Thermal conductive resin composition and molded body

A technology of resin composition and thermal conductivity, applied in the direction of conductors, insulated conductors, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of unrecyclable environment, load, etc., and achieve good dimensional stability and smoothness Excellent, excellent dimensional stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

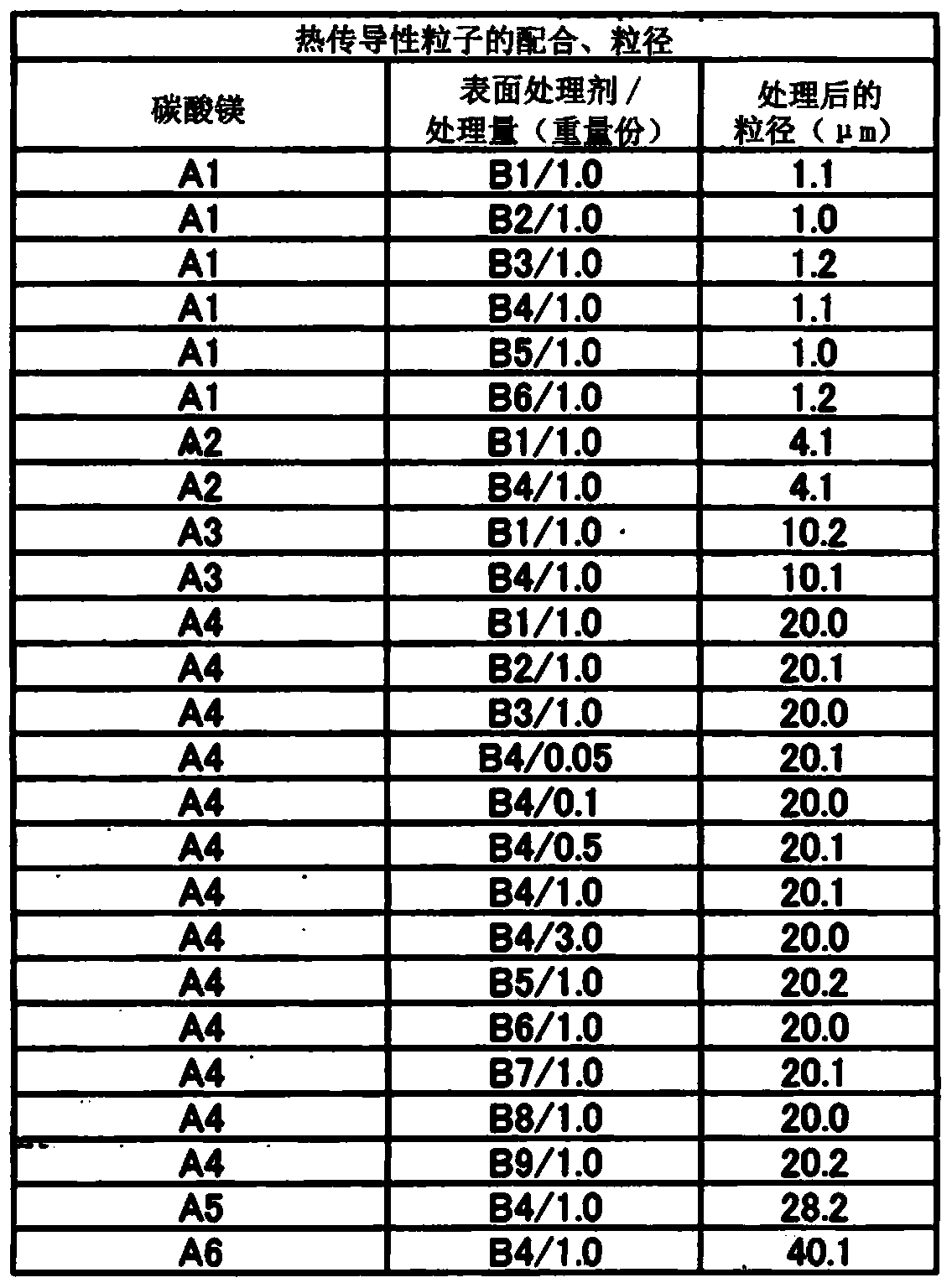

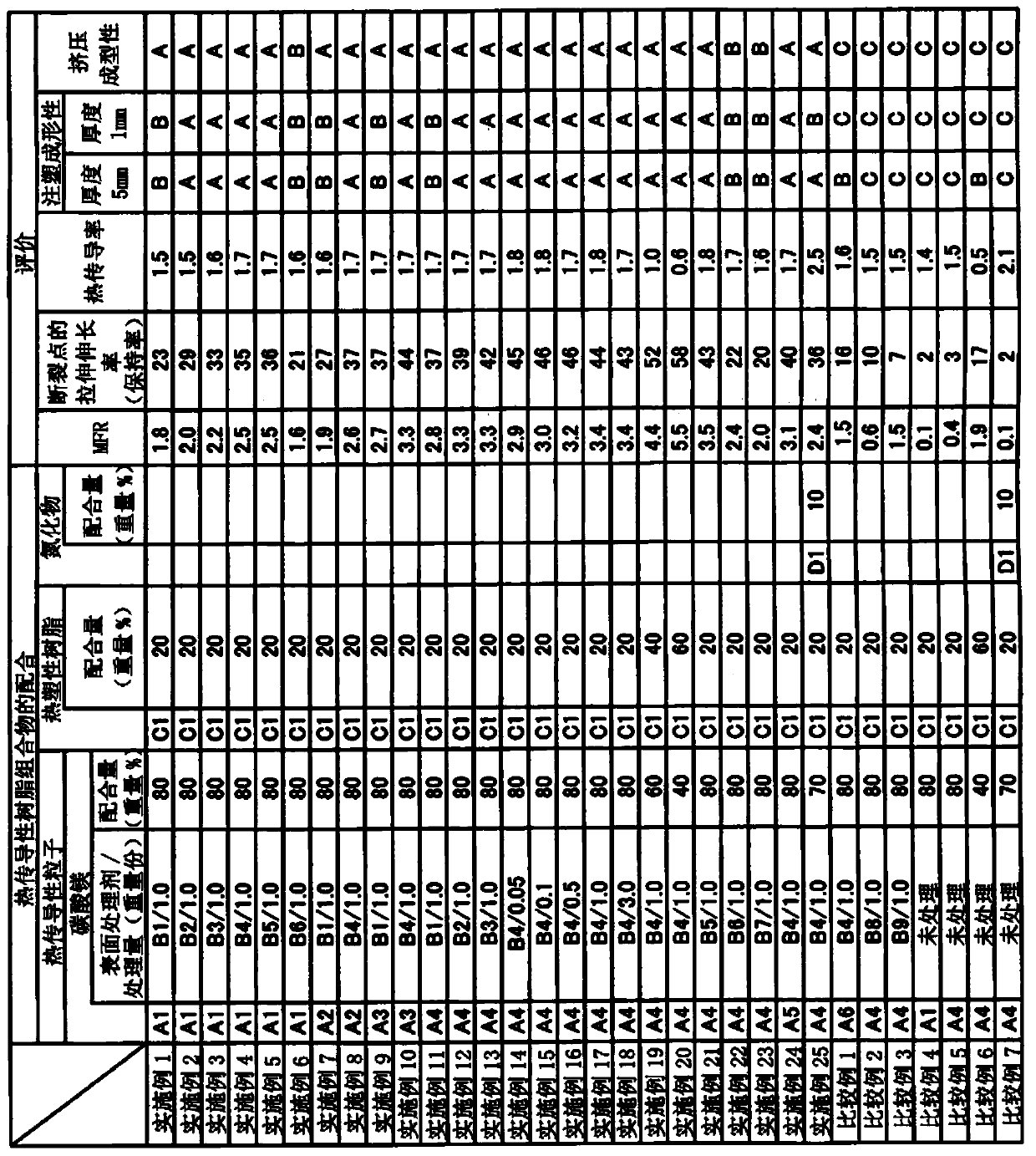

[0077] [Production of Thermally Conductive Resin Composition]

