Pretreatment method for improving lead-bismuth corrosion resistance of ferrite-martensite steel

A technology for martensitic steel and corrosion performance, applied in heat treatment furnaces, heat treatment equipment, coatings, etc., can solve problems such as the decline in mechanical properties and lead-bismuth corrosion resistance, the decline in the stability of fine-grained structures, and the limitation of Al additions , to achieve the effect of facilitating industrialization, convenient operation, and improving the corrosion resistance of lead and bismuth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides 9Cr2WVTa ferrite-martensitic steel plate, chemical composition (wt.%) is: C: 0.11%, Cr: 8.86%, W: 1.62%, V: 0.24%, Ta: 0.11%, Mn : 0.45%, Si: 0.05%, S: 0.005%, P: 0.005%, and the balance is Fe. The pretreatment process steps of the plate are as follows:

[0033] 1) Heat treatment: Quenching and tempering heat treatment of ferritic-martensitic steel plate. The quenching treatment is 1020°C for 60 minutes and then water cooling, and the tempering treatment is 750°C for 2 hours and then air cooling.

[0034] 2) Surface treatment: Mechanical polishing is carried out on the surface of the plate to completely remove the surface oxide skin, so that the surface reveals a metallic luster, and the surface roughness is required to be less than 1 μm.

[0035] 3) Cold deformation: cold rolling deformation treatment is carried out at room temperature, and the cold rolling deformation is 20%.

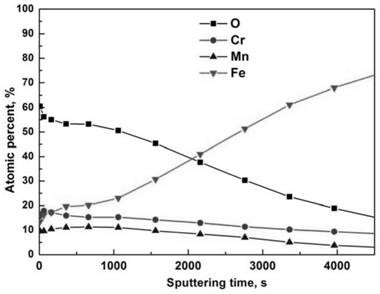

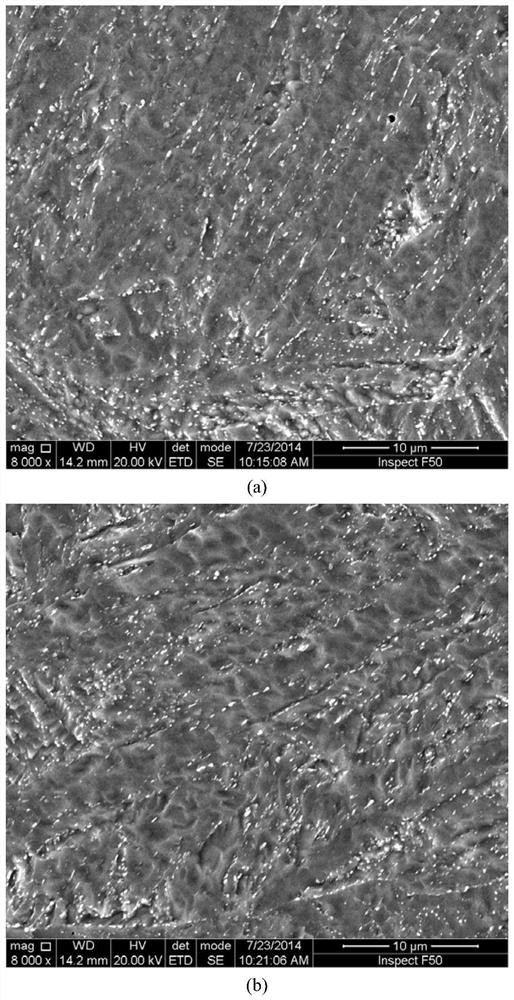

[0036] 4) High-temperature oxidation: the cold-rolled plate is s...

