Preparation method of oriented shish-kebab fiber

A technology of orientation and stringing, which is used in fiber processing, spinning solution preparation, pharmaceutical formulations, etc., can solve the problem of lack of cell binding sites on the surface of the scaffold, and achieve improved cell compatibility, good hydrophilicity, and accelerated precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

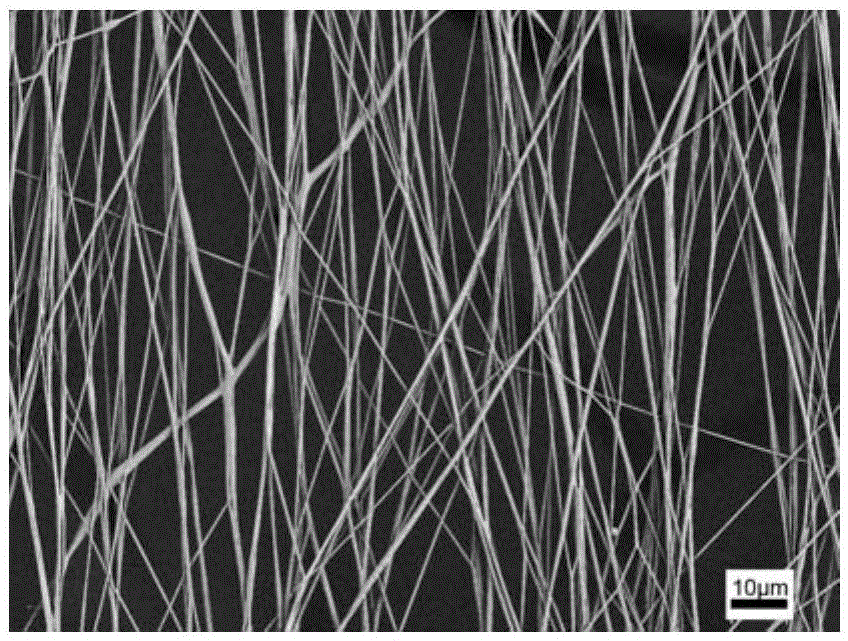

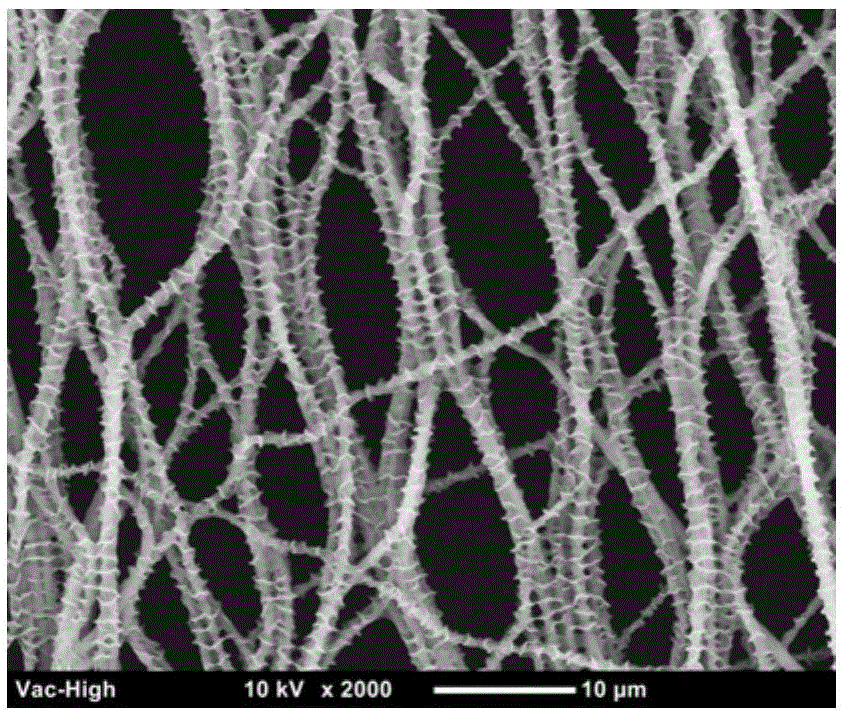

[0035] The present embodiment is a preparation method of polycaprolactone nanofiber / chitosan-g-polycaprolactone skewered fiber, and the detailed steps of the preparation method are as follows:

[0036] (1) Dissolve PCL6500 in a mixed organic solvent of chloroform and dimethylformamide at 45° C., and make a PCL spinning solution with a mass percent concentration of 14% after dissolving; preferably, the relative molecular mass of PCL is 16 Ten thousand grams / mole; The volume ratio of chloroform and dimethylformamide is 6 to 4;

[0037] (2) Utilize the PCL spinning solution obtained in step (1) with an electrospinning device, at a temperature of 20° C., a spinning voltage of 15 kV, and a receiving distance of 15 cm. The receiving device is a stainless steel washer placed on an aluminum foil paper. Spinning and preparing PCL nanofibers;

[0038] (3) Synthesis of CS-g-PCL graft copolymer: (a) dissolving chitosan with a degree of deacetylation of 80% in methanesulfonic acid at 40°C...

Embodiment 2

[0043] (1) Dissolve PCL6500 in a mixed organic solvent of chloroform and dimethylformamide at 45° C., and make a PCL spinning solution with a mass percent concentration of 16% after dissolving; preferably, the relative molecular mass of PCL is 16% Ten thousand grams / mole; The volume ratio of chloroform and dimethylformamide is 6 to 4;

[0044] (2) Utilize the PCL spinning solution that step (1) obtains to utilize electrospinning device, at temperature be 20 ℃, and spinning voltage is 18kV, and receiving distance is 18cm, and receiving device is the stainless steel washer that is placed on the aluminum foil paper, electrospinning Spinning and preparing PCL nanofibers;

[0045] (3) Synthesis of CS-g-PCL graft copolymer: (a) dissolving chitosan with a degree of deacetylation of 80% in methanesulfonic acid at 40°C, the mass-to-volume ratio of chitosan and methanesulfonic acid 30mg / mL, and then the caprolactone monomer with chitosan molar equivalent ratio of 12 was added to the ch...

Embodiment 3

[0050] (1) Dissolve PCL6500 in a mixed organic solvent of chloroform and dimethylformamide at 60°C, and make a PCL spinning solution with a mass percent concentration of 20% after dissolving; preferably, the relative molecular mass of PCL is 16 Ten thousand grams / mole; The volume ratio of chloroform and dimethylformamide is 6 to 4;

[0051] (2) Utilize the PCL spinning solution that step (1) obtains to utilize electrospinning device, at temperature be 20 ℃, and spinning voltage is 25kV, and receiving distance is 18cm, and receiving device is the stainless steel washer that is placed on the aluminum foil paper, electrospinning Spinning and preparing PCL nanofibers;

[0052] (3) Synthesis of CS-g-PCL graft copolymer: (a) dissolving chitosan with a degree of deacetylation of 80% in methanesulfonic acid at 40°C, the mass-to-volume ratio of chitosan and methanesulfonic acid 40mg / mL, and then the caprolactone monomer with a chitosan molar equivalent ratio of 6 was added to the chit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com