Flame-retardant wire and cable material and preparation method thereof

A wire and cable, flame retardant technology, applied in the field of flame retardant wire and cable materials and their preparation, can solve problems such as the imbalance of mechanical and physical indicators, and achieve the effect of improving mechanical physics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

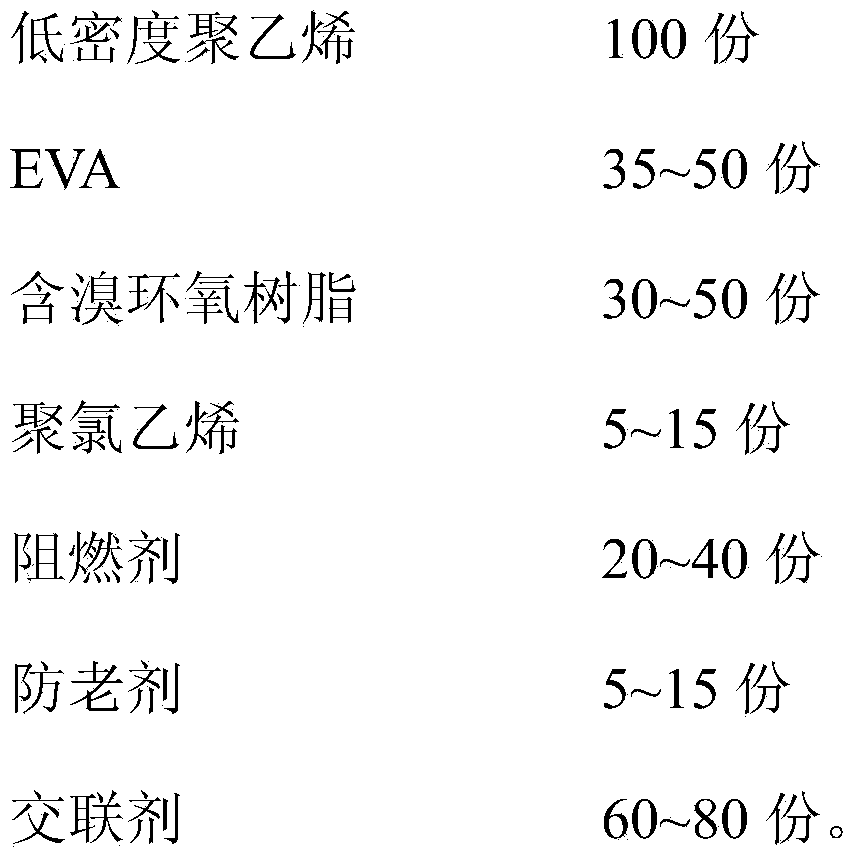

[0033] A flame-retardant wire and cable material, which comprises the following components in parts by weight:

[0034]

[0035] The flame retardant is ammonium polyphosphate.

[0036] The anti-aging agent is selected from anti-aging agent RD.

[0037] The flame retardant wire and cable material also includes antioxidants, lubricants and fillers.

[0038] The parts by weight of the antioxidant is 1 part.

[0039] The parts by weight of the lubricant is 1 part.

[0040] The weight part of the filler is 1 part.

[0041] A preparation method of the flame-retardant wire and cable material as described above, the method is: extruding each raw material in a formulated amount through an extruder to obtain the flame-retardant wire and cable material.

