Functional cyclodextrin flame-retarding polylactic acid composite material and preparation method thereof

A composite material and cyclodextrin technology, applied in the field of flame-retardant polylactic acid composite materials, can solve the problems of large pollution in the preparation process, low flame-retardant efficiency, and damage to the mechanical properties of the matrix material, and achieve simple and easy preparation process, high resistance Fuel efficiency, pollution-free preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

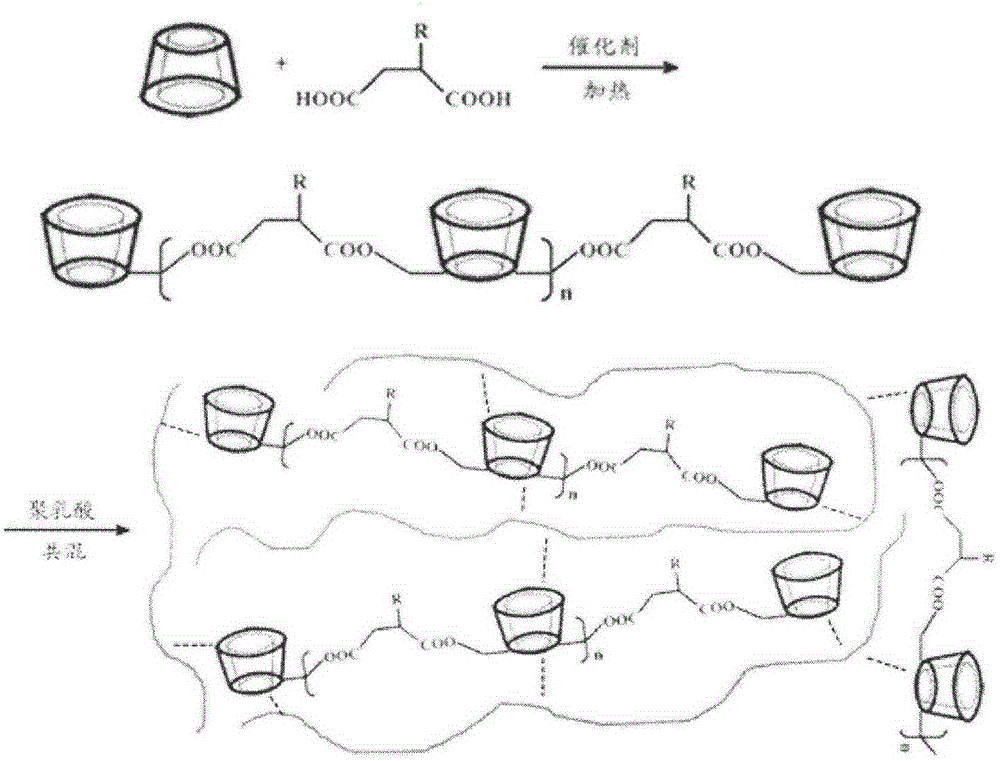

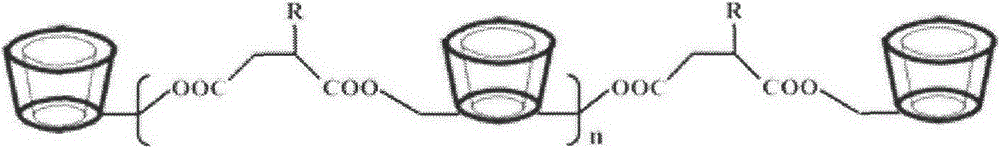

[0026] The preparation method of the functionalized cyclodextrin flame-retardant polylactic acid composite material provided by the present invention can refer to figure 1 A schematic diagram of the preparation process, including the following steps:

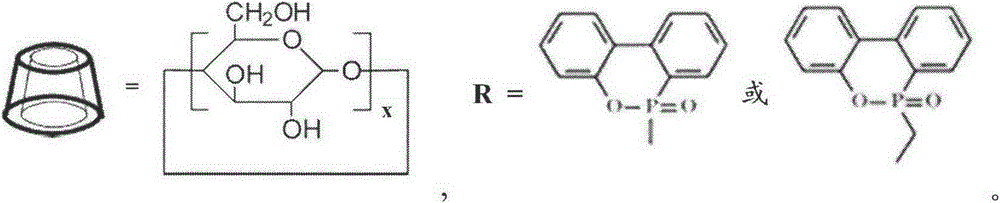

[0027] a) Add a certain proportion of cyclodextrin, phosphorus-containing dibasic acid and catalyst into deionized water, mix evenly, heat to a certain temperature, cool after a certain period of time, wash with water, and dry to obtain a functionalized cyclodextrin flame retardant agent; cyclodextrin is preferably α-cyclodextrin, β-cyclodextrin or γ-cyclodextrin, and the phosphorus-containing dibasic acid preferably has the following chemical structure:

[0028]

[0029] The catalyst is preferably disodium hydrogen phosphate or sodium dihydrogen phosphate, the molar ratio of cyclodextrin and phosphorus-containing dibasic acid is preferably 1:1 to 1:6, and the molar ratio of cyclodextrin and catalyst is preferably 5:1 to 1 :...

Embodiment 1

[0033] Weigh 0.1mol of α-cyclodextrin, 0.6mol of phosphorus-containing dibasic acid A and 0.3mol of sodium dihydrogen phosphate, add them to 1000ml of deionized water, stir until the mixture is even, place at 130°C for 5 hours, and cool to room temperature, washed with deionized water, dried, and set aside. The polylactic acid resin and the functionalized cyclodextrin were dried in an oven at 80°C for more than 12 hours, then mixed uniformly in a twin-screw extruder according to 95:5 (mass ratio), and then extruded, granulated and After drying, the functionalized cyclodextrin flame-retardant polylactic acid composite material is obtained.

Embodiment 2

[0035] Weigh 0.1mol of β-cyclodextrin, 0.3mol of phosphorus-containing dibasic acid B and 0.1mol of sodium dihydrogen phosphate, add them to 1000ml of deionized water, stir until the mixture is even, place at 140°C for 4 hours, and cool to room temperature, washed with deionized water, dried, and set aside. The polylactic acid resin and the functionalized cyclodextrin were dried in an oven at 80°C for more than 12 hours, then mixed uniformly in a twin-screw extruder according to 90:10 (mass ratio), and then extruded, granulated and After drying, the functionalized cyclodextrin flame-retardant polylactic acid composite material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com