[0078] Put 100 parts of magnesium carbonate particles A1 with 1 part of surface treatment agent B1 for surface treatment of 80 parts of thermally conductive particles and 20 parts of thermoplastic resin C1 into the Henschel mixer, under the conditions of a temperature of 20°C and a time of 3 minutes Perform pre-mixing and obtain a mixture. After that, the mixture was supplied to an extruder with a screw diameter of 30 mm and L / D (screw diameter / screw length) = 38 to 42, and melted and kneaded under the conditions of a rotation speed of 250 rpm and a set temperature of 220°C. A pelletizer is used to shape the extruded kneaded product into small balls. In this way, a thermally conductive resin composition is obtained.

[0079] [Evaluation method]

[0080] Using the obtained thermally conductive resin composition, the following evaluation items were tested. The results are shown in Table 2.

[0081] [Melt viscosity]

[00...

Embodiment 2~25、 comparative example 1~3

[0102] With the blending of the thermally conductive resin described in Table 2, pellets were produced in the same manner as in Example 1, and evaluated in the same manner as the above method. The results are shown in Table 2.

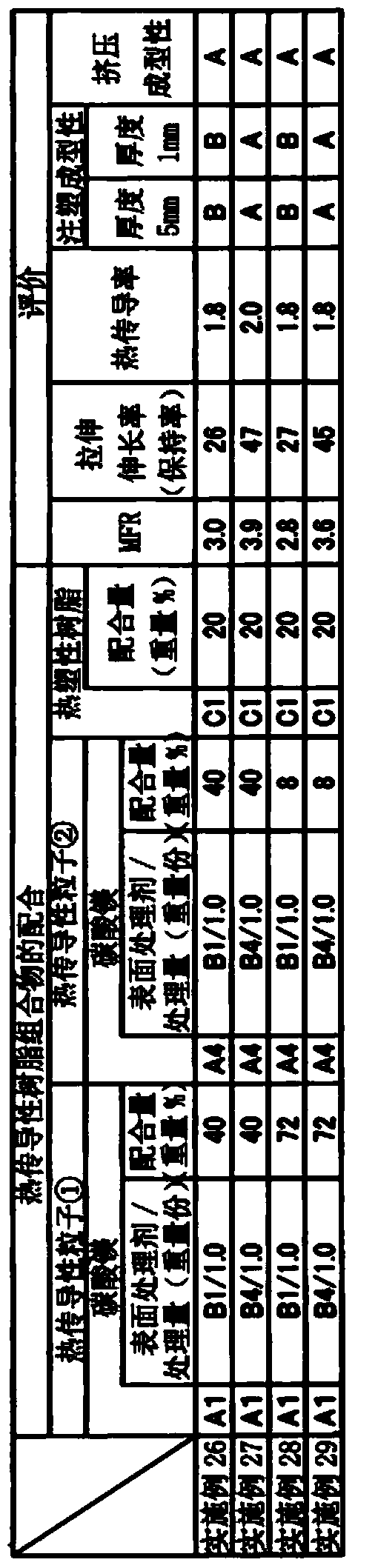

Embodiment 26

[0110] 40 parts of thermally conductive particles obtained by surface treatment of 100 parts of magnesium carbonate particles A1 with 1 part of surface treatment agent B1, 40 parts of thermally conductive particles obtained by surface treatment of 100 parts of magnesium carbonate particles A4 with 1 part of surface treatment agent B1, and Twenty parts of thermoplastic resin C1, except for the above three types, were used to produce pellets in the same manner as in Example 1, and evaluated by the same method as above. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com