Embodiment 2

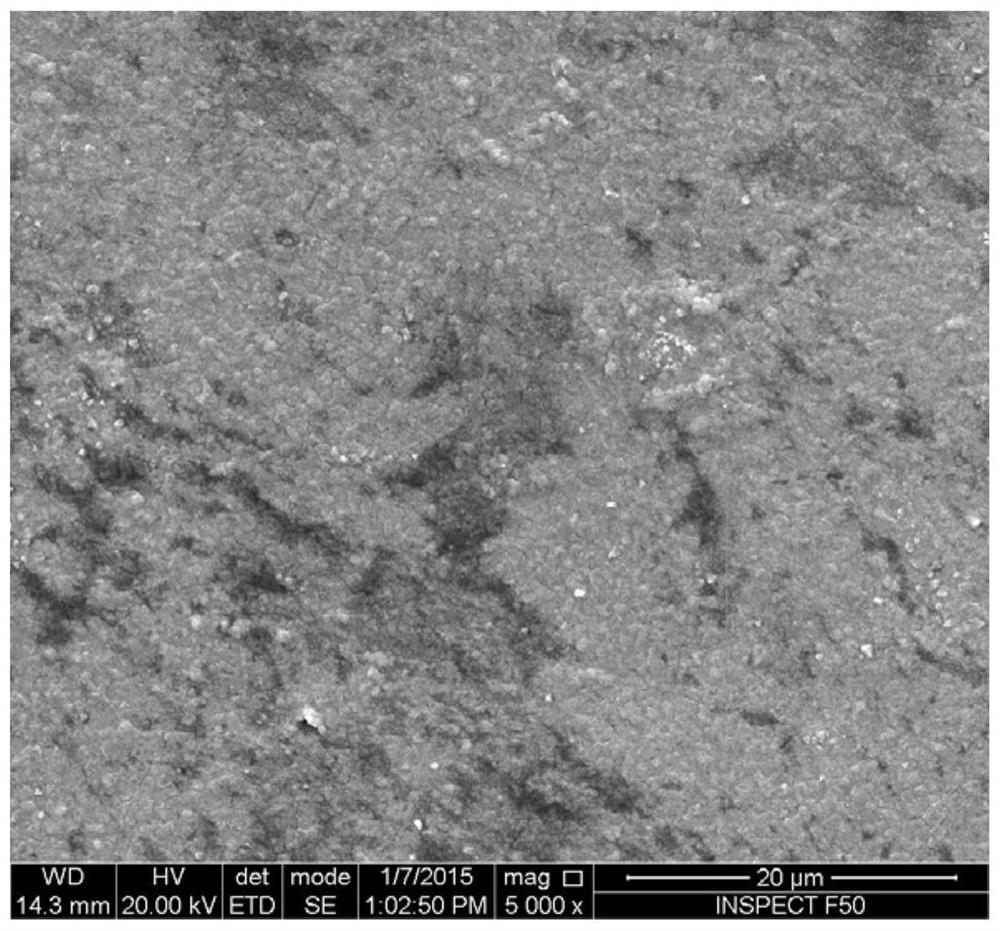

[0039] The same ferritic-martensitic steel sheet as in Example 1 was used and subjected to the same quenching and tempering heat treatment, but no pretreatment of cold deformation and high temperature oxidation was performed. The sample is placed in the same liquid lead-bismuth environment as in Example 1, and the cross-sectional appearance of the corrosion layer is as follows: Figure 5 shown. It can be seen that a corrosion layer with a thickness of about 23 μm is formed on the surface of ferrite-martensitic steel. It can be seen that the ferritic-martensitic steel without pretreatment by the method of the present invention will undergo obvious oxidation corrosion.

Embodiment 3

[0041] The same ferritic-martensitic steel sheet as in Example 1 was used and subjected to the same quenching and tempering heat treatment and high-temperature oxidation treatment, but no cold deformation pretreatment was performed before the oxidation treatment. The sample is placed in the same liquid lead-bismuth environment as in Example 1, and the cross-sectional appearance of the corrosion layer is as follows: Image 6 shown. It can be seen that a corrosion layer with a thickness of about 9 μm is formed on the surface of ferrite-martensitic steel. It can be seen that the ferritic-martensitic steel without cold deformation pretreatment cannot effectively resist the corrosion of liquid lead and bismuth even if it is subjected to high temperature oxidation treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com