Embodiment 2

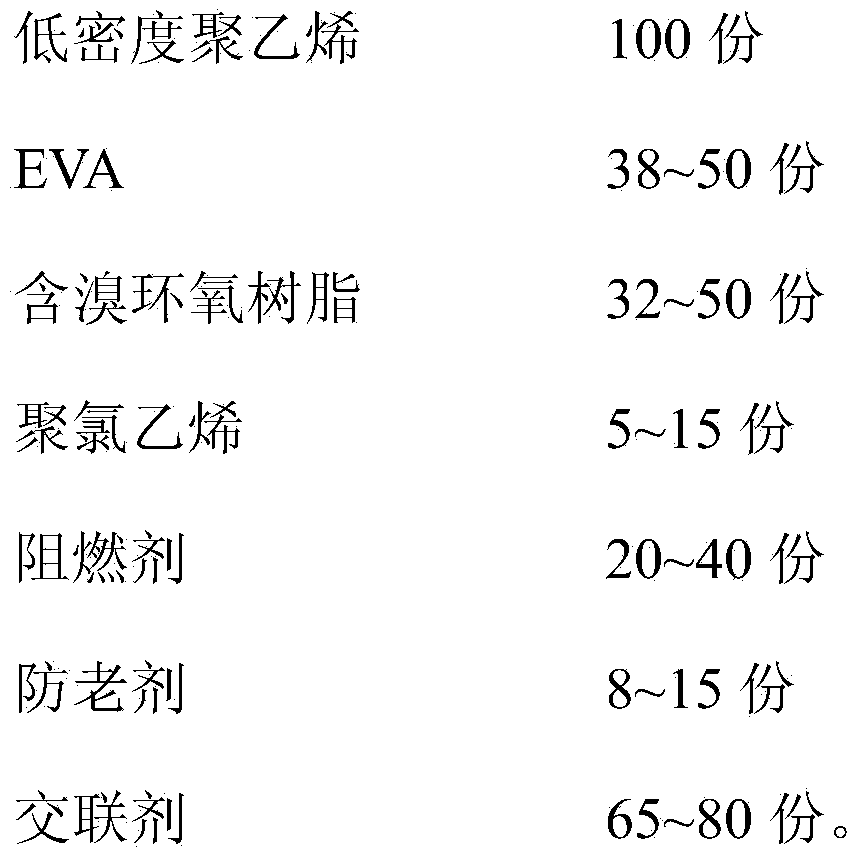

[0043] A flame-retardant wire and cable material, which comprises the following components in parts by weight:

[0044]

[0045] The flame retardant is ammonium polyphosphate.

[0046] The anti-aging agent is selected from anti-aging agent DNP.

[0047] The flame retardant wire and cable material also includes antioxidants, lubricants and fillers.

[0048] The parts by weight of the antioxidant is 5 parts.

[0049] The parts by weight of the lubricant is 5 parts.

[0050] The number of parts by weight of the filler is 3 parts.

[0051] A preparation method of the flame-retardant wire and cable material as described above, the method is: extruding each raw material in a formulated amount through an extruder to obtain the flame-retardant wire and cable material.

Embodiment 3

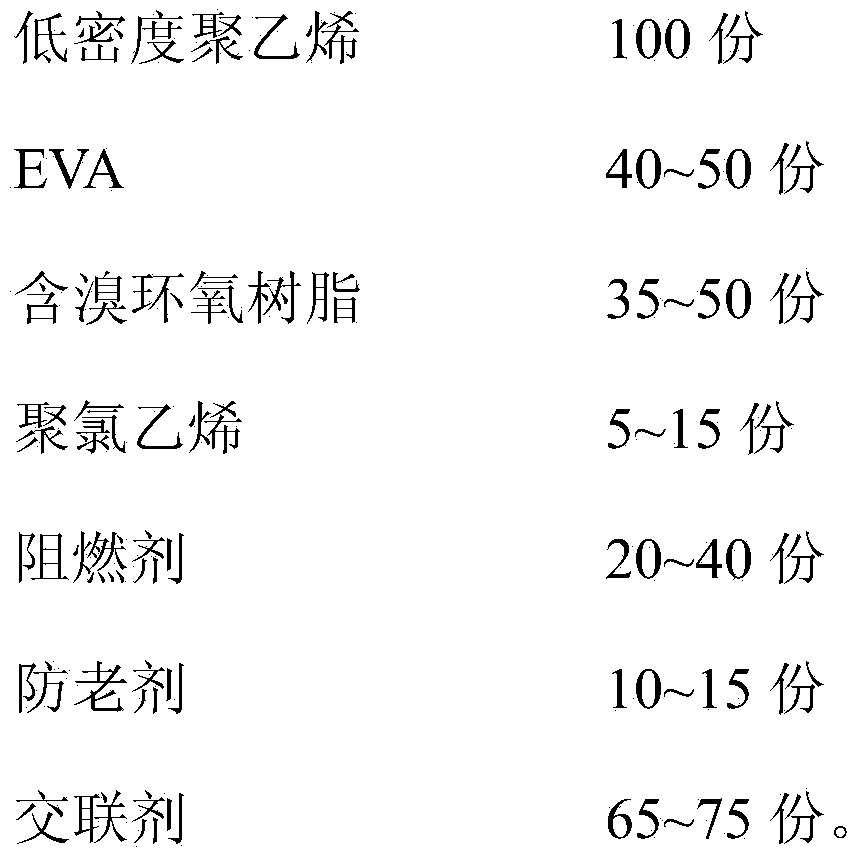

[0053] A flame-retardant wire and cable material, which comprises the following components in parts by weight:

[0054]

[0055] The flame retardant is ammonium polyphosphate.

[0056] The anti-aging agent is selected from anti-aging agent 4010NA.

[0057] The flame retardant wire and cable material also includes antioxidant, lubricant and filler.

[0058] The parts by weight of the antioxidant is 3 parts.

[0059] The parts by weight of the lubricant is 3 parts.

[0060] The number of parts by weight of the filler is 3 parts.

[0061]A preparation method of the flame-retardant wire and cable material as described above, the method is: extruding each raw material in a formulated amount through an extruder to obtain the flame-retardant wire and cable material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com