Active substance for processing rubber composition

A technology for rubber compounds, mixtures, used in tire parts, transportation and packaging, pneumatic tires, etc., which can solve problems such as insufficient fluidity and initial cure time effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

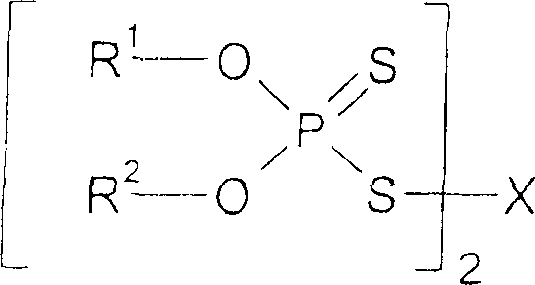

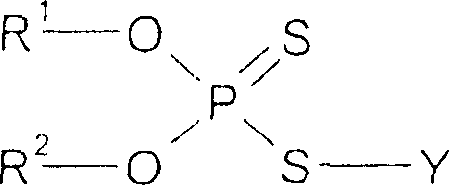

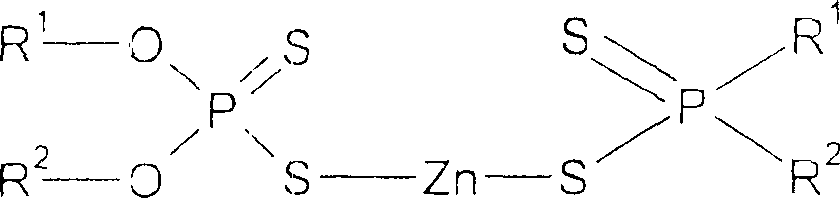

Method used

Image

Examples

example 1、 comparative example 1 and 2

[0139] Prepare rubber mixtures according to the composition of Table 1:

[0140] example

comparative example

1

1

2

parts by weight

parts by weight

parts by weight

NR; SMR-10 1)

30

30

30

S-SBR; Buna VSL 5025-0 2)

30

30

30

BR; Buna CB 25 3)

40

40

40

Ultrasil 7000 4)

100

100

100

Si-69 5)

7.5

7.5

7.5

TDAE oil

40

40

40

Carbon black; N339

10

10

10

ZnO

2.5

2.5

2.5

6PPD 6)

2

2

2

Wax; Antilux 654

2

2

2

1

1

1

Mixture of c)+d) 7)

5

Aktiplast GT 8)

5

Aktiplast ST 9)

5

2

2

2

CBS 10)

2

2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com