discloses a flame-retardant wire and cable material. The material comprises components in parts by weight as follows: 100 parts of low-density polyethylene, 35-50 parts of EVA, 30-50 parts of bromine-containing epoxy resin, 5-15 parts of polyvinyl chloride, 20-40 parts of a flame retardant, 5-15 parts of an anti-aging agent and 60-80 parts of a cross-linking agent. With the adoption of the flame-retardant wire and cable material, the four base materials with certain content are selected and mixed together, so that mechanical properties of wires and cables are not damaged while the flame-retardant performance is excellent under the synergistic effect of the four base materials.

Owner:朱忠良

Sealed and insulating vessel comprising a support foot

ActiveCN103899912ANo damage to mechanical propertiesAvoid or limit the applied forceVessel mounting detailsVessel geometry/arrangement/sizeEngineeringMetal sheet

A vessel wall comprises a sealing barrier (6) and a support foot (10) for an item of equipment immersed in the sealed vessel. The sealing barrier comprises a corrugated metal sheet layer (11) having at least one series of parallel corrugations (15), the corrugated metal sheet layer being interrupted at a window (25) surrounding the support foot. The support foot extends longitudinally through the window. The sealing barrier comprises connecting parts (45, 50) for sealingly connecting the support foot to a marginal portion of the corrugated metal sheet layer that delimits the window. The window (25) interrupts the directrices of a plurality (20) of the parallel corrugations of the series, and the support foot is centered at a position situated between the directrices (A) of two parallel corrugations (20).

Owner:GAZTRANSPORT & TECHNIGAZ SA

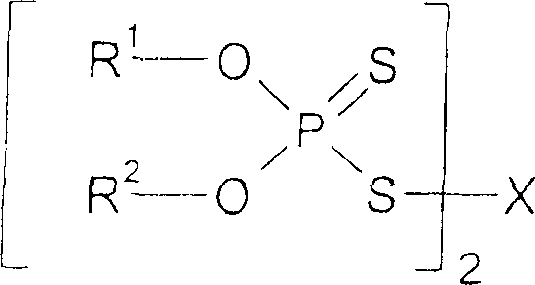

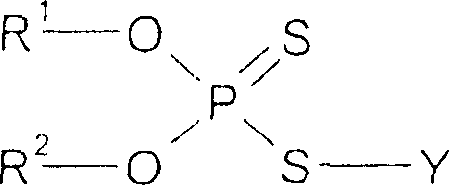

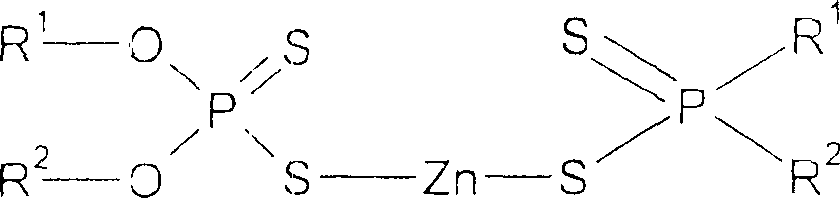

Active substance for processing rubber composition

InactiveCN1765962ALow viscosityNo damage to mechanical propertiesSpecial tyresInflatable tyresChemistryTrimethylolpropane

The present invention relates to a new type of rubber compound containing light-colored fillers, which is prepared using a new processing aid.

Owner:RHEIN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com