Flame-retardant polyurethane flexible foam plastic and preparation method thereof

A polyurethane soft foam and plastic technology, applied in fireproof coatings, alginic acid coatings, coatings, etc., can solve the problems of toxic fumes, large release, and large addition of flame retardants, etc., to delay thermal decomposition, reduce diffusion, The effect of adding a small amount of flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the flame-retardant flexible polyurethane foam plastic includes the following steps:

[0026] Step 1. Preparation of polyelectrolyte dispersion: add C in a mixed solvent of deionized water and absolute ethanol 60 And guar gum, ultrasonic treatment, to obtain C 60 / Guar gum dispersion; add MoS in deionized water 2 Nanosheets and sodium alginate are treated with ultrasound to prepare MoS 2 / Sodium alginate dispersion;

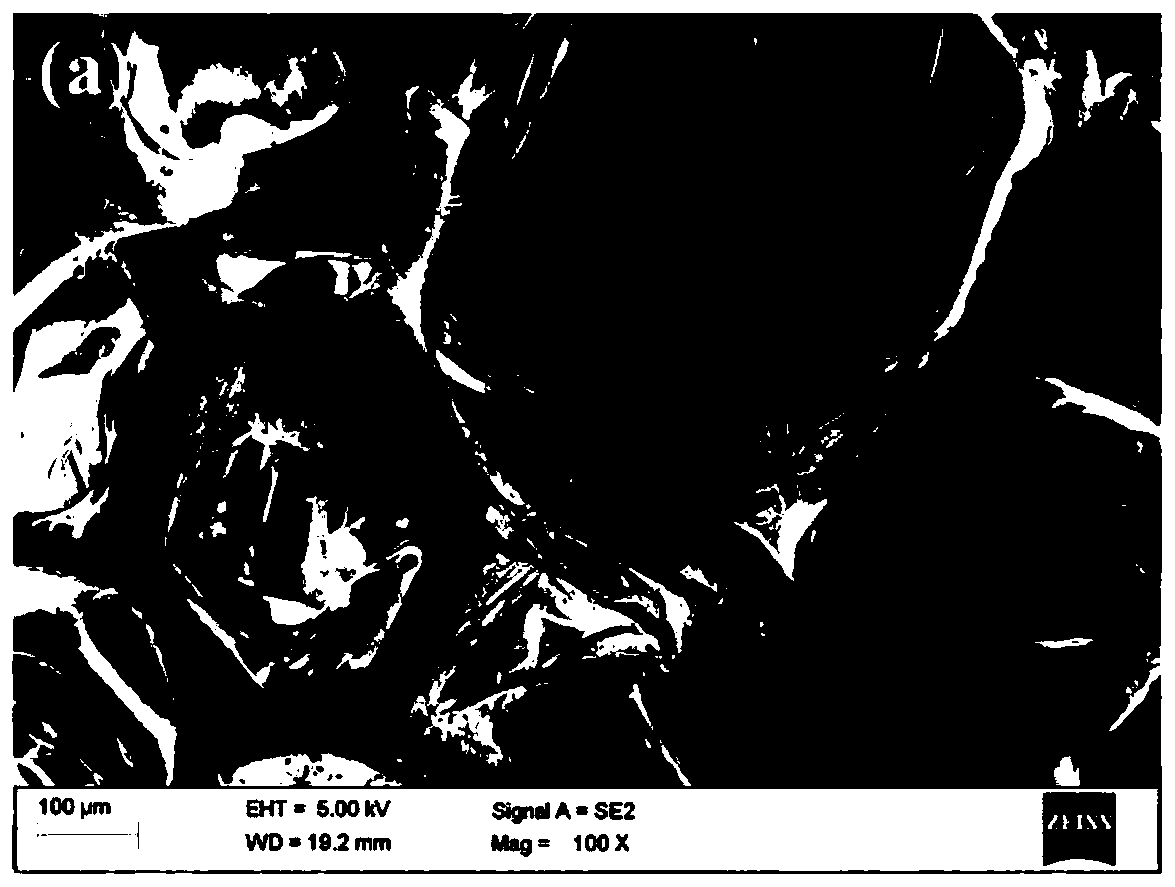

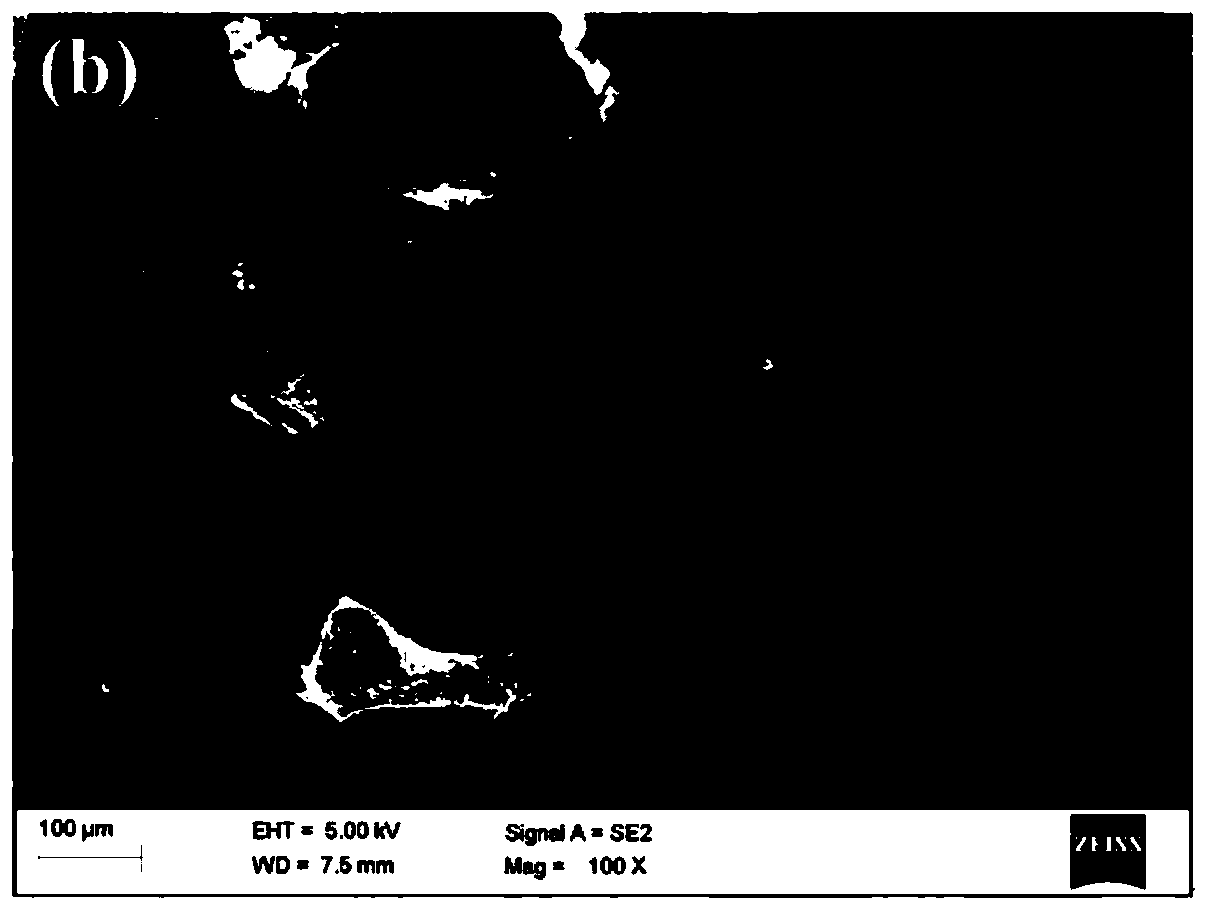

[0027] Step 2: Use layer-by-layer self-assembly method to prepare flame-retardant polyurethane soft foam: Before layer-by-layer self-assembly deposition, pre-foam the soft polyurethane foam in a nitric acid solution for 2-10 minutes to form a positively charged surface on the surface and extrude After too much acid solution, immerse the soft polyurethane foam into the polyacrylic acid solution and let it stand for 2-10 minutes to generate negative charge on the surface, and then alternately immerse the soft polyurethane foam into the C ...

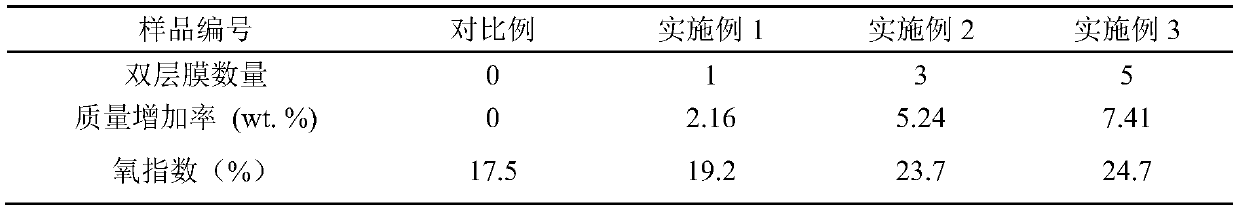

Embodiment 1

[0036] The preparation method of the flame-retardant flexible polyurethane foam plastic includes the following steps:

[0037] (1). Preparation of polyelectrolyte dispersion: in a mixed solvent of 0.5L deionized water and 0.5L absolute ethanol, add 5.0g C 60 And 2.0g guar gum, sonicated for 20min, obtain C 60 / Guar gum dispersion. Add 5.0g MoS to 1L deionized water 2 Nanosheets and 2.0g sodium alginate, ultrasonic treatment for 20min, prepare MoS 2 / Sodium alginate dispersion.

[0038] (2). Use layer-by-layer self-assembly method to prepare flame-retardant polyurethane soft foam: before layer-by-layer self-assembly deposition, pre-foam the polyurethane foam in a 0.1mol / L nitric acid solution for 5 minutes to form a positively charged surface on its surface . After squeezing out too much acid solution, immerse the soft polyurethane foam into 1.0wt.% polyacrylic acid solution and let it stand for 5 minutes to generate negative charge on the surface. Then alternately immerse flexibl...

Embodiment 2

[0040] The preparation method of the flame-retardant flexible polyurethane foam plastic includes the following steps:

[0041] (1). Preparation of polyelectrolyte dispersion: in a mixed solvent of 0.5L deionized water and 0.5L absolute ethanol, add 5.0g C 60 And 2.0g guar gum, sonicated for 20min, obtain C 60 / Guar gum dispersion. Add 5.0g MoS to 1L deionized water 2 Nanosheets and 2.0g sodium alginate, ultrasonic treatment for 20min, prepare MoS 2 / Sodium alginate dispersion.

[0042] (2). Use layer-by-layer self-assembly method to prepare flame-retardant polyurethane soft foam: before layer-by-layer self-assembly deposition, pre-foam the polyurethane foam in a 0.1mol / L nitric acid solution for 5 minutes to form a positively charged surface on its surface . After squeezing out too much acid solution, immerse the soft polyurethane foam into 1.0wt.% polyacrylic acid solution and let it stand for 5 minutes to generate negative charge on the surface. Then alternately immerse flexibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com